Pretreatment method of desulfurization adsorbent and desulfurization method of sulfur-containing hydrocarbon feedstock

An adsorbent and pretreatment technology, applied in the field of desulfurization of hydrocarbon raw materials, can solve the problems of overheating of the reactor, large loss of anti-violence index of desulfurization products, and long time, so as to reduce the difficulty of starting work, improve the adsorption desulfurization effect, and shorten the time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

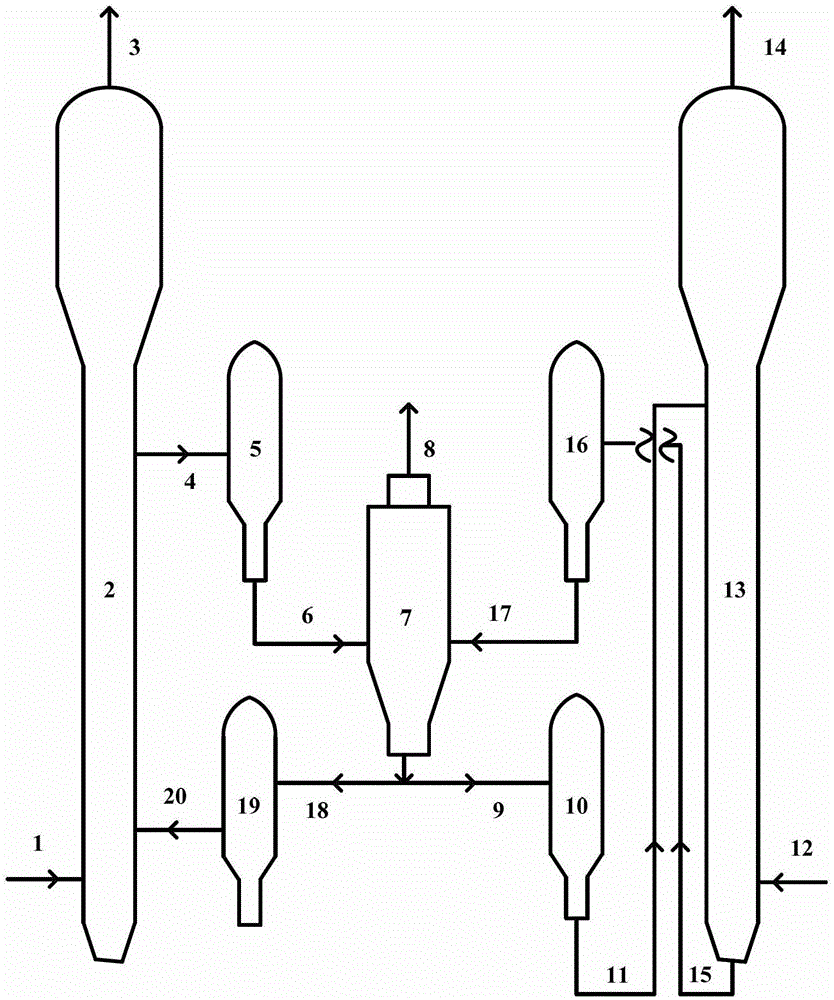

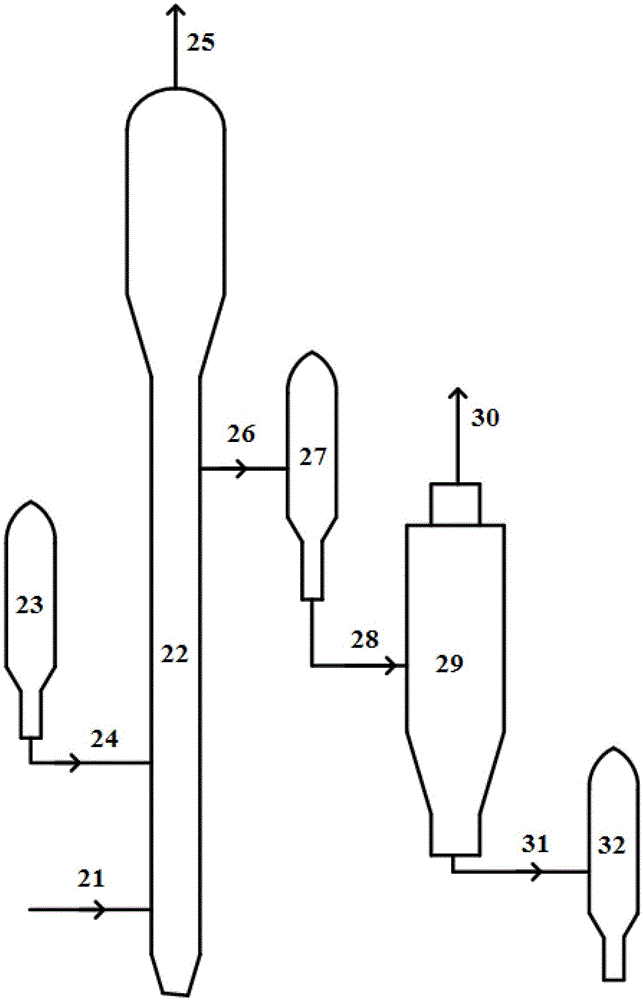

Image

Examples

Embodiment 1

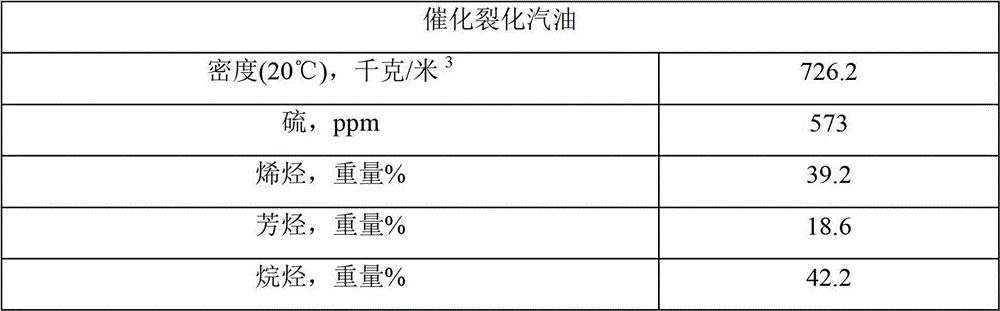

[0058] This example is used to illustrate the pretreatment method of the desulfurization adsorbent and the desulfurization method of sulfur-containing hydrocarbon feedstock in the present invention.

[0059] Pretreat the desulfurization adsorbent according to the above-mentioned pretreatment process outside the desulfurization adsorbent, and use the pretreated desulfurization adsorbent to desulfurize the sulfur-containing hydrocarbon raw material, wherein the pretreatment process is carried out in a cycle for 2 hours, and the pretreatment The implementation conditions of the process and the desulfurization process and the related parameters of the final desulfurized gasoline product are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com