Method for cleaning cadmium coating on surface of workpiece through laser and laser cleaning device

A technology for laser cleaning and workpiece surface application in the field of laser cleaning of cadmium coating on the surface of workpieces and laser cleaning devices can solve the problems of unusable and undisclosed laser cleaning of cadmium coating workpieces, high-strength steel cannot be in contact with acidic solutions, etc., to achieve Simple operation and improved cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

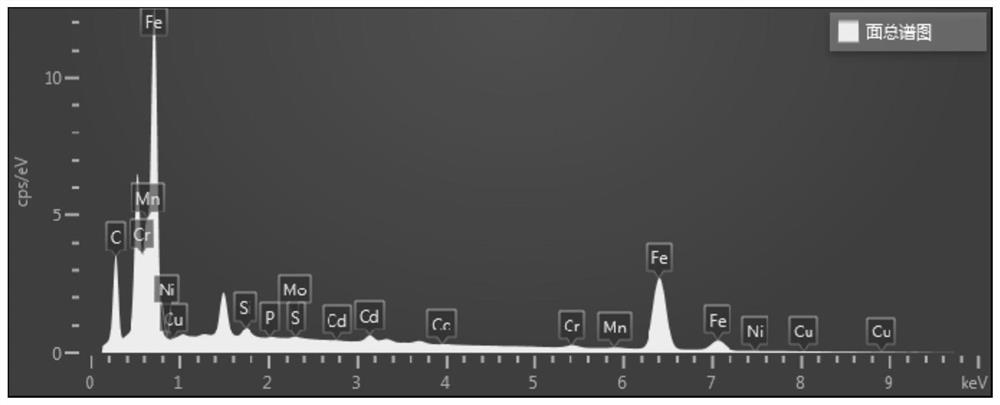

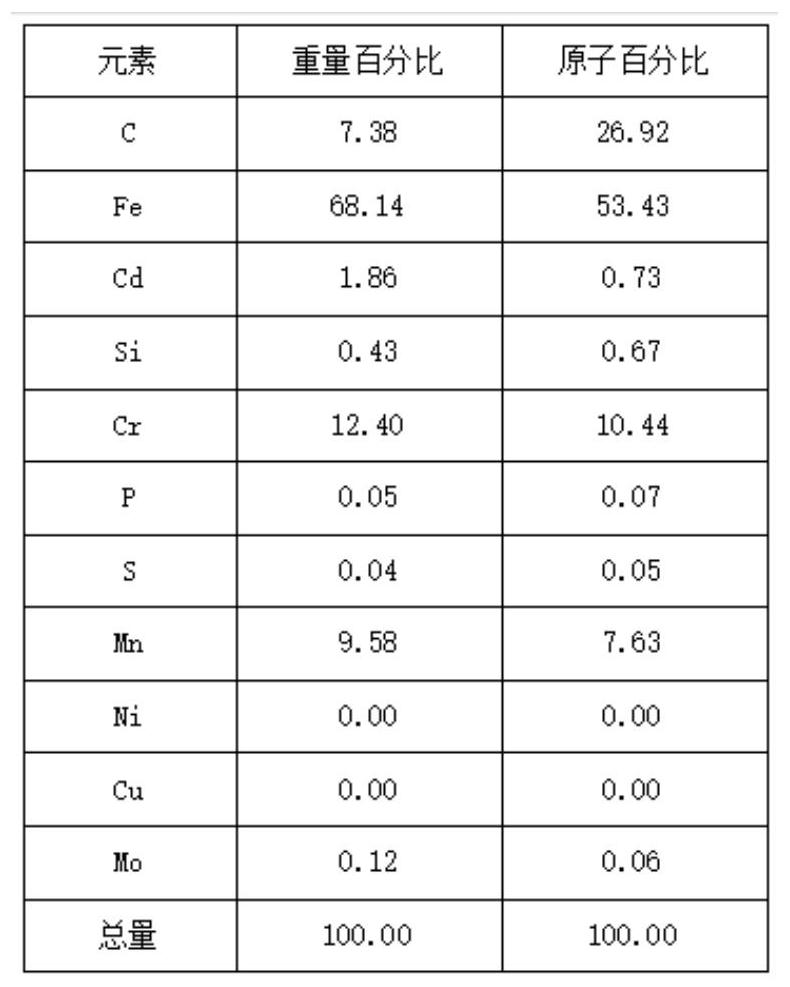

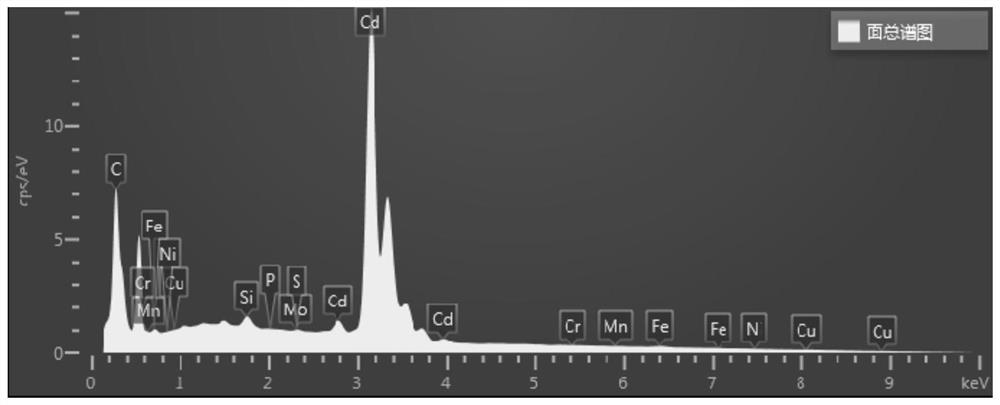

[0025] This embodiment provides a method for laser cleaning the cadmium coating on the surface of a workpiece. Specifically, it adopts a laser output power of 50W, a laser output repetition frequency of 100kHz, a laser pulse width of 12ns, and a laser spot overlap rate of 10%. The single pulse energy is 0.5mJ, the laser scanning speed is 3500mm / s, and the filling spacing (that is, the distance between the centers of two adjacent laser spots in the same laser scanning direction) is 0.05mm. The cadmium coating on the surface of the workpiece is laser cleaned, and the cadmium There is a layer of yellow-green passivation layer on the surface of the coating, and the main element is chromium. At the same time, the number of times of laser scanning, that is, laser cleaning is 9 times.

[0026] In this embodiment, the workpiece is a steel workpiece, which includes a substrate, a cadmium coating, and a passivation layer on the surface of the cadmium coating, wherein the thickness of the...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the laser parameters are: laser output power of 100W, laser output repetition frequency of 1000kHz, laser pulse width of 500ns, laser spot overlapping rate of 30%, laser single pulse energy 0.1mJ, the laser scanning speed is 2500mm / s, the laser cleaning workpiece surface cadmium coating is 0.01mm, and the surface of the cadmium coating has a layer of yellow-green passivation layer, the main element is chromium. At the same time, the laser scanning is The number of times of laser cleaning is 10 times.

Embodiment 3

[0030] The difference between this embodiment and Embodiment 1 is that the laser parameters are: laser output power of 30W, laser output repetition frequency of 100kHz, laser pulse width of 100ns, laser spot overlapping rate of 50%, laser single pulse energy The laser scanning speed is 0.3mJ, the laser scanning speed is 2500mm / s, the filling pitch is 0.045mm, and the laser cleaning times are 8 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com