Heat exchanger arrangement structure of pre-concentration tower

A technology for arranging structures and heat exchangers, applied to indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as volatilization, low concentration efficiency, and high temperature of liquid medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

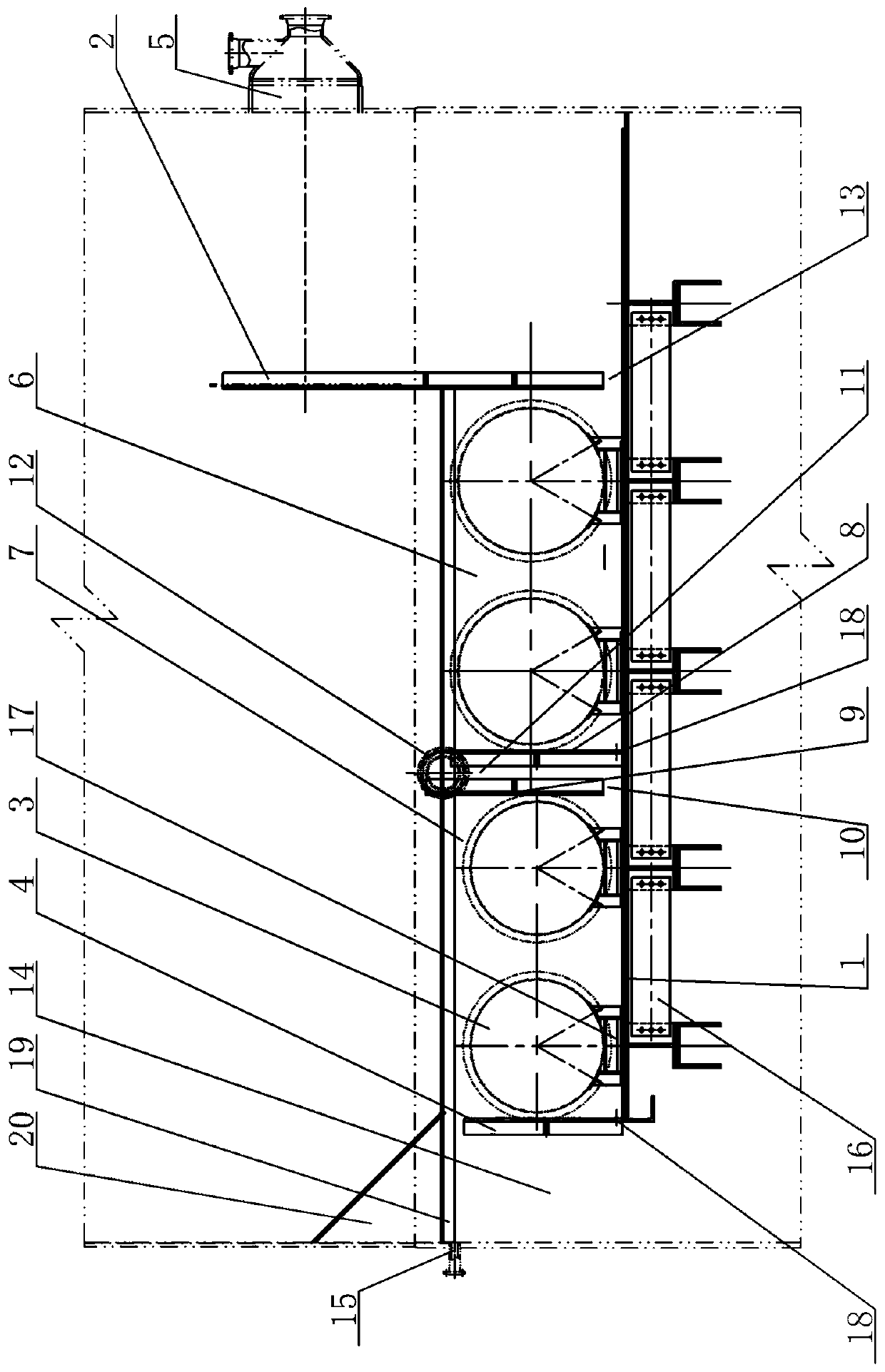

[0018] In a specific embodiment, four heat exchangers 3 are arranged in the region of the corresponding bottom transverse plate 1 from the first longitudinal partition plate 2 to the third longitudinal partition plate 4 , and two heat exchangers 3 are arranged in the first heat exchange cavity 6 . There are two heat exchangers 3, two heat exchangers 3 are arranged in the second heat exchange cavity 7, and each heat exchanger 3 is supported by the bracket 17 at the corresponding position of the bottom horizontal plate 1;

[0019] Small-diameter drain holes 18 are provided at the bottoms of the first upper limit partition plate 8 and the third longitudinal partition plate 4 to ensure that the liquid is drained when no subsequent work is performed;

[0020] It also includes an auxiliary horizontal connecting bar 19, one end of the auxiliary horizontal connecting bar 19 is fixed to the middle area in the height direction of the first longitudinal partition 2, the other end is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com