Asymmetric pipe-plate type bundle pipe reactor and methanol synthesis process

A tube-sheet type, asymmetric technology, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of crowded reactors, low processing costs, and small internal space of the reactors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

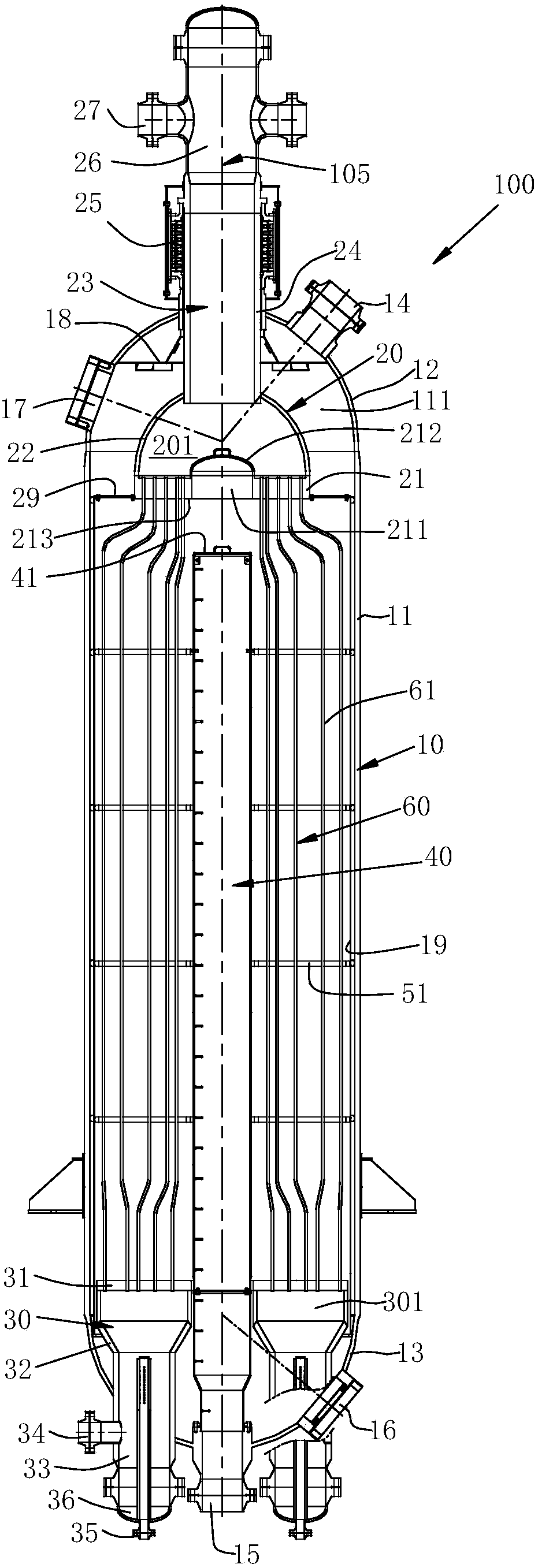

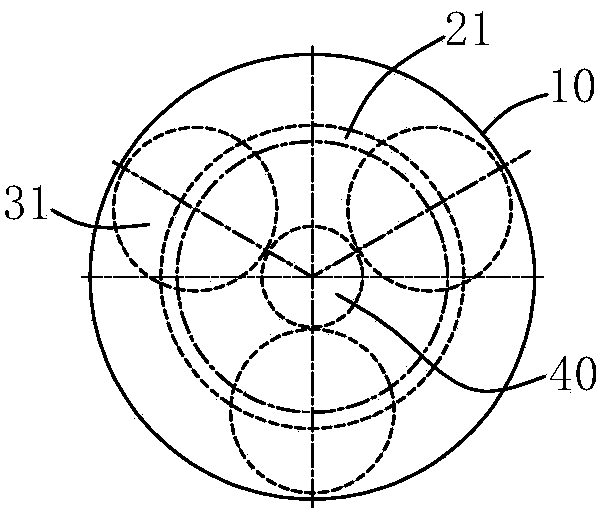

[0032] see figure 1 and figure 2 , an asymmetric tube-sheet bundle tube reactor 100, which includes a shell 10, a plurality of heat exchange tubes 61 are installed in the shell 10, the shell 10 includes a cylindrical cylinder 11, installed in the cylinder 11 The upper head 12 at the upper end of the cylinder and the lower head 13 installed at the lower end of the cylinder. The upper head 12 is provided with a synthesis gas inlet pipe 14 and a steam-water mixture outlet pipe 23 , and the lower head 13 is provided with a synthesis gas outlet pipe 15 and a circulating hot water inlet pipe 33 .

[0033] There is only one first tube-sheet assembly 20 installed at the upper end inside the shell 10 , and three second tube-sheet assemblies 30 are installed at the lower end inside the shell.

[0034]A gas collection pipe 40 and a gas radial distribution cylinder 19 are also installed in the housing 10. The gas collection pipe 40 and the gas radial distribution cylinder 19 extend alo...

Embodiment 2

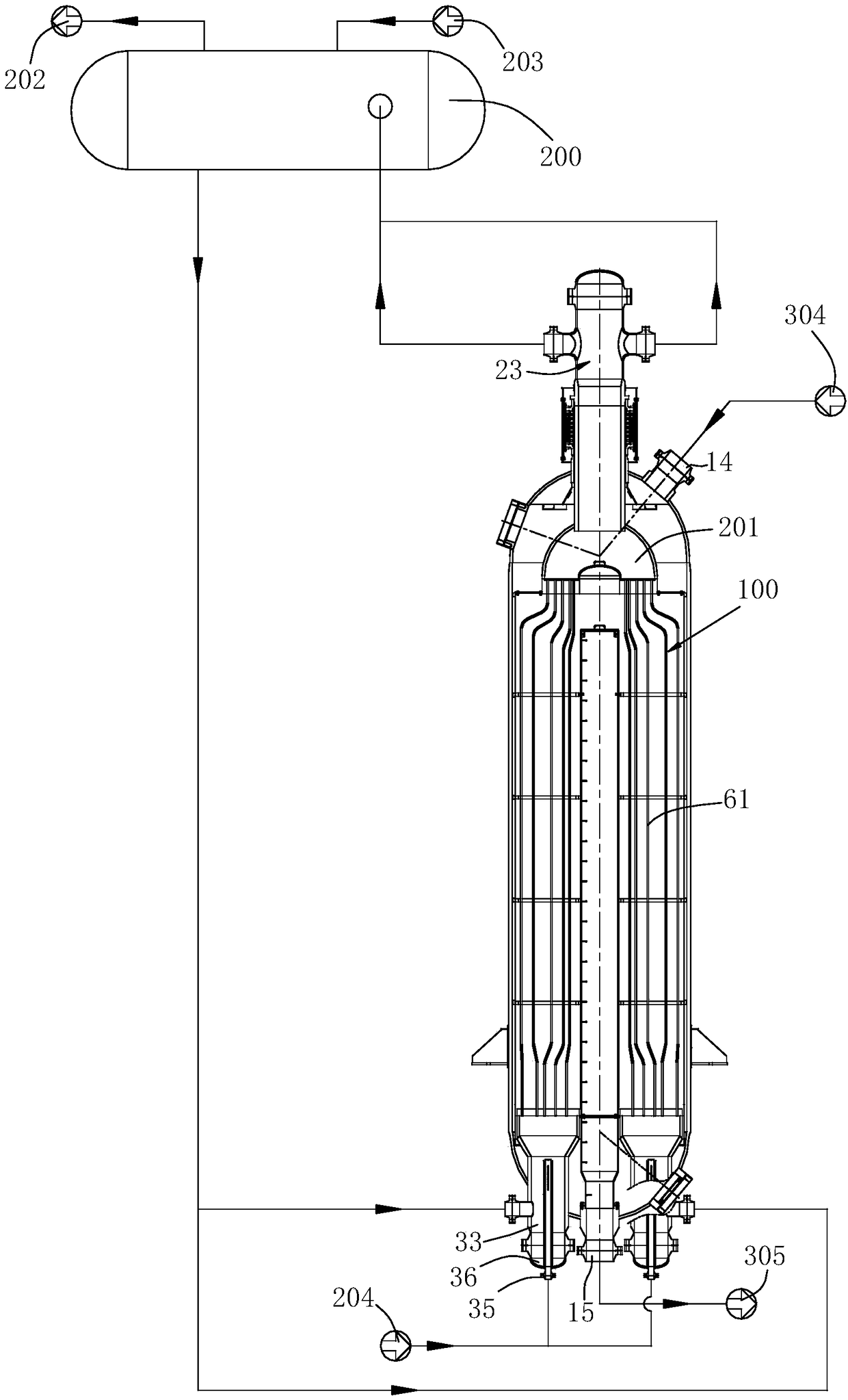

[0046] A methanol synthesis process, see image 3 , which uses the asymmetric tube-plate bundle reactor in Example 1, feeds the raw material gas 304 at 190-210°C from the synthesis gas inlet pipe 14 into the shell side of the asymmetric tube-plate bundle reactor 100, and performs the synthesis reaction , the mixed gas generated after the reaction is discharged from the synthesis gas outlet pipe 15 and enters the next process.

[0047] The hot water enters the tube side of the asymmetric tube-sheet bundled tube reactor 100 from the circulating hot water inlet pipe 33, absorbs the reaction heat of the raw material gas, and becomes a steam-water mixture, then is discharged from the steam-water mixture outlet pipe 23, and enters the steam drum 200 , the steam-water mixture in the steam drum is flashed, and the steam is released to form steam 202 with a pressure of 4.5 MPa. Driven by the steam pressure in the steam drum, the hot water in the steam drum passes through the hot water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com