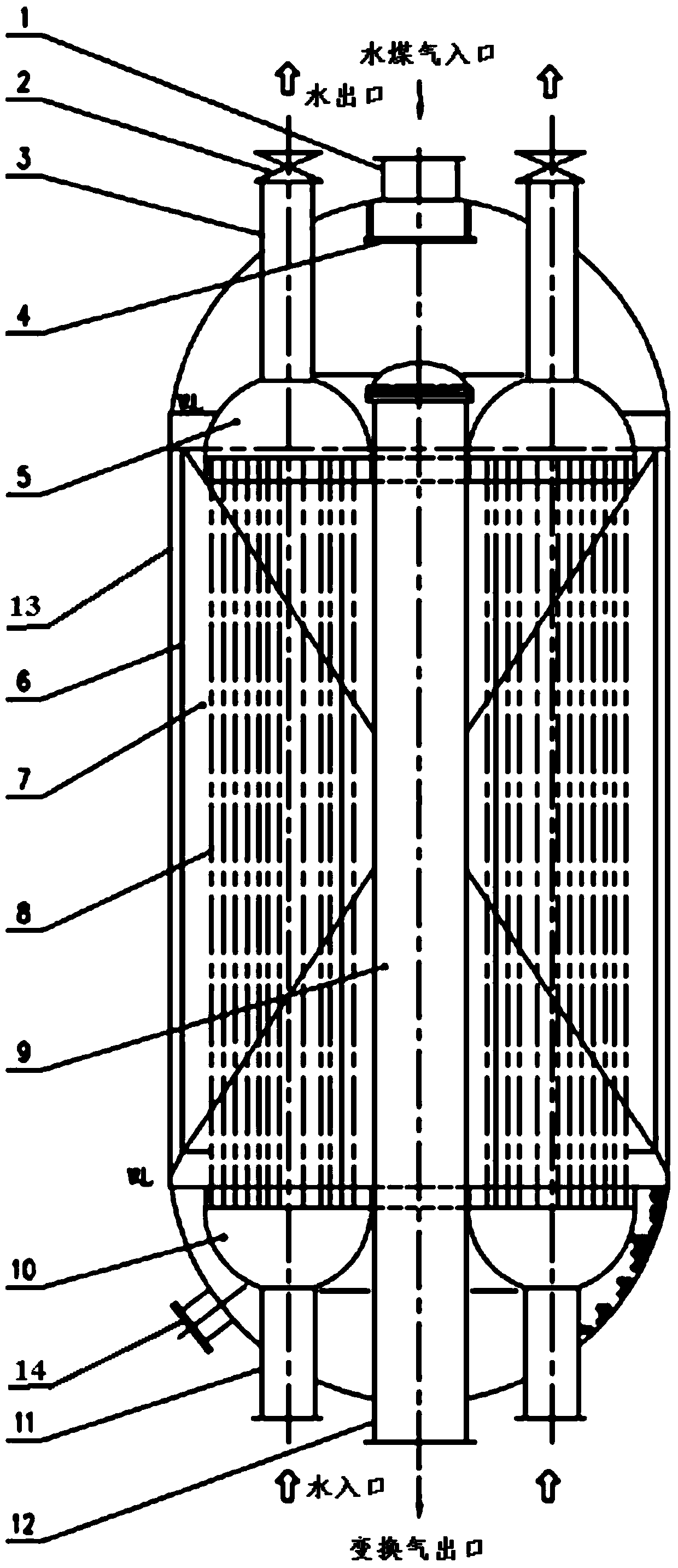

Radial flow by-product steam isothermal shift converter

A technology of isothermal transformation and by-product steam, applied in the field of temperature transformation furnace, can solve the problems of high equipment cost, high material consumption, high sealing and high cost, and achieve the requirements of low temperature application range, uniform temperature distribution and low equipment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment, further illustrate the present invention. These examples are only for illustrating the present invention and are not intended to limit the scope of the present invention. For the experimental methods without specific conditions indicated in the following examples, usually follow the conventional conditions or the conditions suggested by the manufacturer. All percentages and parts are by weight unless otherwise indicated.

[0024] Unless otherwise defined, all professional and scientific terms used herein have the same meanings as commonly understood by those skilled in the art. In addition, any methods and materials similar or equivalent to those described can be applied to the method of the present invention. The preferred implementation methods and materials described herein are for demonstration purposes only.

[0025] Such as figure 1 As shown, a radial flow by-product steam type isothermal shift furnace includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com