Catalyst for CO gas phase synthesis of dimethyl oxalate and preparation method of catalyst

A gas-phase synthesis technology of dimethyl oxalate, which is applied in the direction of carbon monoxide or formate reaction preparation, etc., can solve the problems of not meeting the economic requirements of industrialization, increased side reactions, poor activity, etc., to improve catalytic activity and selectivity of target products , improve stability, improve the effect of active structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

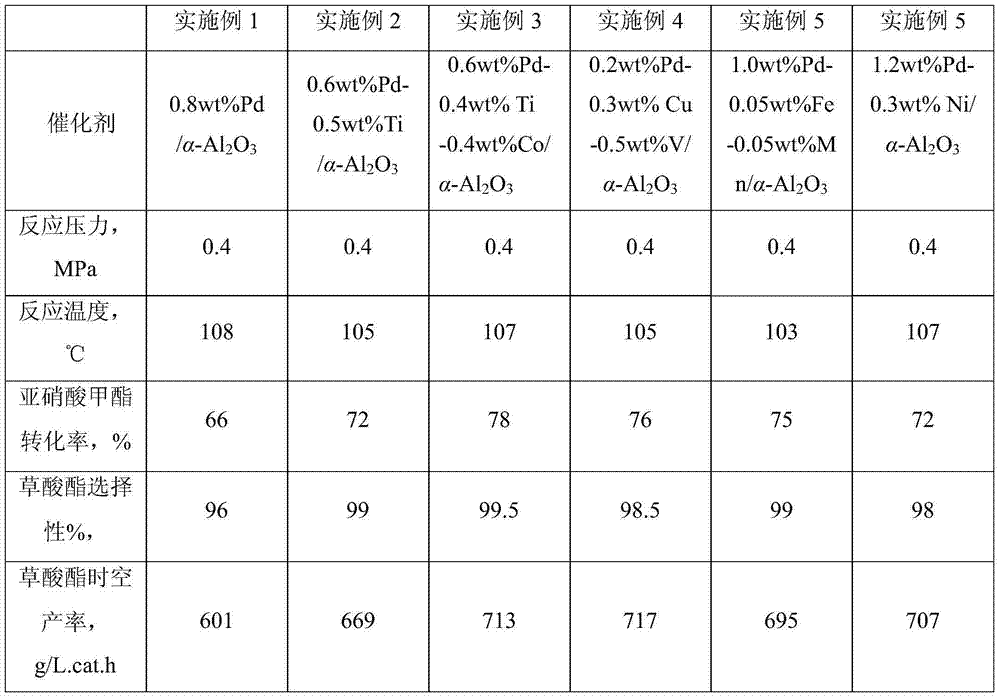

Examples

Embodiment 1

[0033] Weigh 100 grams of α-Al 2 o 3 Carrier, by 0.8wt%Pd / α-Al 2 o 3 (wherein, the percentage refers to the metal Pd accounted for the carrier α-Al 2 o 3 The percentage by weight, other embodiments are the same) content preparation catalyst, and its steps are as follows: select palladium nitrate for use, prepare the palladium nitrate impregnating solution that palladium ion concentration is 1.6wt% according to the load capacity of Pd, and adjust the pH=0.3 of impregnating solution with nitric acid . Set the specific surface area to 8m 2 / g, the pore volume is 0.09cm 3 / g, α-Al with an average pore size of 8nm 2 o 3 Put the carrier into the prepared impregnating solution and soak for 2 hours at 25°C, then take it out and let it dry in the air, dry at 120°C for 12 hours, and bake at 300°C for 2 hours in the air atmosphere to make an eggshell shape with a shell thickness of 0.1 -2mm Pd / α-Al 2 o 3 catalyst.

Embodiment 2

[0035] Weigh 100 grams of α-Al 2 o 3 Carrier, according to 0.6wt%Pd+0.5wt%Ti / α-Al 2 o 3 content to prepare the catalyst, the steps are as follows: prepare a titanium nitrate impregnation solution with a Ti ion concentration of 1.0wt% according to the loading amount of Ti; 2 / g, the pore volume is 0.25cm 3 / g, α-Al with an average pore diameter of 15nm 2 o 3Put the carrier into the prepared titanium nitrate impregnation solution and soak it at 35°C for 2 hours, then take it out and let it dry in the air, dry it at 120°C for 12 hours, and roast it at 600°C for 2 hours in the air atmosphere; then put it into the prepared Nitric acid adjusted pH = 0.3, palladium ion concentration of 1.2wt% palladium nitrate acidic dipping solution soaked at 35 ° C for 2 hours, then took it out and dried it in the air, dried at 120 ° C for 12 hours, and roasted at 300 ° C for 8 hours in an air atmosphere , step by step to make eggshell-shaped, shell thickness 0.1-2mm Pd-Ti / α-Al 2 o 3 cataly...

Embodiment 3

[0037] Weigh 100 grams of α-Al 2 o 3 Support, according to 0.6wt%Pd-0.4wt%Ti-0.4wt%Co / α-Al 2 o 3 Content preparation catalyst, its steps are as follows: According to Ti and Co load capacity preparation Ti and Co ion total concentration is 1.0wt% titanium nitrate and cobalt nitrate impregnation solution; Specific surface area is 20m 2 / g, the pore volume is 0.30cm 3 / g, α-Al with an average pore diameter of 25nm 2 o 3 Put the carrier into the titanium nitrate and cobalt nitrate impregnating solution prepared above and soak for 3 hours at 25°C, then take it out and dry it in the air, dry at 100°C for 12 hours, and bake at 600°C for 2 hours in an air atmosphere. Then put it into the palladium nitrate acidic impregnation solution adjusted with nitric acid to adjust pH=1 and palladium ion concentration to be 1.2wt% and soak for 2 hours, then take it out and put it in the air to dry, and dry it at 100°C for 12 hours. Calcined at 300°C for 8 hours in an air atmosphere, the eggs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com