Catalyst for preparing ethylene glycol by dimethyl oxalate hydrogenation, and preparation and use thereof

A technology of dimethyl oxalate and catalyst, which is applied in the field of catalyst and its preparation for the hydrogenation of dimethyl oxalate to ethylene glycol, can solve the problems of low space-time yield, high pressure, high temperature, etc., to improve catalyst activity, The effect of reducing investment costs and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

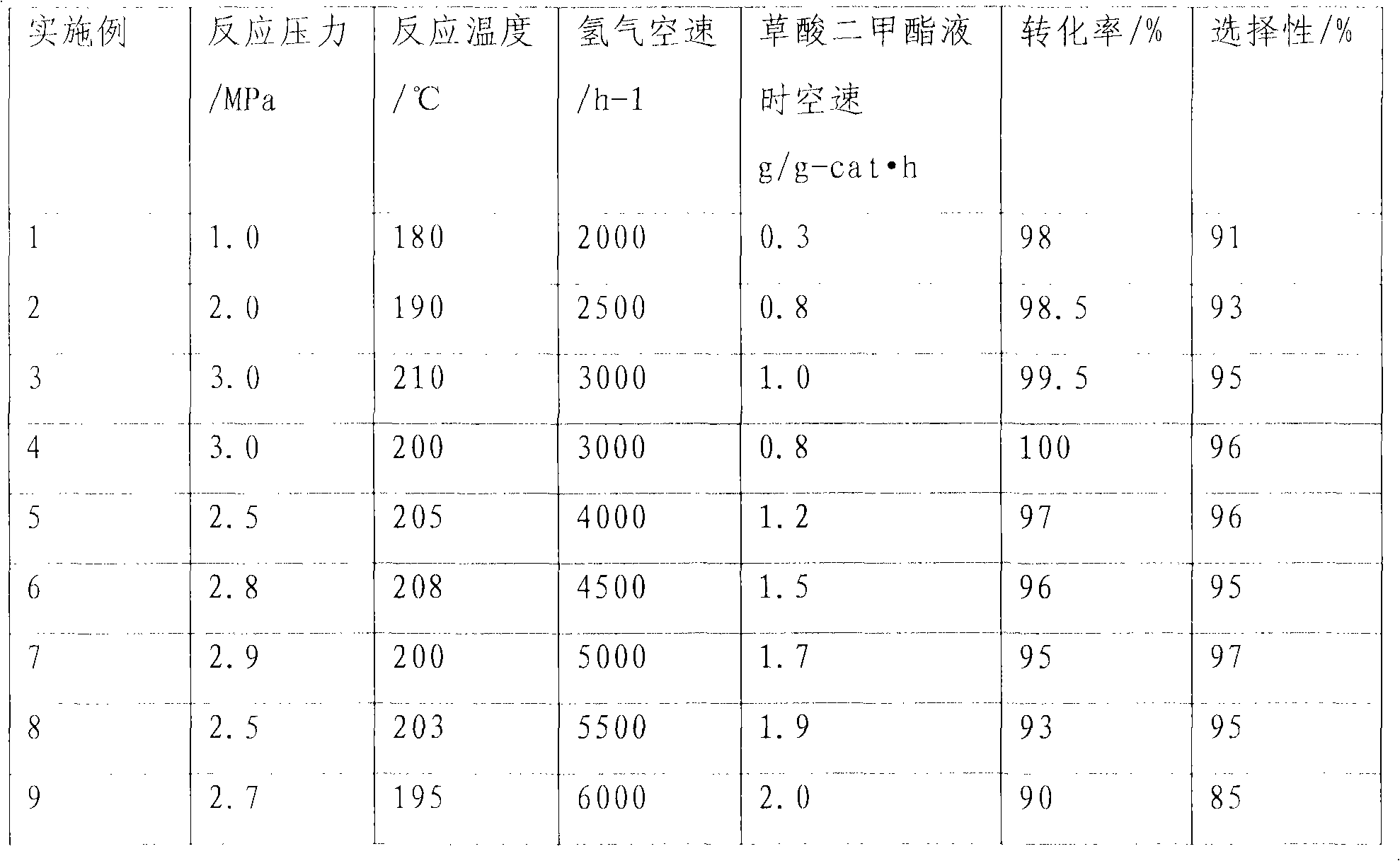

Examples

preparation example Construction

[0039] The preparation method of catalyst provided by the invention is as follows:

[0040] Soluble salts of active metals (one or any combination of two or more of copper nitrate, copper halide, copper acetate and copper sulfate) and soluble salts of auxiliary metals (nitrate of zinc, magnesium, aluminum, silver, ruthenium or iridium) Salt, acetate or sulfate, one or any combination of two or more) are mixed and dissolved to prepare an aqueous solution, wherein the concentration of active metal ions and auxiliary metal ions is 0.1-1.5M, and the silicon source (silica sol) of the carrier Add to the mixed solution to form a mixed solution A, stir well. Dissolve the precipitating agent in water to prepare aqueous solution B with a concentration of 0.1-1.5M. Under the condition of stirring, slowly drop the mixed solution A into the precipitant aqueous solution B, keep the temperature at 50-90°C during the dropping process, adjust the pH value to 6-9, continue stirring for 2-4 ho...

Embodiment 1

[0043] Weigh 25 grams of copper nitrate, 5 grams of magnesium nitrate, and 3 grams of iridium nitrate and dissolve them in water to form an aqueous solution with a total metal ion concentration of 1.0 M, and add 60 mL of silica sol with a mass percentage concentration of 25% to prepare a mixed solution. Weigh 30 grams of sodium carbonate and dissolve it in 200ml of water, place in a 60°C water bath, under stirring, slowly add the mixture into the aqueous sodium carbonate solution, and adjust the pH value to about 7.5 with nitric acid or sulfuric acid. Continue to stir for 2 hours after mixing, filter, wash until the conductivity of the washing liquid is less than 500us / cm, dry at 100°C for 12 hours, heat up to 400°C at 10°C / h in a muffle furnace, and roast at this temperature After 4 hours, granulate in a micro granulator to obtain a catalyst precursor. 20ml of 40-60 mesh catalyst precursors are loaded into the reactor, and 10ml of 20-40 mesh inert ceramic balls are loaded on ...

Embodiment 2

[0049] Weigh 20 grams of copper sulfate, 5 grams of zinc sulfate, and 1 gram of ruthenium nitrate and dissolve them in water to form an aqueous solution with a total metal ion concentration of 0.5 M, and add 50 mL of silica sol with a concentration of 30% by mass to obtain a mixed solution. Weigh 30 grams of sodium bicarbonate and dissolve it in 200ml of water, put it in a water bath at 70°C, under stirring, slowly add the mixed solution into the aqueous sodium bicarbonate solution, and control the pH value of the mixed solution at about 8.5. After mixing, continue to stir for 2 hours, filter, wash until the conductivity of the washing liquid is less than 500us / cm, dry at 90°C for 12 hours, heat up to 450°C at 10°C / h in a muffle furnace, and roast at a constant temperature at this temperature After 4 hours, granulate in a micro granulator to obtain a catalyst precursor. 20ml of 40-60 mesh catalyst precursors are loaded into the reactor, and 10ml of 20-40 mesh inert ceramic bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average hole radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com