Preparation method for synthesizing copper-based catalyst by sol-gel ammonia still process

A copper-based catalyst, sol-gel technology, applied in the field of catalysis, to achieve the effects of industrial scale-up, high catalytic activity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

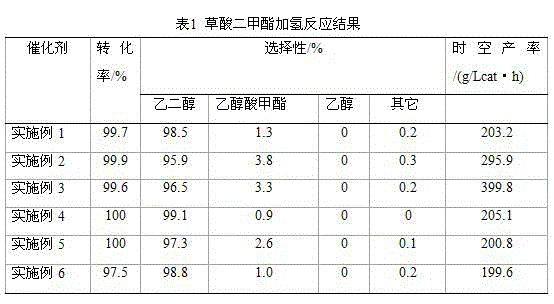

Embodiment 1

[0028] (1) Catalyst preparation: 12.3g Cu (NO 3 ) 2 ·3H 2 O was dissolved in 25.0g distilled water, fully dissolved and then added to the mixed solution formed by 42.0g ethanol and 46.5g tetraethyl orthosilicate, mechanically stirred the above mixed solution and placed in a water bath at 40°C for 2 hours to form a sol-gel. After aging at room temperature for 36 hours, the gel was cut into thin slices, soaked in ammonia water with pH = 13 for 12 hours, then placed in a 90°C water bath to evaporate the liquid, and then transferred to an oven to dry at 120°C for 24 hours. The obtained solid particles were calcined and dried for 5 hours at ℃. After calcined, the solid particles were pressed into tablets, crushed and sieved, and 40-80 mesh particles were sieved.

[0029] (2) Performance evaluation: Weigh a certain amount of 40-80 mesh catalyst precursor particles and reduce them in a hydrogen atmosphere at 150°C for 24 hours, with a hydrogen air velocity of 5000 hours -1 , the r...

Embodiment 2

[0031] (1) Catalyst preparation: 16.4g Cu (NO 3 ) 2 ·3H 2 O hydrated copper nitrate was dissolved in 50.0g of distilled water, fully dissolved and then added to the mixed solution formed by 42.0g of ethanol and 46.5g of ethyl orthosilicate, mechanically stirred the above mixed solution and placed in a water bath at 80°C for 0.5h to form a sol Gel, after aging the gel at room temperature for 48 hours, cut it into thin slices, add ammonia water with pH=11 to soak, then put it in a water bath at 80 ℃ to evaporate the liquid, then transfer it to an oven and dry it at 100 ℃ for 24 hours, and then dry it in a muffle The obtained solid particles were calcined and dried at 450°C in a furnace for 3 hours. After calcined, the solid particles were pressed into tablets, crushed and sieved, and 40-80 mesh particles were sieved.

[0032] (2) Performance evaluation: Weigh a certain amount of 40-80 mesh catalyst precursor particles and reduce them in a hydrogen atmosphere at 200°C for 12 ho...

Embodiment 3

[0034] (1) Catalyst preparation: 21.1g Cu (NO 3 ) 2 ·3H 2O hydrated copper nitrate was dissolved in 100.0g of distilled water, fully dissolved and then added to the mixed solution formed by 75.0g of ethanol and 46.5g of ethyl orthosilicate, mechanically stirred the above mixed solution and placed in a water bath at 40°C for 1 hour to form a sol gel After aging the gel at room temperature for 48 hours, cut the gel into thin slices, add ammonia water with pH=13 to soak, then put it in a water bath at 80 ℃ to evaporate the liquid, and then transfer it to an oven to dry at 120 ℃ for 24 hours. The obtained solid particles were calcined and dried at 350° C. for 5 hours. After calcined, the solid particles were compressed into tablets, crushed and sieved, and 40-80 mesh particles were sieved.

[0035] (2) Performance evaluation: Weigh a certain amount of 40-80 mesh catalyst precursor particles and reduce them in a hydrogen atmosphere at 250°C for 8 hours with a hydrogen air velocit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com