Method for preparing ethylene glycol by using dimethyl oxalate plus hydrogen

A technology containing dimethyl oxalate and dimethyl oxalate, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., to achieve the effects of good selectivity, easy industrial production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Cu-B / γ—Al 2 o 3 Preparation of amorphous catalyst (Cu 20w%, B=6w%)

[0045] (1) Weigh 8g of carrier γ-Al 2 o 3 , roasted at 600°C for 6h;

[0046] (2) At room temperature, under a vacuum of 0.04Mpa, the formed γ-Al 2 o 3 Immerse in 16g of copper nitrate aqueous solution, dry at 120°C for 10h, wash the impregnated γ-Al 2 o 3 to Cu-free 2+ precipitation;

[0047] The weight of the copper in the copper nitrate aqueous solution is 2g;

[0048] (3) Add 20g of NaBH to the product of step (2) at 0°C in a nitrogen atmosphere 4 -The KOH aqueous solution is reduced until no more gas is released in the system, washed, and the reaction product is collected, which is the catalyst of the present invention, put into absolute ethanol and preserved for subsequent use;

[0049] NaBH 4 —In KOH aqueous solution, NaBH 4 The weight concentration of KOH is 60%, and the weight concentration of KOH is 40%;

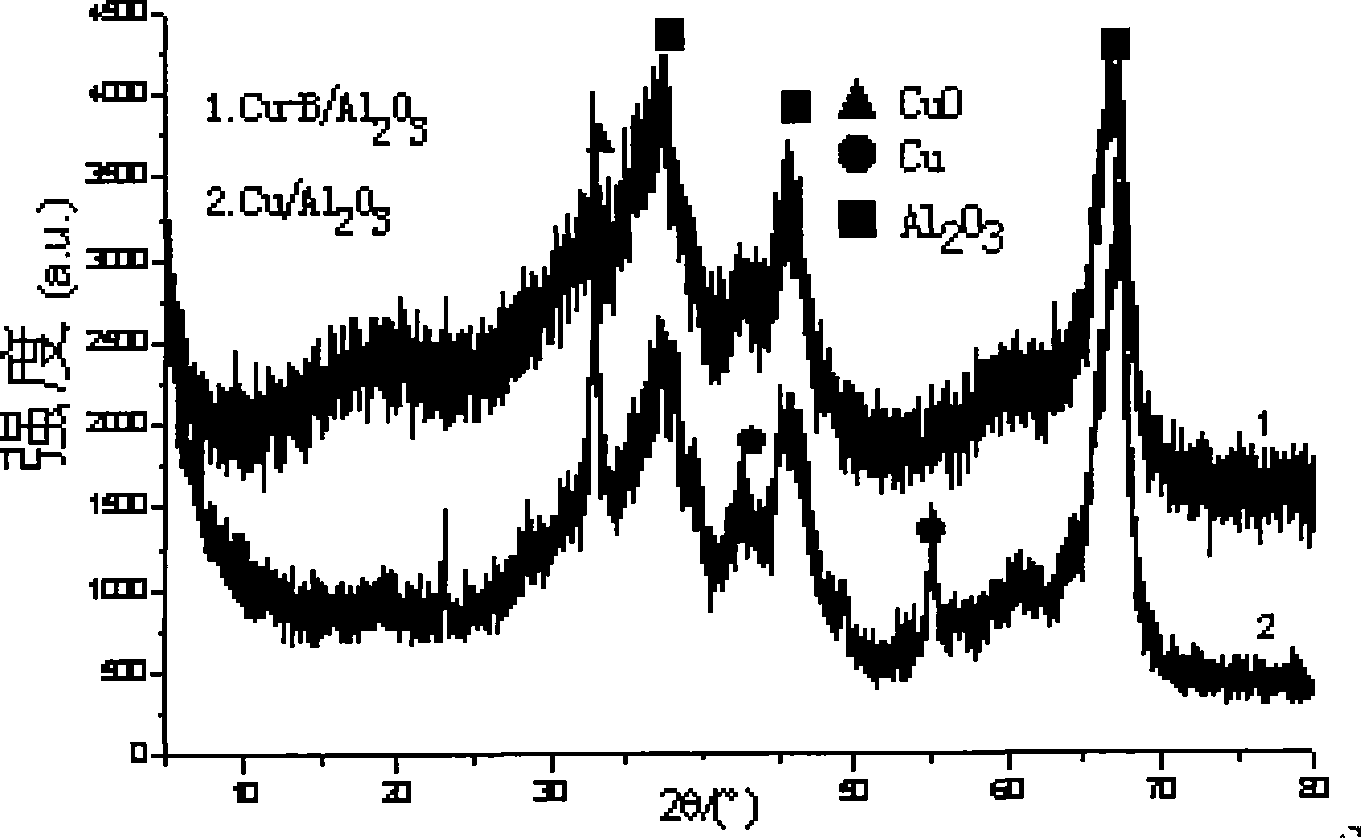

[0050] figure 1 It is the catalyst XRD spectrum, see curve 1 in the figu...

Embodiment 2

[0052] Cu-Co-B / γ—Al 2 o 3 Preparation of amorphous catalyst (Cu 15w%, B=5w%, Co 5w%)

[0053] (1) Weigh 8g carrier γ-Al 2 o 3 , roasted at 900°C for 2h;

[0054] (2) At room temperature, under a vacuum of 0.04Mpa, the formed γ-Al 2 o 3 Immerse in 16g of copper nitrate and cobalt nitrate aqueous solution, dry at 100°C for 6 hours, wash the impregnated γ-Al 2 o 3 to Cu-free 2+ precipitation;

[0055] The weight of copper in the copper nitrate aqueous solution is 1.5g; The weight of cobalt in the cobalt nitrate solution is 0.5g;

[0056] (3) With the product of step (2), at 0°C, in a nitrogen atmosphere, add 20g NaBH 4 —The KOH aqueous solution is reduced until there is no gas release in the system, washing and collecting the reaction product, which is the catalyst of the present invention, which is Cu-Co-B / Al 2 o 3 Amorphous alloy catalyst, stored in absolute ethanol for later use; NaBH 4 —In KOH aqueous solution, NaBH 4 The weight concentration of KOH is 60%, and ...

Embodiment 3

[0058] Cu-B / SiO 2 Preparation of amorphous catalyst (Cu 20w%, B=6w%)

[0059] The preparation method is the same as in Example 1, wherein, in step (3), the product of step (2) is added to 20 g of NaBH in a nitrogen atmosphere at 0°C 4 —KOH aqueous solution, NaBH 4 —In KOH aqueous solution, NaBH 4 The weight concentration of KOH is 60%, and the weight concentration of KOH is 40%;

[0060] The catalyst 3 of the present invention was obtained.

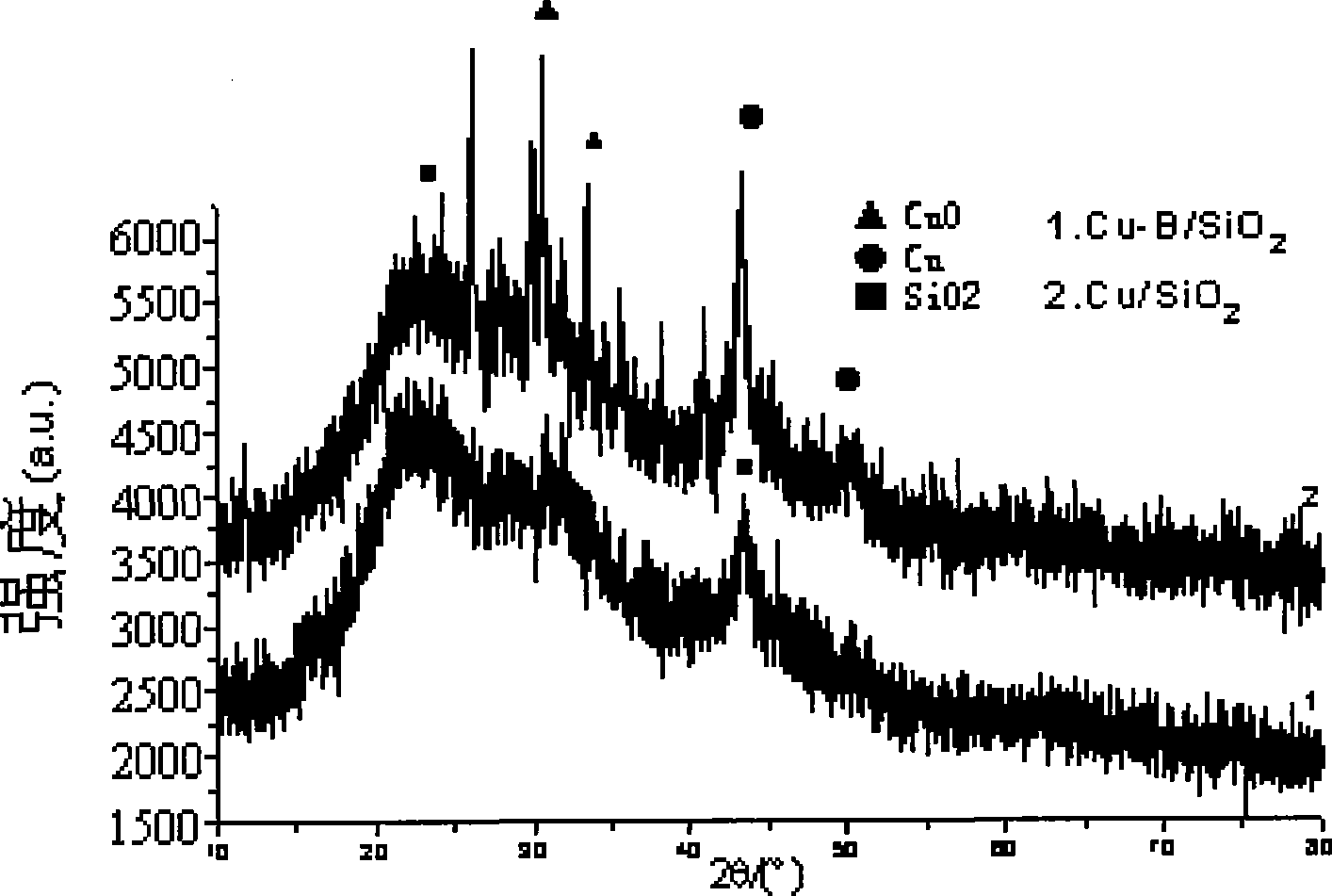

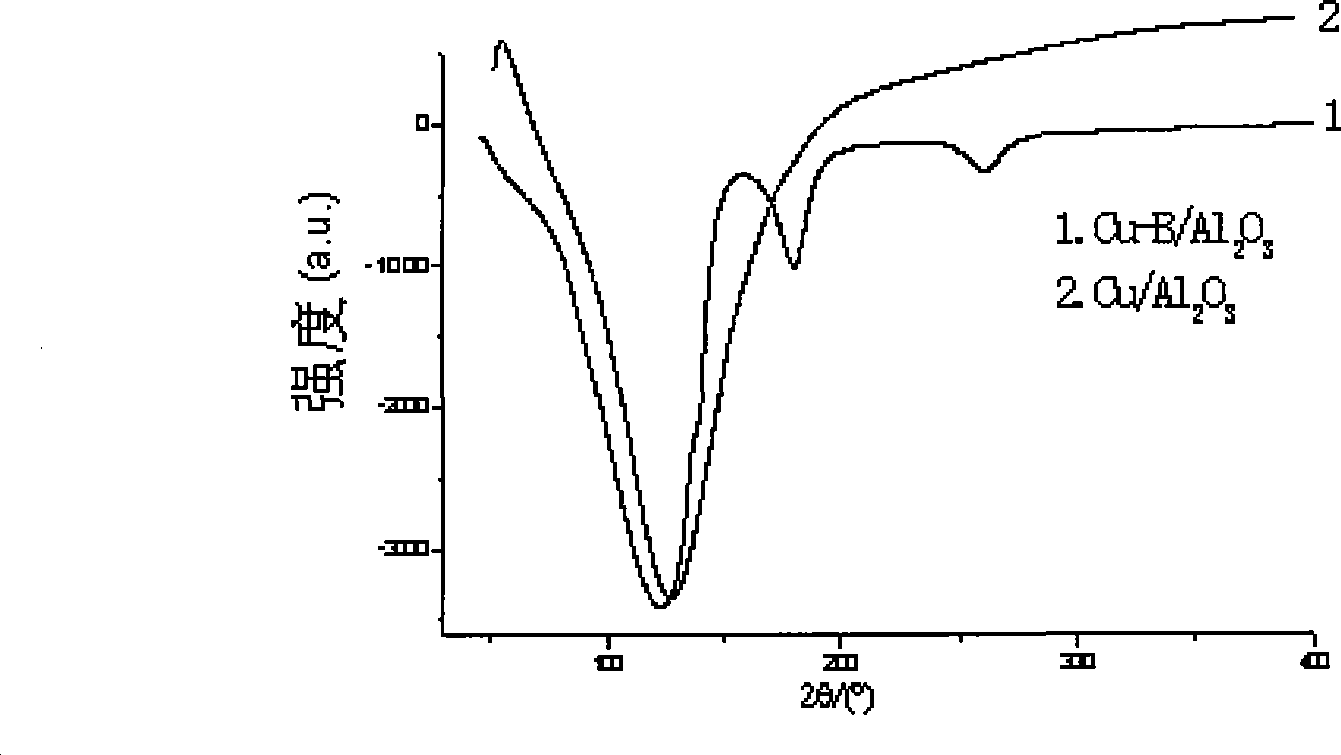

[0061] figure 2 It is the catalyst XRD spectrum, see curve 1 in the figure. Figure 4 It is the catalyst DTA diagram, see the curve 1 in the figure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com