Method for preparing ethylene glycol from oxalic ester

A technology of ethylene glycol and oxalate, which is applied in the field of hydrogenation of dimethyl oxalate or hydrogenation of diethyl oxalate to produce ethylene glycol, which can solve the problems of short life and poor catalyst stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

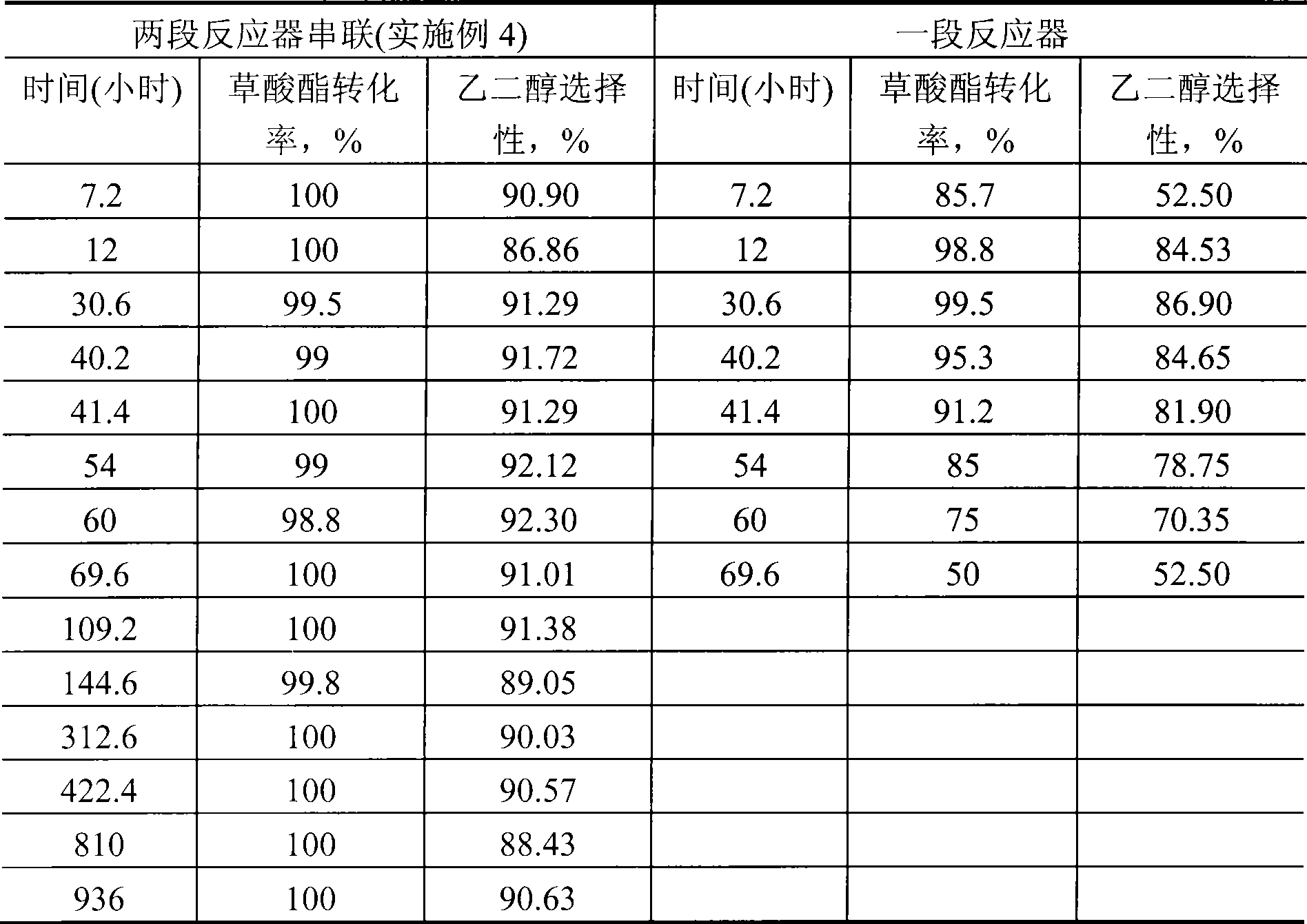

Examples

Embodiment 1

[0018] Weigh 100 grams of silicon oxide carrier whose specific surface area is 200 square meters per gram, according to 25% CuO / SiO 2 Content configuration catalyst, the steps are as follows: select copper nitrate, prepare an impregnation solution according to the Cu loading capacity, impregnate the silicon oxide carrier in the solution for 20 hours, and dry it in vacuum at room temperature for 8 hours to obtain a solid. The solid was then dried at 120°C for 10 hours and calcined at 500°C for 6 hours to obtain the desired CuO / SiO2 catalyst precursor.

[0019] Weigh the prepared CuO / SiO 2 The catalyst precursor is loaded into the tube reactor with a diameter of 18 mm according to the required amount. The pre-reaction catalyst is at 100 ml / min, the hydrogen molar content is 20%, and the nitrogen molar content is 80%. Minutes to 450 ° C, constant temperature for 4 hours for activation to obtain catalyst I and catalyst II with the same composition.

[0020] Using hydrogen and di...

Embodiment 2

[0022] According to the various steps and conditions of Example 1, 35%Cu+10%Cu was produced 2 O+5%Zn / SiO 2 Cu-Cu 2 O-Zn / SiO 2 Catalyst I and 20% Cu+5% Cu 2 O / Al 2 o 3 Cu-Cu 2 O / Al 2 o 3 Catalyst II.

[0023] Using hydrogen and dimethyl oxalate as raw materials, the dimethyl oxalate raw material is divided into the first raw material and the second raw material, the molar ratio of the first raw material and the second raw material is 1:1, hydrogen and the first raw material and The total molar ratio of the sum of the second raw materials is 60:1, and both the first raw material and the second raw material are selected from dimethyl oxalate. Hydrogen and the first stream of raw material first enter the first reactor to contact with catalyst I to generate the first reaction effluent containing ethylene glycol; the first reaction effluent and the second raw material enter the second reactor to be contacted with Catalyst II is contacted to generate a second reaction efflu...

Embodiment 3

[0025] Prepare 48%Cu+2%Cu according to the various steps and conditions of Example 1 2 O+5%Fe 2 o 3 / SiO 2 Cu-Cu 2 O-Fe 2 o 3 / SiO 2 Catalyst I and 40% Cu+20% Cu 2 O / Al 2 o 3 Cu-Cu 2 O / Al 2 o 3 Catalyst II.

[0026] Hydrogen and oxalate are used as raw materials. The oxalate is a mixture of dimethyl oxalate and diethyl oxalate with a molar ratio of 1:1. The raw material of oxalate is divided into the first raw material and the second raw material. The molar ratio of the raw material to the second raw material is 3:1, and the total molar ratio of hydrogen to the sum of the first raw material and the second raw material is 160:1, and the first raw material and the second raw material are all selected from dioxalic acid A mixture of methyl ester and diethyl oxalate with a molar ratio of 1:1. Hydrogen and the first stream of raw material first enter the first reactor to contact with catalyst I to generate the first reaction effluent containing ethylene glycol; the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com