Copper-hydroxyapatite catalyst for synthesizing methyl glycolate and ethylene glycol and preparation method thereof

A kind of technology of methyl glycolate and hydroxyapatite, applied in the field of chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

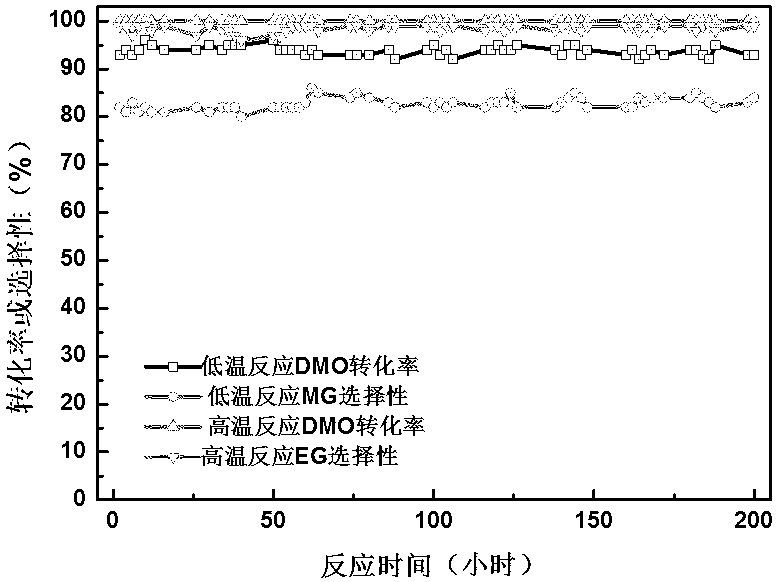

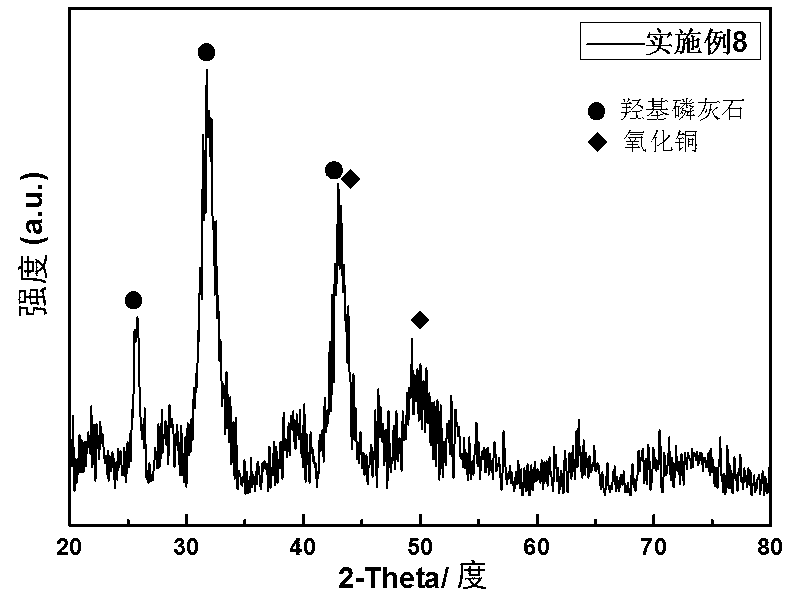

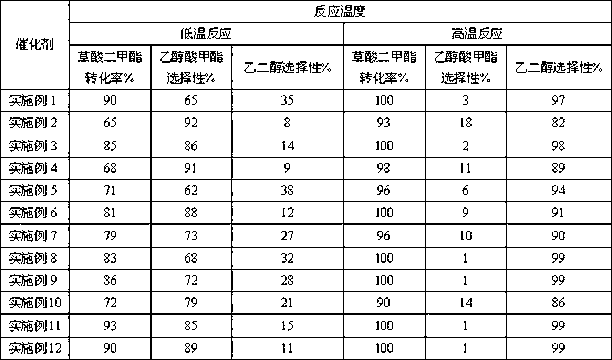

Examples

Embodiment 1

[0020] Example 1: Preparation of carrier hydroxyapatite

[0021] 23.52 g Ca(NO 3 ) 2 4H 2 O was dissolved in 300 mL water, and the pH was adjusted to 11~12 with ammonia water to make a calcium nitrate solution (about 0.33 M), and 200 mL containing 7.89 g (NH 4 ) 2 HPO 4 The aqueous solution (about 0.30 M, Ca / P=1.67 (mol / mol)) was slowly dropped into the above calcium nitrate solution, and stirred and heated at 50°C for 16 h to obtain a suspension containing apatite carrier for use. The mass fraction of hydroxyapatite in the suspension is about 2%.

[0022] Active metal copper and auxiliary metal loading: 13.10 g Cu(NO 3 ) 2 ·3H 2 O and 3.01 g Fe(NO 3 ) 3 9H 2 Add O to the carrier suspension at the same time, adjust the pH of the suspension to 11~12 with ammonia water, stir and react in a water bath at 30°C for 14 hours, then increase the temperature of the water bath, and continue stirring at 80°C until the suspension The pH value is 9~10, the reaction is stopped, ...

Embodiment 2

[0024] Example 2: Preparation of carrier hydroxyapatite

[0025] 23.52 g Ca(NO 3 ) 2 4H 2 O was dissolved in 300 mL of water, and the pH was adjusted to 11~12 with ammonia water to make a calcium nitrate solution (about 0.33 M), and 200 mL containing 4.39 g (NH 4 ) 2 HPO 4 The aqueous solution (about 0.20 M, Ca / P=3.0 (mol / mol)) was slowly dropped into the above calcium nitrate solution, and stirred and heated at 50°C for 16 h to obtain a suspension containing apatite carrier for use. The mass fraction of hydroxyapatite in the suspension is about 2%.

[0026] Active metal copper and auxiliary metal loading: 13.10 g Cu(NO 3 ) 2 ·3H 2 O and 7.56 g Mn(NO 3 ) 2 4H 2 Add O to the suspension containing the carrier hydroxyapatite at the same time, adjust the pH of the suspension to 10~11 with ammonia water, stir and react in a water bath at 50 °C for 6 h, increase the temperature of the water bath, and continue to stir and react at 80 °C , until the pH value of the suspens...

Embodiment 3

[0028] Embodiment 3: The preparation of carrier hydroxyapatite is the same as that in Embodiment 1.

[0029] Active metal copper and auxiliary metal loading: 13.10 g Cu(NO 3 ) 2 ·3H 2 O and 1.91 g Zn(NO 3 ) 2 ·6H 2 Add O to the suspension containing the carrier hydroxyapatite at the same time, adjust the pH of the suspension to 11~12 with ammonia water, stir and react in a water bath at 50°C for 6 h, increase the temperature of the water bath, and continue to stir and react at 80°C , until the pH value of the suspension is 7~7.5, stop the reaction, obtain the suspension containing the catalyst, then filter it, wash it with deionized water for 5 times, bake the filter cake at 120°C, and put it in a muffle furnace for 10 °C / min, the temperature was raised to 600 °C and kept for 5 h to obtain catalyst powder.

[0030] Activity evaluation is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com