Catalyst and method for synthesizing methyl glycollate and ethylene glycol by virtue of dimethyl oxalate hydrogenation

A technology of methyl glycolate and dimethyl oxalate, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of poor stability, low catalyst activity, etc. problems, to achieve mild reaction conditions, high activity, and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

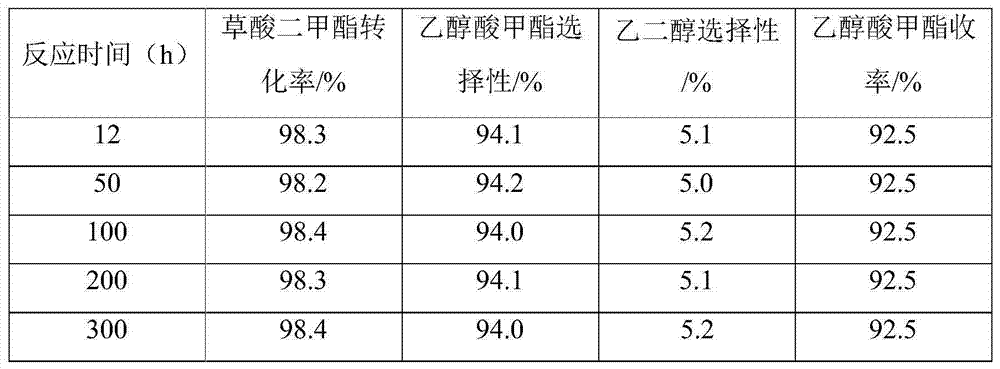

Embodiment 1

[0031] Dissolve 23.6g of silver nitrate in 100mL of water, immerse 100g of titanium dioxide in the prepared solution, soak for 2 hours, separate the solid after fully absorbed, dry at 80°C for 4 hours, and then roast at 400°C for 5 The catalyst was produced after hours. After sieving the catalyst, take 20-30 mesh particles, fill them in a fixed-bed reactor, pass through hydrogen for reduction at 300°C for 4 hours, and then react at a reaction temperature of 250°C, a pressure of 2.5Mpa, and a hydrogen ester molar ratio of 50 , Feed liquid hourly space velocity 0.7h -1 Hydrogenation reaction was carried out under certain conditions, and the reaction results obtained: the conversion rate of dimethyl oxalate was 98.3%, the selectivity of methyl glycolate was 94.1%, the selectivity of ethylene glycol was 5.1%, and the yield of methyl glycolate was 92.5%. , and no carrier components were detected in the product.

Embodiment 2

[0033]Dissolve 23.6g of silver nitrate in 90mL of water, immerse 100g of titanium dioxide into the prepared solution, soak for 2 hours, and after complete absorption, dry the solid at 80°C for 4 hours, and then bake it at 300°C for 4 hours The catalyst is prepared. After sieving the catalyst, take 20-30 mesh particles, fill them in a fixed-bed reactor, pass through hydrogen for reduction at 300°C for 4 hours, and then react at a reaction temperature of 240°C, a pressure of 2.5Mpa, and a hydrogen ester molar ratio of 50 , Feed liquid hourly space velocity 0.7h -1 Hydrogenation reaction was carried out under certain conditions, and the reaction results obtained: the conversion rate of dimethyl oxalate was 98.2%, the selectivity of methyl glycolate was 93.1%, the selectivity of ethylene glycol was 6.1%, and the yield of methyl glycolate was 91.4%. , and no carrier components were detected in the product.

Embodiment 3

[0035] Dissolve 23.6g of silver nitrate in 100mL of water, immerse 100g of carbon nanotubes in the prepared solution, soak for 2 hours, separate the solid after full absorption, dry at 80°C for 4 hours, and then roast at 400°C for 5 hours The catalyst is then prepared. After sieving the catalyst, take 20-30 mesh particles, fill them in a fixed-bed reactor, pass through hydrogen for reduction at 300°C for 4 hours, and then react at a reaction temperature of 250°C, a pressure of 2.5Mpa, and a hydrogen ester molar ratio of 50 , Feed liquid hourly space velocity 0.7h -1 Hydrogenation reaction was carried out under certain conditions, and the reaction results obtained: the conversion rate of dimethyl oxalate was 99.3%, the selectivity of methyl glycolate was 97.1%, the selectivity of ethylene glycol was 2.1%, and the yield of methyl glycolate was 96.4%. , and no carrier components were detected in the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com