Method for preparing catalyst used in method for preparing ethanediol by dimethyl oxalate hydrogenation

A dimethyl oxalate and catalyst technology, applied in the chemical industry, can solve the problems of production cost dependence, cost increase, unsuitability, etc., and achieve the effects of easy control, long life and stable reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

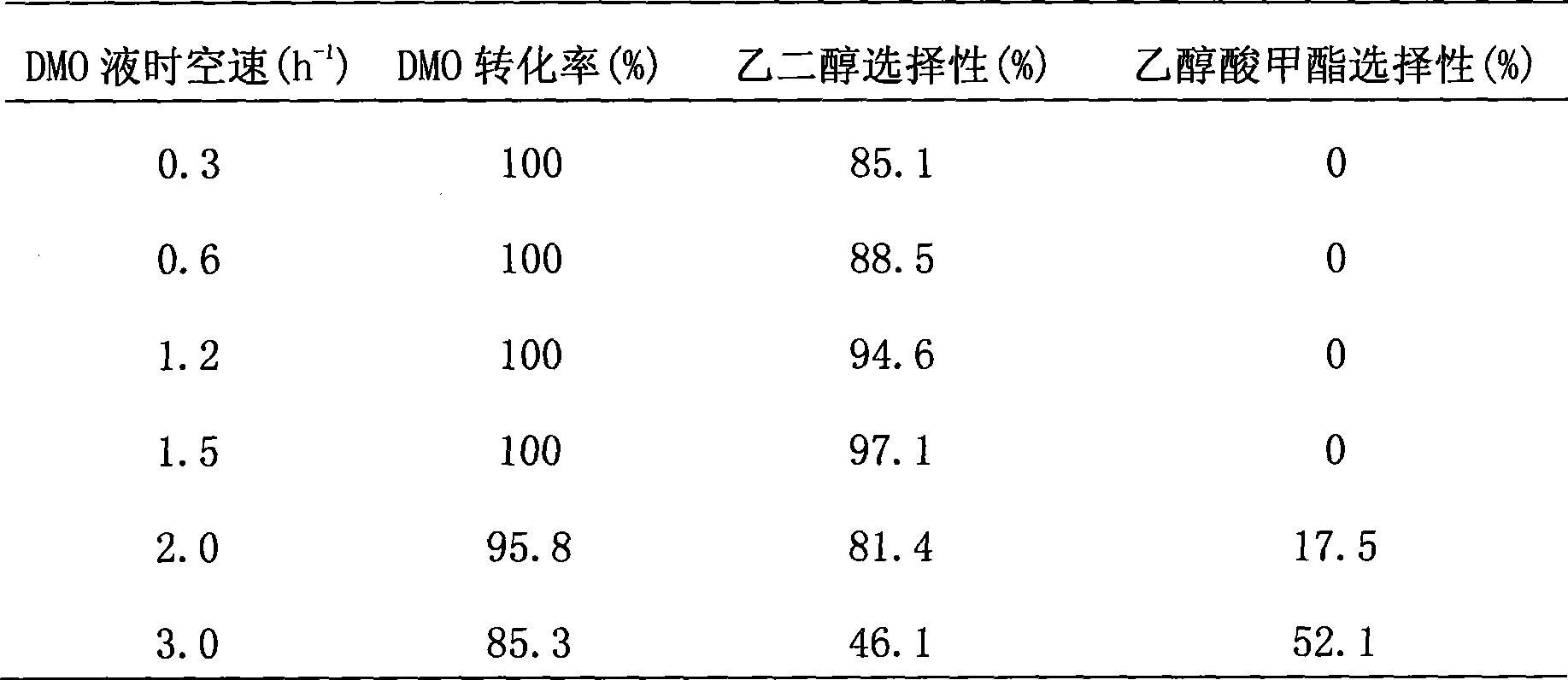

Embodiment 1

[0028] The present invention is further described by the following examples, but the present invention is not limited thereto. Embodiment 1: Mesoporous silica molecular sieve SBA-15 supported catalyst:

[0029] The catalyst preparation method used in the hydrogenation of dimethyl oxalate to prepare ethylene glycol method may further comprise the steps:

[0030] The first step: at room temperature, 7.56g Cu(NO 3 ) 2 ·3H 2 O was dissolved in 200ml of distilled water, 25wt% concentrated ammonia water was added dropwise to pH = 9.0±0.2, and stirred for 50 minutes to form a copper ammonia complex;

[0031] Step 2: Add 10g of mesoporous silica molecular sieve SBA-15 to the copper ammonium complex, stir at room temperature for 50min, then continue to stir in an ice-water bath, and at the same time add 5000ml of distilled water dropwise at a speed of 10ml / min, dropwise Continue to stir for 60 minutes after completion; filter, wash with distilled water and ethanol three times respe...

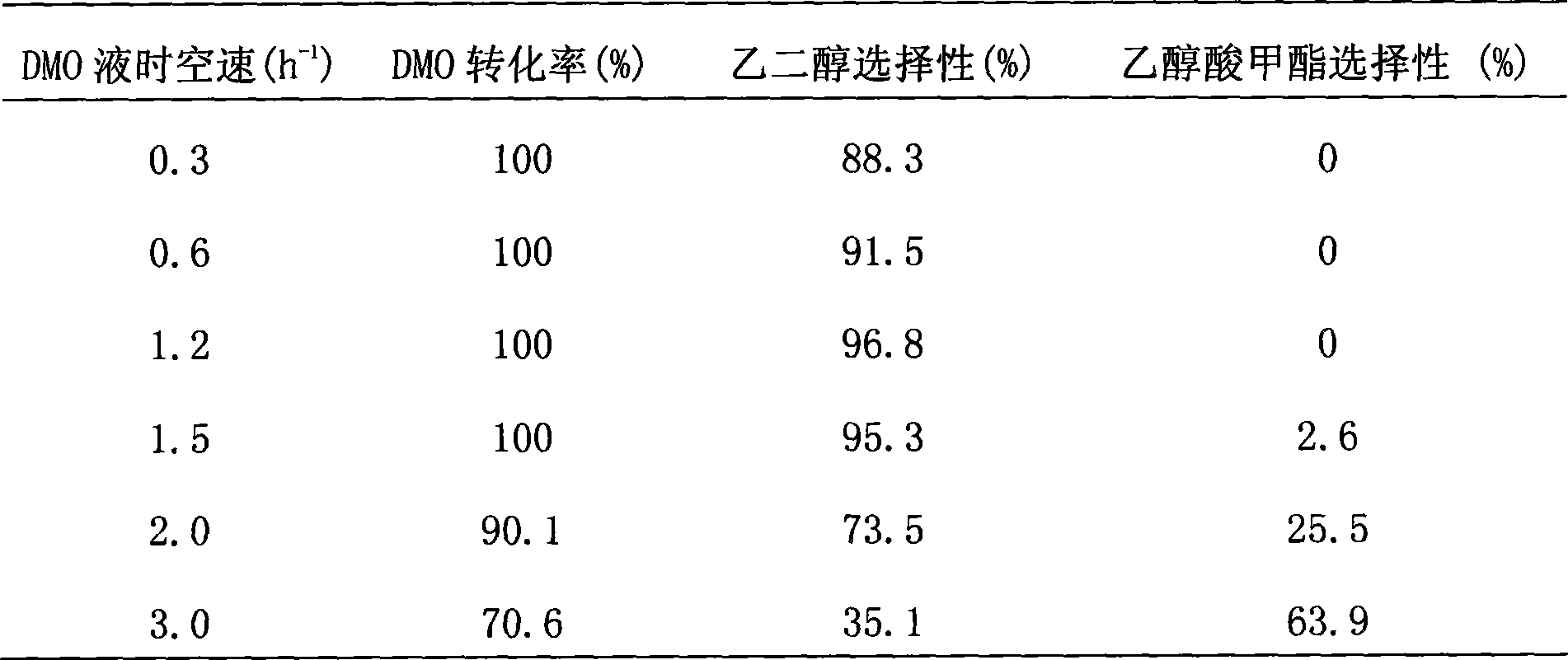

Embodiment 2

[0033] Embodiment 2: The catalyst preparation method used in the method for preparing ethylene glycol by hydrogenation of dimethyl oxalate supported by mesoporous silica molecular sieve MCM-41 comprises the following steps:

[0034] The first step: with embodiment 1;

[0035] Step 2: Add 10g of mesoporous silica molecular sieve MCM-41 to the copper ammonium complex, stir at room temperature for 50min, then continue to stir in an ice-water bath, and at the same time add 5000ml of distilled water dropwise at a speed of 10ml / min, dropwise Continue to stir for 60 minutes after completion; filter, wash with distilled water and ethanol three times respectively, then dry at 100°C for 10h, and then roast at 450°C for 4h to make a catalyst precursor;

[0036] The third step: the same as in Example 1, the catalyst Cu / MCM-41 was obtained, and the copper content in the catalyst was determined by ICP to be 16.8 wt%.

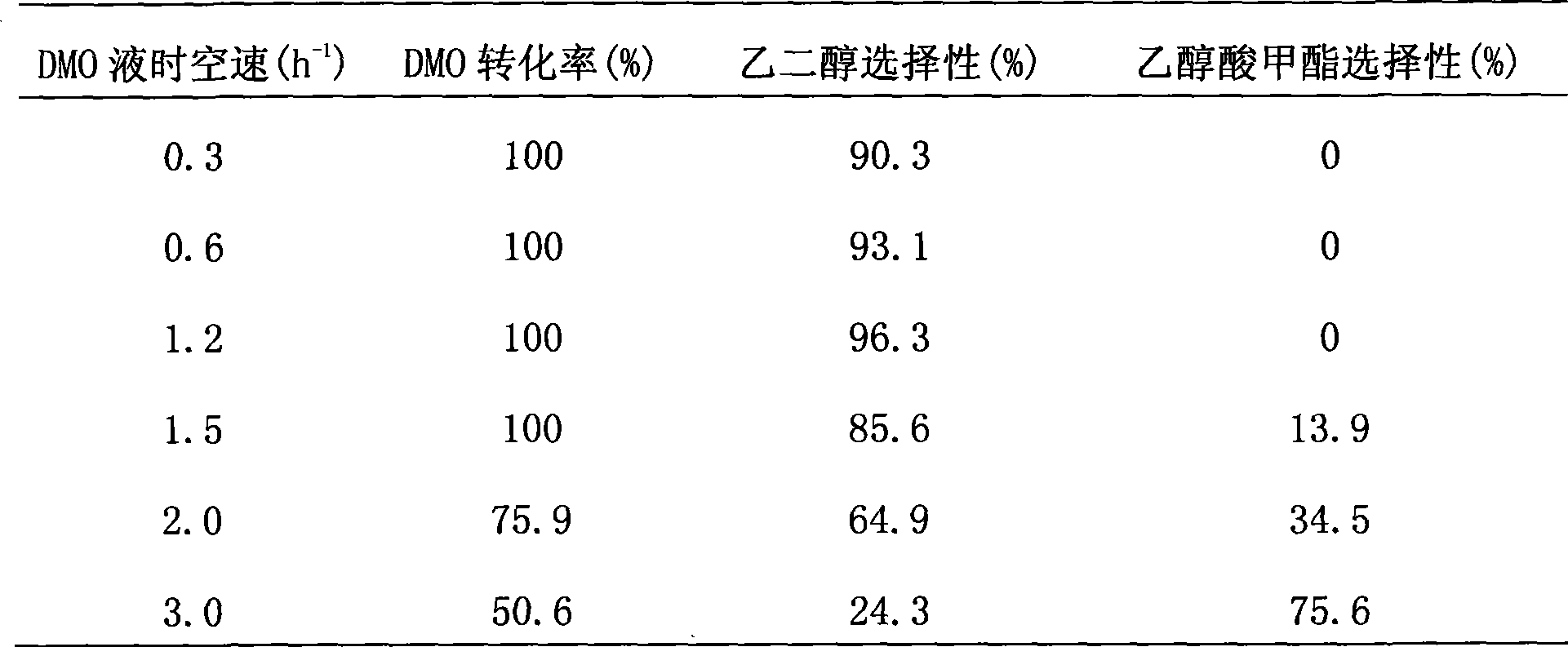

Embodiment 3

[0037] Example 3: Catalyst supported by mesoporous silica molecular sieve MCF

[0038] The catalyst preparation method used in the hydrogenation of dimethyl oxalate to prepare ethylene glycol method may further comprise the steps:

[0039] The first step: with embodiment 1;

[0040] Step 2: Add 10g of mesoporous silica molecular sieve MCF to the copper ammonium complex, stir at room temperature for 50min, then continue to stir in the ice-water bath, and at the same time add 5000ml of distilled water dropwise at a speed of 10ml / min, after the dropwise addition Continue to stir for 60 minutes; filter, wash with distilled water and ethanol three times respectively, then dry at 100°C for 10h, and then roast at 450°C for 4h to make a catalyst precursor;

[0041] The third step: the same as in Example 1, the catalyst Cu / MCF was obtained, and the copper content in the catalyst was determined by ICP to be 16.2 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com