Low-power dual-frequency ultrasonic/Fenton oxidation reactor device

An oxidation reactor and ultrasonic technology, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problems of uneven ultrasonic irradiation, low OH yield, etc. The effect of high stability, fast degradation rate and strong oxidative ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

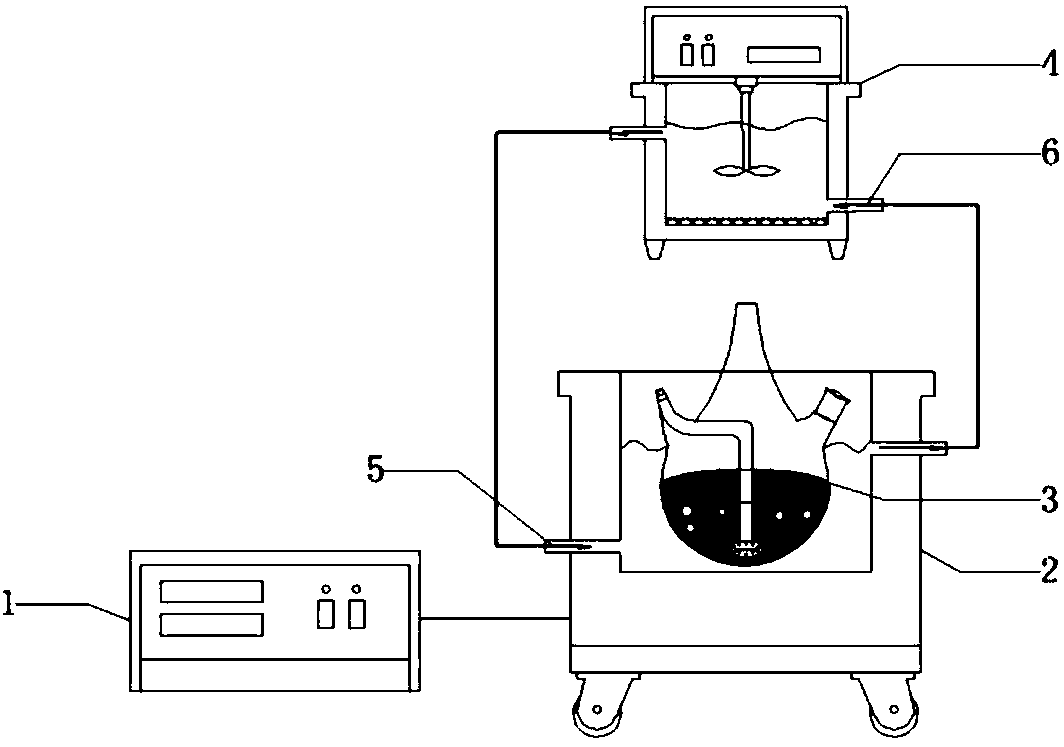

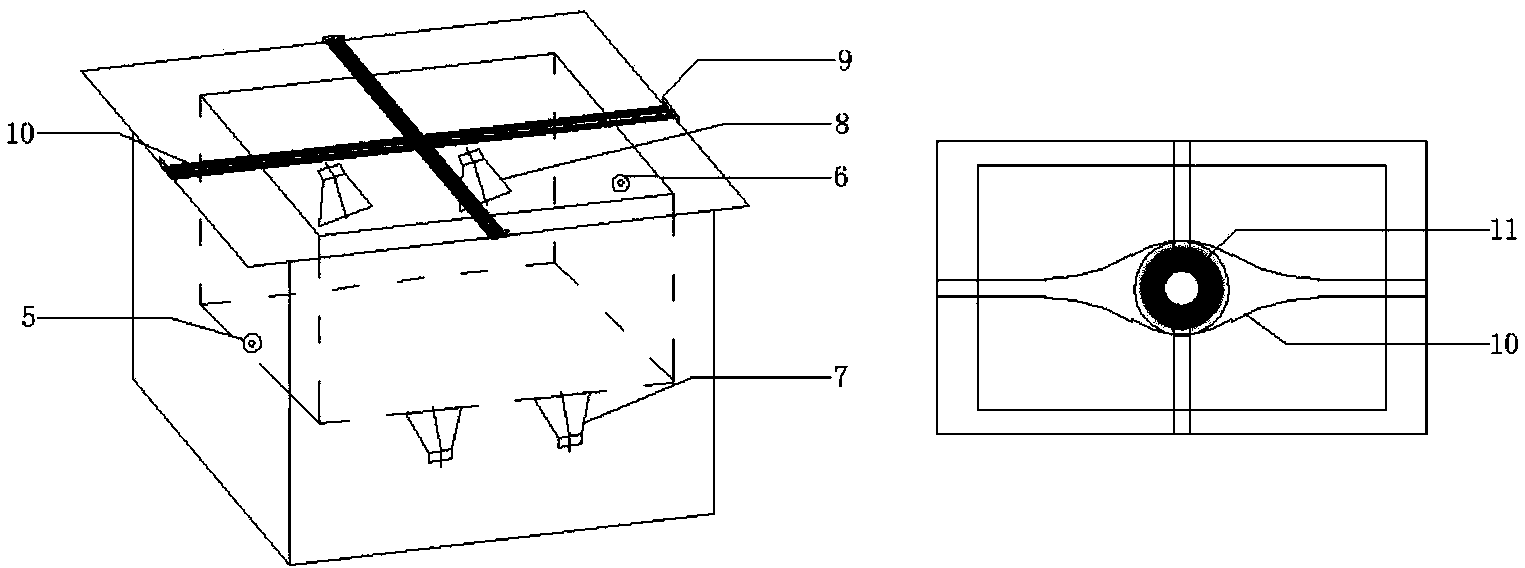

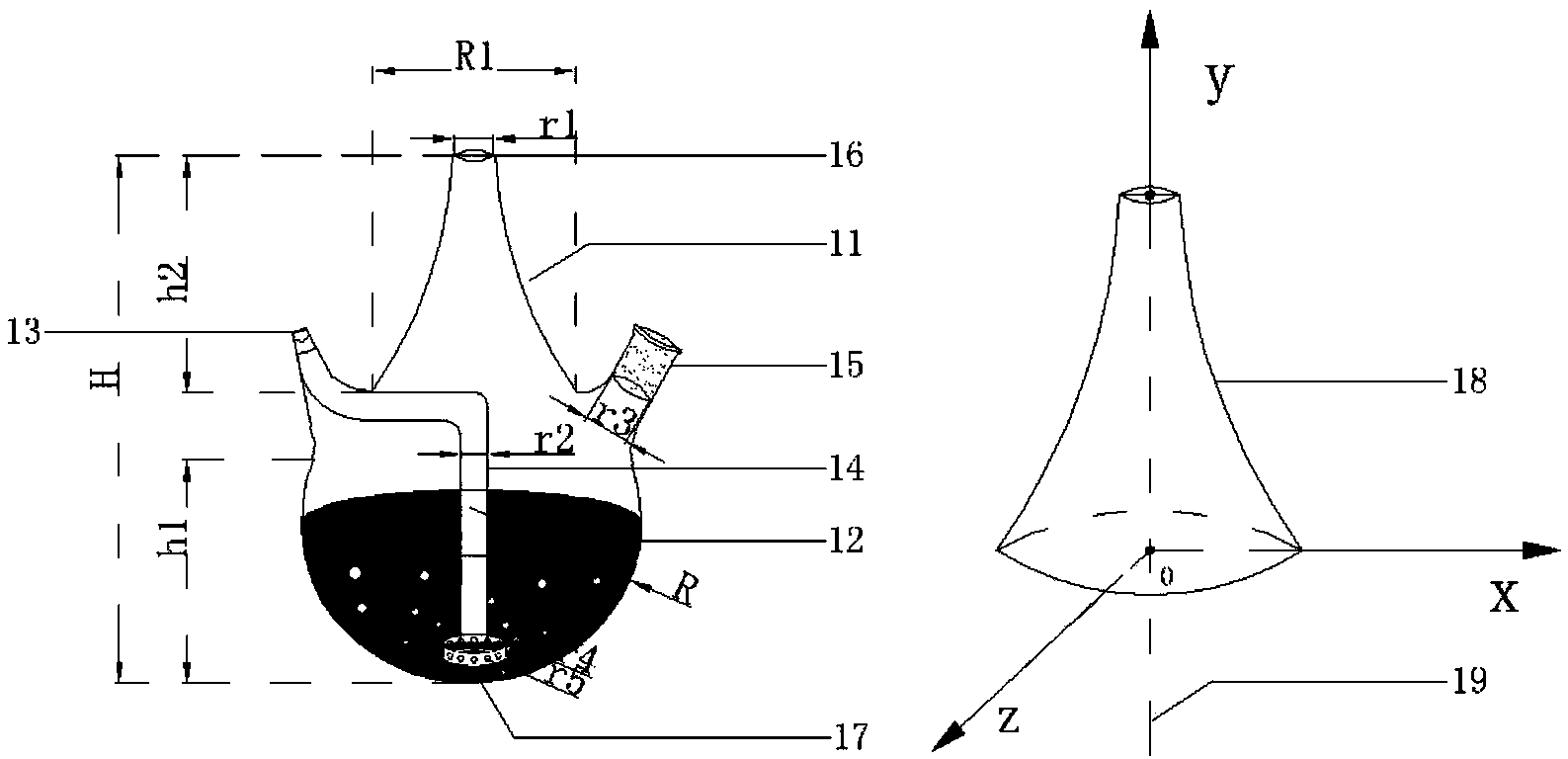

[0026] Such as figure 1 Shown: low-power dual-frequency ultrasonic Fenton oxidation reactor device, including dual-frequency ultrasonic generator 1, ultrasonic cleaning tank 2 and Fenton oxidation reactor 3; the dual-frequency ultrasonic generator can generate 40KHz and 20KHz high and low independently or simultaneously Ultrasonic waves of two frequencies; the ultrasonic cleaning tank is made of stainless steel, a vertical ultrasonic transducer 7 is arranged at the bottom of the cleaning tank, and a horizontal ultrasonic transducer 8 is arranged on the vertical wall of the cleaning tank, which is connected and controlled by the ultrasonic generator , the frequency matches the ultrasonic generator, the vertical transducer 7 receives ultrasonic signals with a frequency of 40KHz, and the horizontal transducer 8 receives ultrasonic signals with a frequency of 20KHz, and converts ultrasonic signals of different frequencies into mechanical energy and transmits them to the cleaning tank...

Embodiment 2

[0030] Embodiment 2 adopts the device of the present invention to treat waste water

[0031] Carry out oxidation treatment to chlorpyrifos pesticide waste water, the chemical oxygen demand of waste water is 5000mg / L; Waste water volume is 1L; Fenton reagent adds molar ratio (H 2 o 2 / Fe 2+ ) is 50:1, H 2 o 2 (30%) dosage is 2000mg / L (about 0.2% volume ratio), which is much lower than the dosage ratio of 1:1~10:1 of similar wastewater and the volume ratio of 0.5%~2% H 2 o 2 (30%) dosage; the air flow rate is 0.5L / min; the oxidation reaction time is 60min; when the reaction temperature is maintained at 23-25°C, the degradation rate of chemical oxygen demand in wastewater is 74%, which is much higher than that of similar wastewater 42 ~55% degradation rate, wastewater B / C increased from 0.18 to 0.64, biodegradability greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com