Degradable bio-based seedling raising pot, production method thereof, regulation method in degradation period and application of degradable bio-based seedling raising pot

An adjustment method and bio-based technology, applied in the field of bio-based seedling pots and their preparation, can solve the problems of difficulty in maintaining the uprightness of the pot body, slow degradation rate, and easy damage, and achieve the goal of promoting starch gelatinization and other thermochemical reactions, Mobility-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The present invention also provides a manufacturing method (preparation method) of the above-mentioned biodegradable bio-based seedling pot, which includes the following steps: material pretreatment, proportioning and mixing; dry hot pressing molding; cooling, edge removal and packaging. Specifically, the following steps are included:

[0057] 1) Pretreat the raw materials, adjust their moisture content to 8% to 15%, and mix them evenly according to the proportion;

[0058] 2) Set the temperature of the upper mold at 150-230°C, the temperature of the lower mold is 10-30°C lower than the temperature of the upper mold, the pressing pressure is 25-300MPa each time, the holding time is 1.5s-20s each time, and the molding pressing times are 1-4 times , performing dry hot-press molding on the raw material; and

[0059] 3) Cooling, edge removal and packaging of the pressed raw materials.

[0060] Wherein, in the preparation method of the degradable bio-based seedling pot, in...

Embodiment 11

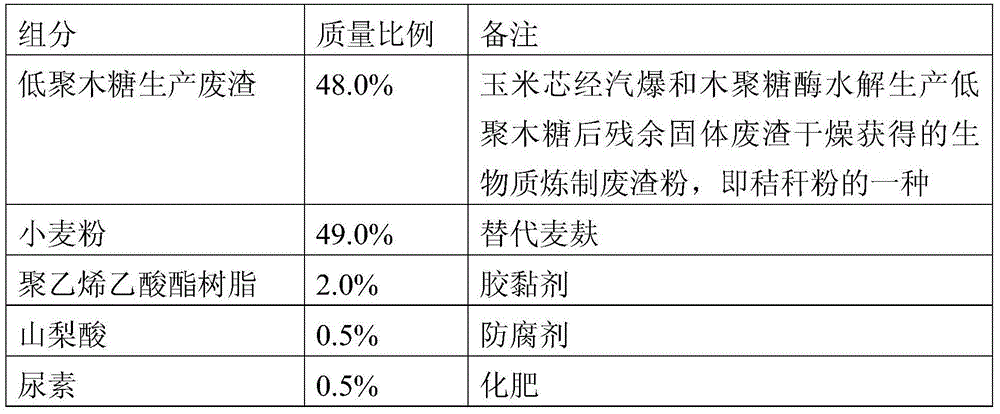

[0069] The degradable bio-based seedling pot is made according to the following ratio and method:

[0070] raw material name

[0071] The rice husk and wheat bran are crushed to 40 mesh, and dried to a moisture content of 10% to 12%; each powder is stirred and mixed evenly according to the raw material formula for subsequent use. The specifications of the seedling bowl are: thickness 0.7mm, inner diameter of the mouth of the bowl Ф70mm, inner diameter of the bottom of the bowl Ф60mm, height 72mm; weigh 20g±0.5g of the stirred powder, put it into the mold cavity, and perform dry hot pressing. Molding process parameters: upper mold temperature 185°C±5°C, lower mold temperature 165°C±5°C; two press moldings; one molding pressure 25MPa, one holding time 5s; deflation 0.5s; secondary molding pressure 300MPa, The holding time for one time is 2s. The results show that the molding reject rate is less than 3%. The result of the fungal erosion test (GB / T19275-2003) of the d...

Embodiment 12

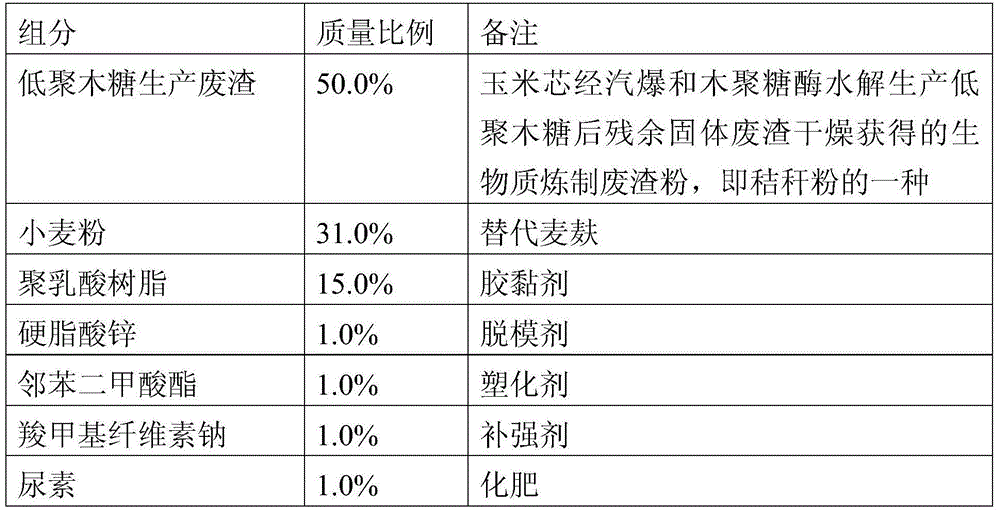

[0073] The degradable bio-based seedling pot is made according to the following ratio and method:

[0074] raw material name

[0075] sodium alginate

[0076] The rice husk and wheat bran are crushed to 40 mesh, and dried to a moisture content of 10% to 12%; each powder is stirred and mixed evenly according to the raw material formula for subsequent use. The specifications of the seedling bowl are: thickness 0.7mm, inner diameter of the mouth of the bowl Ф70mm, inner diameter of the bottom of the bowl Ф60mm, height 72mm; weigh 20g±0.5g of the stirred powder, put it into the mold cavity, and perform dry hot pressing. Molding process parameters: upper mold temperature 165°C±5°C, lower mold temperature 155°C±5°C; two press moldings; one molding pressure 80MPa, one holding time 9s; air release 0.5s; secondary molding pressure 200MPa, The holding time for one time is 3s. The results show that the molding reject rate is less than 3%. The result of the fungal e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com