Nanometer hydroxyapatite/chitosan porous composite scaffold material as well as bionic dialysis mineralization preparation method and application thereof

A technology of nano-hydroxyapatite and composite scaffolds, applied in tissue regeneration, medical science, prostheses, etc., can solve the problems of poor host bonding ability, low matching degree of degradation absorption rate and growth rate, low mechanical strength and toughness, etc. , to achieve controllable degradability, excellent bone conduction, and full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

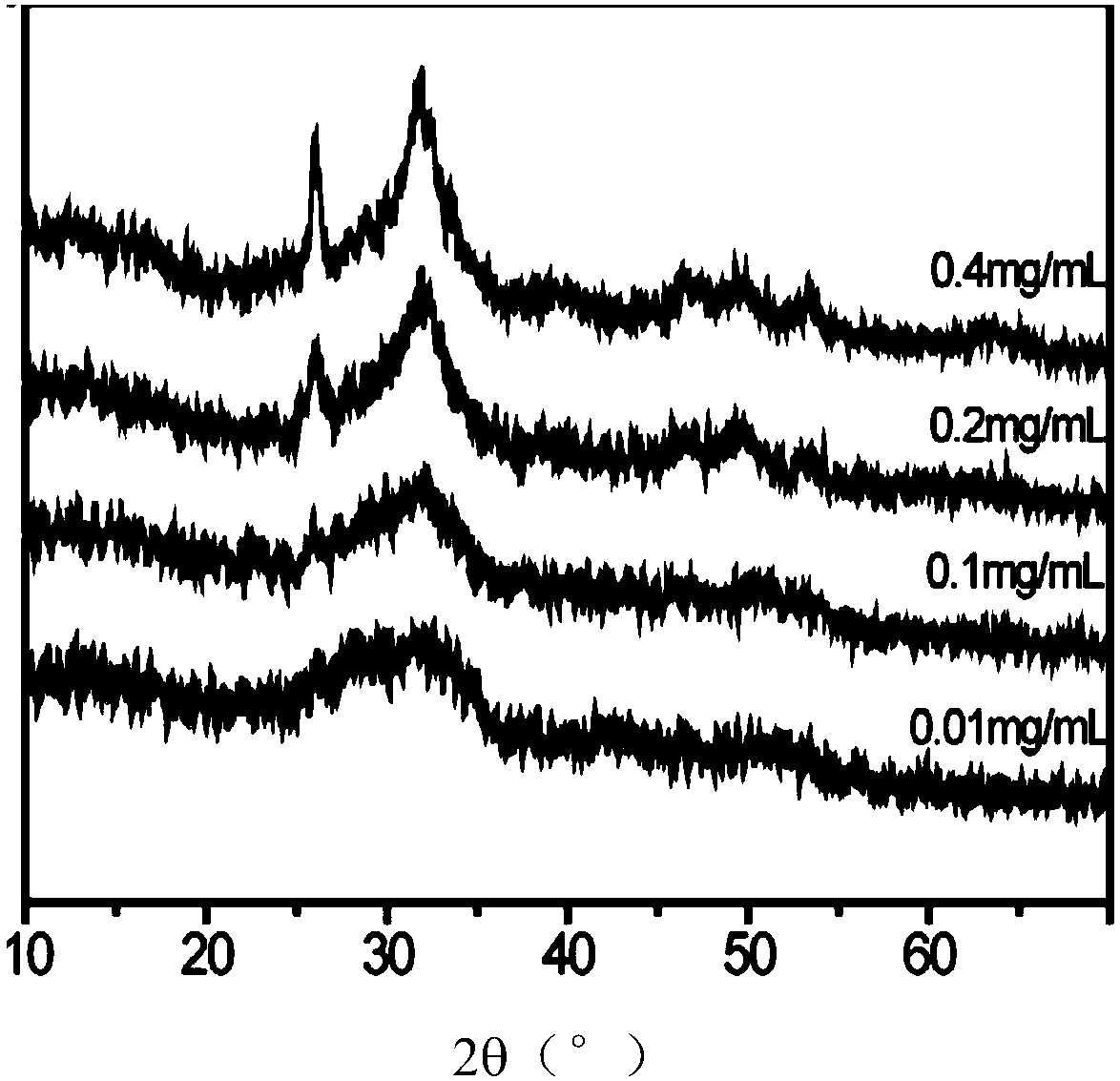

[0058] A preparation method of n-HAP porous composite support material, comprising the following steps:

[0059] (1) the chitosan powder that takes 2.5g is dissolved in the acetic acid solution of 50mL 3% (v / v), and stirs 24h at a constant speed, after chitosan dissolves completely, the final concentration that obtains chitosan is 5% ( Wt). Add the chitosan solution into the 96-well plate with a 2.5mL needle-free syringe, add 0.5mL to each well, let it stand for a while, and put the orifice plate into a 70°C refrigerator after there are no air bubbles in each well Freezing and icing, and finally freeze-drying at low temperature to obtain the porous chitosan scaffold in the early stage. Soak the dried stent together with the orifice plate in a 5% NaOH solution for 24 hours, soak in distilled water and wash the stent repeatedly until the pH is about 7-8, then freeze-dry at low temperature again to obtain the final solution required for this experiment. chitosan porous scaffold...

Embodiment 2

[0065] A preparation method of n-HAP porous composite support material, comprising the following steps:

[0066] (1) the chitosan powder that takes 2.5g is dissolved in the acetic acid solution of 50mL 3% (v / v), and stirs 24h at a constant speed, after chitosan dissolves completely, the final concentration that obtains chitosan is 5% ( Wt). Add the chitosan solution into the 96-well plate with a 2.5mL needle-free syringe, add 0.5mL to each well, let it stand for a while, and put the orifice plate into a 70°C refrigerator after there are no air bubbles in each well Freeze and freeze in medium, and finally freeze-dry at low temperature to obtain the CS scaffold in the early stage. Soak the dried CS scaffold together with the orifice plate in NaOH solution with a mass fraction of 5% for 24 hours, soak in distilled water and wash the scaffold repeatedly until the pH=7-8, then freeze-dry at low temperature again to obtain the final Desired to obtain a mineralized organic template...

Embodiment 3

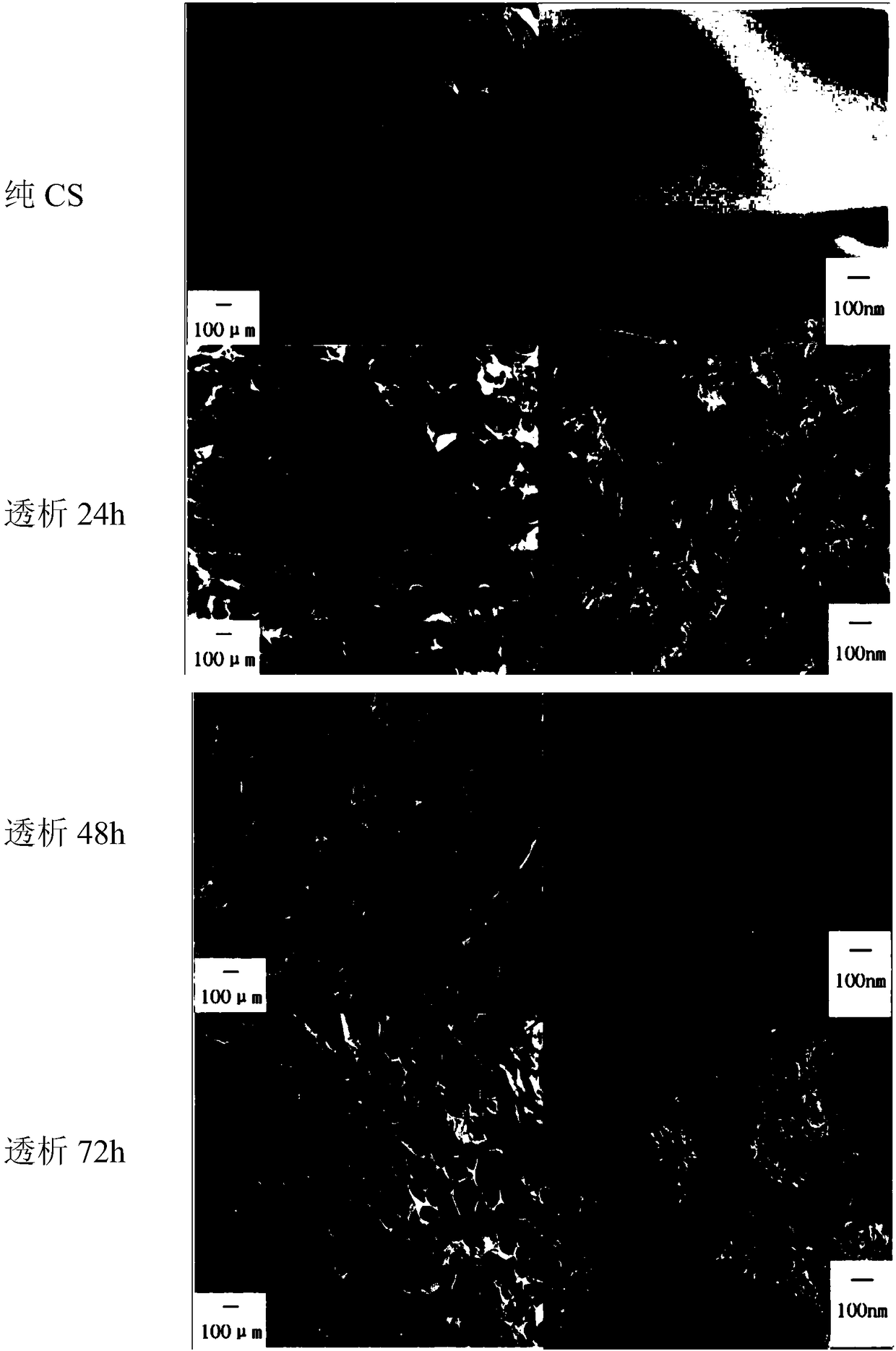

[0073] A preparation method of n-HAP porous composite support material, comprising the following steps:

[0074] (1) Prepare the n-HAP / CS composite scaffold material according to the material preparation method in the above-mentioned Example 2, and mark the material as dialysis 24h, dialysis 48h and dialysis 72h according to the different dialysis time.

[0075] (2) Select the mineralized scaffold material and pure CS scaffold as the research object of the cell culture experiment, sterilize the scaffold material with cobalt 60 (radiation intensity is 15k gy), soak it with 75% alcohol on the ultra-clean bench After 30 minutes, rinse with PBS three times for later use. Take the third-generation MC3T3-E1 cells. After the density reaches 90%, digest with 0.25% trypsin for 3 minutes, stop the digestion with 2 times the volume of complete medium, and centrifuge at 1000r / min. Cells were collected for 5 minutes and resuspended in complete medium. Dilute the above treated cell suspens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com