Patents

Literature

129 results about "Glycerophosphates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

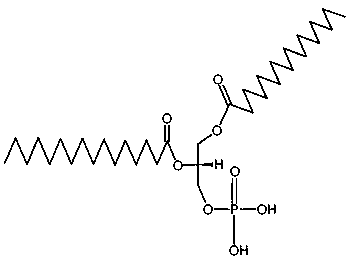

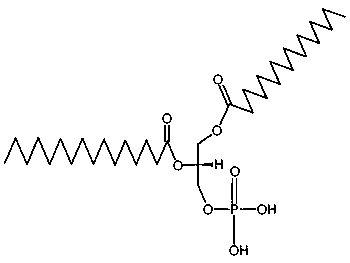

Any salt or ester of glycerophosphoric acid.

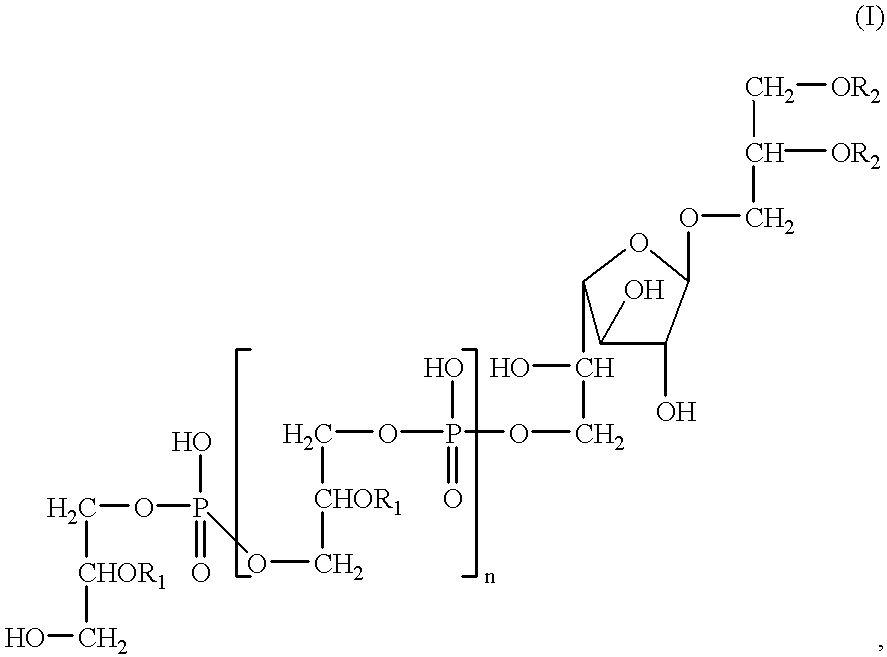

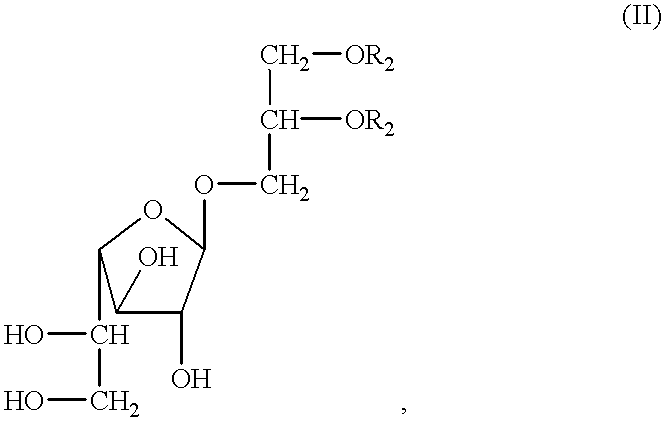

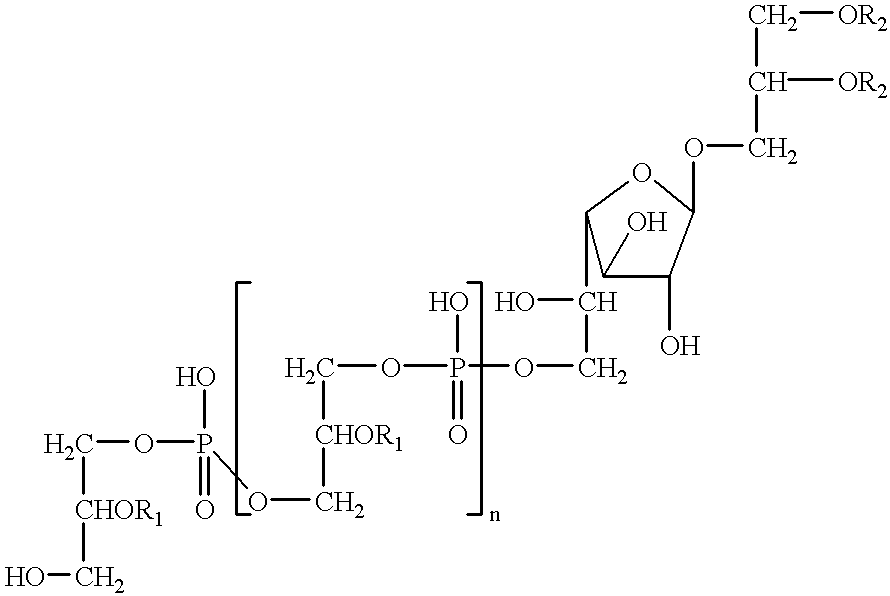

Antitumor and anticholesterol preparations containing a lipoteichoic acid from streptococcus

InactiveUS6214978B1Improve usabilityImprove liquidityBacteriaPeptide/protein ingredientsBackbone chainHyaluronidase

The invention concerns a new lipoteichoic acid which can be isolated from the new Streptococcus sp DSM 8747. The new LTA is called LTA-T. It has a lipid anchor, which is a galacto-furanosyl-beta-1-3-glycerol with different rests of fatty acids esterified in the two adjacent hydroxy groups in the glycerol moiety and a non-glycosylated, linear, unbranched GroP chain with an unusual short hydrophilic GroP chain. The hydrophilic backbone consists of only 10 glycerophosphate units esterified with D-alanine in an extent of 30%. The invention further concerns a pharmaceutical composition with the new LTA-T, optionally together with a monokine and / or hyaluronidase, a method of treating cancer comprising administration of an antitumor effective amount thereof, a method of producing the new compound and the new pharmaceutical composition, two degradation products of the new LTA-T and their use, and the new Streptococcus strain from which the new compound can be isolated.

Owner:LUNAMED

Pharmaceutical compositions comprising cyclic glycerophosphates and analogs thereof for promoting neural cell differentiation

InactiveUS6914056B1Reduce and prevent appearanceBiocideNervous disorderNerve degenerationBrain section

Cyclic glycerophosphates and analogs thereof (CGs) are shown to exert neutral promoting activities in target cells. Such activities include promotion of neuronal outgrowth, promotion of nerve growth, provision of dopaminotrophic supporting envrionment in a diseased portion of the brain, prevention of nerve degeneration and nerve rescue. These activities of the CGs render them useful for treatment of various disorders including but not limited to mental disorders such as, for example, schizophrenia, dementia or disorders resulting in learning disablities. In addition, these CGs may be used for the treatment of neurodegenerative conditions such as Altzheimer's diesease, Parkinson's disease, conditions resulting from exposure to harmful environmental factors or resulting from a mechanical injury. The CGs may also be used to treat an individual suffering from a primary neurodengenerative condition in order to prevent or reduce the appearance of secondary degeneration in additional nerves (“nerve rescue”).

Owner:YEDA RES & DEV CO LTD

A method for preparing lysophosphatidylcholine by enzymatic alcoholysis

InactiveCN102277393AImprove conversion rateImprove solubilityFermentationPhosphoric Acid EstersPhosphoric acid

The invention discloses a method for preparing lysophosphatidyl choline by enzymatic alcoholysis, which comprises: adding phosphatidylcholine into low-carbon alcohol solution, uniformly stirring and mixing at a certain temperature, adding lipase, and allowing the lipase to catalyze the alcoholysis of phosphatidylcholine with constant-temperature stirring to obtain the lysophosphatidyl choline. The method has the advantages that: (1) the solubility of phosphatidylcholine, lysophosphatidyl choline serving as the product, and aliphatic ester, glycerophosphorylcholine and very small amount of fatty acid, which serve as byproducts, in the reaction system is improved, and the conversion rate of the lysophosphatidyl choline is high; (2) the aliphatic ester, a small amount of glycerophosphate and a very small amount of fatty acid are generated in an alcoholysis reaction process, but the pH value of the system is not changed, and the influence of the solvent on the activity of the lipase is relieved and the catalytic reaction activity of the lipase is high; (3) the properties of the fatty acid, the aliphatic ester and glycerophosphorylcholine, which are products of side reactions, are very different from those of the lysophosphatidyl choline, so the lysophosphatidyl choline product can be separated and purified very easily; and (4) the alcohol, which is the product of the reaction, can be removed easily.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Oral cavity care curative and prophylactic composition

InactiveUS20090016972A1Safe for viable tissuesEfficient removalCosmetic preparationsHydroxy compound active ingredientsMagnesium saltAdditive ingredient

The invention relates to stomatology and perfume industry in particular to therapeutic formulation for oral cavity care. The invention refers to oral hygiene means and can be applied for preparation of medical and prophylactic tooth-pastes, gels, liquids for oral care as well as other compositions like chewing gums, jellies, etc. Formulation containing orally applicable active and inert components involves bromelain in amount of 0.01÷1 wt %, xylitol 1.5÷20 wt %. At best bromelain content is 0.1—0.8 wt %, xylitol content—2.2-18 wt %. For attaining remineralizing effect formulation contains anti-carious mineral additive 0.05-3.0 wt % of the list of active components. At best anti-carious mineral additive content is 0.2-2.5 wt %. There are used calcium glycerophosphate and inorganic or organic magnesium salt as anti-carious mineral additive. It is acceptable to use sodium monofluorphosphate, potassium monofluorphosphate, calcium monofluorphosphate or magnesium monofluorphosphate in amount of 0.5-1.5 wt % as anti-carious mineral additive Optimum concentration is 0.8-1.1 wt %.

Owner:MANASHEROV TAMAZI OMAROVICH +2

Sunscreen and gel composition, preparation method and application thereof

InactiveCN102210634AAvoid stimulationAvoid allergiesCosmetic preparationsToilet preparationsChemical compositionIrritation

The invention provides a sunscreen and gel composition, a preparation method and an application in cosmetics thereof. The sunscreen and gel composition comprises the following components in percentage by weight: 2 to 20 percent of chitin, 5 to 25 percent of glycerophosphate, 2 to 20 percent of sunscreen, and 40 to 80 percent of water, on the basis of the total weight of the sunscreen and gel composition. The sunscreen and gel composition can stably cover the sunscreen to prevent the sunscreen from directly contacting with human skins and effectively avoid irritation and allergy of a human body, and can remarkably improve the ultraviolet protection capability of sunscreen products.

Owner:SHANGHAI LIGHT IND RES INST

Method and composition for gel mixture

InactiveUS20050118320A1Rate of gelling is determinedQuickly the pH of the product is loweredFood preparationGlucono delta-lactonePowder mixture

A quick-gel mixture is prepared from a liquid mixture and a powder blend. The liquid mixture is an alginate blended with sugar and solubilized in water and, optionally, ethyl alcohol. The powder blend is a mix of sugar, calcium, acids, and sodium citrate, which acts as a sequestering agent to control the release of calcium. The acids used are a combination of adipic and glucono delta lactone. The acids being used are slow-release-type acids and control the rate of gelling. The source of calcium is calcium glycerophosphate, which is readily soluble in the liquid phase and reacts with the alginate to form the gel. Granular sugar is used as a carrier and to solubilize the powder blend mix. To prepare the final product, the liquid mixture and the powder blend are combined and shaken for about 15 seconds. The gel sets in approximately 15 to 30 minutes.

Owner:J MANHEIMER

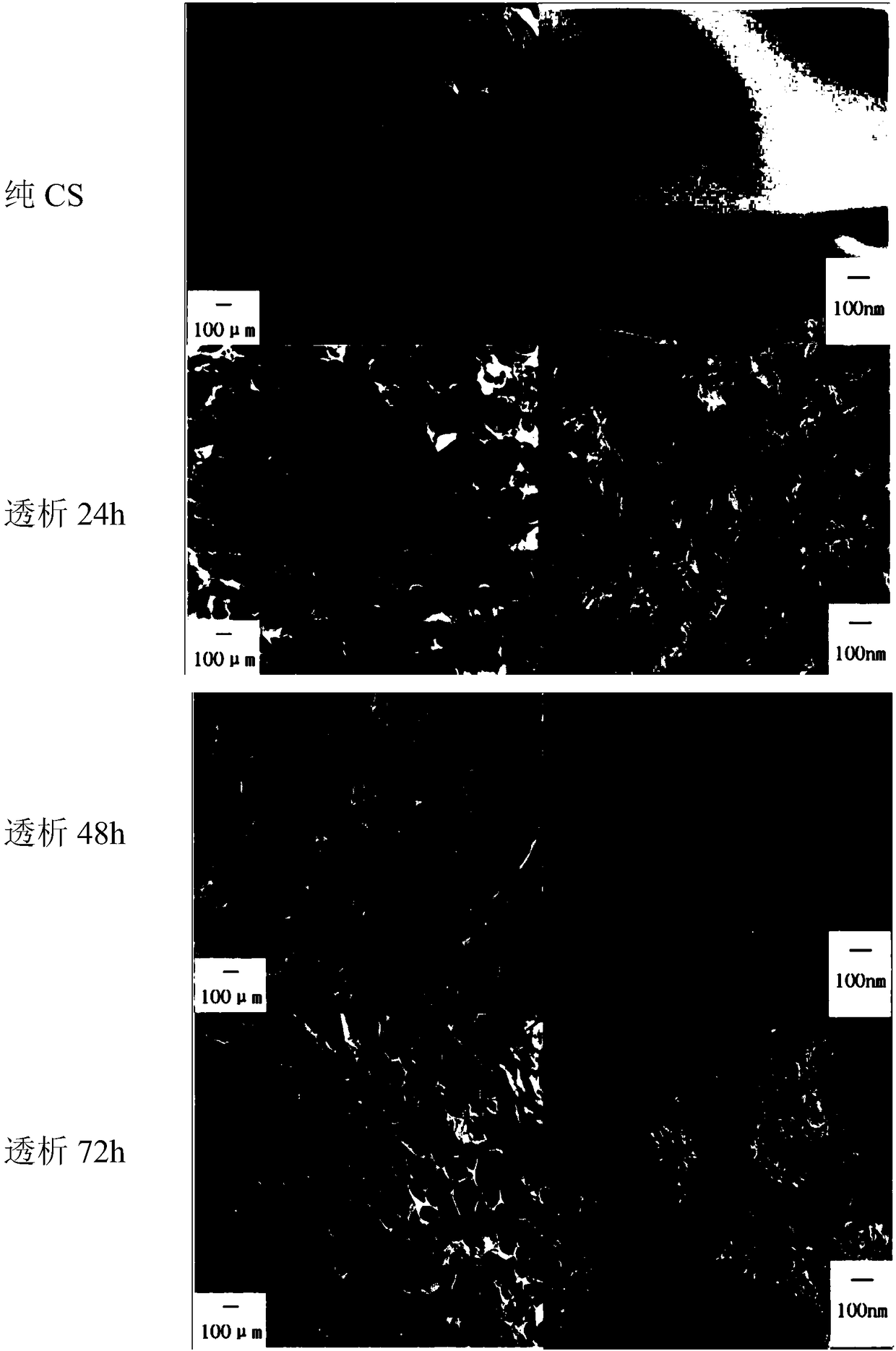

Nanometer hydroxyapatite/chitosan porous composite scaffold material as well as bionic dialysis mineralization preparation method and application thereof

InactiveCN108478880AGood biocompatibilityHigh biosecurityTissue regenerationProsthesisFreeze-dryingPorous composite

The invention belongs to the technical field of bone tissue engineering, and discloses a nanometer hydroxyapatite / chitosan porous composite scaffold material as well as a bionic dialysis mineralization preparation method and application thereof. The method comprises the following steps that (1) chitosan is dissolved in an acetic acid solution to obtain a chitosan solution; the chitosan solution isput into a container for freezing; freeze drying is performed to obtain an early-period chitosan porous scaffold; (2) the early-period chitosan porous scaffold is soaked in alkali liquid; water washing is performed until the pH is 7 to 8; freeze drying is performed to obtain a chitosan porous scaffold; (3) the chitosan porous scaffold is soaked in an alkaline phosphatase solution; then, the chitosan porous scaffold and the alkaline phosphatase solution are charged into a dialysis bag; the dialysis bag is put into a mixed solution of calcium glycerophosphate and CaCl2; constant-temperature constant-speed stirring is performed for mineralization; taking out, washing and freeze drying are performed to obtain the nanometer hydroxyapatite / chitosan porous composite scaffold material. The nanometer hydroxyapatite / chitosan porous composite scaffold material can be applied to the field of bone tissue engineering, particularly the bone defect repair.

Owner:JINAN UNIVERSITY

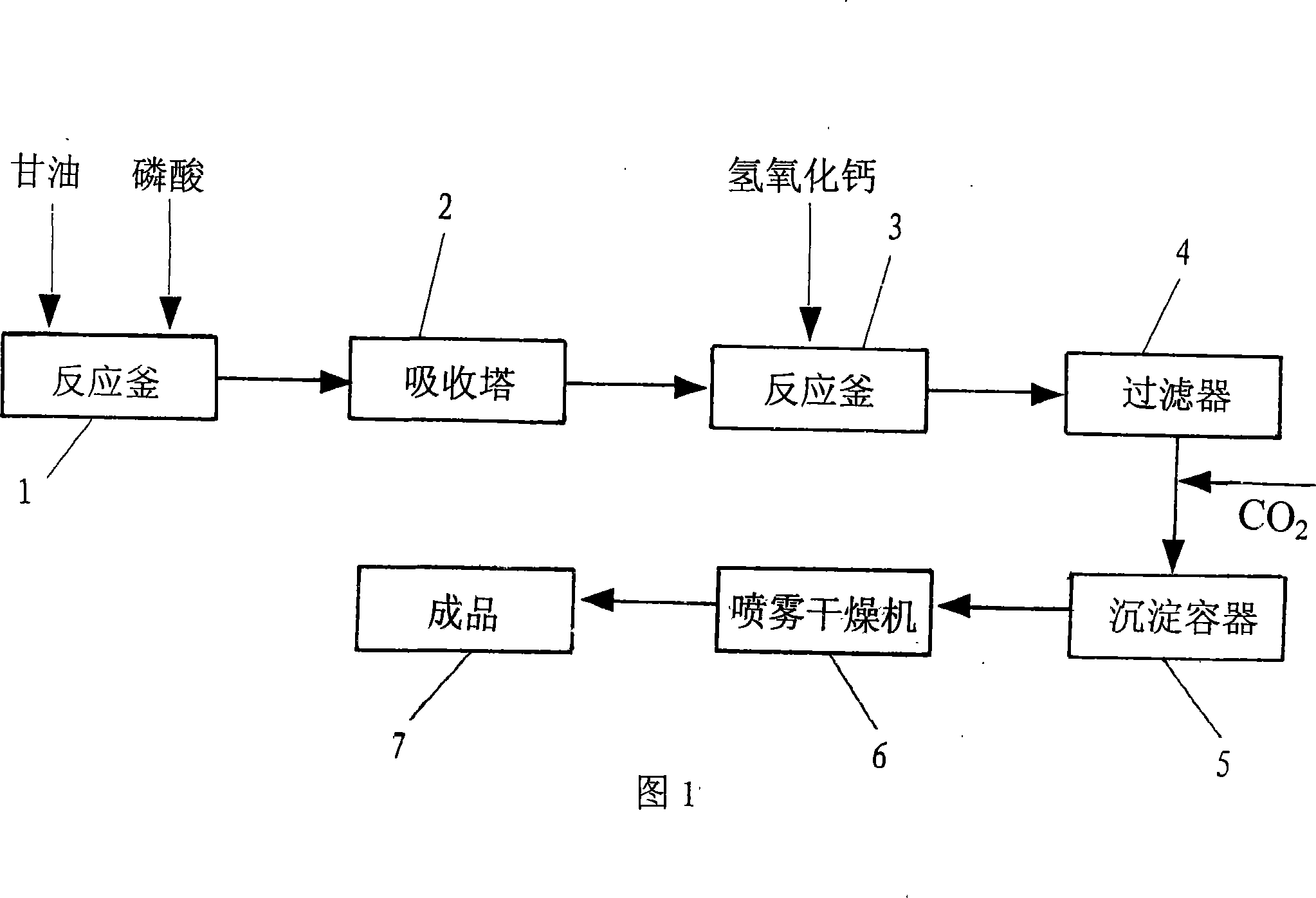

Method for synthesizing calcium glycerinophosphate

ActiveCN101220053ASimple production processImprove product qualityPhosphatide foodstuff compositionsSynthesis methodsPhosphoric acid

The invention discloses a synthesis method of calcium glycerophosphate. The method includes the following procedures: esterification is performed in a reactor with pharmaceutical-grade glycerine and food-grade phosphonic acid as the raw materials; cooling the reaction solution after completion of the reaction and adding deionized water for dilution; adding active carbon into the solution for decolorization; then adding a certain amount of calcium hydroxide and filtering the reactants to get a clear filtrate after reaction under ultrasonic wave agitation; pumping CO2 into the filtrate to keep PH of the filtrate ranging from 8 to 10 and then filtering again; then adding alcohol into the filtrate and performing spray drying after agitation. The white powder obtained is the product. The invention has the advantages of simple process and low cost. The synthesized calcium glycerophosphate has stable quality and meets the standard of European Pharmacopoeia (63 Edition).

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

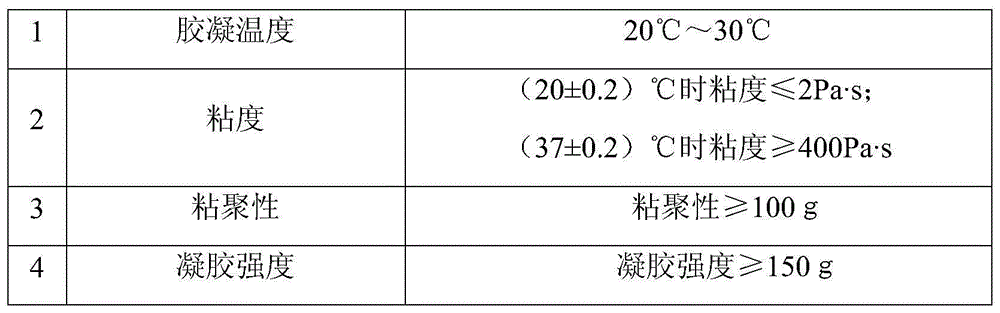

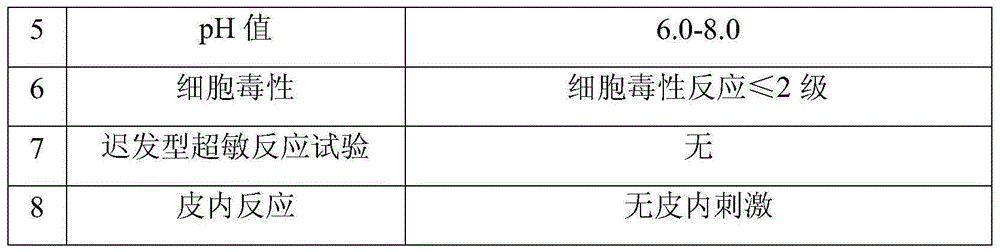

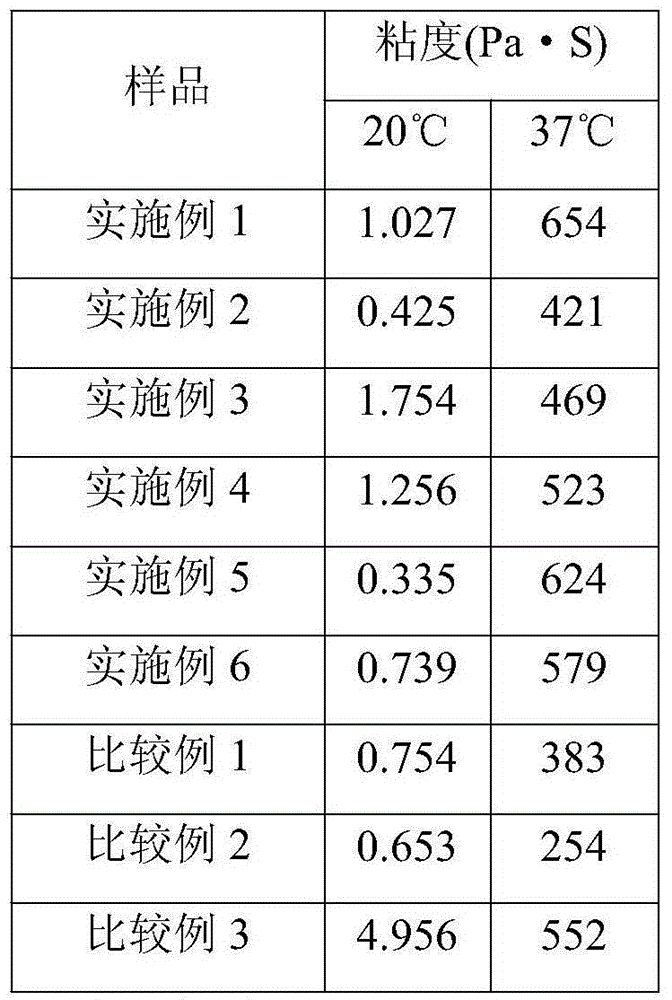

Temperature-sensitive gel preparation, preparation method thereof and application of temperature-sensitive gel preparation to preventing transfer of calculus in lithotripsy

ActiveCN105147723AAdhesiveImprove adhesionHydroxy compound active ingredientsAerosol deliveryGel preparationMathematical Calculus

The invention discloses a temperature-sensitive gel preparation, a preparation method thereof and an application of the temperature-sensitive gel preparation to preventing the transfer of calculus in lithotripsy. The preparation is prepared from the following components by weight percent: 16.5 to 26.5 percent of poloxamer, 1.0 to 3.0 percent of chitosan hydrochloride, 0.5 to 2.5 percent of glycerophosphate, 0.01 to 1 percent of synergistic auxiliary materials, and 67.0 to 81.99 percent of neutral buffer solution. The preparation method is simple, and when used in the lithotripsy, the product has a good effect of preventing the transfer of the calculus, so that the damage risk of the lithotripsy on peripheral tissues can be alleviated; moreover, the product is convenient to wash and high in application value.

Owner:SAIKE SAISI BIOTECH CO LTD

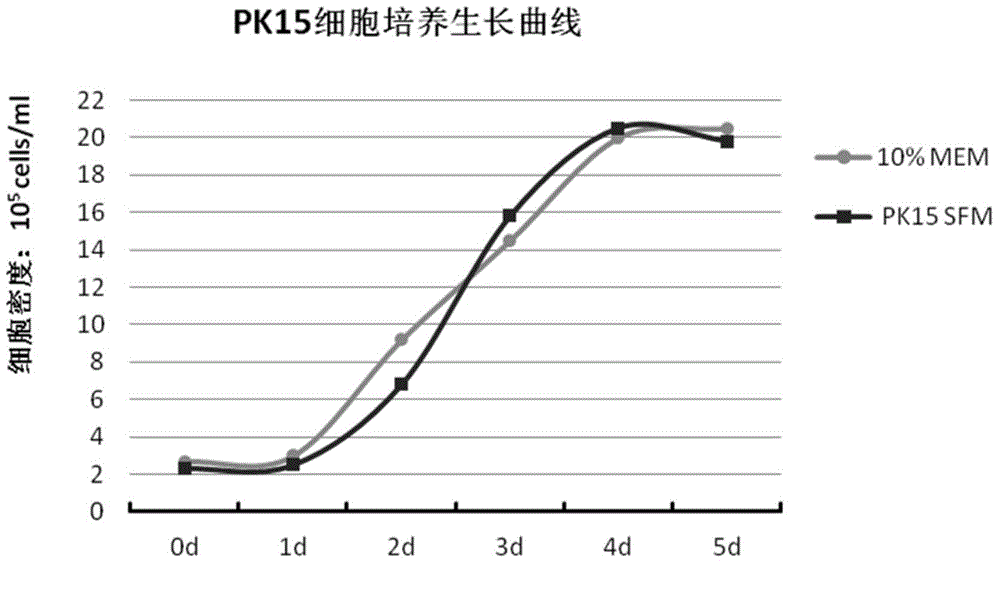

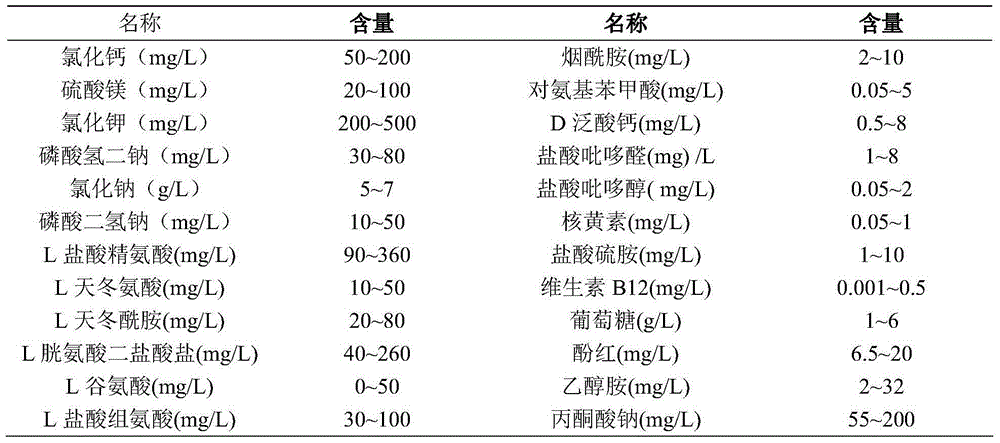

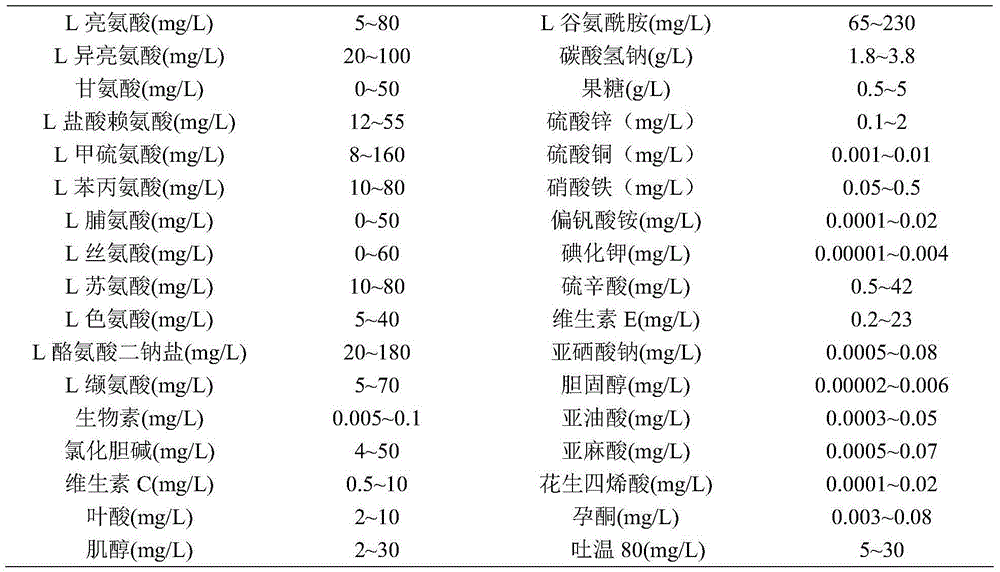

Protein-free, hydrolysate-free and serum-free culture medium and preparation method thereof

ActiveCN104911143AReduce manufacturing costSimplified purification stepsArtificial cell constructsVertebrate cellsDisodium EdetateHydrolysate

The invention relates to a protein-free, hydrolysate-free and serum-free culture medium and a preparation method thereof. The culture medium contains the following substances: manganese gluconate, calcium citrate malate, disodium edetate, progesterone, alanyl-glutamine,glycerophosphate, fructose, vitamin C, vitamin E, sodium selenite, hydroxypropyl-beta-cyclodextrin, cholesterol, malic acid, oxaloacetic acid, vitamin B12, lipoic acid, ferrous sulfate, ferric citrate, uric acid, taurine, reduced glutathione, zinc sulfate, copper sulfate and ferric nitrate. The protein-free, hydrolysate-free and serum-free culture medium has the advantages that the cost is low, the difference among different batches of products is small, the purification step of down-stream products is simplified, and potential safety hazards are reduced.

Owner:SICHUAN BAINUOJI TECH CO LTD

Recombinant escherichia coli, method for preparing phospholipase C and application

InactiveCN103525744ASimple production processShorten the production cycleBacteriaHydrolasesMononucleosisCompanion animal

The invention discloses recombinant escherichia coli, a method for preparing phospholipase C and application. The recombinant escherichia coli BL21(DE-3)-pET-28a-L.m-phospholipase C (PLC) of which the target gene is from listeria monocyogenes (L.monocytogenes) is utilized as a fermentation strain to carry out liquid fermentation, so as to prepare phospholipase C. The method disclosed by the invention is simple in enzyme production process, short in production cycle and low in cost. A glycerophosphate bond on glyceryl phosphatide C3 can be specifically hydrolyzed to produce diglyceride (DAG) by using recombinant phospholipase C; plant crude oil (soybean oil, colleseed oil, rice bran oil and the like) is degummed by phospholipase C.

Owner:JIANGNAN UNIV

Laying hen feed additive

InactiveCN101396067AEven distribution of nutrientsGood application effectAnimal feeding stuffAccessory food factorsGARLIC POWDERGlycerophosphates

The invention relates to the field of animal feed additive, in particular to a layer feed additive. The layer feed additive is characterized by comprising according to the weight parts: 60-80 of spirulina powder, 10-15 of garlic powder, 20-30 of licorice powder, 2-5 of calcium glycerophosphate and 0.01-0.05 of citric acid; superfine crushing is carried out for the spirulina powder, garlic powder and licorice powder; subsequently, according to the proportioning, the crushed raw materials are mixed uniformly with the calcium glycerophosphate and citric acid; subsequently, sterilizing, cooling and packaging operations are carried out to prepare the layer feed additive. The layer feed additive can provide sufficient nutritional compositions such as calcium element, phosphorus element, selenium element and the like for the layer, improve the immunity of the layer, balance the gastrointestinal microbial community, provide balanced nutrition, is easy to be absorbed and utilized and has low price.

Owner:TIANJIN SHENGJI GRP CO LTD

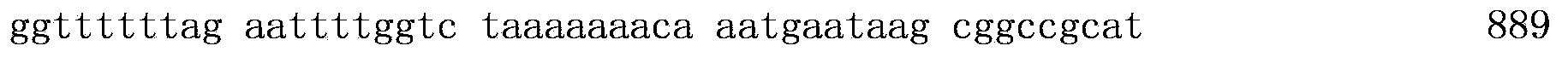

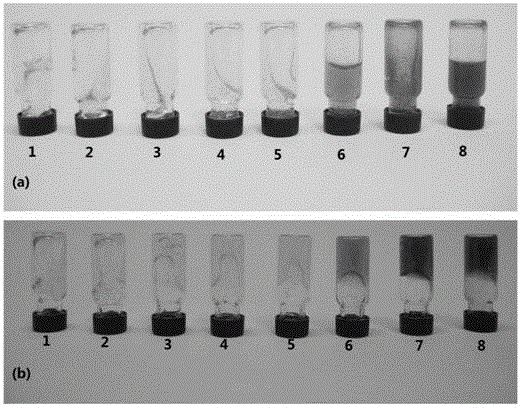

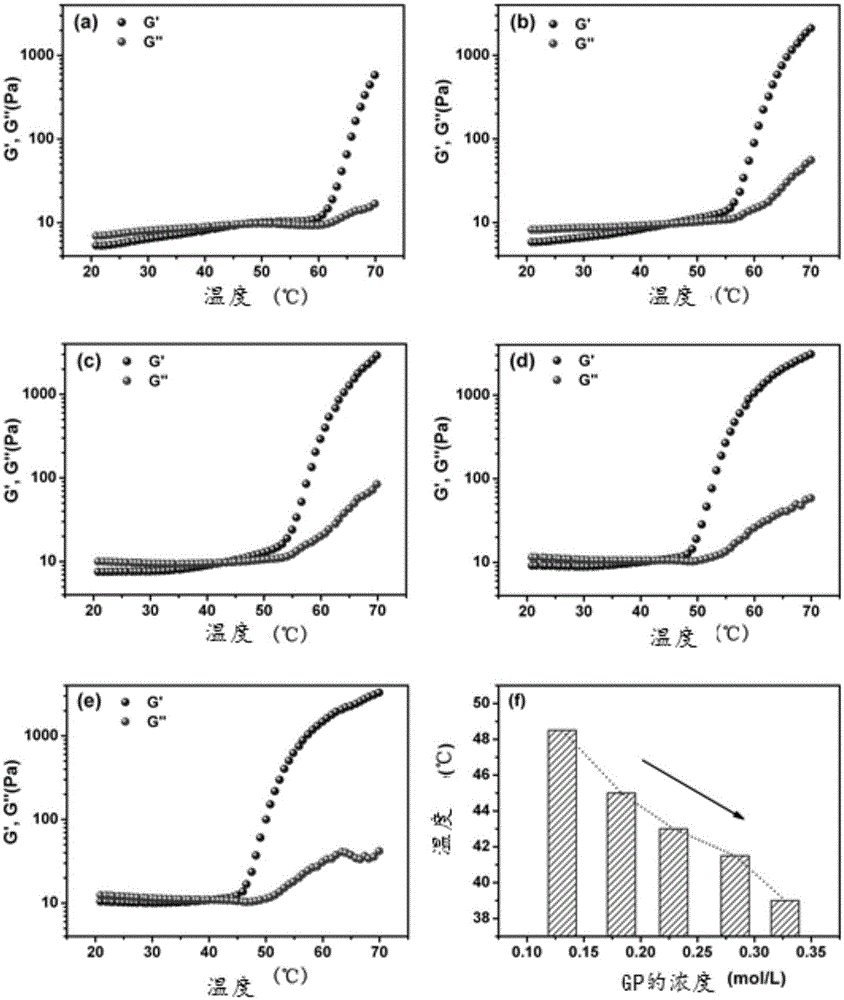

Chitosan low-temperature hydrogel and preparation method thereof

ActiveCN105037820ASensitive to temperatureLow gelling temperatureDisodium glycerophosphateGlycerophosphates

The invention provides a simple mixing preparation method with which a gel form of chitosan / graphene oxide / beta-isodium glycerophosphate thermosensitive hydrogel can be formed under a temperature below 37 DEG C. Through rheological tests, the influences of chitosan concentration, beta-isodium glycerophosphate concentration and graphene oxide concentration upon chitosan hydrogel gelling temperature and time are researched. As a result, the chitosan concentration, beta-isodium glycerophosphate concentration and graphene oxide concentration are negatively correlated to chitosan thermosensitive hydrogel gelling temperature and time.

Owner:GUANGDONG OCEAN UNIVERSITY

Passivation antibacterium treatment technology for surface of grinding roll of corn flour mill

InactiveCN105887070AImprove compactnessImprove physical and chemical propertiesMetallic material coating processesPhytic acidDimethyl siloxane

The invention discloses a passivation antibacterium treatment technology for the surface of a grinding roll of a corn flour mill. The passivation antibacterium treatment technology comprises the steps of (1) surface polishing; (2) deoiling treatment; (3) cleaning treatment; (4) passivation treatment; and (5) cleaning and drying. According to the passivation antibacterium treatment technology, under the action of a film coalescing aid composed of hydroxypropyl methyl cellulose, tributyl phosphate, calcium glycerophosphate, methacrylate modified 1,2-polybutadiene resin, polydimethylsiloxane and triethanolamine borate, phytic acid, citric acid, tartaric acid, potassium molybdate, zinc molybdate, calcium molybdate, nano silica and modified nano diatomite react with iron on the surface of the grinding roll while exerting a chelating connection function, and a uniform and compact meshy composite molecular film is formed, so that the hardness, toughness, abrasion resistance and corrosion resistance of the grinding roll are improved, the grinding roll has relatively high insect resistance and antibacterial performance, and the safety of food processing is guaranteed; and through the auxiliary function of ultrasonic, the service life of the finally prepared grinding roll is prolonged by 3 to 4 times.

Owner:WUHE HUANGHUAI GRAIN & OIL MACHINERY CO LTD

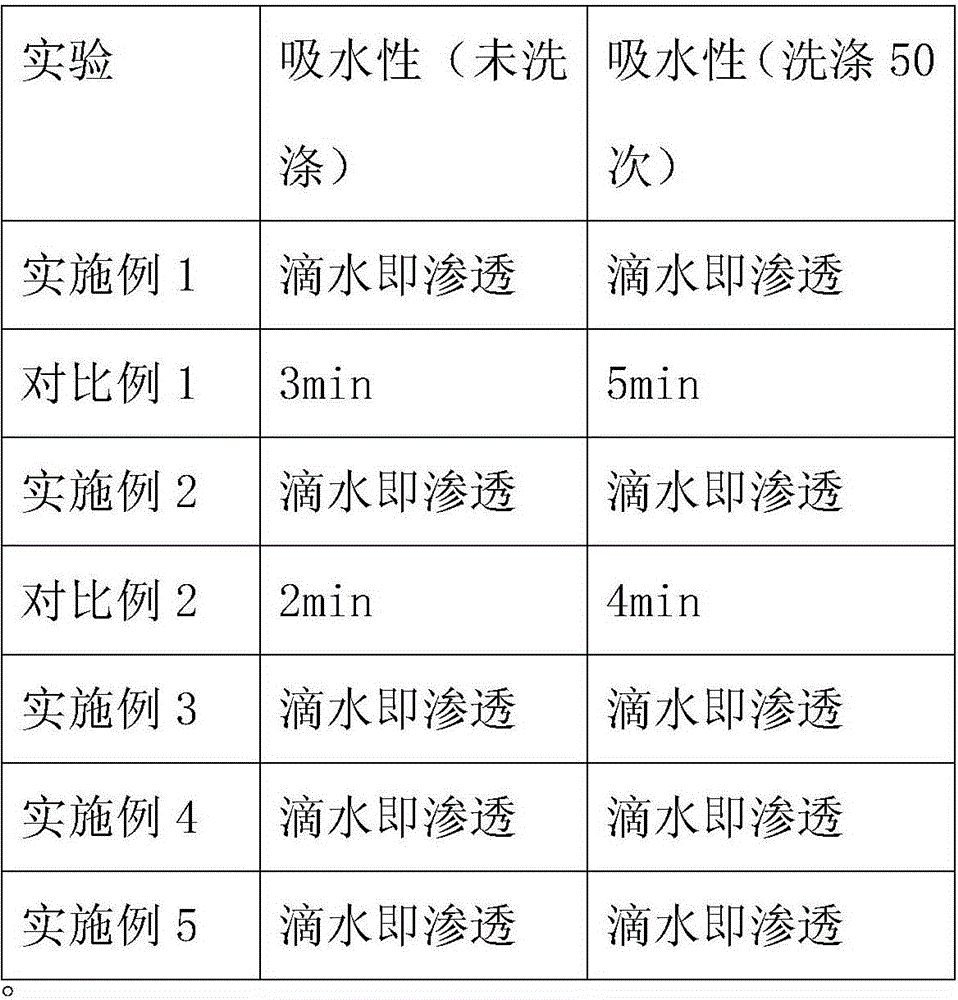

Moisture absorbing and sweat releasing finishing agent and preparing method thereof

InactiveCN105714557AGood moisture absorptionImprove perspirationFibre treatmentMonopotassium phosphatePhenol

The invention discloses a moisture absorbing and sweat releasing finishing agent. The finishing agent comprises, by weight, 13-20 parts of 4,4'-binitro benzhydrol, 20-25 parts of glycol dimercaptoacetate, 15-25 parts of nonyl phenol polyoxyethylene ether, 8-12 parts of 2-hydroxy-5-chloro benzophenone, 10-15 parts of silicone oil, 3-8 parts of 4-hydroxyphenylethylamine, 7-16 parts of glycerophosphate, 2-6 parts of sodium citrate, 1-6 parts of monopotassium phosphate and 30-50 parts of deionized water. The moisture absorbing and sweat releasing performance of textile fabric is improved remarkably after the finishing agent is adopted, sweat can be released effectively and timely, and generation of a stuffy feeling is avoided.

Owner:SUZHOU FANGYOU NEW MATERIAL

Leather softening agent and preparing method thereof

InactiveCN105671224AComprehensive moisturizing and nourishing careQuality assuranceLeather surface finishingEpoxyEthylhexyl palmitate

The invention discloses a leather softening agent and a preparing method thereof, and relates to the technical field of leather. The leather softening agent is mainly made of vinyl cyanide, glycerophosphate, lauryl diethanolamide, sodium carboxymethylcellulose, epoxy chloropropane, tributyl citrate, ammonium citrate, jojoba oil, Tween 80, ethylhexyl palmitate, amino silicon oil, microcrystalline wax, cetearyl glucoside, propylene glycol, water and auxiliaries. By means of the leather softening agent, the comprehensive moisturizing and nourishing care can be conducted on the leather, a surface layer is softer, and grease in the leather can be effectively prevented from volatilizing and getting lost so that the leather can be prevented from becoming hard. Components such as dipropylene glycol mono butyl ether, suet-base dihydroxy ethoxy amine oxide and ammonium alcohol ether sulphate are added in the auxiliaries so that the leather softening agent can further have the good dirt removing capability, and the quality of the leather can be better guaranteed.

Owner:季资朝

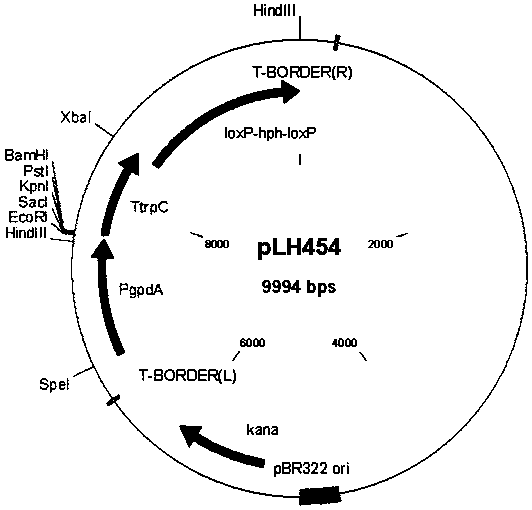

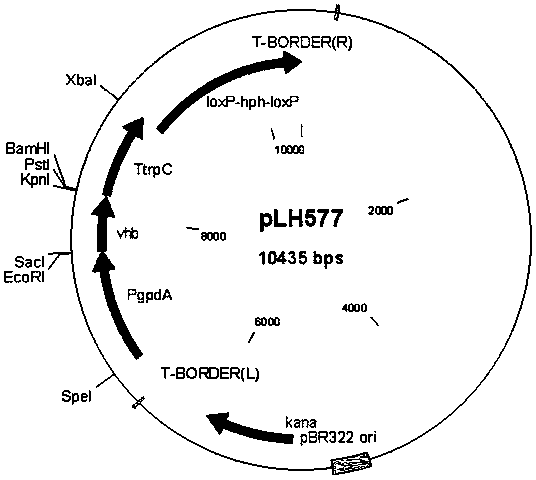

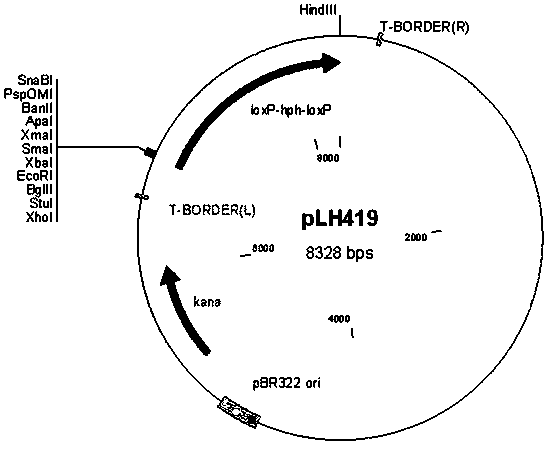

Aspergillus niger genetic engineering strain with high yield of organic acid under low-dissolved oxygen condition and application thereof

ActiveCN110029068AImproved ability to produce organic acidsExcellent strainFungiMicroorganism based processesOrganic acidMicroorganism

The invention relates to an Aspergillus niger genetic engineering strain with high yield of organic acid under a low-dissolved oxygen condition. The construction steps of the genetic engineering strain are as follows: step 1, constructing a heterologously-expressed vhb gene plasmid, wherein the sequence fragment of the gene vhb is controlled by an Aspergillus niger 3-glycerophosphate dehydrogenasegene promoter PgpdA; and step 2, acquiring a heterogeneously-expressed vhb gene strain so as to obtain the Aspergillus niger genetic engineering strain with high yield of organic acid under a low-dissolved oxygen condition. Based on the natural characteristics that Aspergillus niger generates organic acid, the Aspergillus niger genetic engineering strain is obtained by modifying the physiologicalcharacteristics of Aspergillus niger through genetic recombination. Experiments prove that the ability of the aspergillus niger genetic engineering strain for producing organic acid under the condition of low dissolved oxygen is obviously improved, and an excellent strain is provided for preparing organic acid by a microbial fermentation method.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Efficient whitening anti-cavity toothpaste and preparation method thereof

The invention discloses efficient whitening anti-cavity toothpaste and a preparation method thereof. The efficient whitening anti-cavity toothpaste is prepared from 15-45 wt% of abradant, 6-25 wt% of a wetting agent, 0.4-1.6 wt% of an adhesive, 2-5 wt% of a foaming agent and the balance diluent, and the efficient whitening anti-cavity toothpaste is also prepared from 0.1-0.3 wt% of calcium glycerophosphate, 0.5-1 wt% of sodium monofluorophosphate, 0.1-0.3 wt% of sodium fluoride, 0.5-3 wt% of sodium phytate and 0.1-0.5 wt% of sodium pyrophosphate. According to the efficient whitening anti-cavity toothpaste, by taking the abradant, the wetting agent, the foaming agent, the adhesive, the diluent, a compound anti-activity agent and a compound stain removing agent as raw materials and conducting proper proportioning, the prepared efficient whitening anti-cavity toothpaste has the stability required by conventional toothpaste, better anti-cavity, repairing, stain removing and whitening effects can be achieved, and a user can obtain healthy and bright white teeth easily.

Owner:重庆一夫日用品有限责任公司

Therapeutic and prophylactic formulation for oral care

Technical result of invention lies in practical realization of high-efficient remineralizing formulation using available and cheap components. Due to absence of fluorides it can be recommended to patients suffering from fluorosis, endocrine system diseases for the purpose of caries prophylaxis and non-carious affections. The formulation contains acceptable active and inert components. To the group of active components there belongs complex including sources of elements of magnesium, sodium, silica and potassium in quantity 1-11 wt. %. Here are ratios of atomic masses of elements of magnesium, sodium, silica, potassium, parts of active components complex, correspondingly, 21.3:9.3:1.67:1. As a source of magnesium element there is used magnesium chloride or magnesium glycerophosphate or magnesium citrate. As a source of sodium element there is used sodium chloride or sodium silicate. As a source of silica element there is used sodium metasilicate or potassium metasilicate. As a source of potassium element there is used potassium silicate.

Owner:OBSHCHESTVO S OGRANICHENNOJ OTVETABTVENNOSTJU VDS

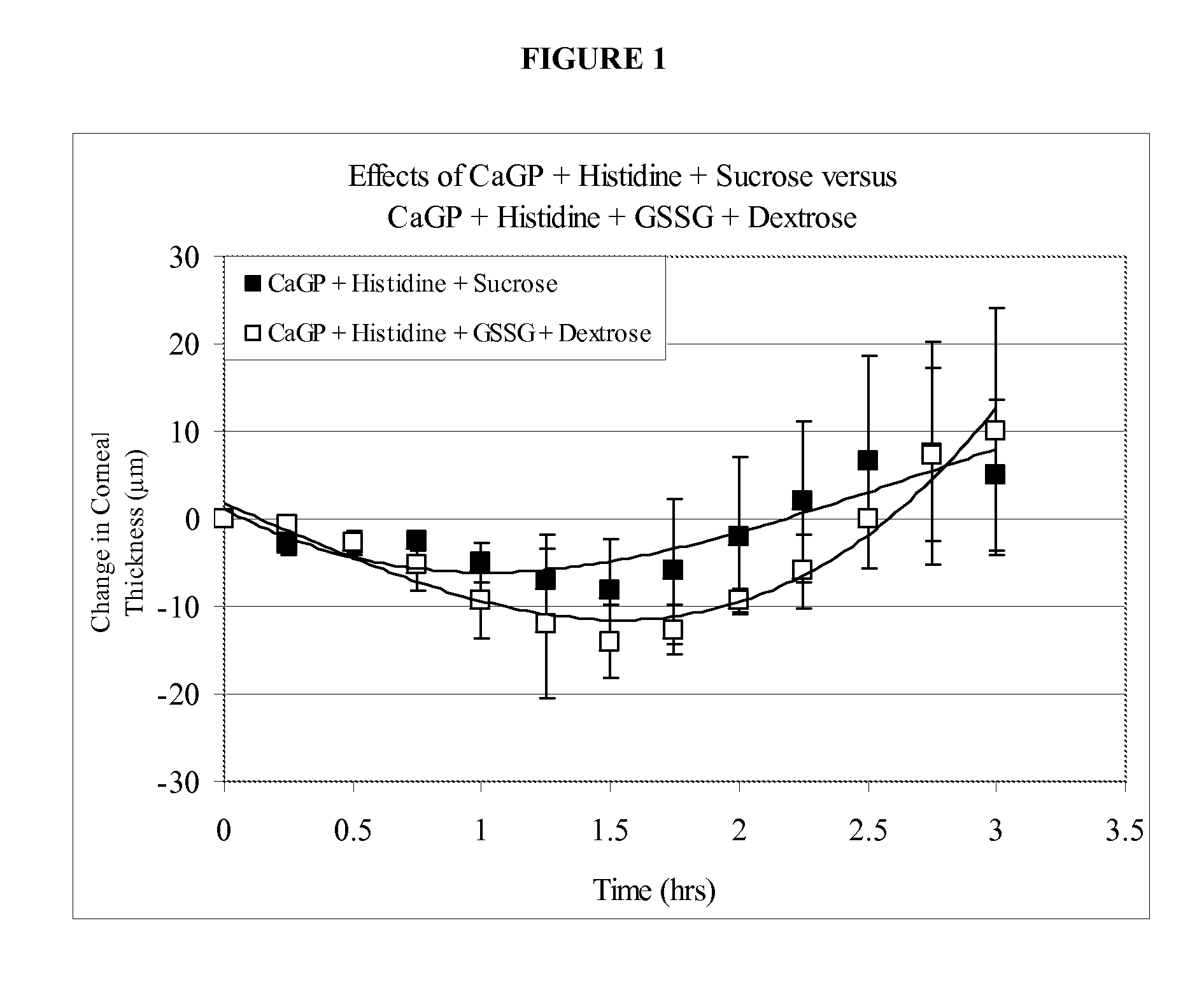

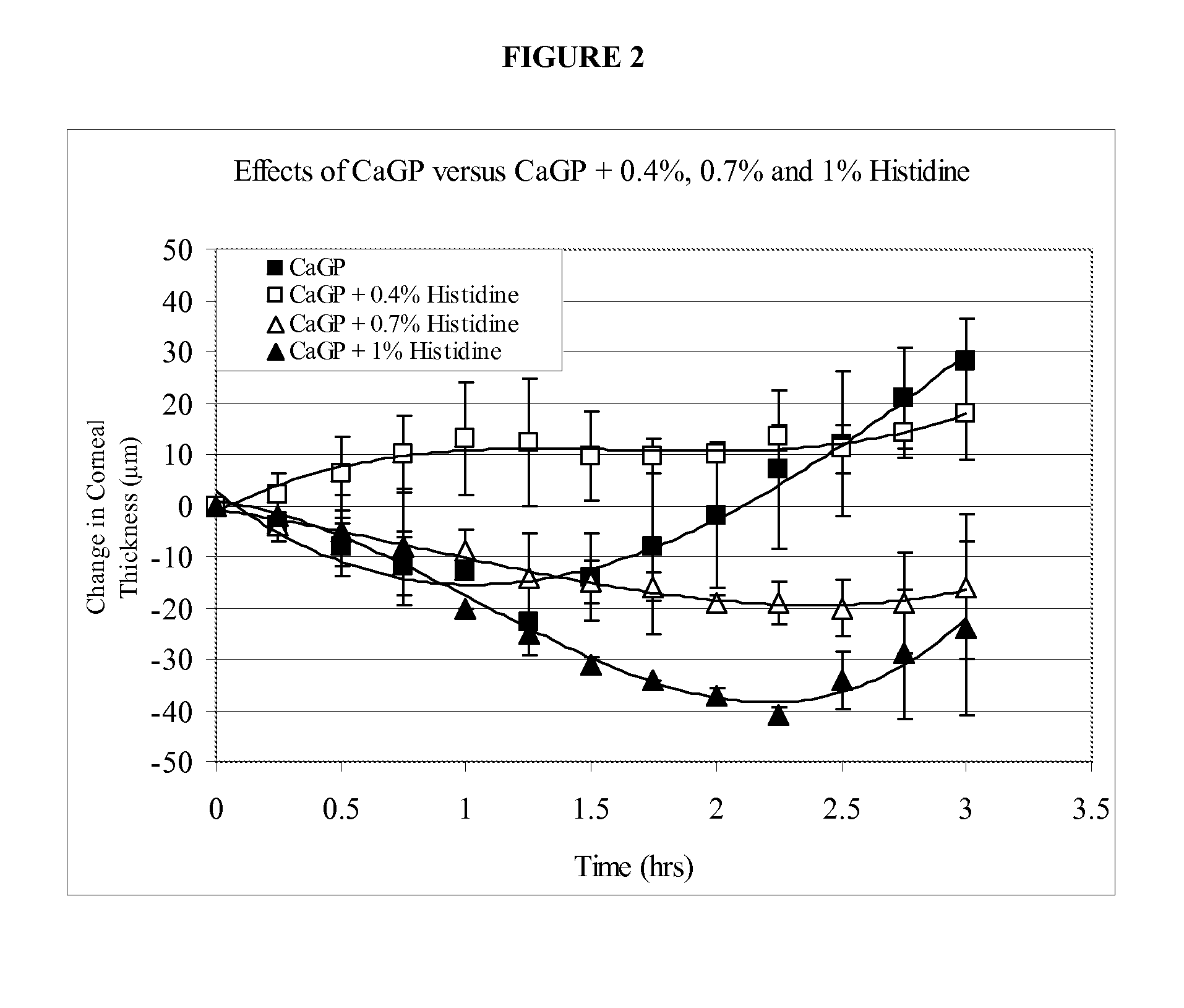

Intraocular irrigating solutions and methods for treating corneal edema

InactiveUS20090264375A1Effective treatmentImprove stabilityBiocideSenses disorderGlutathione disulfideGlycerophosphates

One aspect of the present invention relates to methods of treating corneal edema comprising contacting a cornea with an ophthalmic irrigating composition comprising histidine. In certain embodiments, the ophthalmic irrigating compositions contact the corneal endothelium. Another aspect of the present invention relates to ophthalmic irrigating compositions for treating corneal edema comprising histidine and optionally, calcium glycerophosphate and / or glutathione disulfide.

Owner:ALCON RES LTD

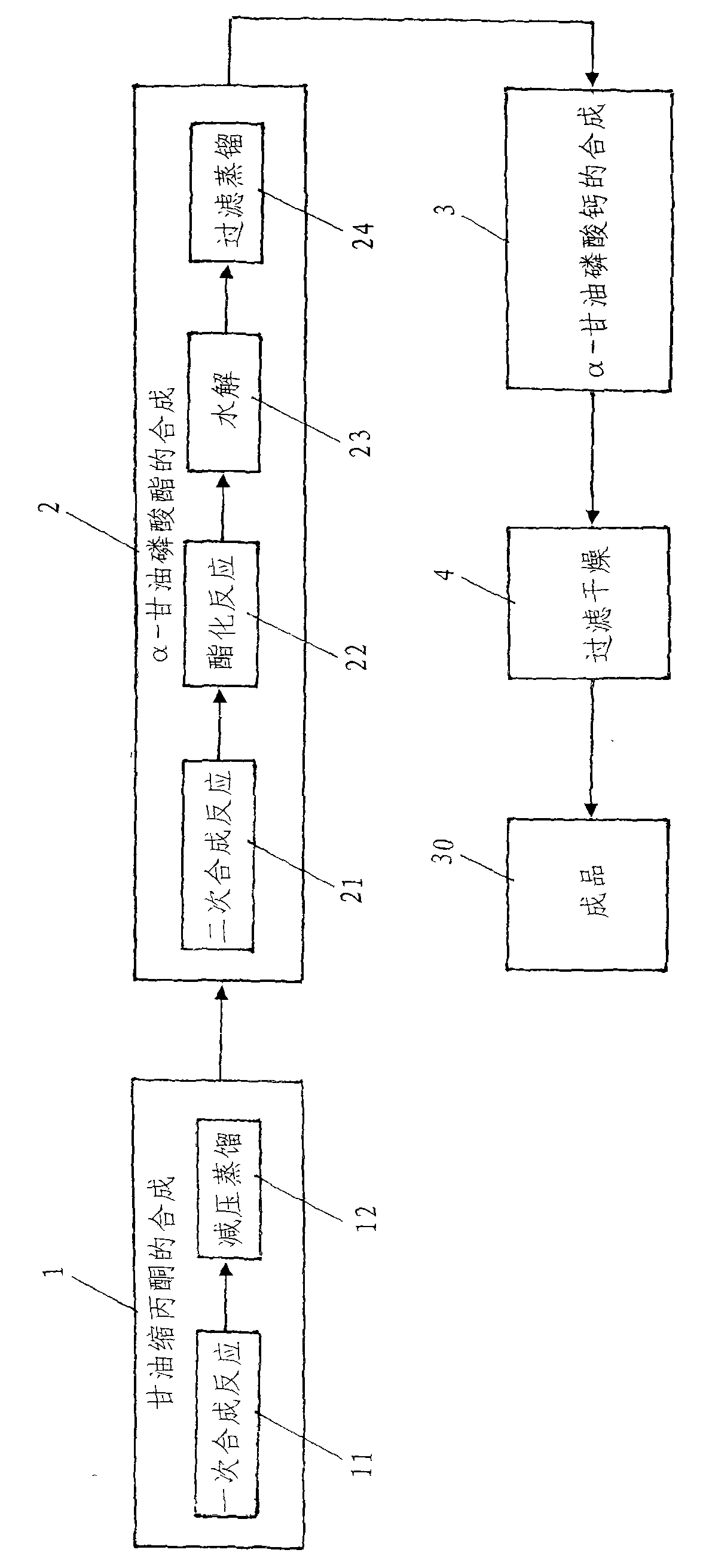

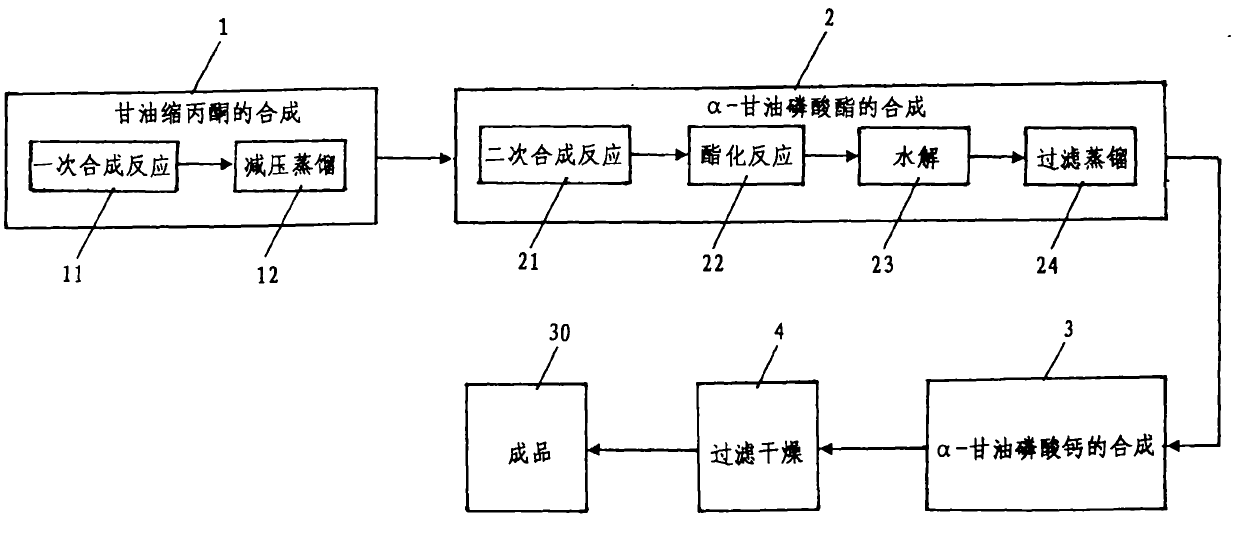

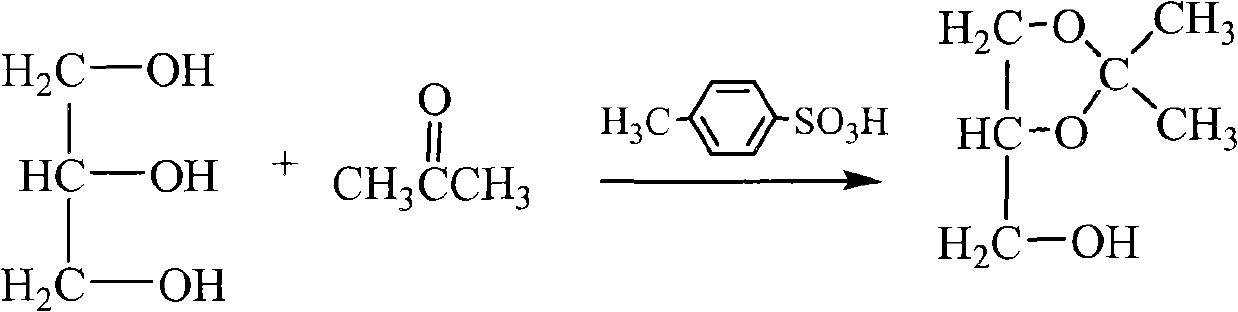

Method for synthesizing high-purity alpha-calcium glycerophosphate

ActiveCN102002067AQuality improvementEliminate distractionsPhosphorus organic compoundsGlycerol acetonideGlycerophosphates

The invention discloses a method for synthesizing high-purity alpha-calcium glycerophosphate, which comprises the following steps of: synthesizing glycerol acetonide; (2) synthesizing alpha-glycerophosphate; (3) synthesizing alpha-calcium glycerophosphate; and (4) filtering, drying and the like. The synthesized alpha-calcium glycerophosphate has stable quality and high purity, the interference of difficultly separated beta-calcium glycerophosphate is effectively avoided, and the content of the alpha-calcium glycerophosphate is over 90 percent.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

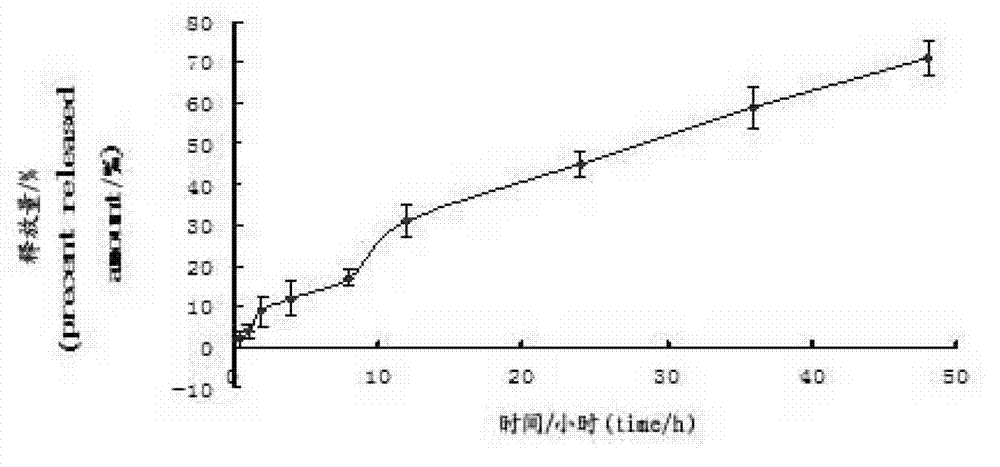

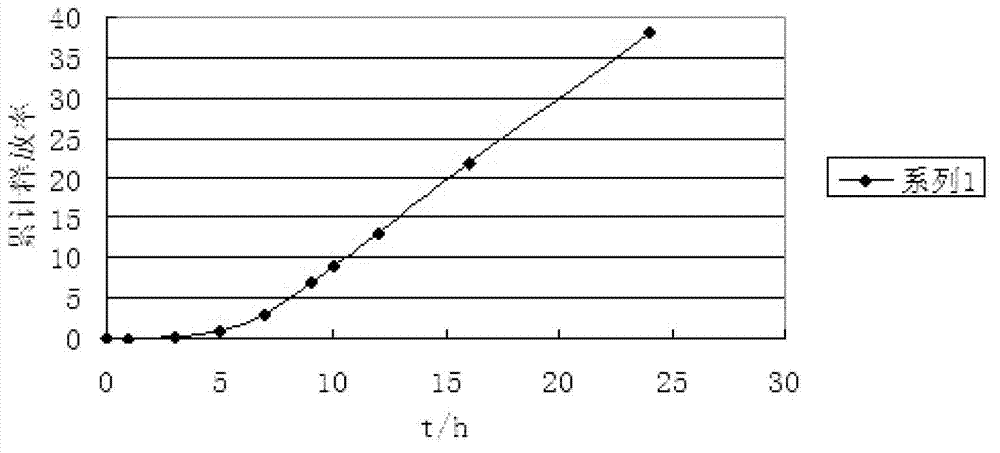

Preparation process for thermosensitive controlled-release material for marine antifouling agent

ActiveCN102726382ARealize intelligent temperature control releaseImprove antifouling performanceBiocideAntifouling/underwater paintsCross-linkIce water

The invention relates to a preparation process for a thermosensitive controlled-release material for a marine antifouling agent, which belongs to the field of marine antifouling technologies. The process comprises the following steps: dissolving chitosan in an HAc solution, adding tween 80 and acetone, carrying out high speed stirring and ultrasonic treatment, then adding isopropanol to form an oil / water dispersion system which is in an emulsified clear state, adding sodium tripolyphosphate for a cross-linking solidification reaction, carrying out filtration so as to remove liquor, flushing aresidual solvent with acetone and water, and carrying out refrigeration and vacuum drying so as to obtain microencapsulated particles; dissolving chitosan in the HAc solution again, dissolving sodiumbeta-glycerophosphate in water, adding a sodium beta-glycerophosphate solution into a chitosan solution under the conditions of ice water bath and stirring, continuing stirring, and adjusting the pH value of the solution to be 7.0; and dispersing the microencapsulated particles with water, then adding the dispersed particles into the chitosan solution, carrying out stirring, and then carrying outcentrifugation and drying so as to obtain the thermosensitive controlled-release material. The preparation process is simple and is convenient to control; and the prepared material has good quality, good controlled release performance, environment friendliness and a good application effect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Novel ophthalmic curcumin multi-core vesicle gel preparation and preparation method thereof

InactiveCN103040726ALow costImproved dwell timeSenses disorderAerosol deliveryGel preparationPolyethylene glycol

The invention relates to a novel ophthalmic curcumin multi-core vesicle gel preparation and a preparation method thereof. The preparation consists of the following medicaments: 0.5 to 2.5 milligrams of curcumin, 5 to 25 milligrams of polyethylene glycol monooleate or polyethylene glycol dioleate, 5 to 25 milligrams of polyethylene glycol monolaurate or polyethylene glycol dilaurate, 5 to 25 milligrams of poloxamer F68, 20 to 200 milligrams of soybean phospholipid or lecithin, and mixed solution of 0.1 to 0.7 mg / L of glycerophosphate solution and 0.01 to 0.05 mg / L of chitosan hydrochloride solution in a volume ratio of 1:1-1:10. By organically combining a multi-core vesicle preparation technology with thermo-sensitive gel, the medicament loading capacity is improved, the bioavailability is also improved, meanwhile, an effect of slow release is achieved, the blank of the ophthalmic curcumin multi-core vesicle gel preparation is filled, and a novel ophthalmic preparation with good treatment effect and low price is provided for clinic.

Owner:YANTAI UNIV

Multifunctional feed additive for milk cows

InactiveCN101564115AIncrease profitPromote absorptionAnimal feeding stuffAccessory food factorsSodium bicarbonatePotassium

The invention discloses a multifunctional feed additive for milk cows, which is characterized by comprising the following components according to the weight portion: 4-7 of hoantchy root, 3-6 of angelica, 4-7 of seed of cowherb, 2-5 of liquorice, 5-8 of potassium chloride, 2-5 of sodium chloride, 1-2 of magnesium chloride, 2-5 of sodium bicarbonate, 0.006-0.03 of sodium monofluorophosphate, 0.02-0.05 of calcium glycerophosphate, 0.002-0.005 of citric acid and 5-10 of carriers. The multifunctional feed additive can increase the stress resistance capacity and the disease-resistant capacity, improves the milk cow improvement, has no residue and no drug resistance and can prevent decayed teeth and protect the teeth.

Owner:TIANJIN SHENGJI GRP CO LTD

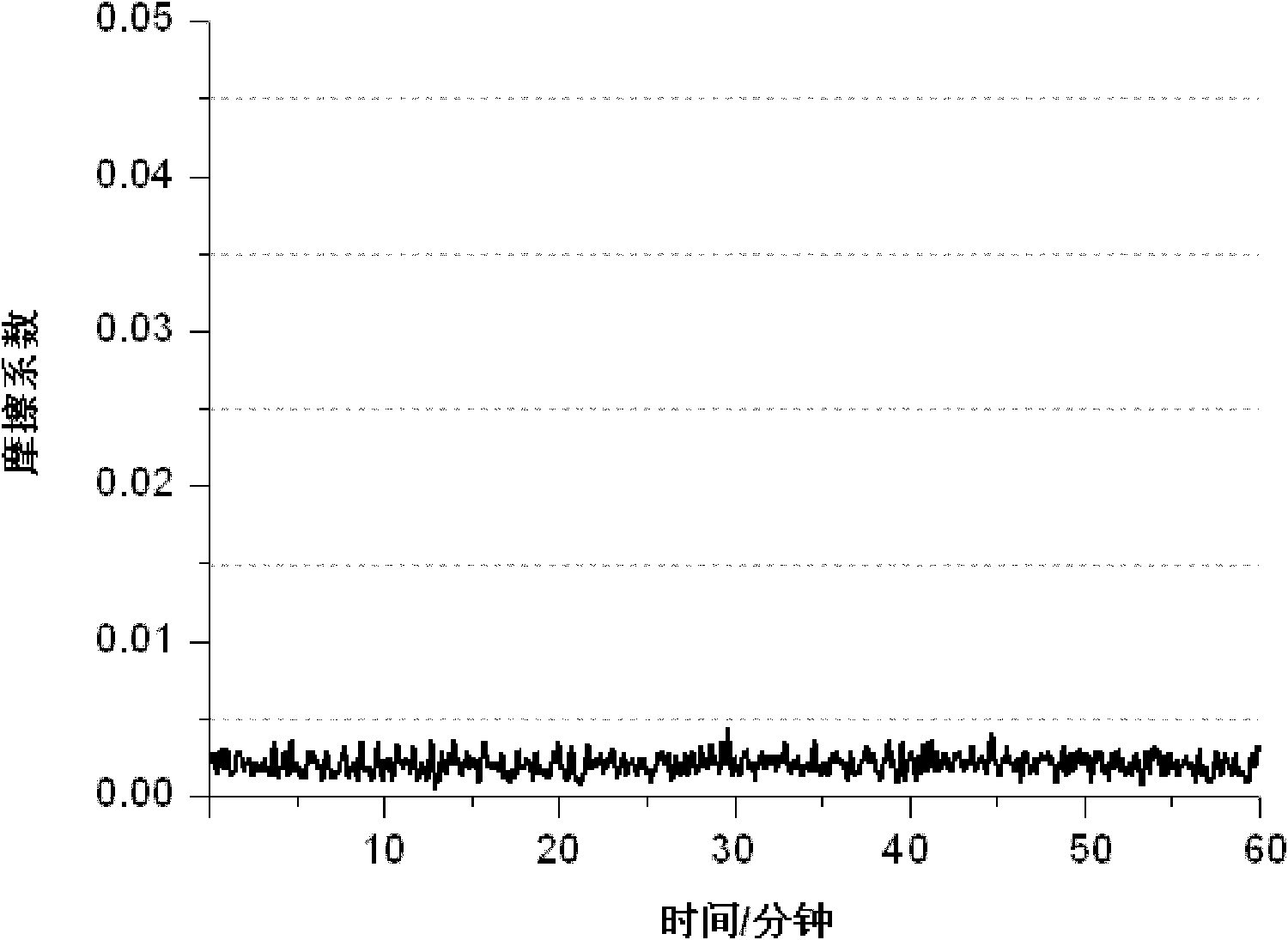

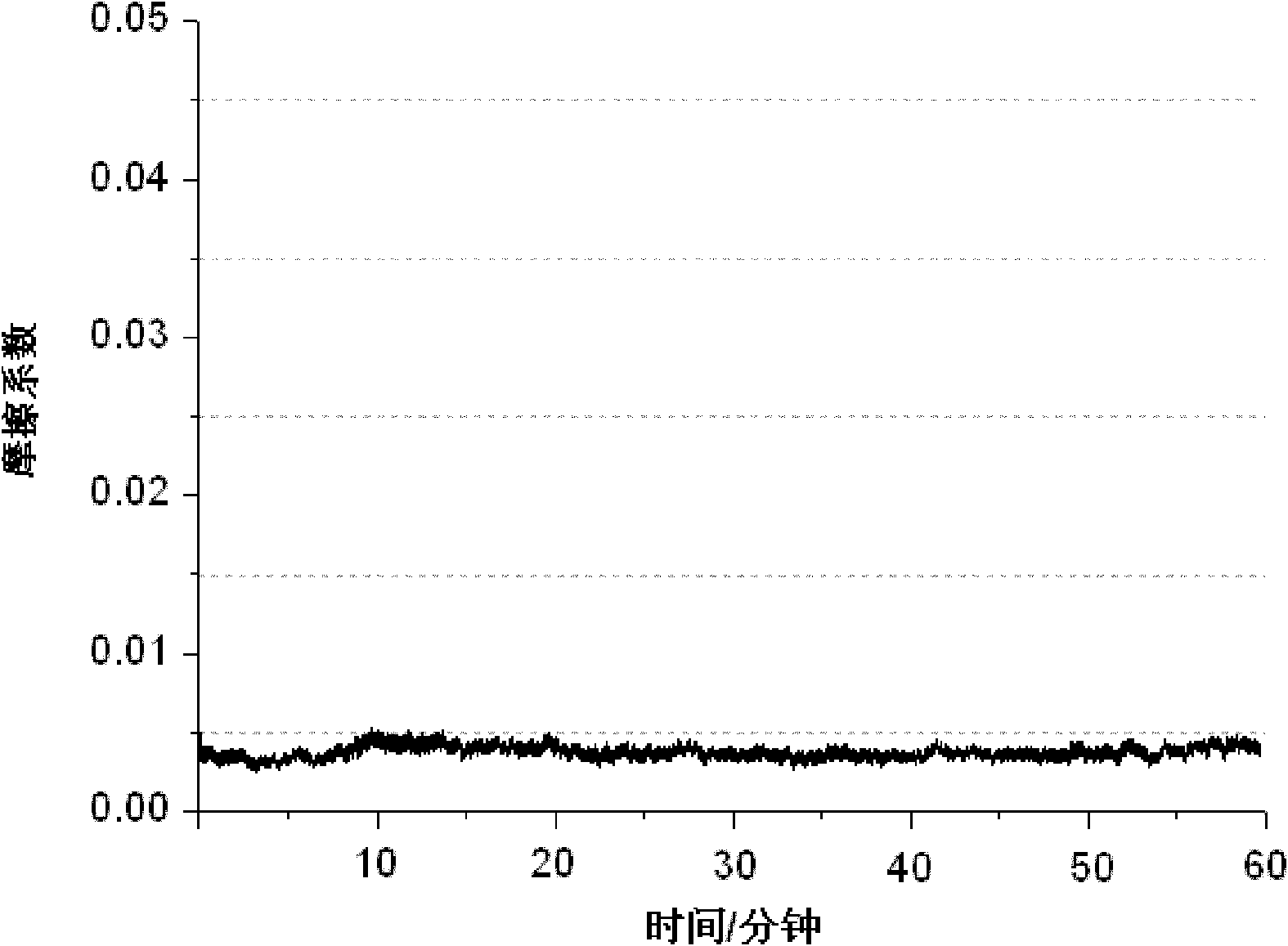

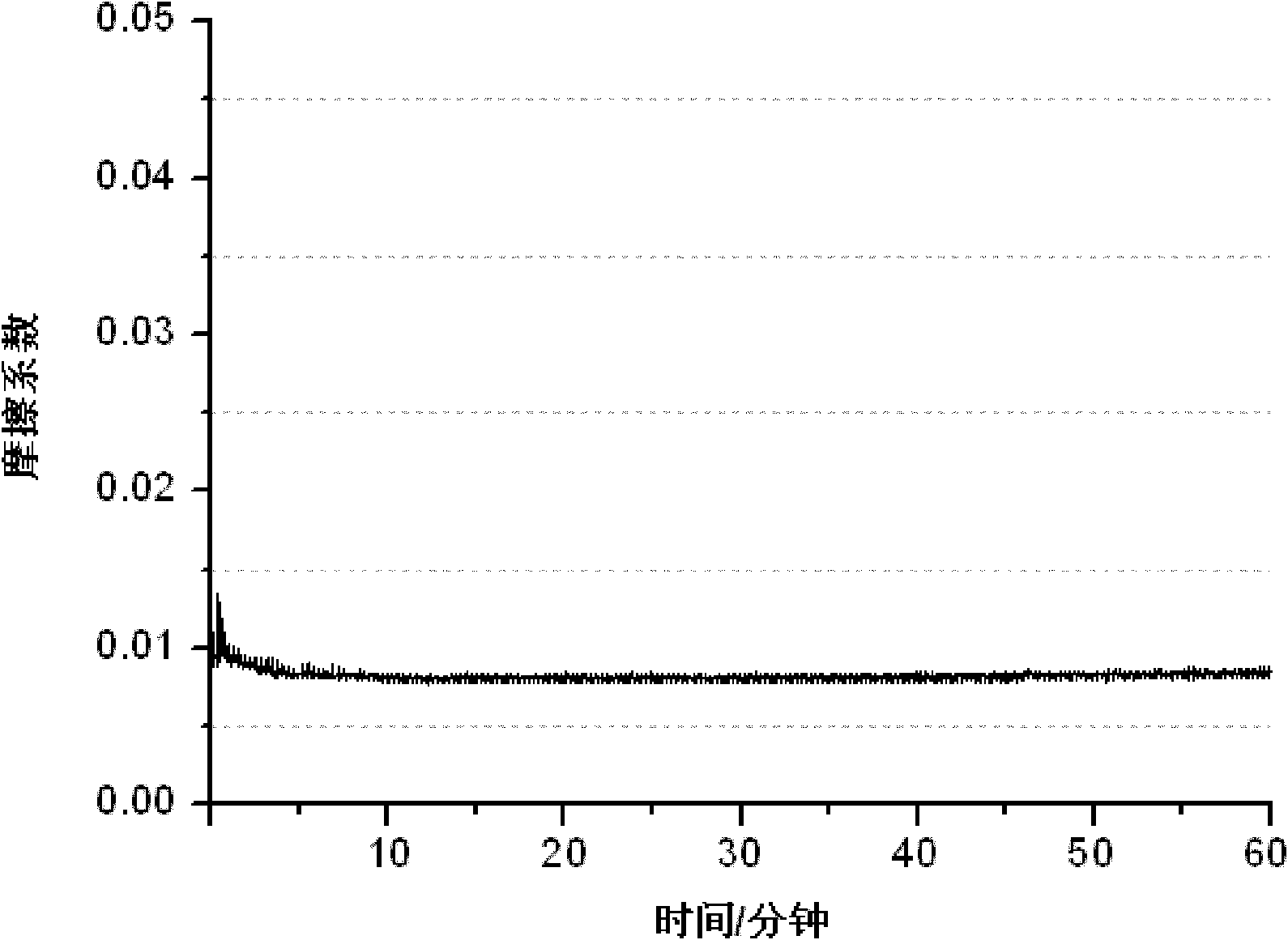

Lubricant composition

The invention discloses a lubricant composition. The lubricant composition contains the following components in parts by weight: 20-60 parts of lower polyol, 0.001-5 parts of glycerophosphate, 0.001-5 parts of boride and 25-80 parts of water. The lubricant composition has at least one of the following advantages: the friction coefficient is low, and the lubricant composition is nontoxic, harmlessand environment-friendly.

Owner:TSINGHUA UNIV

Preparation method of calcium glycerophosphate with high calcium content

ActiveCN102127107AHigh in calciumQuality improvementPhosphorus organic compoundsPhosphoric acidGlycerol

The invention discloses a preparation method of calcium glycerophosphate with high calcium content. The preparation method comprises the following steps of: (i) synthetic reaction: putting glycerol, monocalcium phosphate and phosphoric acid into an agitated reactor in proportion, and simultaneously adding a small amount of citric acid to undergo a synthetic reaction; (ii) diluting; (iii) filtering; (iv) concentrating; (v) precipitating; (vi) drying, and the like. The calcium glycerophosphate product prepared by adopting the preparation method disclosed by the invention has stable quality and high calcium content up to more than 95 percent and can simultaneously meet requirements of a calcium supplement and a toothpaste additive.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Antistatic PBAT fiber

InactiveCN110158196AImprove antistatic performanceHigh strengthElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsFiberAntistatic agent

The invention discloses antistatic PBAT fiber which is composed of, by weight, 100 parts of polyadipic acid / polybutyl terephthalate, 25 parts of PLA, 0.5 part of antistatic agent, 0.1 part of blender,2 parts of plasticizer and 0.1 part of antioxidant, wherein the antistatic agent is a phosphate antistatic agent, and the blender is palmityl glycerophosphate. Using effect of the phosphate antistatic agent is improved by adding the blender in key technology; in actual application, consumption of the antistatic agent can be reduced greatly, so that the obtained fiber has good antistatic effect.

Owner:福建经纬新纤科技实业有限公司

Decayed tooth preventing feed additive for improving animal immunizing power

The invention discloses a decayed tooth preventing feed additive for improving animal immunizing power, which is characterized by comprising the following components according to the weight portion: 5-10 of spirulina powder, 1-3 of hoantchy root, 1-3 of radix codonopsitis, 1-5 of forsythia, 3-7 of purslane, 0.4-1 of honeysuckle, 0.2-0.5 of liquorice, 0.006-0.02 of sodium monofluorophosphate, 0.02-0.05 of calcium glycerophosphate and 0.002-0.005 of citric acid. The decayed tooth preventing feed additive is a pure natural Chinese material medical preparation, has no drug residue and side effects by being used for a long time, increases the organism immunizing power, has the function of preventing decayed teeth and low cost of raw materials, and is suitable for industrialized massive production; and products made of animals using the decayed tooth preventing feed additive always accord with the export standard without drug resistance.

Owner:TIANJIN SHENGJI GRP CO LTD

Water-based fruit and vegetable fresh-keeping paint and preparation method thereof

InactiveCN107114471ASimple ingredientsAchieve preparationFood ingredient as thickening agentNatural extract food ingredientsWater basedAqueous extract

The invention belongs to the technical field of paints, and particularly relates to water-based fruit and vegetable fresh-keeping paint and a preparation method thereof. According to the water-based fruit and vegetable fresh-keeping paint and the preparation method thereof, aqueous extract liquid of platycodon roots, aqueous extract liquid of tree peony bark, aqueous extract liquid of wild chrysanthemums, and aqueous extract liquid of rhizoma gastrodiae are used as preservatives, mixed liquid which is prepared by modifying a mixture consisting of D-calcium pantothenate, calcium glycerophosphate and zinc sulfate through a phosphate aqueous solution of which the pH is 4.3-5.2 is used as a fruit and vegetable softening inhibitor, an emulsifying agent, a thickening agent and a gelling agent are matched for use, so that the water-based fruit and vegetable fresh-keeping paint is prepared. The water-based fruit and vegetable fresh-keeping paint is simple in components, the used materials are green and non-toxic and the paint can be prepared without severe production equipment.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com