Moisture absorbing and sweat releasing finishing agent and preparing method thereof

A moisture-wicking and finishing agent technology, applied in fiber processing, textiles and papermaking, etc., can solve problems such as perspiration, insignificant moisture absorption, inability to emit sweat, lack of water, irritability, etc., to avoid stuffy feeling, Improved perspiration performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

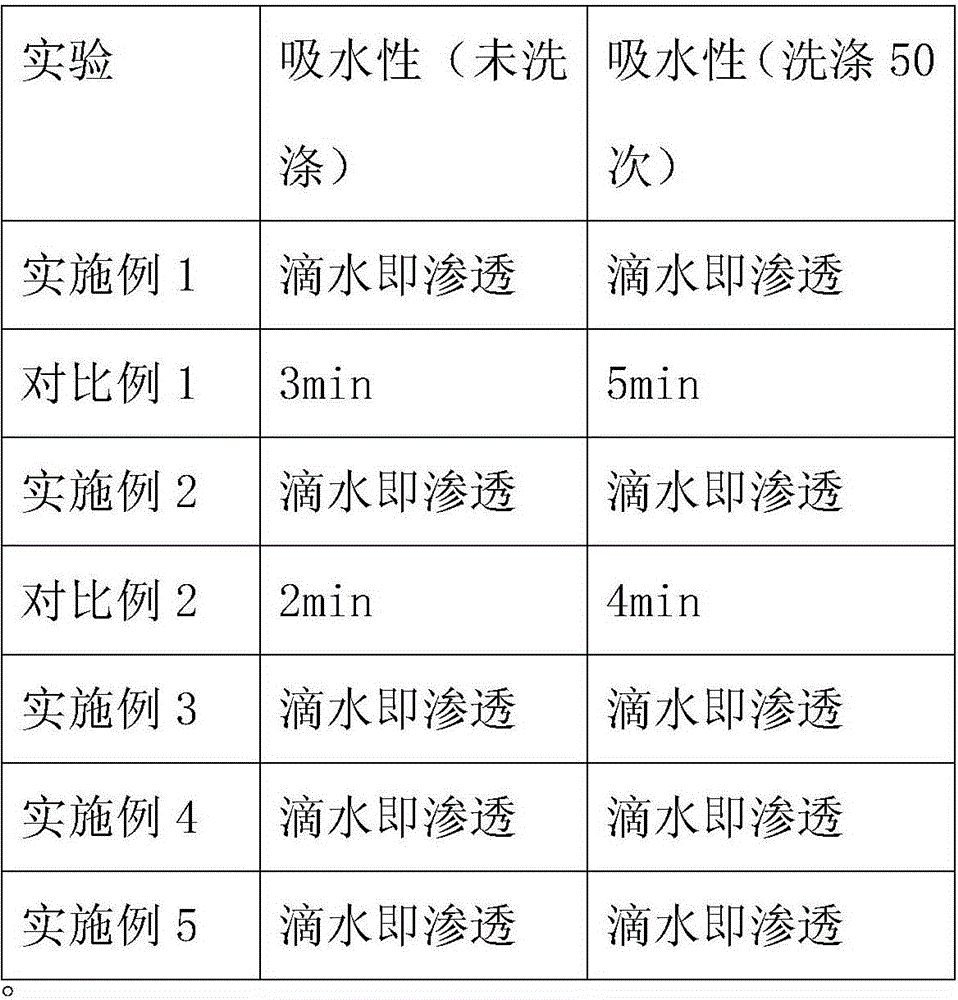

Examples

Embodiment 1

[0016] S1: Add 13 parts of 4,4'-dinitrobenzhydryl alcohol, 20 parts of ethylene glycol bisthioglycolate, 8 parts of 2-hydroxy-5-chlorobenzophenone and 10 parts of silicone oil into the reactor with magnetic stirring 20 minutes, then raise the temperature to 40°C, continue to add 2 parts of sodium citrate and 1 part of potassium dihydrogen phosphate, and react for 1 hour while adding dropwise;

[0017] S2: Fully stir and mix 15 parts of nonylphenol polyoxyethylene ether, 3 parts of 4-hydroxyphenylethylamine, 7 parts of glycerol phosphate and 30 parts of deionized water at a temperature of 30 ° C, and then the reaction solution obtained in step S1 , without stirring for 10 minutes;

[0018] S3: continue to heat up to 100° C., reflux reaction for 2 hours, and the moisture-absorbing and sweat-wicking finishing agent can be obtained after the reaction solution is cooled.

Embodiment 2

[0024] S1: Add 20 parts of 4,4'-dinitrobenzhydryl alcohol, 25 parts of ethylene glycol bisthioglycolate, 12 parts of 2-hydroxy-5-chlorobenzophenone and 15 parts of silicone oil into the reactor with magnetic stirring 30min, then raise the temperature to 50°C, continue to add 6 parts of sodium citrate and 6 parts of potassium dihydrogen phosphate, and react for 2 hours while adding dropwise;

[0025] S2: Fully stir and mix 25 parts of nonylphenol polyoxyethylene ether, 8 parts of 4-hydroxyphenylethylamine, 16 parts of glycerol phosphate and 50 parts of deionized water at a temperature of 40 ° C, and then the reaction solution obtained in step S1 , without stirring for 15 minutes;

[0026] S3: continue to heat up to 110° C., reflux reaction for 3 hours, and the moisture-absorbing and sweat-wicking finishing agent can be obtained after the reaction solution is cooled.

Embodiment 3

[0032] S1: Add 15 parts of 4,4'-dinitrobenzhydryl alcohol, 22 parts of ethylene glycol bisthioglycolate, 9 parts of 2-hydroxy-5-chlorobenzophenone and 12 parts of silicone oil into the reactor with magnetic stirring After 20 minutes, raise the temperature to 40°C, continue to add 3 parts of sodium citrate and 2 parts of potassium dihydrogen phosphate, and react for 1 hour while adding dropwise;

[0033] S2: Fully stir and mix 18 parts of nonylphenol polyoxyethylene ether, 4 parts of 4-hydroxyphenylethylamine, 10 parts of glycerol phosphate and 35 parts of deionized water at a temperature of 30 ° C, and then the reaction solution obtained in step S1 , without stirring for 10 minutes;

[0034] S3: continue to heat up to 100° C., reflux reaction for 2 hours, and the moisture-absorbing and sweat-wicking finishing agent can be obtained after the reaction solution is cooled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com