Lubricant composition

A lubricant composition and a boride technology, applied in the field of lubrication, can solve the problems that the lubricant needs to be improved and the friction coefficient of water-based lubricants is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] 1. Preparation of lubricant composition

[0043] A lubricant composition with a total weight of 1000 grams was prepared at room temperature as follows:

[0044] According to the component content listed in Table 1, first weigh the lower polyols of required weight, pour it into a beaker with a capacity of 1500 milliliters, then add deionized water of required weight in turn, and place it in On a magnetic stirrer with a power of 350 watts, add glycerophosphate, boride hydrate and / or antibacterial agent colistin sulfate while stirring until transparent to obtain lubricant composition experimental examples 1-7.

PUM

| Property | Measurement | Unit |

|---|---|---|

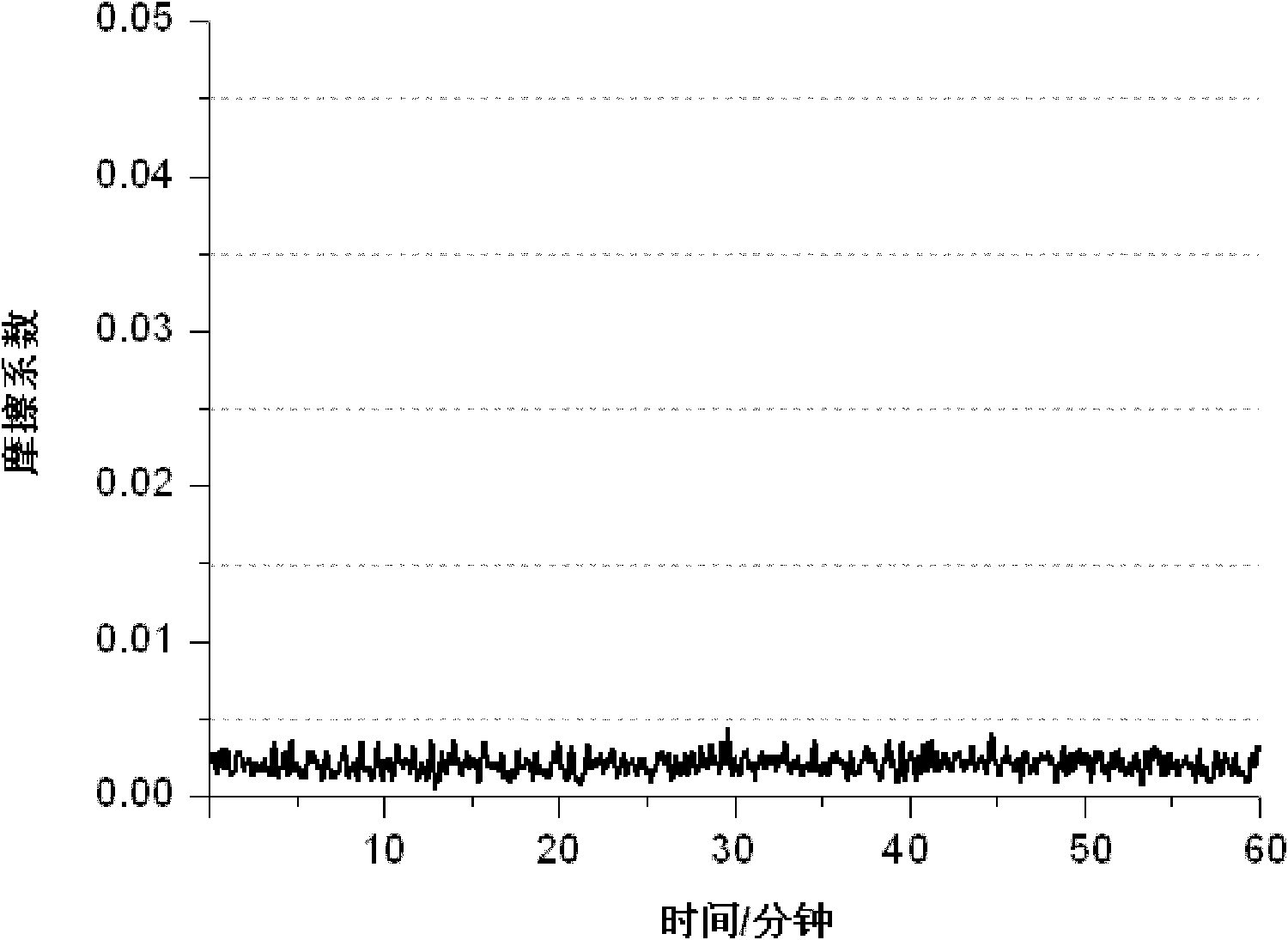

| friction coefficient | aaaaa | aaaaa |

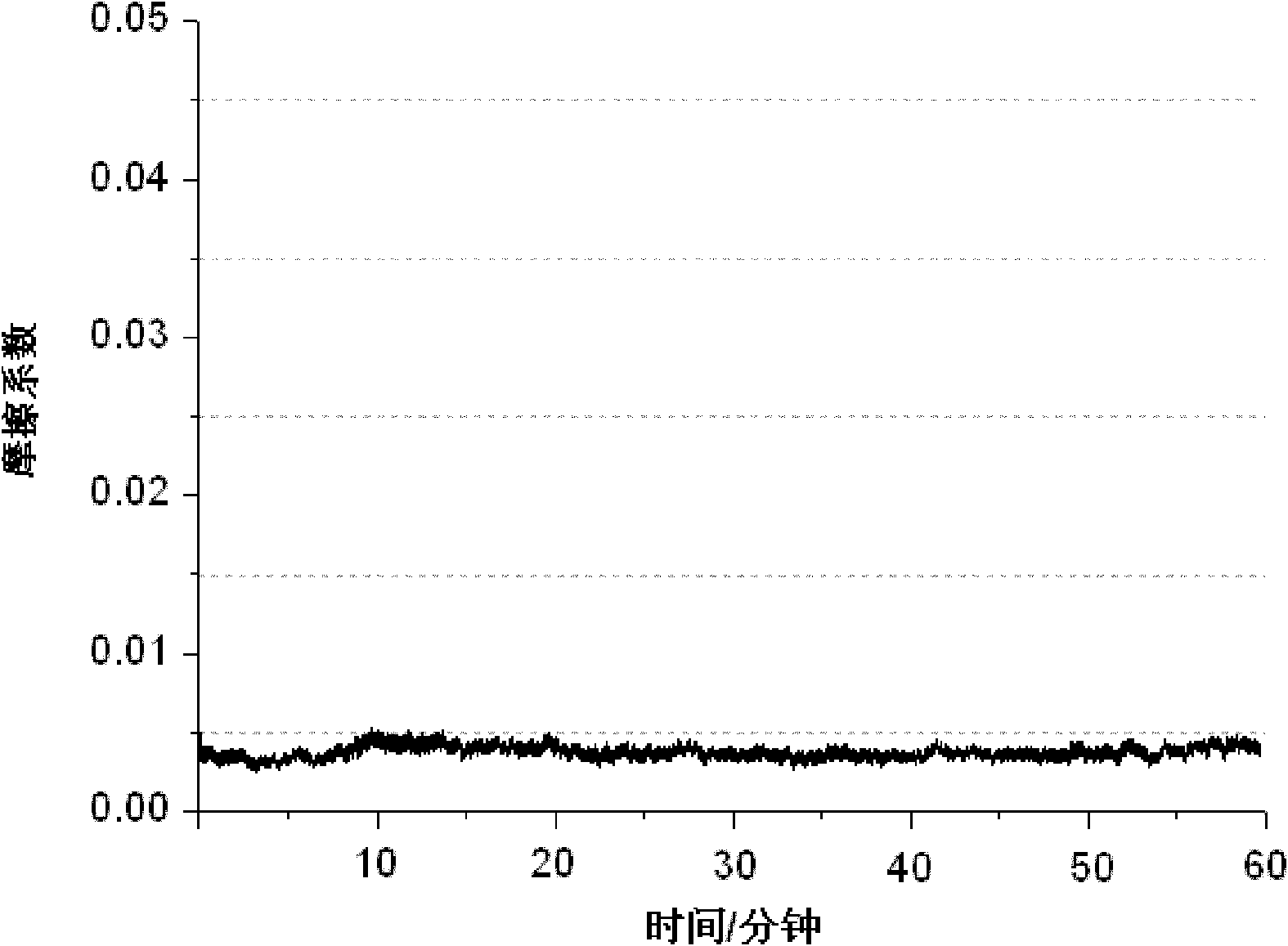

| friction coefficient | aaaaa | aaaaa |

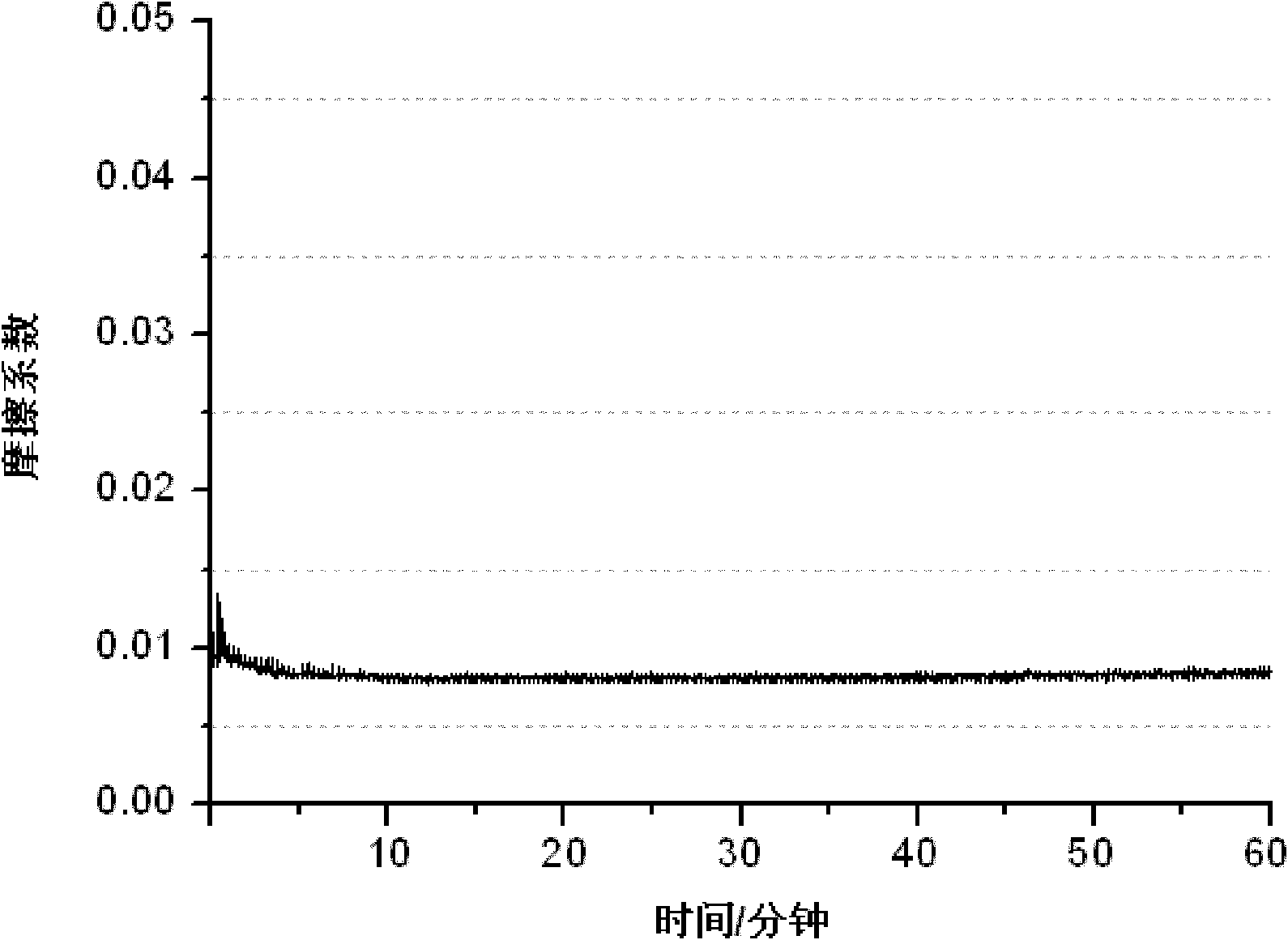

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com