Antistatic PBAT fiber

An antistatic and antistatic agent technology, applied in the fiber field, can solve the problems of poor antistatic ability on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] It consists of the following parts by weight:

[0033] Polybutylene adipic acid / terephthalate: 100 parts

[0034] PLA: 25 servings

[0035] Antistatic agent: 0.5 part

[0036] Conditioner: 0.1 part

[0037] Plasticizer: 2 parts

[0038] Antioxidant: 0.1 part

[0039] The antistatic agent is a phosphate ester antistatic agent

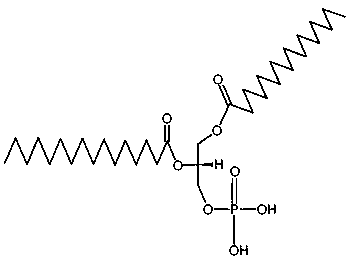

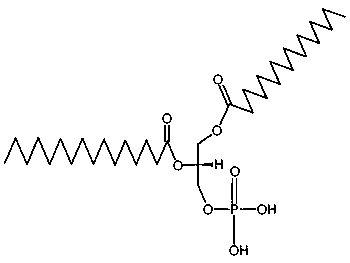

[0040] Described reconciling agent is palmityl glycerophosphate;

[0041] Described palm-based glycerophosphate molecular formula is:

[0042] .

[0043] The antistatic agent is tristearyl phosphate.

[0044] The plasticizer is diethylene glycol dibenzoate.

[0045] The antioxidant is N,N'-bis(2-naphthyl)-p-phenylenediamine.

[0046] The preparation method is as follows: weighing raw materials and mixing,

[0047] The mixture is vacuum dried to a moisture content of less than 100 ppm;

[0048] The mixture is melt-spun, cooled and wound to form pre-drawn fibers directly.

[0049] The vacuum drying time is 12 hours, the vacuum drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com