Method for synthesizing calcium glycerinophosphate

A technique for calcium glycerophosphate and its synthesis method, which is applied in the field of synthesis of calcium glycerophosphate, can solve problems such as obsolete production methods, expensive prices, and complex production processes, and achieve the effects of stable quality, low cost, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

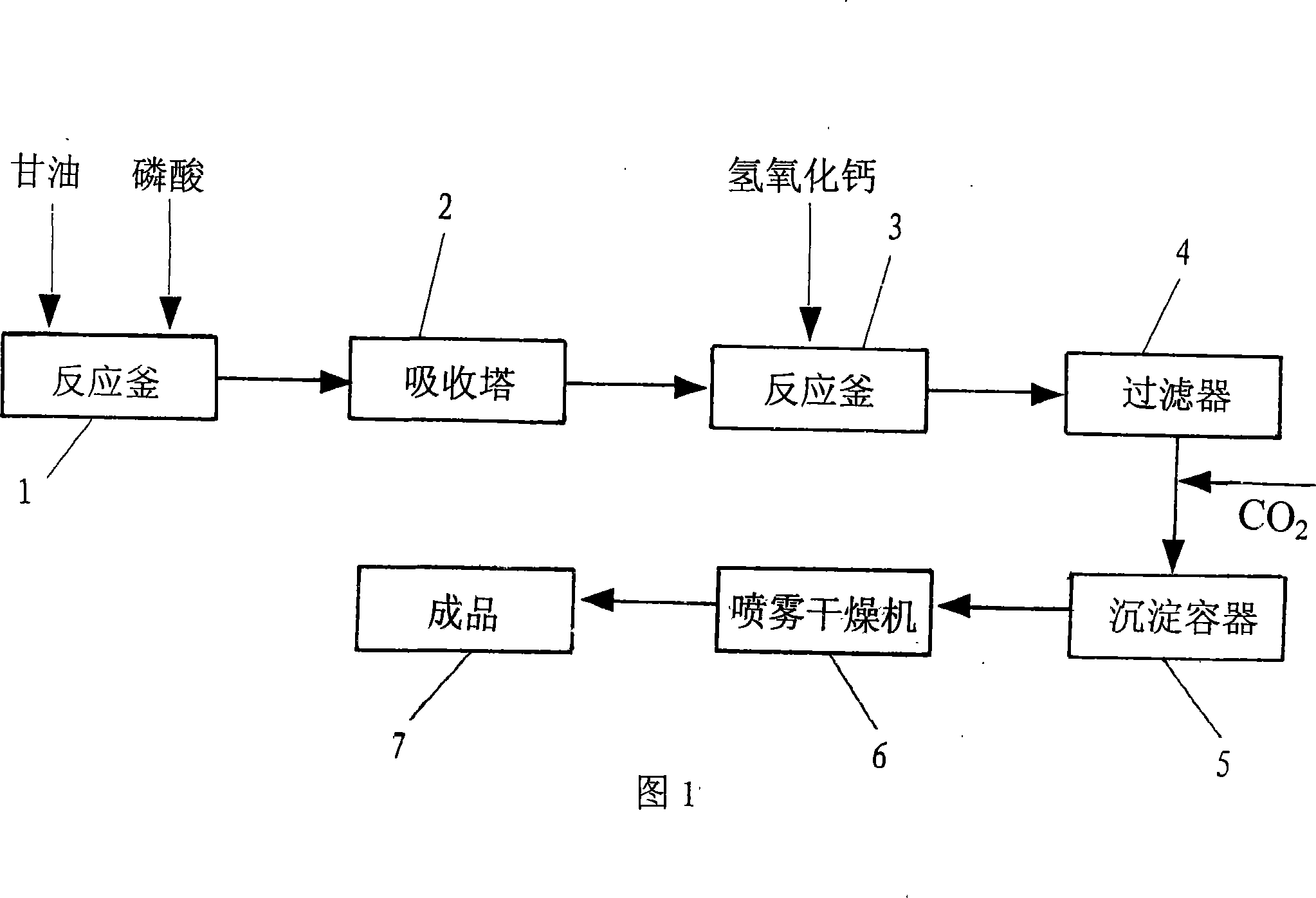

Image

Examples

Embodiment 1

[0015] Pharmaceutical grade glycerin 1000ml Food grade phosphoric acid 1060ml

[0016] The temperature is 120℃ and the vacuum is 0.05MPa

[0017] Esterification reaction time 7 hours

Embodiment 2

[0019] Pharmaceutical grade glycerin 2500ml Food grade phosphoric acid 2500ml

[0020] The temperature is 150℃ and the vacuum is 0.1MPa

[0021] Esterification reaction time 14 hours

[0022] When the temperature drops to about 110° C., 2000 ml of deionized water is taken to dilute the product obtained from the chemical reaction of the above-mentioned examples 1 and 2, and 0.3% activated carbon of the mass of the reaction system is added for decolorization. Pour the decolorized reaction product into an ultrasonic stirrer, and add 60 g of food-grade calcium hydroxide with a mass concentration of 6%. The reaction was stirred for 3-5 hours and filtered. Bubble CO into the filtrate 2 , so that the pH of the filtrate is 8-10, stop feeding carbon dioxide and filter. 45% (volume) food-grade ethanol of the filtrate was added to the filtrate for precipitation. Then, it is dried by a spray dryer, wherein the inlet air temperature is 110° C., and the air frequency is 60 Hz to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com