H-occupied BiVO4-OVs photocatalytic material and production method and application thereof

A photocatalytic material, 3·5H2O technology, applied in the field of photocatalytic materials, can solve the problems of photocatalytic performance reduction, short carrier diffusion length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

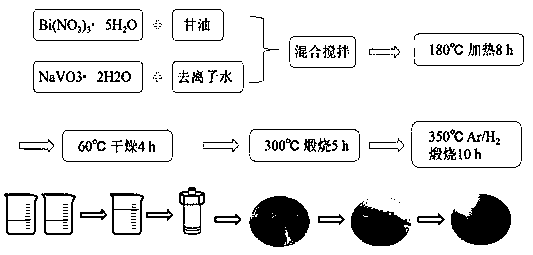

[0038] (1) Add 0.4 mmol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 16 ml glycerin to obtain precursor solution A;

[0039] (2) Add 0.4 mmol NaVO 3 2H 2 O was dissolved in 16 ml deionized water to obtain precursor solution B;

[0040] (3) Add solution A to solution B and stir vigorously to obtain solution C;

[0041] (4) The solution C was transferred to a polytetrafluoroethylene-lined autoclave, and the synthetic product D was obtained after maintaining at 120 °C for 6 h;

[0042] (5) The solvothermally synthesized product D was centrifuged at 10,000 rpm, washed with deionized water and ethanol, and dried at 60 °C for 4 h to obtain product E;

[0043] (6) Product E was calcined in a muffle furnace at 300 °C for 5 h to obtain product F;

[0044] (7) The product F is in Ar / H 2 In atmosphere at 350 ℃, Ar / H 2 (Vol: 95%: 5%) annealed under atmosphere for 10 h to obtain H-occupied BiVO 4 -OVs photocatalytic materials.

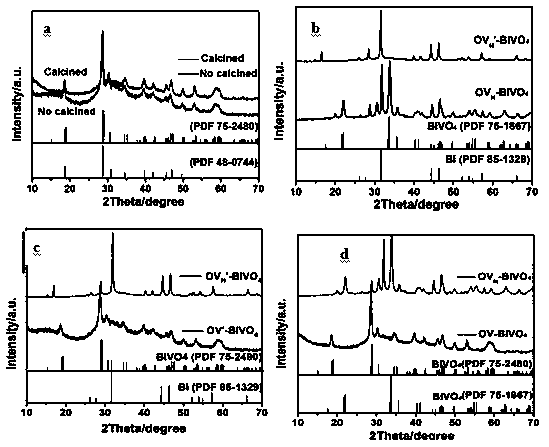

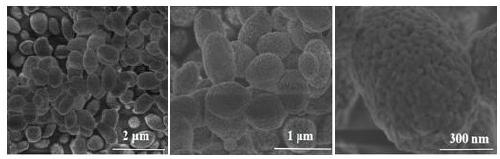

[0045] The resulting H occupies the BiVO 4 -OVs photocata...

Embodiment 2

[0048] (1) Add 0.4 mmol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 16 ml glycerin to obtain precursor solution A;

[0049] (2) Add 0.4 mmol NaVO 3 2H 2 O was dissolved in 16 ml deionized water to obtain precursor solution B;

[0050] (3) Add solution A to solution B and stir vigorously to obtain solution C;

[0051] (4) The solution C was transferred to a polytetrafluoroethylene-lined autoclave, and the synthetic product D was obtained after maintaining at 180 °C for 8 h;

[0052](5) The solvothermally synthesized product D was centrifuged at 10,000 rpm, washed with deionized water and ethanol, and dried at 60 °C for 4 h to obtain product E;

[0053] (6) Product E was calcined in a muffle furnace at 300 °C for 5 h to obtain product F;

[0054] (7) The product F is in Ar / H 2 In atmosphere at 350 ℃, Ar / H 2 (Vol: 95%: 5%) annealed under atmosphere for 10 h to obtain H-occupied BiVO 4 -OVs photocatalytic materials.

[0055] The resulting H occupies the BiVO 4 -OVs photocatal...

Embodiment 3

[0058] (1) Add 0.4 mmol Bi(NO 3 ) 3 ·5H 2 O was dissolved in 16 ml glycerin to obtain precursor solution A;

[0059] (2) Add 0.4 mmol NaVO 3 2H 2 O was dissolved in 16 ml deionized water to obtain precursor solution B;

[0060] (3) Add solution A to solution B and stir vigorously to obtain solution C;

[0061] (4) The solution C was transferred to a polytetrafluoroethylene-lined autoclave and kept at 180 °C for 10 h to obtain the synthetic product D;

[0062] (5) The solvothermally synthesized product D was centrifuged at 10,000 rpm, washed with deionized water and ethanol, and dried at 60 °C for 4 h to obtain product E;

[0063] (6) Product E was calcined in a muffle furnace at 300 °C for 5 h to obtain product F;

[0064] (7) The product F is in Ar / H 2 In the atmosphere at 350 ℃, Ar / H 2 (Vol: 95%: 5%) annealed under atmosphere for 10 h to obtain H-occupied BiVO 4 -OVs photocatalytic materials.

[0065] The resulting H occupies the BiVO 4 -OVs photocatalytic materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com