Production method of dissolving pulp

A technology for dissolving pulp and pulp, which is used in textiles, papermaking, and fiber raw material processing. and cooking time, the effect of preventing degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

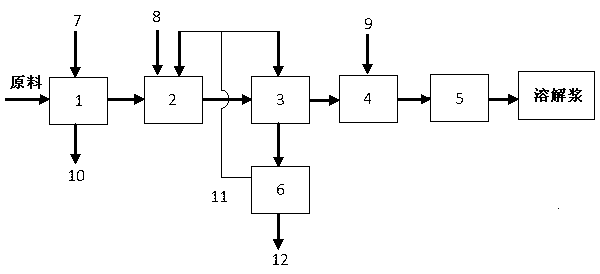

[0046] Poplar adopts technology of the present invention to carry out cooking and bleaching, and cooking flow process is as follows: figure 1 shown. After cooking, the pulp was treated with hemicellulase, followed by alkaline extraction, oxygen delignification, chlorine dioxide bleaching and hydrogen peroxide bleaching, that is, the EODP bleaching process was used for bleaching. The specific process conditions and pulp properties are shown in Table 1. Show. The amount of bleaching chemicals in Table 1 is relative to the absolute dry pulp. The resulting dissolving pulp had a brightness of 91%ISO, an α-cellulose content of 97.0%, an intrinsic viscosity of 810 ml / g and a pentosan content of 1.95%.

[0047] process Process conditions Prehydrolysis Steam pressure 0.8 MPa, liquid ratio 1:6, time 45 min peroxyacid cooking Formic acid concentration 80% (v / v), hydrogen peroxide 2% (for absolute dry pulp), liquid ratio 1:6, temperature 120oC, time 40 min ...

Embodiment 2

[0049] Eucalyptus adopts technology of the present invention to carry out cooking and bleaching, and flow process and process condition are the same as Table 1. The resulting dissolving pulp had a brightness of 90% ISO, a content of α-cellulose of 96.5%, an intrinsic viscosity of 795 ml / g and a content of pentosan of 1.85%.

Embodiment 3

[0051] Bamboo adopts technology of the present invention to carry out cooking and bleaching, flow process and technology as shown in table 1, difference is that what prehydrolysis adopts is the sulfuric acid of 0.2%, formic acid concentration is 75% during peroxyacid cooking, and hydrogen peroxide consumption is 3 %, the time is 30 min. And there is no chlorine dioxide bleaching stage in the bleaching process, that is, the EOP bleaching process is used for bleaching. The resulting dissolving pulp had a whiteness of 91% ISO, an α-cellulose content of 96.2%, an intrinsic viscosity of 745 ml / g and a pentosan content of 1.90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com