Process for continuous preparation of high purity epsilon-caprolactone

A technology of caprolactone and process, which is applied in the field of ε-caprolactone preparation, can solve the problems of inability to realize continuous industrial production, difficulty in separation and purification, and many side reactions, so as to achieve small fluctuations in process parameters and stable and controllable process flow , The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

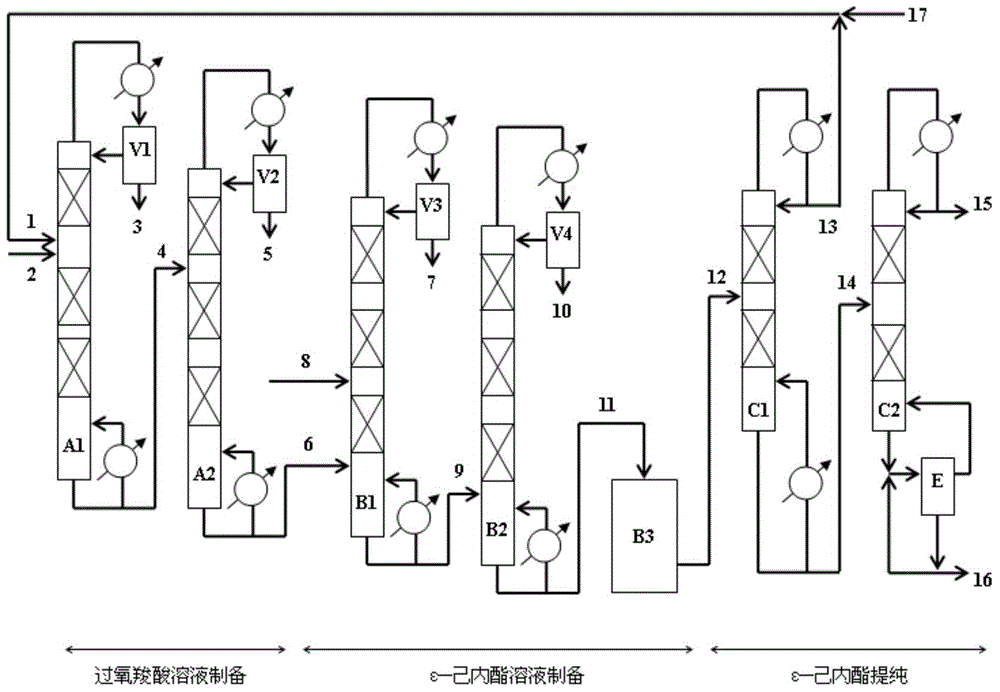

[0030] Build the experimental device according to the accompanying drawings, wherein A1 and A2 are equipped with catalysts, B1, B2, C1, and C2 are packed towers, and the bottom of each tower is a 500mL three-necked flask, A1, A2, B1, and B2 are heated in a water bath, and C1 and C2 are used Electric heating mantle heating. Except that tap water is used for condensation at the top of the C2 tower, all other towers use low-temperature water for condensation.

[0031] First, wrap the perfluorosulfonic acid resin into a sandbag shape with glass fiber cloth, with an equivalent diameter of about 6-8 mm, and put it into the middle section of catalytic distillation reactors A1 and A2 with a diameter of 45 mm. The catalyst bed is about 600 mm high. The upper and lower sides of the distillation tower are equipped with 400mm long glass spring packing, the top of the tower is equipped with a condenser and a water separation and reflux device, and the bottom of the tower is heated by a wat...

Embodiment 2

[0038] The experimental device of embodiment 2 is exactly the same as embodiment 1, but raw material and proportioning are different, and the solvent that is added in each kettle in advance is changed into ethyl propionate, and the operating conditions of each tower are different.

[0039] Weigh 3000g propionic acid, 3000g ethyl propionate, 50% H 2 o 2 Add 1000g to a 10L bottle, shake well, and then use a pump to introduce from pipe 1 or 2 at a speed of about 280g / h. The pressure of A1 and A2 is controlled at about 15kPa, and the temperature of the kettle is about 60°C. Cyclohexanone is introduced into B1 at a rate of about 56g / h, the pressure of B1 and B2 is controlled at about 12kPa, the kettle temperature is about 55°C, the pressure of C1 and C2 is controlled at about 0.5kPa, and the kettle temperature is about 100-110°C.

[0040] Calculated from the product composition, H 2 o 2 The conversion rate is 99.7%, the conversion rate of cyclohexanone is 99.9%, the selectivity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com