Method of producing diisobutylene using mixed C4

A technology of diisobutylene and isobutylene, applied in the production field of diisobutylene, can solve the problems of high trimer content and low utilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

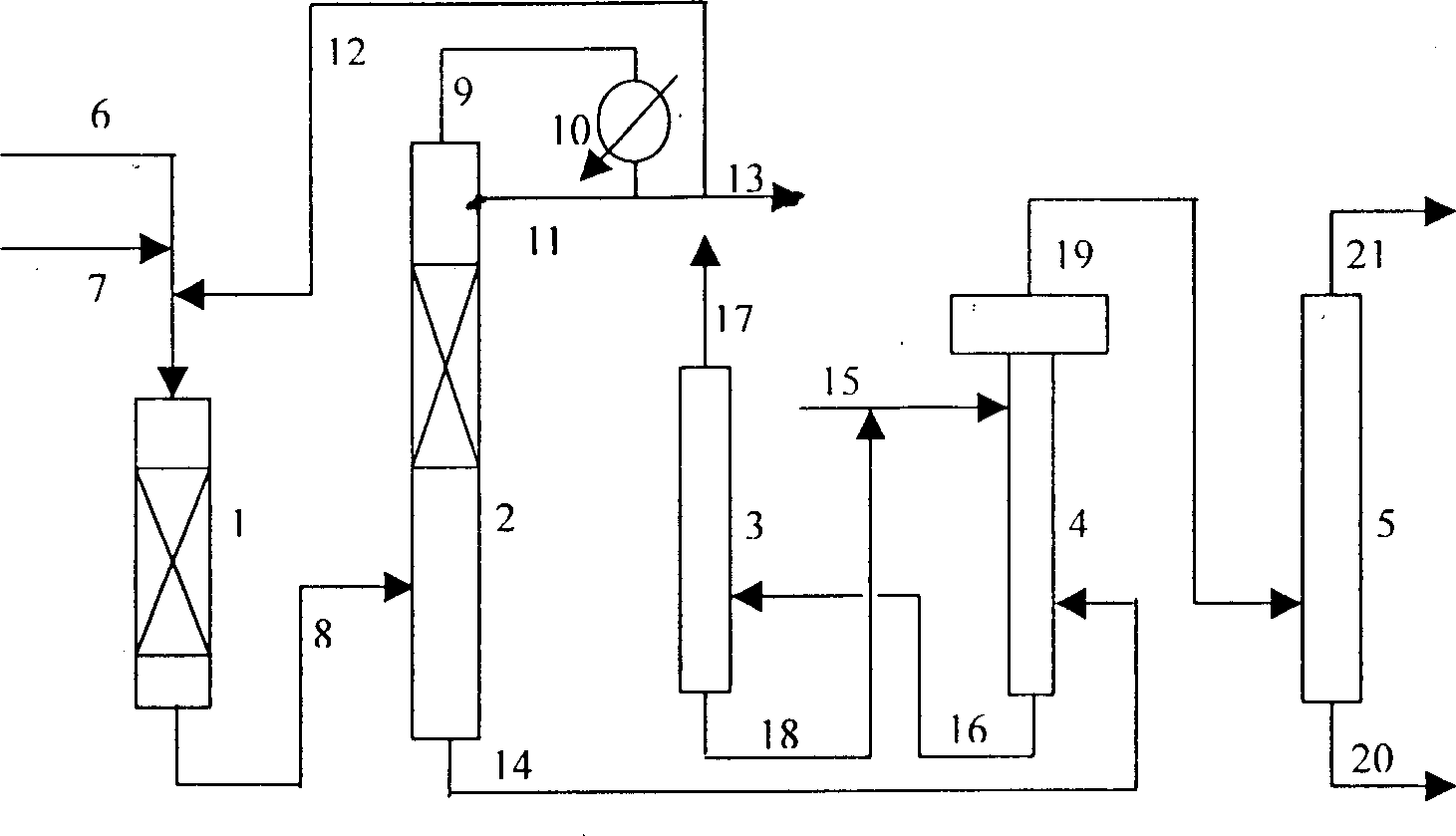

[0034] use as figure 1 catalytic distillation process.

[0035] mix C 4 Contains 48.5% isobutene and 26.3% n-butene

[0036] Feed amount: 300g / h

[0037] Fixed bed polymerization reactor catalyst loading: 500ml

[0038] Catalytic distillation tower catalyst loading: 200ml

[0039] A polymerization inhibitor (tert-butanol) is added to the raw material, and the molar ratio of the inhibitor to isobutene in the fresh feed is 0.015:1.

[0040] Fixed bed polymerization reaction temperature 50.0°C, reaction pressure 0.65Mpa

[0041] The inlet temperature of the catalytic distillation tower bed layer is 62°C, and the reaction pressure is 0.65Mpa

[0042] The temperature at the top of the separation tower is 104.5°C, which is normal pressure separation

[0043] 185 g / h of polymerized product was obtained from the water washing tower, wherein the C8 content was 93.7%, and the diisobutylene content was 76.9%. The purity of diisobutene obtained from the separation tower is 98.3%. ...

Embodiment 2

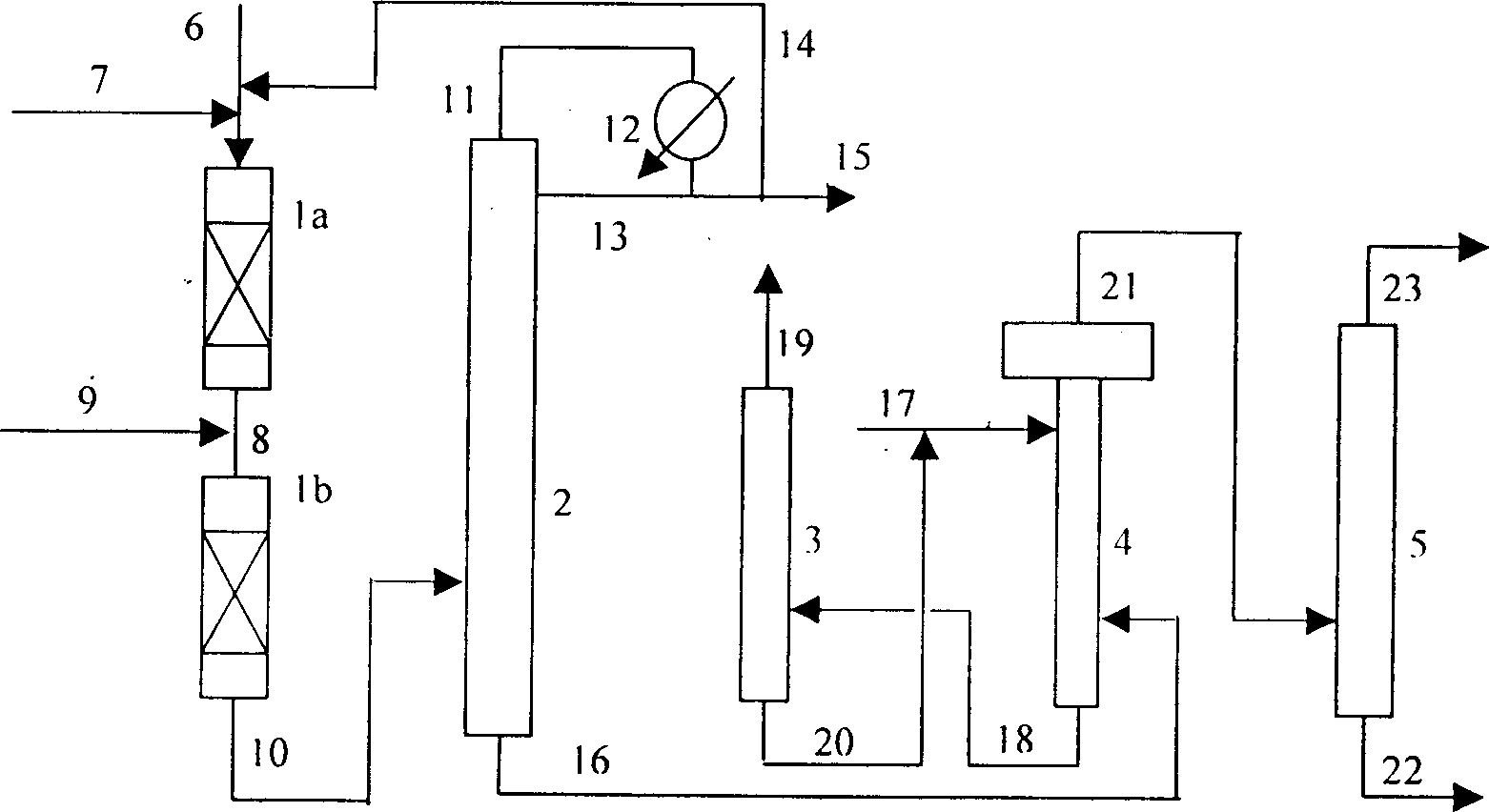

[0045] use as figure 2 Tandem fixed bed process

[0046] mix C 4 Contains 48.5% isobutene and 26.3% n-butene

[0047] Feed amount: 300g / h

[0048] The catalyst loading capacity of the first and second fixed bed polymerization reactors are respectively: 500ml and 300ml

[0049] Add appropriate amount of polymerization inhibitor (water) respectively in the feed of the two-stage reactor, the mol ratio of total inhibitor amount and the isobutylene in the fresh feed is 0.02: 1, the add-on amount of the first stage reaction is 70% of total amount .

[0050] The first-stage fixed-bed polymerization reaction temperature is 50.0°C, and the reaction pressure is 1.0Mpa

[0051] The second-stage fixed-bed polymerization reaction temperature is 70.0°C, and the reaction pressure is 1.0Mpa

[0052] Hydrogenation bed temperature: 160°C, hydrogenation pressure 1.0Mpa

[0053] 178g / h of the polymerized product was obtained, wherein the C8 content was 92.3%, the diisobutene content was 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com