Method for preparing clean fuel oil from coal tar

A technology for coal tar and fuel oil, applied in the fields of energy technology and environmental protection, can solve the problems of low yield of gasoline and diesel, serious environmental pollution, low added value, etc., and achieve the effects of reducing gum content, simplifying process and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

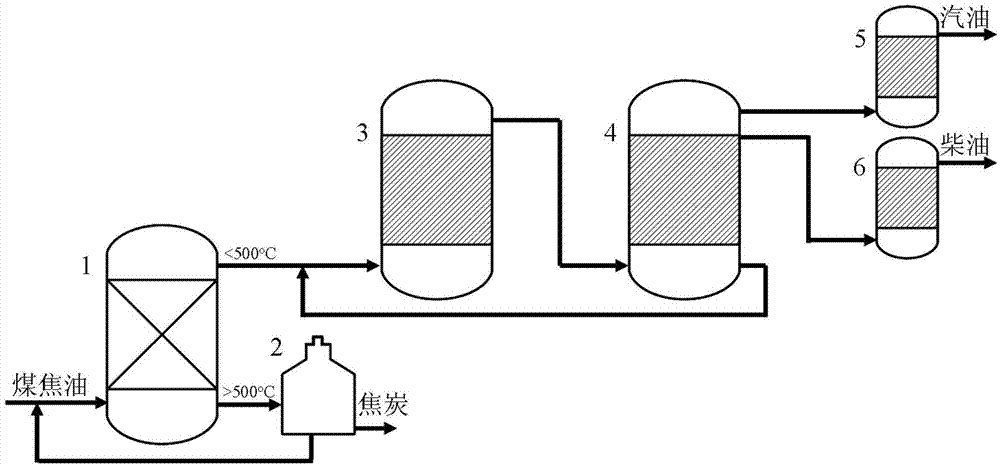

Method used

Image

Examples

Embodiment 1

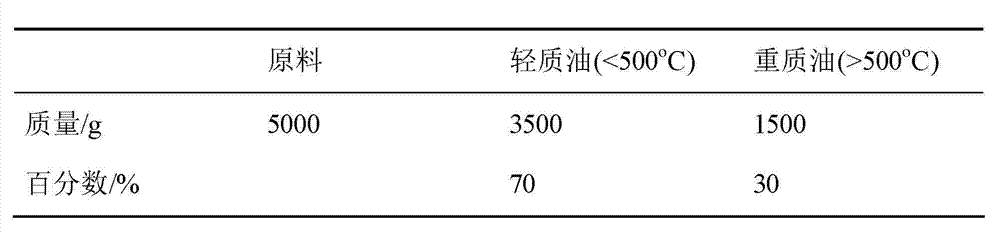

[0023] Embodiment 1: high temperature coal tar is divided into light oil (o C) and heavy oil (>500 o C). The following table 1 sees the atmospheric distillation mass balance test results

[0024]

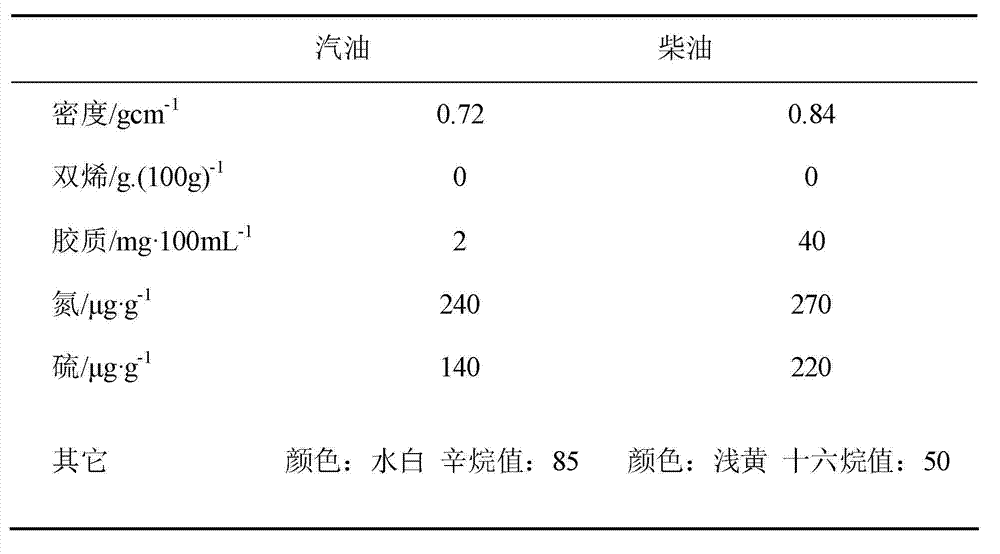

[0025] The following table 2 distillate oil properties before and after atmospheric distillation.

[0026]

Embodiment 2

[0027] Embodiment 2: heavy oil (>500 o C) Distillate oil is obtained after delayed coking. See Table 3 below for delayed coking material balance test results

[0028]

Embodiment 3

[0029] Example 3: Supported NiMo sulfide catalyst The sulfide catalyst is a high-pressure hydrotreating catalyst. The carrier adopts SiO 2 -Al 2 o 3 , the specific surface area is 200-400 m 2 / g, the pore volume is 0.5-2.0 cm 3 / g, the most probable pore size distribution is 2-4 nm and 10-15nm. The following table 4 sees reaction process conditions and product composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com