Method for separating and refining etherification material from catalytic cracking gasoline

A technology for catalytic cracking of gasoline and refining ether, which is applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process, etc. It can solve the problems of poor removal effect, achieve the effects of preventing poisoning, shortening the process flow, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

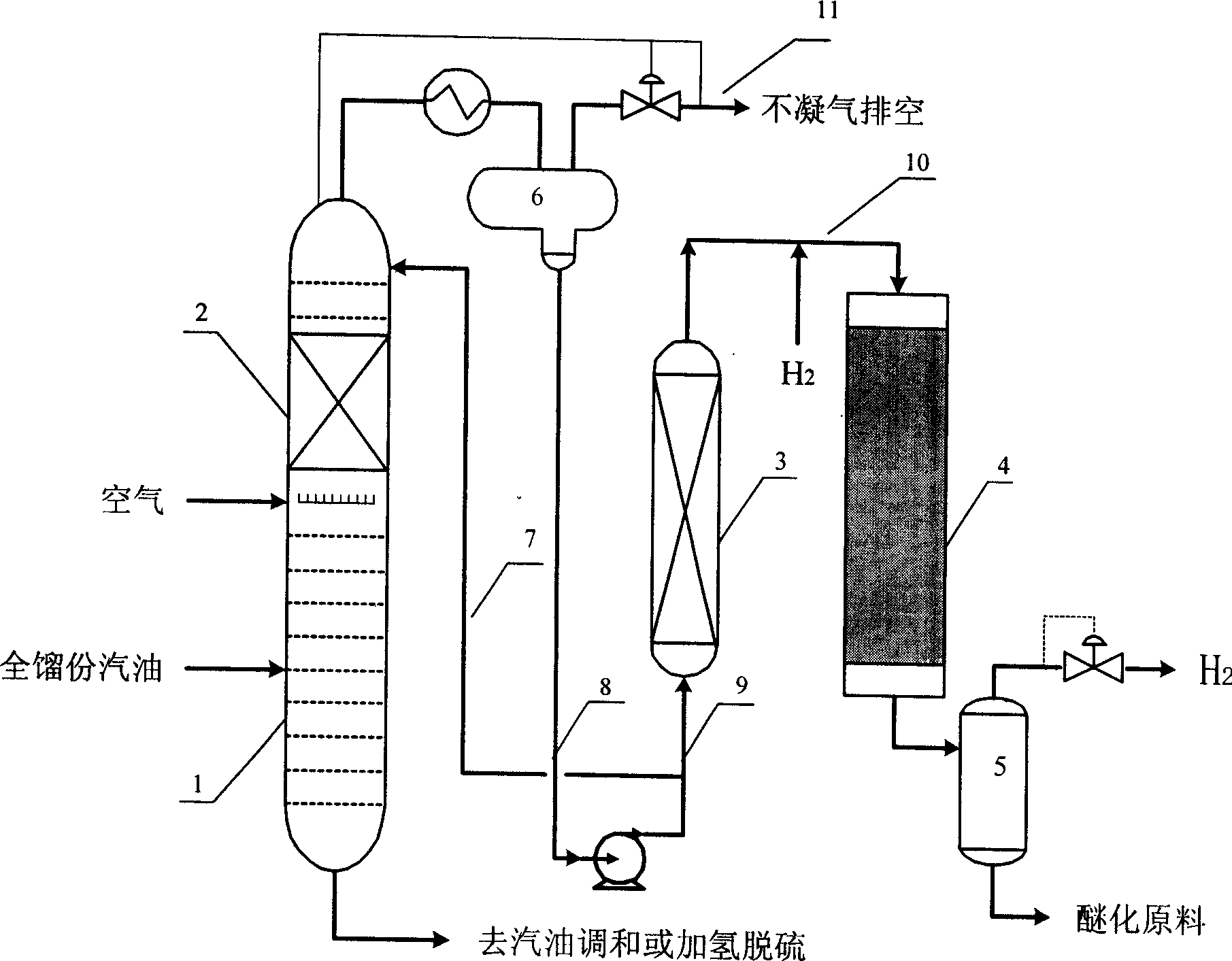

Image

Examples

preparation example Construction

[0018] The preparation method of the solid denitrification adsorbent loaded with metaphosphoric acid is to mix the porous carrier and phosphoric acid in a ratio of 2 to 5:1 by solid-liquid mass ratio, and the amount of phosphoric acid used should make the amount of metaphosphoric acid in the solid denitrification agent reach 20-5:1. 40% by weight. The porous carrier and phosphoric acid are mixed in proportion, impregnated at room temperature for 1-10 hours, and calcined at 300-500° C. for 1-6 hours.

[0019] The denitrification adsorbent can be used for repeated regeneration, and the regeneration method is a low-temperature solvent regeneration method, that is, the solution mixed with toluene and methanol in a ratio of 1:5 is used as a solvent, and the liquid-solid ratio is 3 to 10: The ratio of 1 is soaked at 10-40°C for 2-24 hours, and the operation is repeated 1-3 times, and the performance of the denitrification agent can be restored.

[0020] The active component of the ...

example 1

[0028] The effect of catalytic distillation sweetening was investigated with FCC whole fraction gasoline as raw material, and the mercaptan content in gasoline was determined by potentiometric titration. The properties of raw materials are shown in Table 1.

[0029] The experiment uses a small fractionation column filled with stainless steel triangular packing. The tower height is 600 mm, the inner diameter is 25 mm, and the volume of the tower kettle is 3 liters. The feed inlet of the distillation tower is 250 millimeters away from the tower still, and 30 grams of sweetening catalyst (commodity brand AFS-12, produced by Beijing Zhongshi University Chemical Reagent Factory) are filled at 450 millimeters away from the tower still, which contains 0.3% by weight of cobalt sulfonated phthalocyanine , the carrier is activated carbon. The lower part of the catalyst bed is equipped with an air inlet, and the upper part is filled with 100 mm stainless steel packing, and the upper and l...

example 2

[0035] This example examines the denitrification effect of solid adsorbent.

[0036] The light gasoline fraction that distilled off the overhead of the catalytic distillation tower in Example 1 was adopted to denitrify by fixed bed adsorption. Strongly acidic ion exchange resin (trade name is S54, produced by Beijing Daxing Anding Resin Factory) made of sulfonated macroporous network structure copolymer of styrene and divinylbenzene is a denitrification agent, and the loading capacity is 40 grams, when the feed weight hourly space velocity is 1.0 -1 , temperature 30°C, pressure 0.6MPa. The basic nitrogen content of the treated light gasoline was measured by perchloric acid titration method, and the total nitrogen content was measured by chemiluminescence method. The results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com