Gasoline hydrodesulfurization method

A technology for hydrodesulfurization and gasoline hydrogenation, which is applied in the field of removing sulfur impurities in gasoline and catalytically cracked gasoline, can solve the problems of reducing olefin saturation, not considering the distribution law of olefins and sulfides, and being unfavorable for further improving the desulfurization rate of products. , to achieve the effect of improving gasoline desulfurization rate and small loss of octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

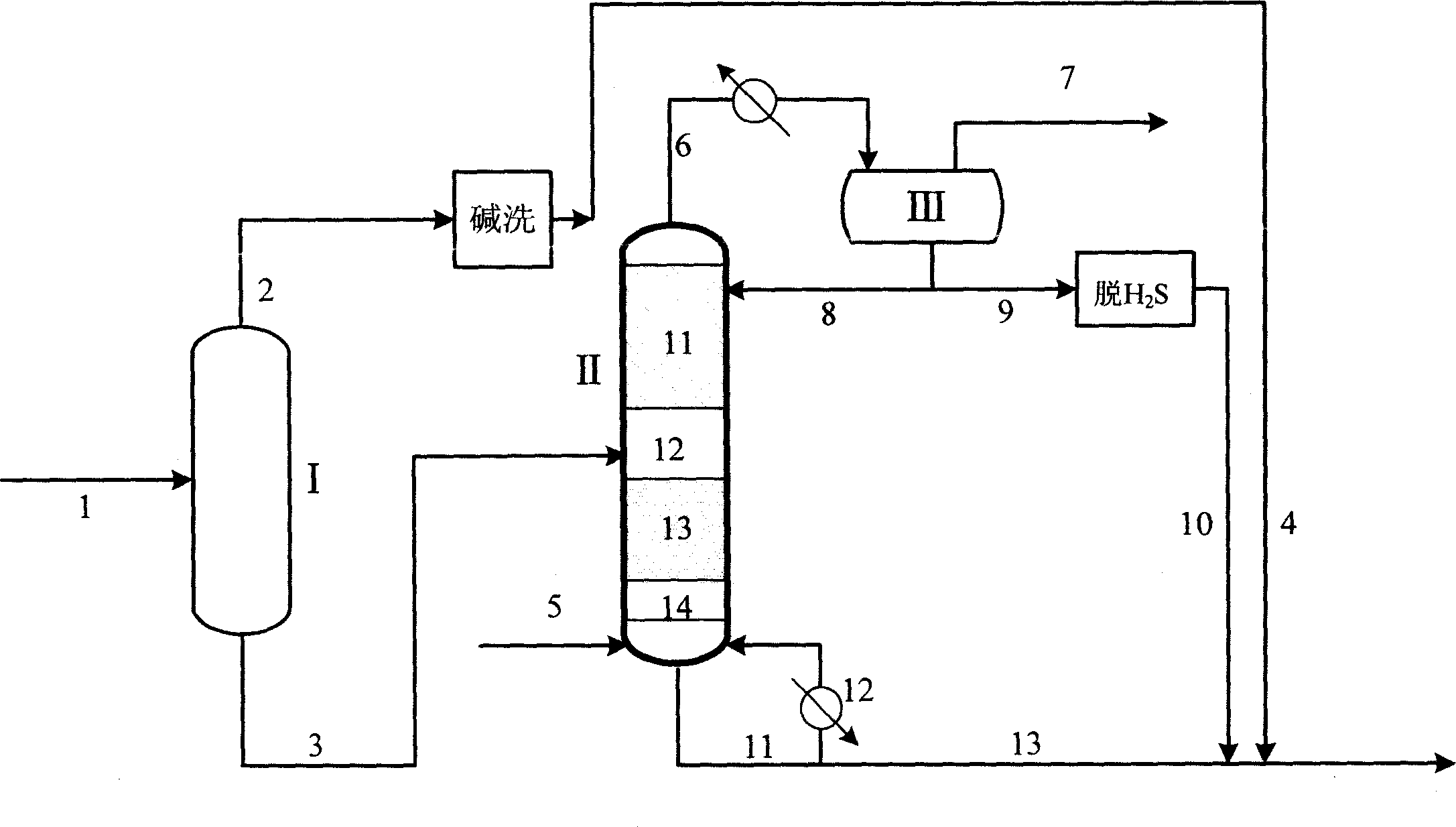

Method used

Image

Examples

Embodiment 1

[0033] The raw materials used, the processing capacity, and the reaction conditions are the same as those of the comparative example, except that a fractionation section is added to the feed port in the middle of the tower. The height of the fractionation section is 40 cm, and the fractionation section is filled with 25 grams of selective hydrogenation catalyst RGO-2 catalyst. The height of the bottom stripping section is 30cm. Both the rectification reaction zone and the stripping reaction zone are filled with RSDS-1 catalyst. The height of the rectification reaction zone is 220cm, and the height of the stripping reaction zone is 110cm. The properties of the products after desulfurization are shown in Table 3.

Embodiment 2

[0035] The raw materials used, processing capacity, reaction conditions, and catalyst loading position are the same as those in Example 1, except that the rectification reaction section is filled with RSDS-1 catalyst, and the stripping reaction section is loaded with high-activity hydrodesulfurization catalyst CH-18. The properties of the product after desulfurization are see table 2

[0036] Table 1

[0037] catalyst

CH-18

RGO-2

RSDS-1

WO 3 ,%

≮19.0

/

/

MoO 3 ,%

/

≮5.0

≮8.0

NiO,%

≮2.0

≮2.5

/

CoO,%

≮0.04

/

≮2.5

Specific surface, m 2 / g

≮130

≮170

≮250

Pore volume, ml / g

≮0.27

≮0.50

≮0.35

[0038] * The percentages in the table are percentages by weight.

[0039] Table 2

[0040] raw material

sweetened light fraction

heavy fraction

Density, g / cm3

0.7157

0.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com