Steel billet conveying system

A conveying system and steel billet technology, applied in the direction of conveyor objects, transportation and packaging, roller tables, etc., can solve problems such as unreasonable and complicated process routes, and achieve the effects of fast conveying speed, flexible process routes, and advanced automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and embodiments.

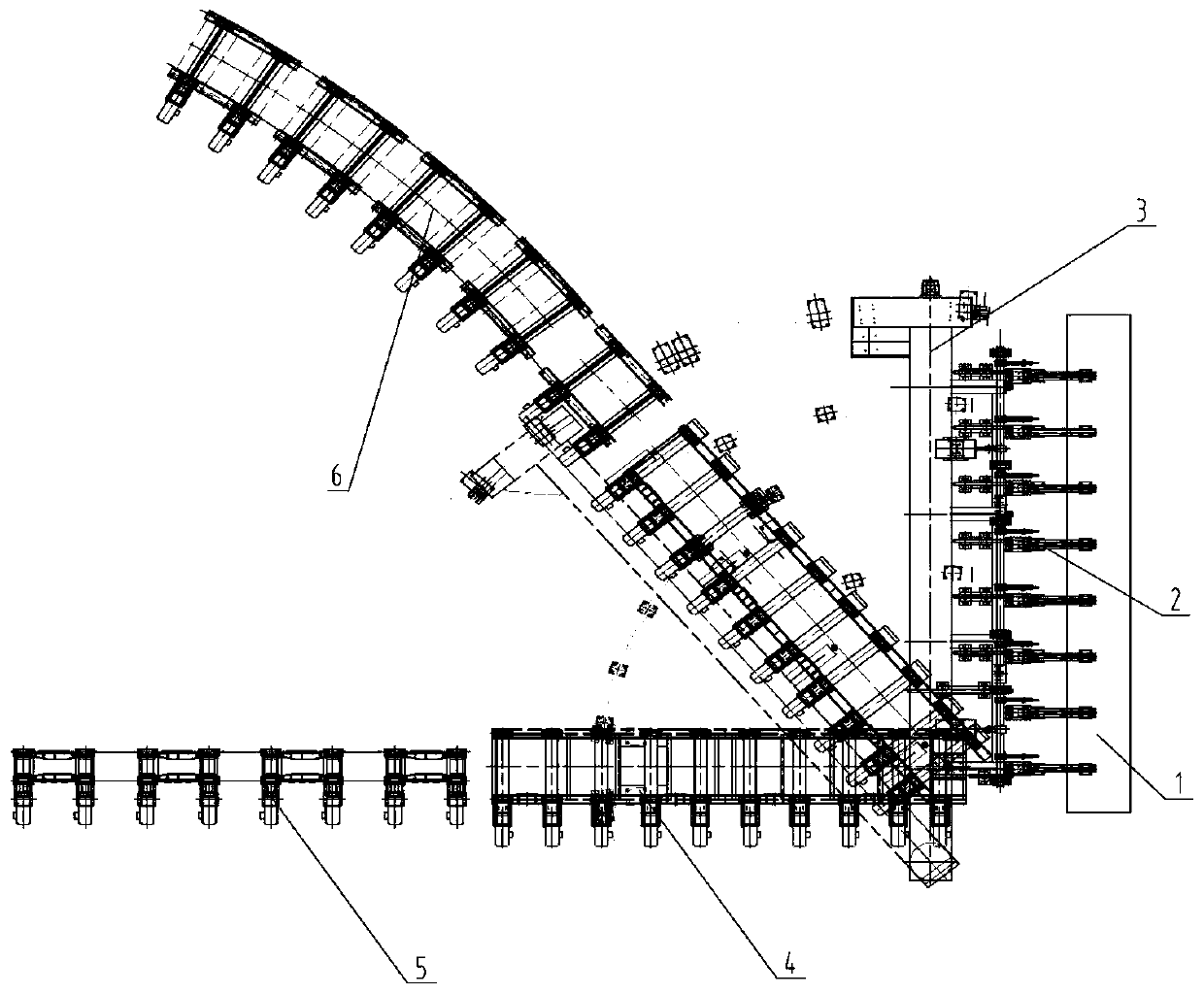

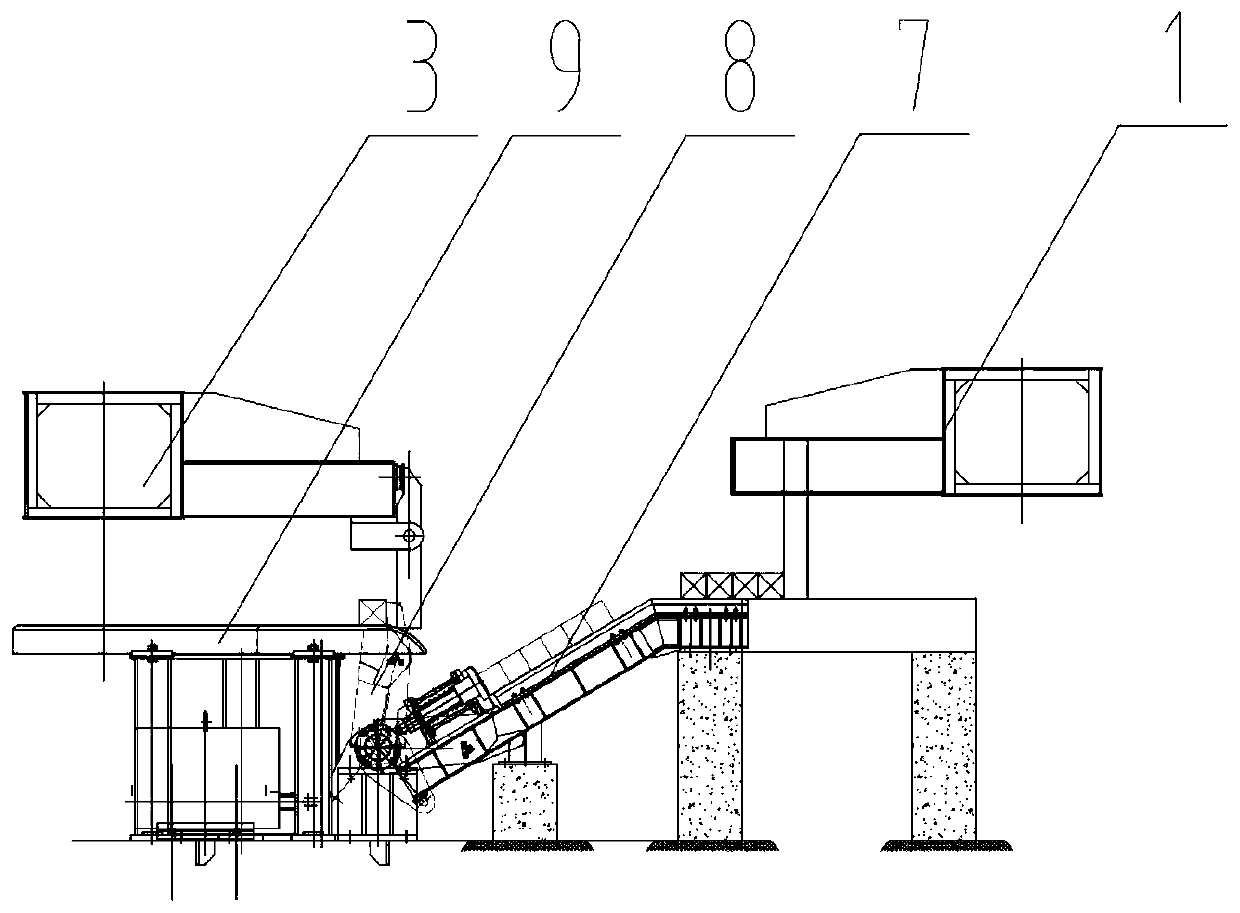

[0036] see figure 2 and 3 , a billet conveying system, the main equipment of the system is composed of a pusher 1, a steel splitter 2, a rotary steel transfer machine 3, a rotating roller table 4, a straight roller conveying roller table 5, and an arc-shaped conveying roller table 6; among them, The steel dividing machine 2 includes a steel dividing groove 7 , a steel dividing claw 8 , and a steel storage platform 9 .

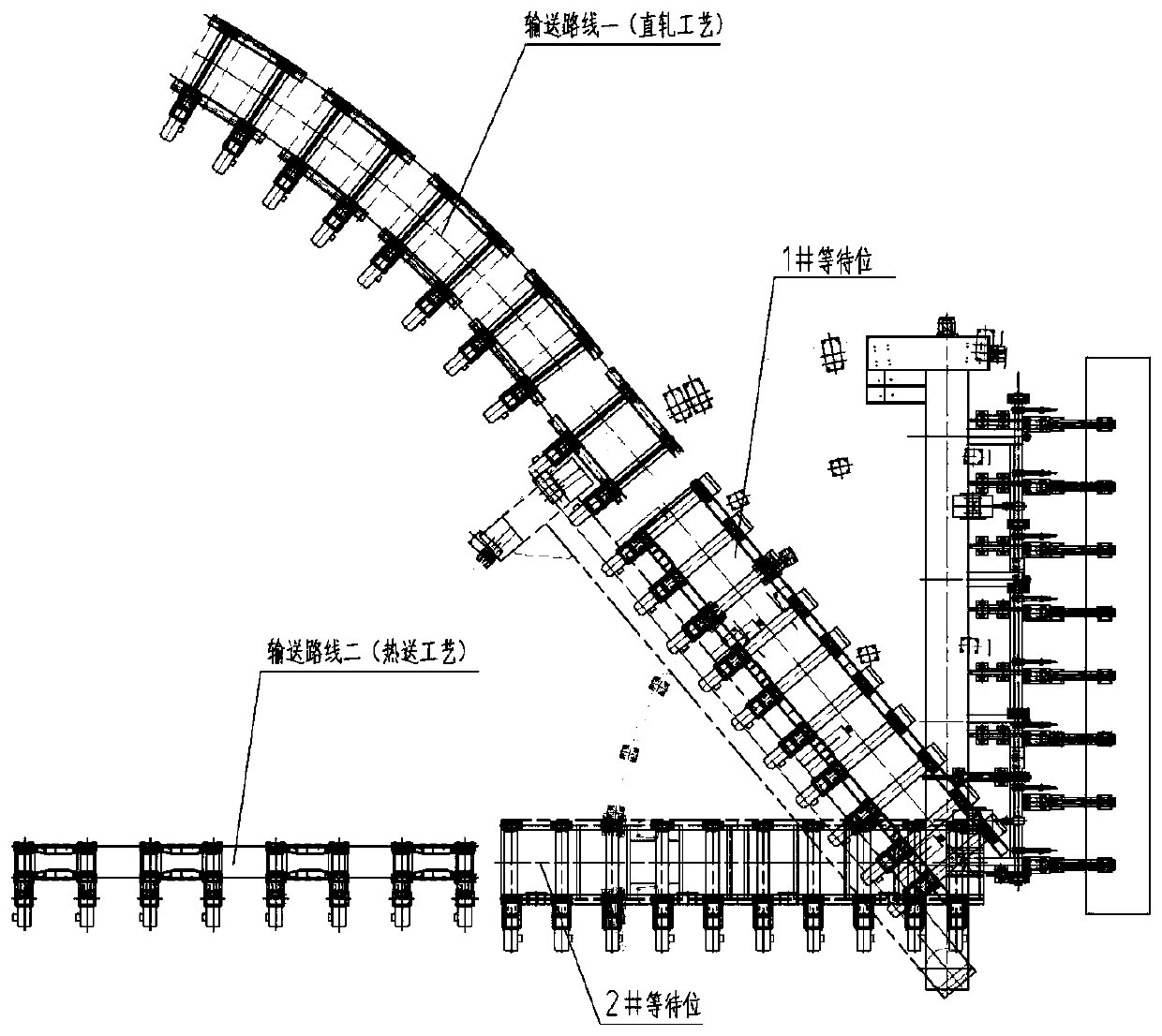

[0037] See attached figure 1 , The billet conveying system mainly sets two conveying routes, conveying routes 1 and 2 respectively correspond to the direct rolling and hot conveying processes; at the same time, the conveying system sets two billet waiting positions, 1# and 2# waiting positions correspond to the direct rolling and Hot delivery process.

[0038] Conveying route one:

[0039] If the steel rolling workshop adopts the dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com