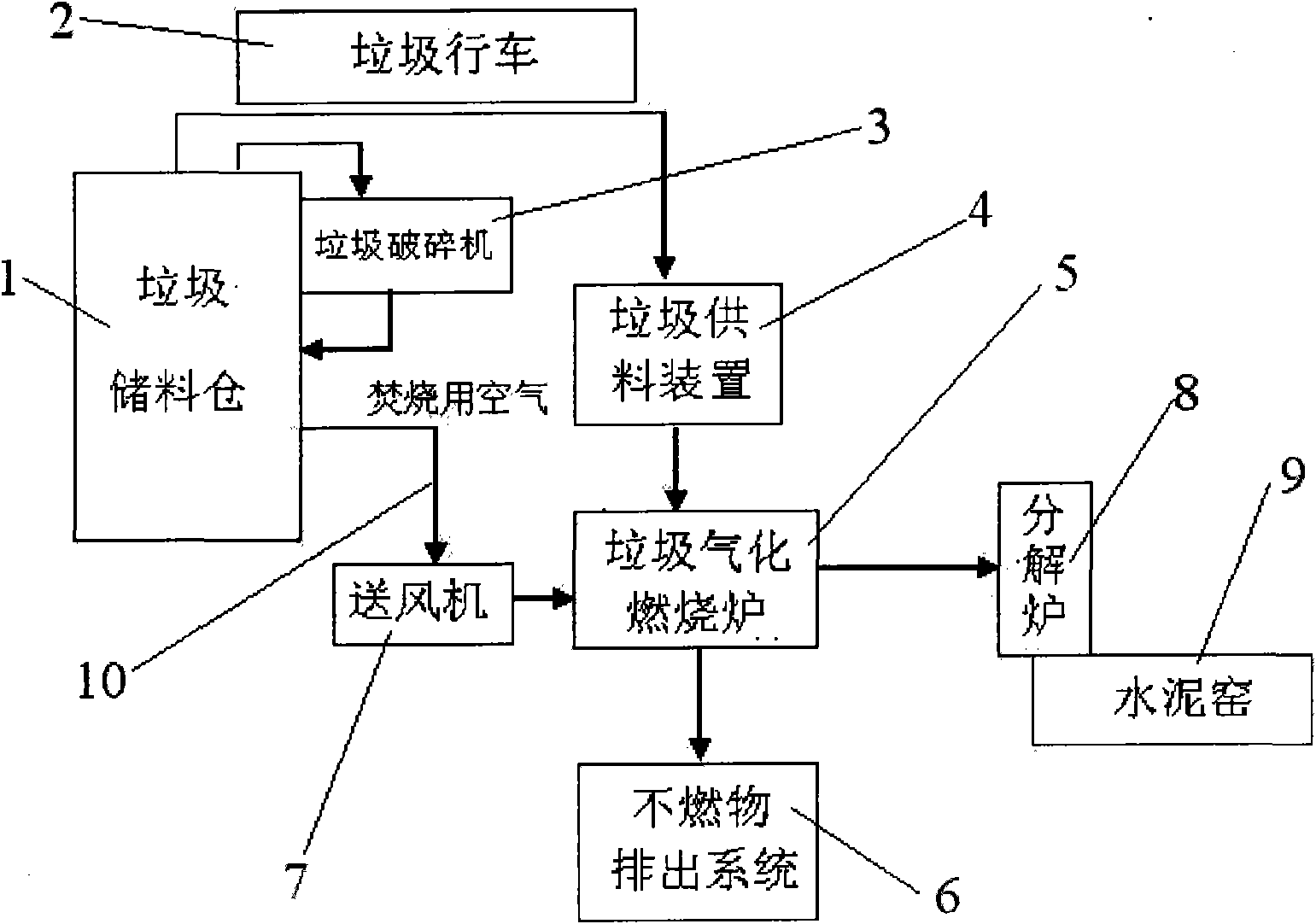

Garbage disposal system used in cement dry kiln production and disposal method thereof

A waste treatment system and dry process kiln technology, applied in cement production, clinker production, etc., can solve the problems of non-combustible parts, air odor pollution, etc., achieve good waste gas treatment performance, control acidic substance emissions, stay long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

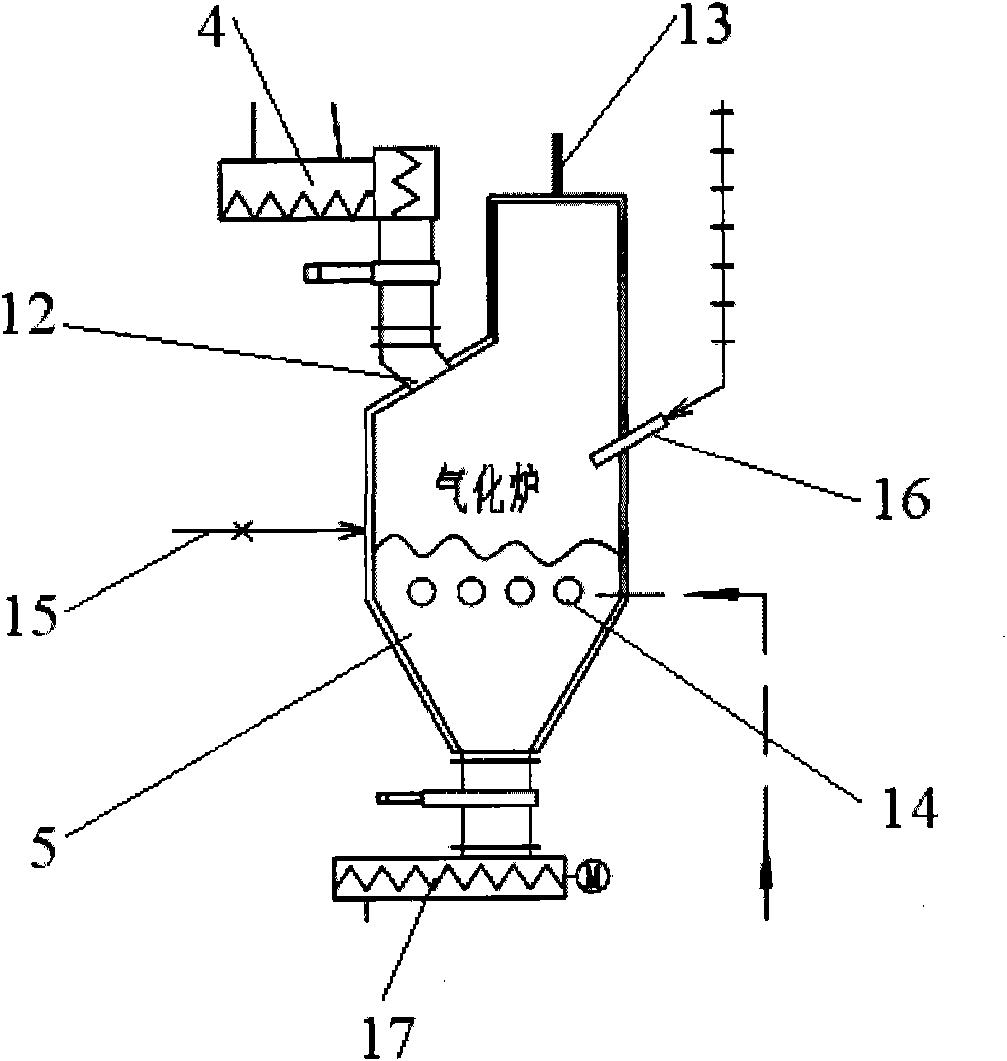

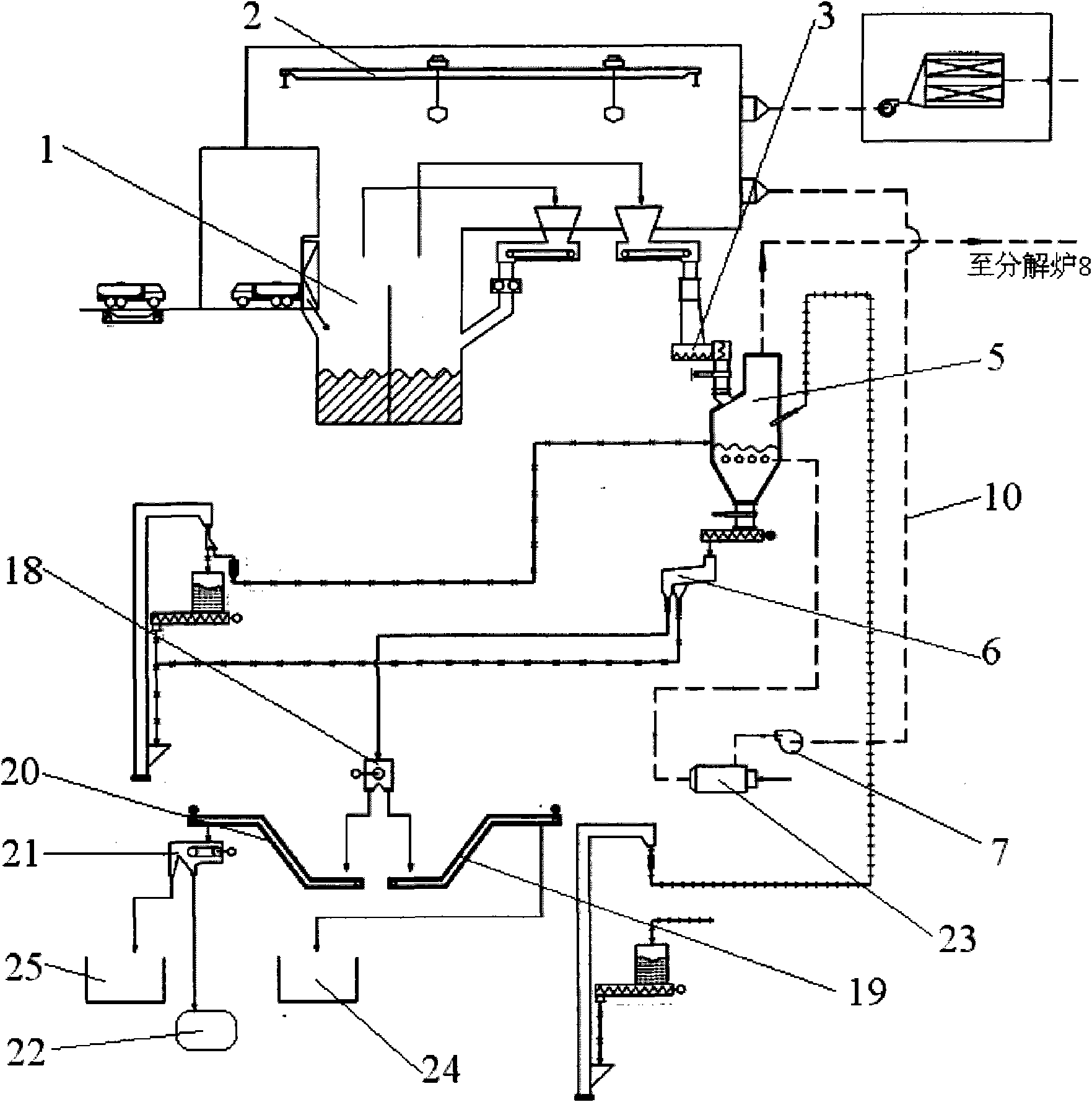

[0062] 1. A non-combustible discharge system 6 is provided at the bottom of the garbage gasification furnace 5 according to the present invention.

[0063] The non-combustible discharge system 6 communicates with the ash outlet 17 .

[0064] The purpose of this program is to achieve the most thorough reduction in volume and quantity, and all the separated components can be recycled.

[0065] The use of cement burning system to treat municipal solid waste is the only one among various waste treatment methods that does not discharge waste residue and waste gas. In the production process of the cement industry, there are only raw materials and clinker produced by the calcination process, and there is no problem of slag incineration in general incinerators; and the entire system operates under negative pressure, and there is almost no leakage of smoke and dust. question.

[0066] Solidification of heavy metal ions:

[0067] Using the rotary kiln calcination process in the cemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com