[0005] The outstanding feature of the present invention is that the

copper alloy LC68700 stretched net with anti-

fouling and anti-

corrosion functions is used in the production of combined net clothing for turbot breeding cages, which effectively solves the anti-

pollution of the existing net cage net clothing. and anti-

corrosion problems, improve the anti-

fouling and anti-

corrosion functions of cage equipment, reduce the number of times cage farmers change nets, reduce the level drift of net clothing, reduce the damage to farmed fish caused by frequent net changes, and improve the quality of net cage farmers.

economic benefits; the present invention uses high-strength

fishing polyethylene ropes, high-strength single-knot polyethylene nets, high-strength

polyamide warp-knitted nets, and high-strength

fishing net wires and other energy-saving and consumption-reducing rope net wire materials for the production of net cages. Under the premise that the mesh foot thickness of the net, the nominal

diameter of the net wire and the nominal

diameter of the rope are all greatly reduced compared with the common rope and net wire materials used in the existing net cages, it not only reduces the consumption of rope net wire materials for the net cage box, but also facilitates the net cage The exchange of internal and external water bodies; it not only solves the problem of energy saving and consumption reduction of the existing net cages, but also promotes the growth and development of fish cultured in cages, improves the

economic benefits of cage farmers, and promotes energy saving and consumption reduction in

fishery production; A square galvanized iron pipe frame with a perimeter of 20.0m is hung under the bottom of the turbot culture cage to ensure that the cage has a volume

retention rate. The test shows that this method is better than that of the net without a galvanized iron pipe frame at the bottom of the cage. The cage greatly improves the cage volume

retention rate of the cage and the number of fish that can be cultured in the cage, improves the

cage culture space, and improves the equipment level of the cage facilities; the invention adopts hot-dip galvanized iron pipes to effectively prevent cold-dip galvanized iron pipes in

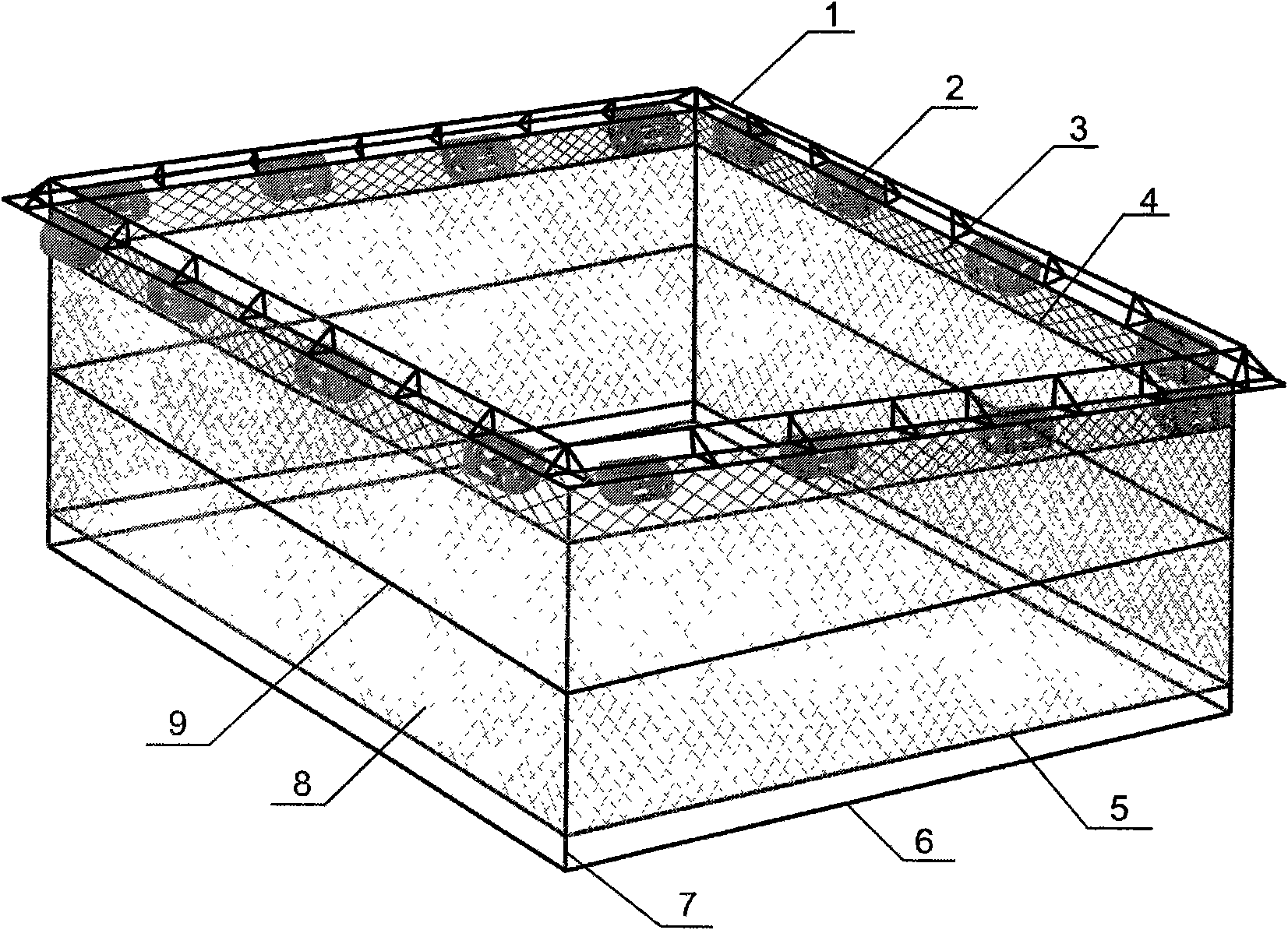

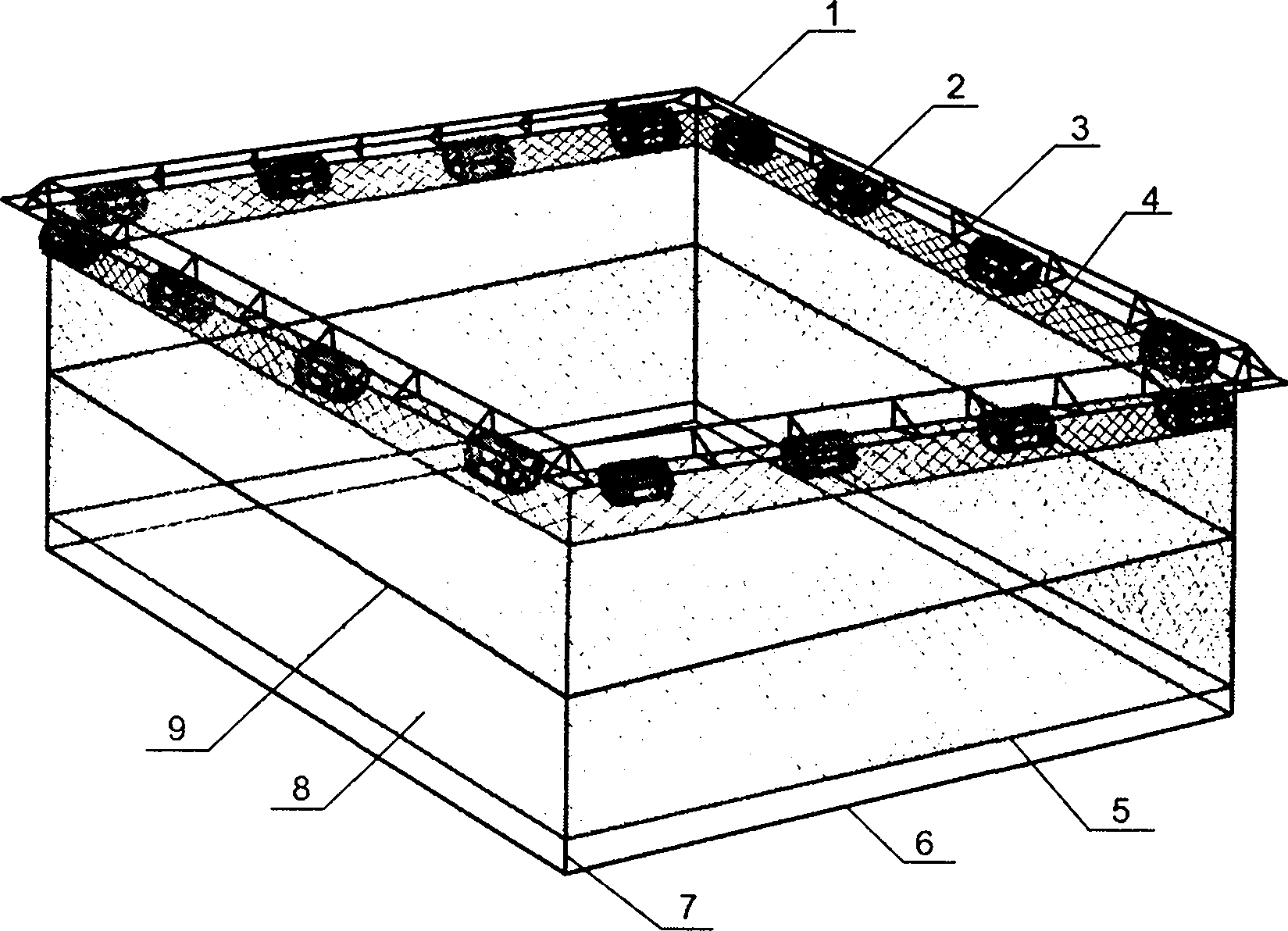

seawater corrosion problem; the netting

system of the present invention adopts the form of combined netting, which effectively avoids the direct wear between the metal netting and the rigid floating frame system when the prior art adopts a single metal netting form, and improves the equipment level of the cage facilities ; The present invention outsources 1-2

layers of waterproof cloth and 1 layer of net clothing on the cylindrical

plastic foam float, which greatly improves the service life and safety of use of the cylindrical plastic foam float of the net cage

buoyancy system; the present invention uses a square galvanized iron pipe frame with A certain distance is hung on the bottom of the net cage with synthetic

fiber ropes, which effectively prevents direct wear and direct contact corrosion between the second net and the hot-dip galvanized iron pipe, and improves the life of the galvanized iron pipe frame and the facilities and equipment of the net cage. level; according to the characteristics that turbot is a non-swimming fish, the present invention selects the high box netting height of 2.8m for use, which saves the manufacturing cost of turbot breeding net cage; The side length of the box, and the width of the

copper alloy LC68700 stretched net is 1.0m and the length can be more than 5.0m. In the second combined netting, the

copper alloy LC68700 stretched net is installed horizontally instead of other net cages The medium

copper alloy LC68700 tensile net adopts vertical installation, which greatly reduces the semi-soft connecting material required for the entire cage body compared with the longitudinal installation of the copper alloy LC68700 tensile net in the cage, and effectively realizes energy saving and reduction in

fishery production. consumption; the present invention uses copper alloy LC68700 stretching nets to be used for long-term cultivation and production in net cages, and its waste copper alloy LC68700 stretching nets can be recycled at a high price, while the synthetic

fiber nets used in existing net cages can be used in 1 to 2 years. After

aquaculture production, the waste nets are generally discarded by farmers or breeding units; in addition, this solution can increase the overall number of fish cultured, reduce fish diseases, increase fish

survival rate, and reduce daily net replacement costs compared with traditional cages of the same size Compared with traditional net cages, it has a cost-effective

advantage; in the present invention, the soft connection of nets, the nets at the bottom of the net cage, and the ropes used for assembling the nets are all treated with anti-

algae agent for fishing nets, which greatly improves the quality of the nets. The comprehensive antifouling function of the body net clothing system; the present invention uses the ropes after heat-setting treatment for both the

horizontal and vertical forces, which effectively avoids the deformation of the cage system when the existing cages use ropes that have not been heat-set.

impact, greatly improving the strength, service life and volume retention of the net cage; the present invention uses opposite twisted ropes for the lower horizontal line of the second net and the edge line of the net at the bottom of the net to reduce the Kink effect of adjacent cables with the same lay direction in use

Login to View More

Login to View More