Energy-saving system of cooling air hose of glass annealing kiln and cooling method of glass tape

A cooling air duct and energy-saving system technology, applied in the field of annealing kiln, can solve the problems of affecting the stability of annealing temperature, increasing power consumption, low control precision and regulating valves, so as to improve energy utilization rate, reduce the difficulty of control, and avoid mutual interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

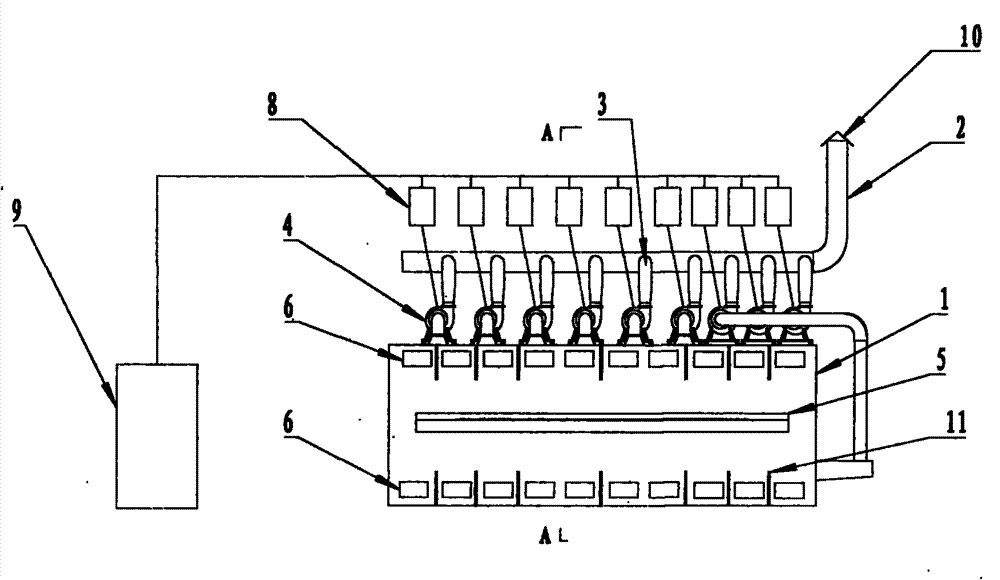

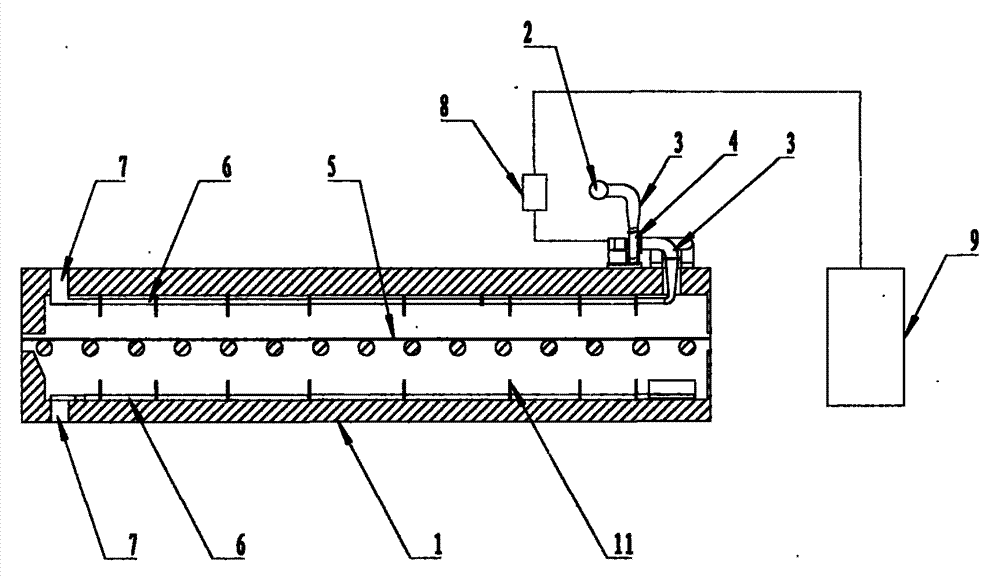

[0021] A main air duct 2 is arranged outside the annealing kiln 1, an air outlet 10 is arranged at one end of the main air duct 2, and at least two branch air ducts 3 outside the kiln are arranged on one side of the main air duct 2; a glass belt 5 is arranged in the middle of the annealing kiln 1, Multiple sets of thermocouples 11 are arranged on the top and bottom of the annealing kiln 1 corresponding to the glass ribbon 5, each group is at least two, and multiple sets of branch air pipes 6 in the kiln are arranged between multiple sets of thermocouples 11 corresponding to the glass ribbon 5, and each group is at least The kiln branch air pipe 6 in the annealing kiln 1 is set corresponding to the kiln external branch air pipe 3 outside the annealing kiln 1, and the upper and lower walls of the annealing kiln 1 are provided with an air inlet 7 corresponding to the kiln internal branch air pipe 6 An industrial computer 9 is set on one side of the annealing kiln 1; a blower fan 4...

Embodiment 2

[0023] The thermocouples 11 above and below the annealing kiln 1 measure the temperature above and below the running glass ribbon 5, and transmit the temperature data to the industrial computer 9, which controls the branch air duct 3 outside the kiln through the frequency converter 8 The speed of the upper fan 4 draws the cold gas from the air inlet 7 of the annealing kiln 1 into the branch air pipe 6 in the kiln, and the cold gas in the kiln branch air pipe 6 exchanges heat with the hot gas in the annealing kiln 1 indirectly, and the heat exchange recedes The cold air in the furnace 1 cools the glass ribbon 5 evenly, and the cold air in the branch air pipe 6 inside the kiln is heated and then enters the branch air pipe 3 outside the kiln and the main air pipe 2, and from the air outlet 10 of the main air pipe 2 Exhaust outside.

Embodiment 3

[0025] After the industrial computer 9 receives the temperature data transmitted by the thermocouple 11, the industrial computer 9 controls the frequency converter 8 according to the set temperature parameters to adjust the speed of the fan 4 on the branch air duct 3 outside the kiln, and increase or decrease the temperature in the kiln in different areas. The air intake of the branch air duct 6 keeps the temperature of the space above or below the glass ribbon 5 at 610°C-380°C, so that the glass ribbon 5 is evenly cooled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com