Method for synthesis of terpineol by supersonic wave assistance

A technology of ultrasonic wave and terpineol, applied in the field of ultrasonic-assisted synthesis of terpineol, can solve the problems of low yield of terpineol, poor purity and aroma, short production cycle, etc., and achieves enhanced neutralization and washing efficiency, stable aroma, The effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

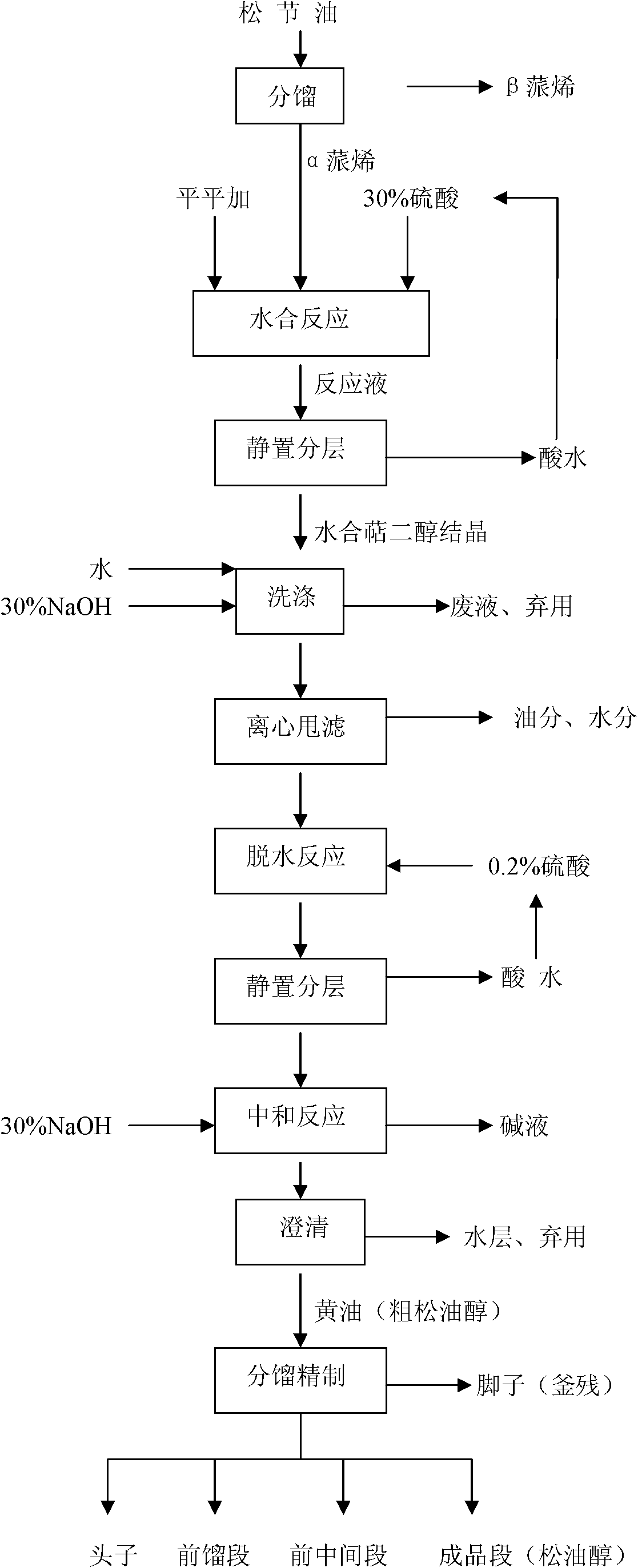

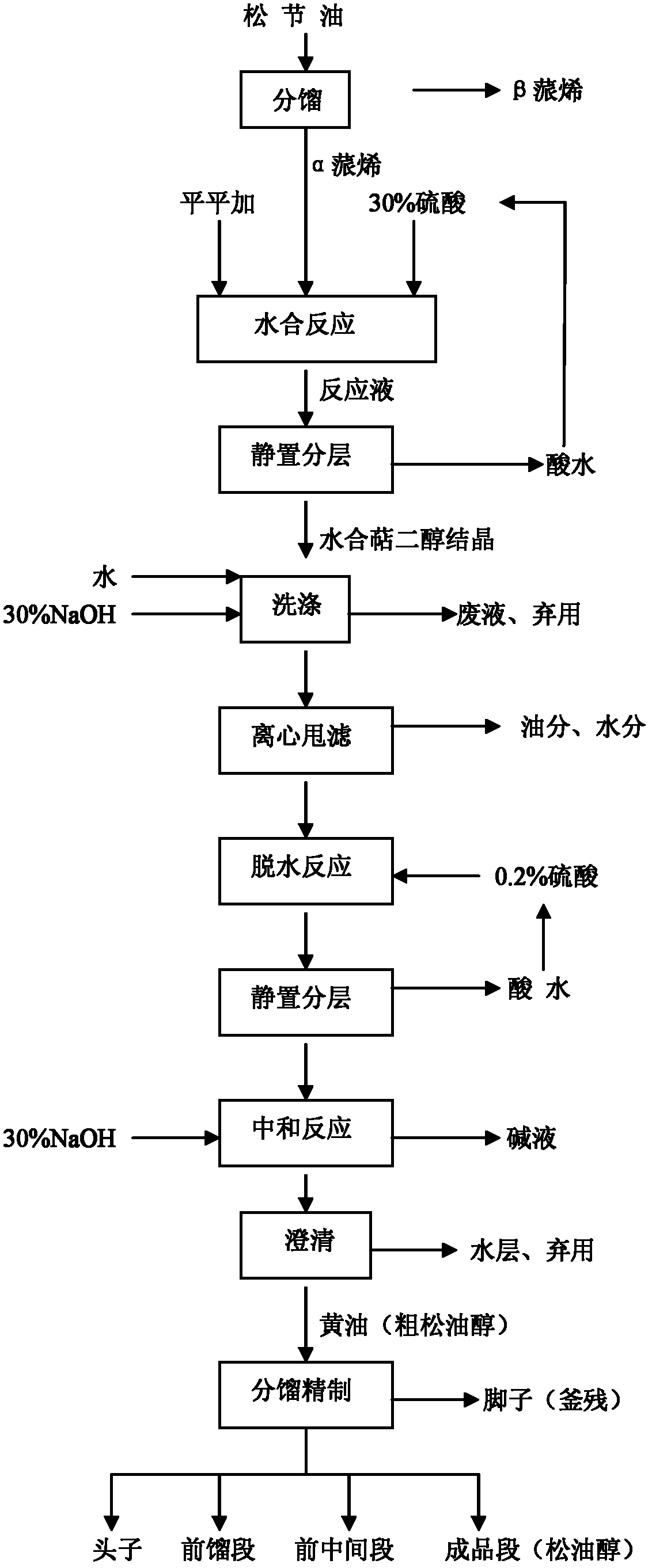

[0017] The specific embodiment of the present invention is further illustrated by the following steps:

[0018] 1. Fractionation of turpentine oil, 95% of α-pinene and β-pinene can be obtained after turpentine oil fractionation.

[0019] 2. Hydration

[0020] (1) The feeding ratio (weight ratio) is pinene: 30% sulfuric acid = 1:1.7.

[0021] (2) In the 5M equipped with stirring device 3 In the enamel reaction pot, first add 30% sulfuric acid, then add turpentine and emulsifier Pingping plus Pergal, the amount added is 1000kg turpentine plus 400ml 10% Pingping. After the addition is complete, stir vigorously to make the reactant completely become an emulsion. During the reaction, pass through cold brine to keep the temperature at 28-30°C for 24 hours. A large amount of hydrated terpene diol crystals are precipitated,

[0022] (3) Static stratification. The hydrated terpene diol crystals float on the acid water, and the lower layer of acid water is removed and reused.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com