Low-noise asphalt pavement mixture and pavement construction quality control method

A technology of asphalt mixture and low-noise asphalt, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of noise pollution, asphalt mixture road noise, etc., and achieve the effect of low road noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0054] Implementation Case 1: Prepare porous asphalt mixture with mineral mixture, asphalt and fiber. Select three gradations (fine, medium and coarse), the asphalt content is 6.0%, and the fiber filling amount is 0.4%, to make Marshall test pieces (50 times on both sides). Synthetic gradation 1: 39% for basalt 10-15; 47% for basalt 5-10; 8% for stone chips; 3% for limestone machine-made sand; 3% for mineral powder. Synthetic gradation 2: 43% for basalt 10-15; 47% for basalt 5-10; 4% for stone chips; 3% for limestone machine-made sand; 3% for mineral powder. Synthetic gradation 3: 47% for basalt 10-15; 47% for basalt 5-10; 0% for stone chips; 3% for limestone machine-made sand; 3% for mineral powder. The asphalt mixture was prepared with the above three gradations, and the porous asphalt mixture was designed by the Marshall design method. The volume parameters of each group of Marshall specimens are shown in Table 1.

[0055] Table 1 Relevant parameters of each group of Mars...

Embodiment example 2

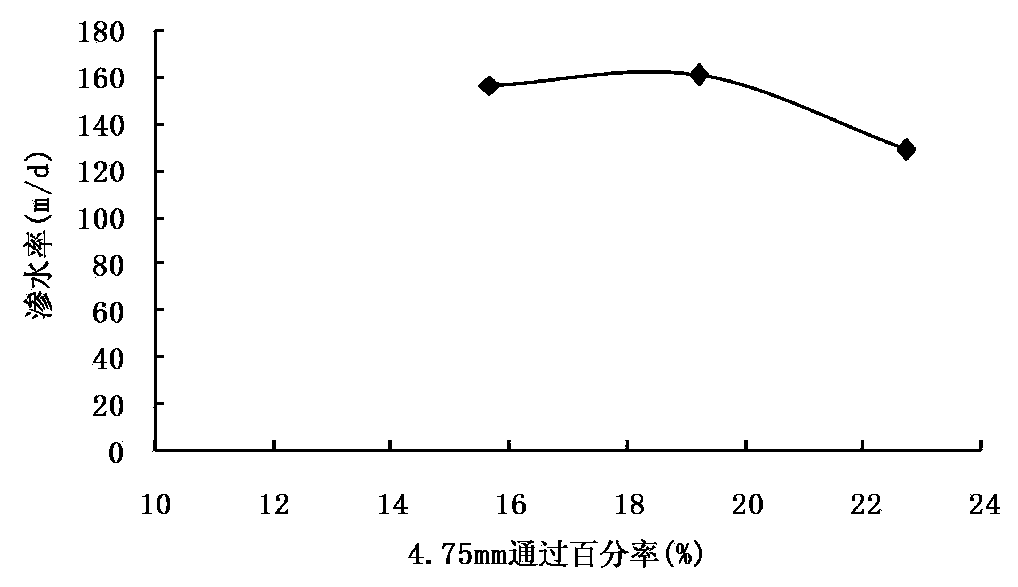

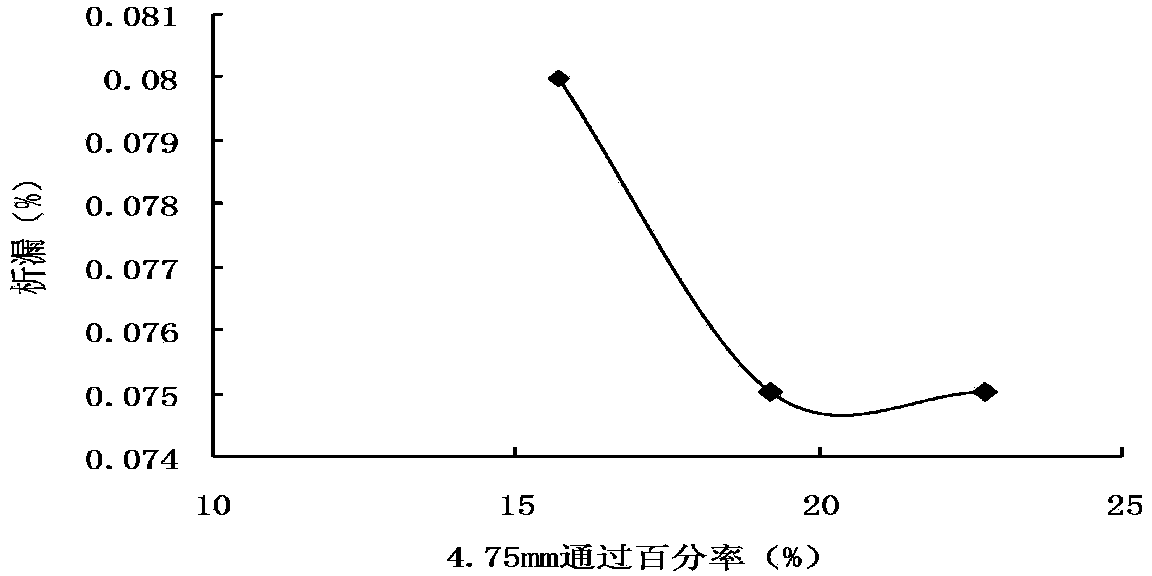

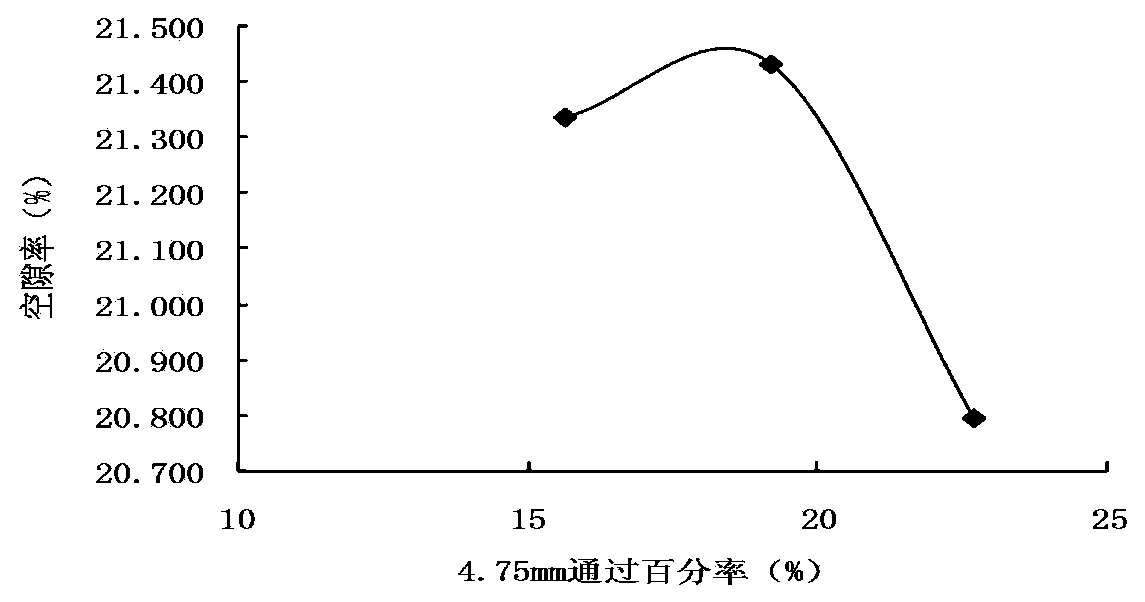

[0058] Implementation case 2: in the implementation case 1, the synthetic gradation 2 is the best gradation, the asphalt content is 6.0%, 6.3%, 6.6%, and the fiber content is 0.4% to make a Marshall specimen (both sides are hit on each side) 50 times), the measured indicators are shown in Table 2, Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 .

[0059] Table 2 Test index of Marshall specimen

[0060]

[0061] The target mix ratio design porosity is about 18%, the asphalt content is 6.2%, and other indicators (leakage analysis, scattering loss and water seepage rate, etc.) all meet the requirements, and the density is the largest.

Embodiment example 3

[0062] Implementation Case 3: The porous asphalt mixture was designed based on the asphalt mixture material composition in Cases 1 and 2, in which the asphalt content was 6.2%, and the fiber content was 0.4%. The rutting test and the freeze-thaw splitting test were carried out. The results are shown in Table 3 . The test road was paved with this porous asphalt mixture, and the samples of the mixing building were analyzed. The leakage test is shown in Table 4, and the field void ratio and scattering results are shown in Table 5 (the maximum theoretical density is 2.546).

[0063] Table 3 Results of rutting and freeze-thaw splitting tests

[0064] indicators

[0065] Table 4 Results of leak test

[0066] sample

[0067] Table 5 The results of the Kentaburg scatter test

[0068] Specimen

[0069] It can be seen from the above that under the premise of limiting the void ratio to 20%, the optimal asphalt content of the newly improved ore grading ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com