Method for detecting content of river sand and fly ash in concrete mixture

A detection method and technology for concrete, which are applied in the preparation of test samples, weighing by removing certain components, and material analysis by observing the influence of chemical indicators, which can solve the problems of inability to analyze the content of fly ash. , to achieve the effect of accurate and reliable detection results, simple detection methods and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

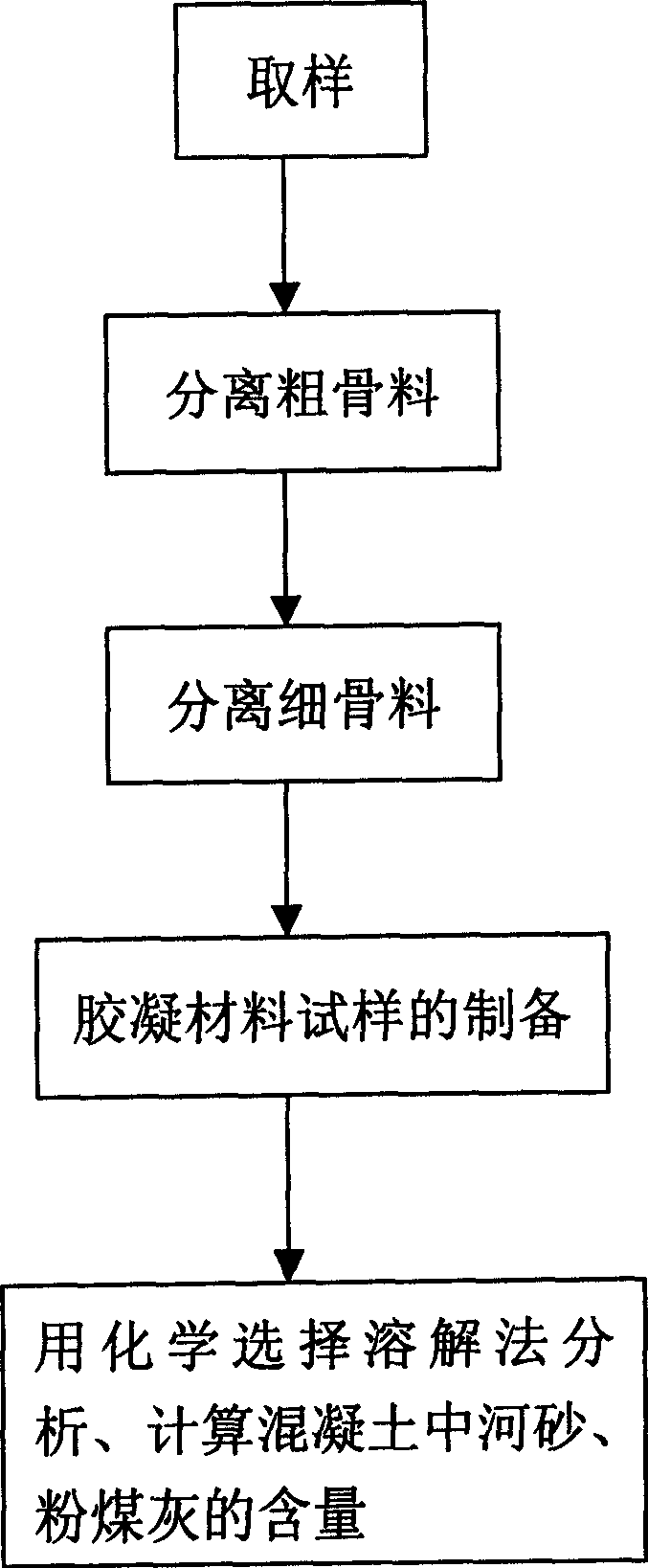

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: preparation river sand content is 10%, fly ash content is the standard concrete sample of 3%, then detects according to the inventive method, and its detection step is:

[0042] (1), sampling, obtain 11.75kg of concrete mixture samples from the above-mentioned prepared standard concrete samples, and simultaneously extract cement, river sand and fly ash samples in the concrete raw materials, and use sample bags for cement and fly ash samples respectively seal;

[0043] (2), separate the coarse aggregate, move the sample of the concrete mixture taken to a 4.75mm standard square hole sieve to fully wash and sieve, and collect the sieved mortar and water mixture with a container for use, and the coarse aggregate on the sieve Aggregate discard;

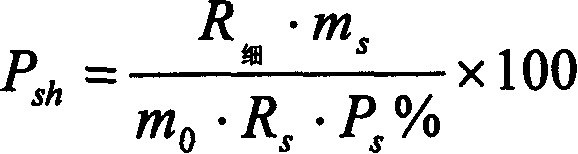

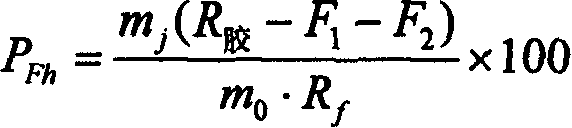

[0044] (3), separate the fine aggregate, move the above-mentioned collected mortar and water mixture to a 0.15mm standard square hole sieve for full washing and sieving, and collect the sieved cementitious material an...

Embodiment 2

[0075] Embodiment 2: preparation river sand content is 13.25%, fly ash content is the standard concrete sample of 1.67%, then detects according to the inventive method, and its detection step is:

[0076] (1), sampling, obtain 11.80kg of concrete mixture sample from above-mentioned prepared standard concrete sample, extract cement, river sand and fly ash sample in concrete raw material simultaneously, cement and fly ash sample use sample bag respectively seal;

[0077] (2), separate the coarse aggregate, move the sample of the concrete mixture taken to a 4.75mm standard square hole sieve to fully wash and sieve, and collect the sieved mortar and water mixture with a container for use, and the coarse aggregate on the sieve Aggregate discard;

[0078] (3), separate the fine aggregate, move the above-mentioned collected mortar and water mixture to a 0.15mm standard square hole sieve for full washing and sieving, and collect the sieved cementitious material and water mixture with...

Embodiment 3

[0109] Embodiment 3: preparation river sand content is 19.67%, fly ash content is the standard concrete sample of 1%, then detects according to the inventive method, and its detection step is:

[0110] (1), sampling, obtain 11.70kg of concrete mixture samples from the above-mentioned prepared standard concrete samples, and simultaneously extract cement, river sand and fly ash samples from the concrete raw materials, and use sample bags for cement and fly ash samples respectively seal;

[0111] (2), separate the coarse aggregate, move the sample of the concrete mixture taken to a 4.75mm standard square hole sieve to fully wash and sieve, and collect the sieved mortar and water mixture with a container for use, and the coarse aggregate on the sieve Aggregate discard;

[0112] (3), separate the fine aggregate, move the above-mentioned collected mortar and water mixture to a 0.15mm standard square hole sieve for full washing and sieving, and collect the sieved cementitious materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com