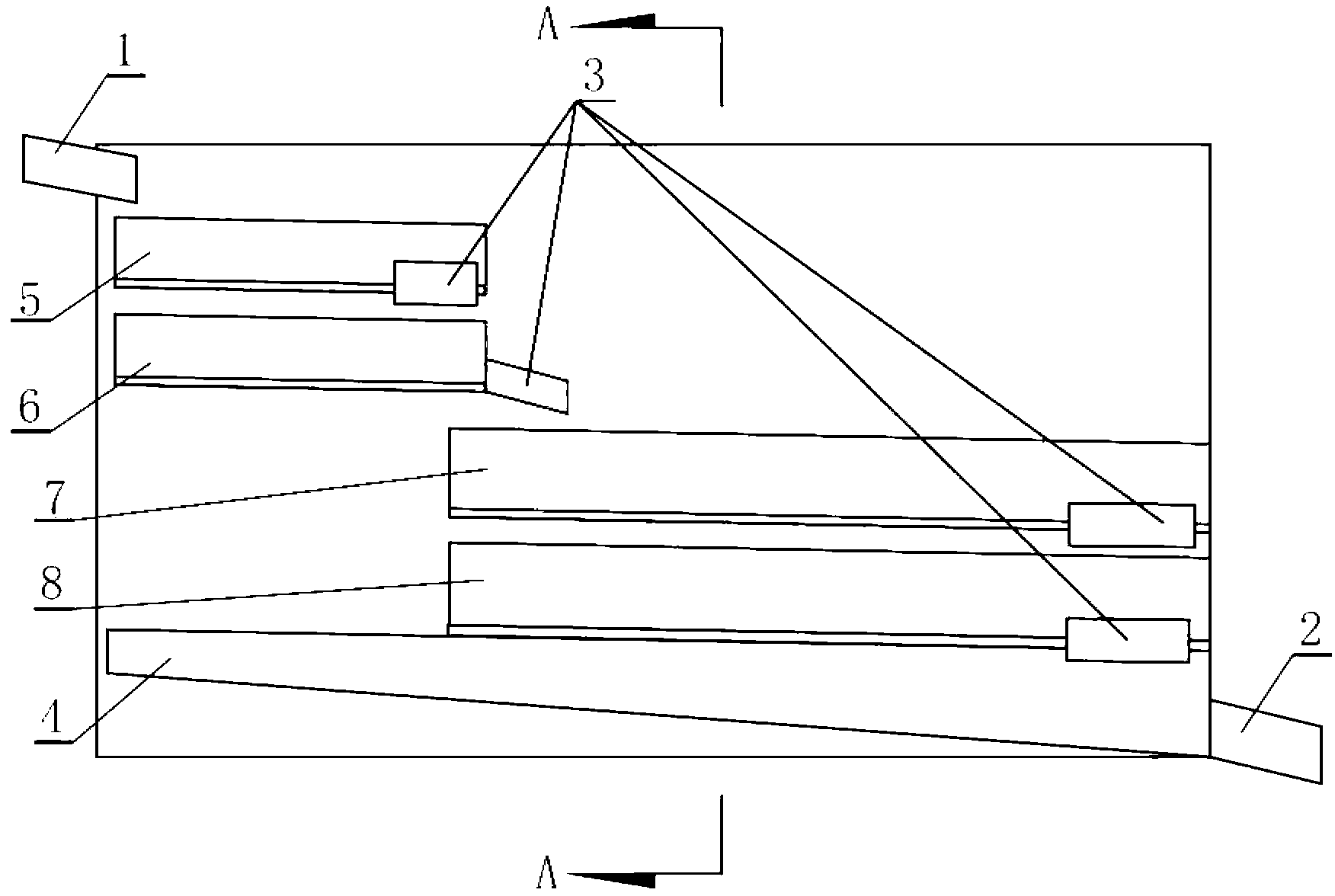

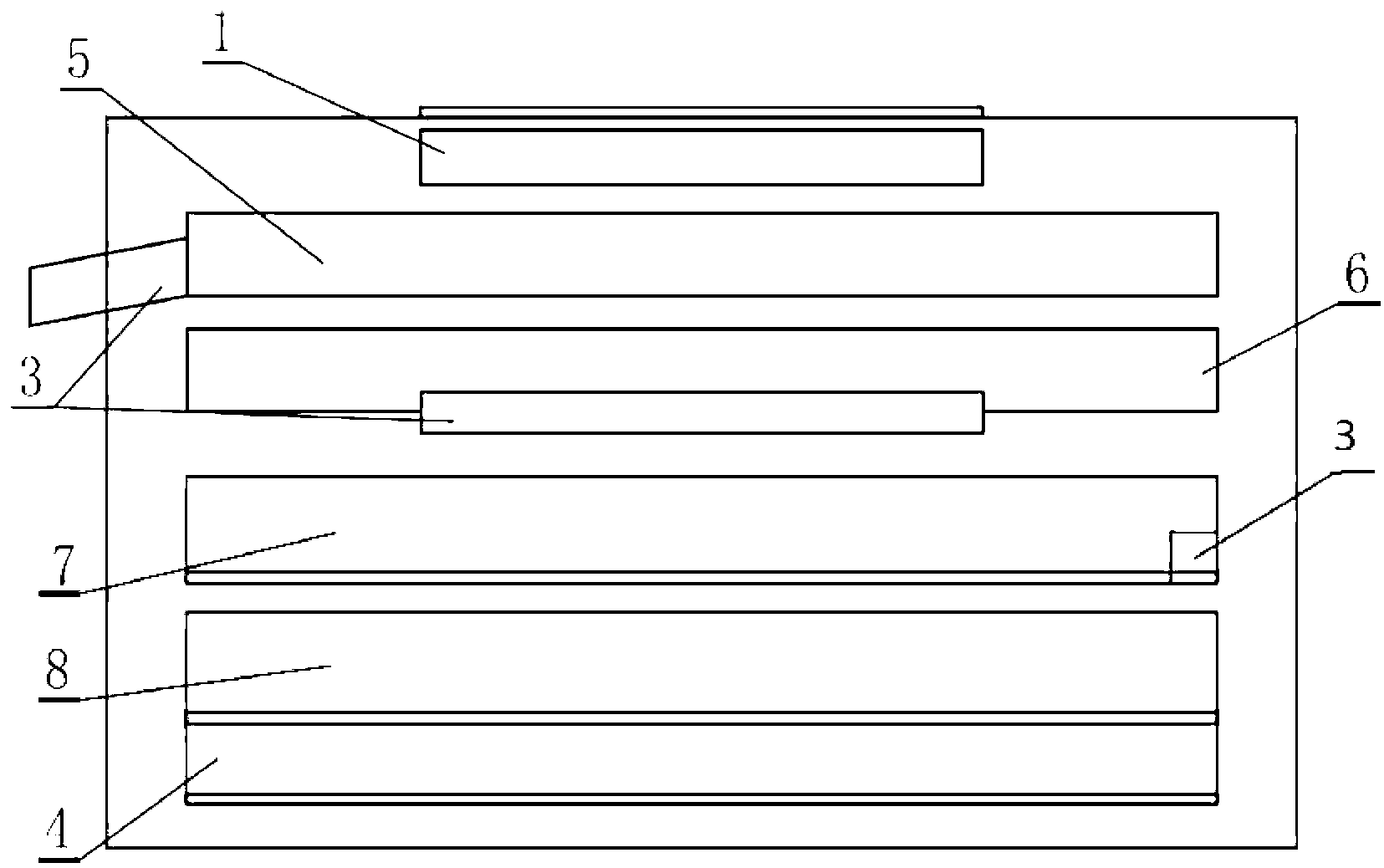

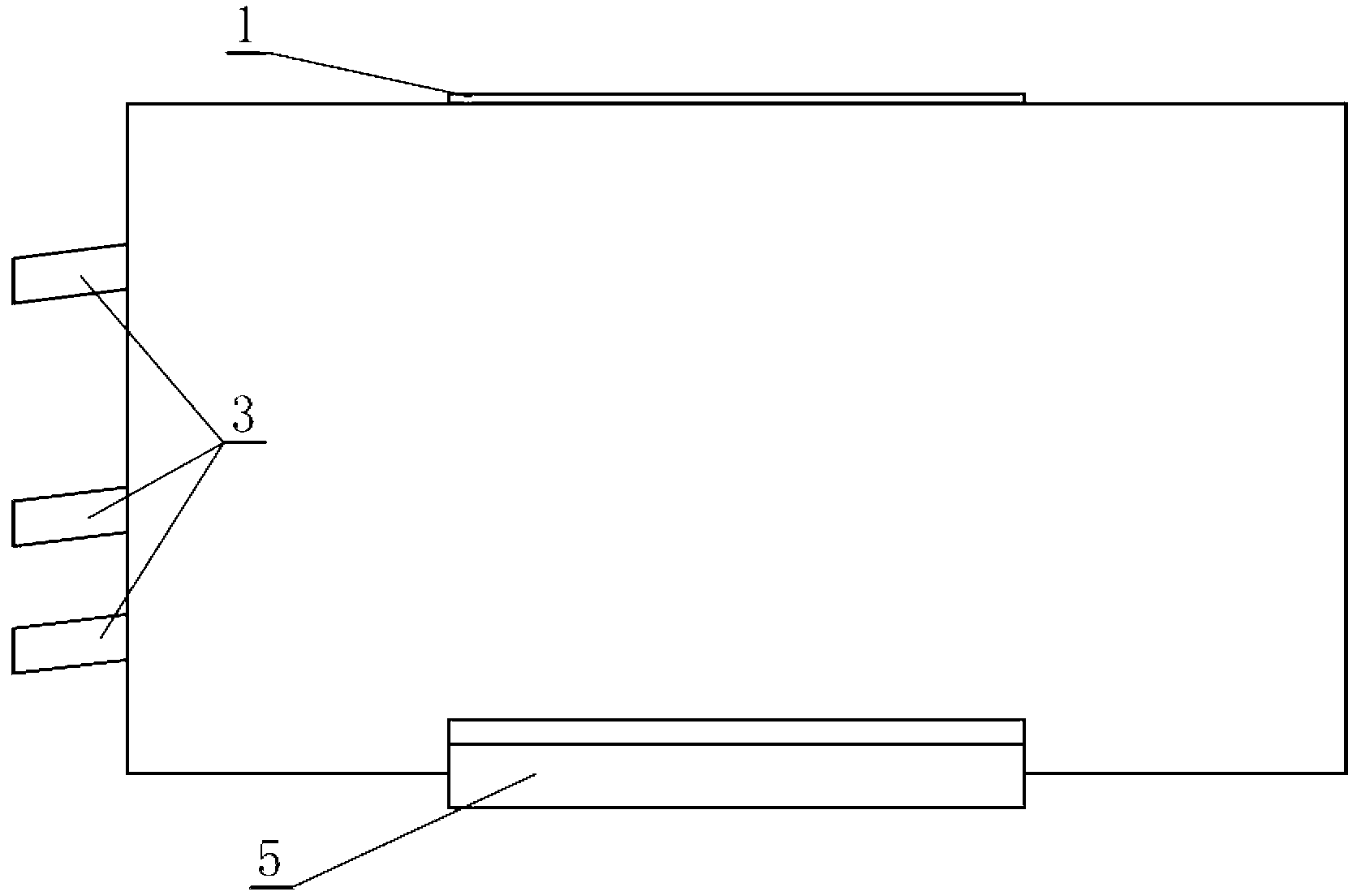

Multi-level thinning screen separation device for caboes

A screening device and tobacco stem technology are applied in the field of multi-stage refinement and screening devices for tobacco stems, which can solve the problem that the screening specifications of tobacco stems are not further refined, the stems cannot be effectively removed, and the purity of the packaging tobacco stems is poor. and other problems, to achieve the effect of improving the screening efficiency of long stems, improving the screening efficiency of long stems, and facilitating classification and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Taking the processing of Qujing 1 K326 B3F tobacco as an example, the sieving device of the prior art and the device of the present invention are used to sieve the packaged finished product: (1) After sieving by the original sieving device, the packaged product is larger than 20mm The long stem rate was 85.61%, the long stem rate greater than 50.8mm was 28.41%, the excessively long stem rate greater than 101.6mm was 10.17%, and the short stem rate was 4.22%. (2) After screening by the device of the present invention, the percentage of long stems larger than 25.4mm in the packaged finished product is 95.49%, the rate of long stems larger than 50.8mm is 40.17%, the rate of overlong stems larger than 101.6mm is 3.21%, and the rate of short stems was 1.3%.

Embodiment 2

[0032] Taking the processing of Qujing 2 cloud 87 C3F tobacco as an example, the sieving device of the prior art and the device of the present invention are used to sieve the packaged finished product: (1) After sieving by the original sieving device, the packaged product is greater than 20mm The long-stem rate is 86.24%, the long-stem rate greater than 50.8mm is 29.77%, the over-long-stem rate is greater than 101.6mm is 9.65%, and the short-stem rate is 4.11%. (2) After screening by the device of the present invention, the percentage of long stems larger than 25.4mm in the packaged finished product is 97.22%, the rate of long stems larger than 50.8mm is 42.17%, the rate of overlong stems larger than 101.6mm is 1.62%, and the rate of short stems was 1.16%.

[0033] Carry out a month's production test according to the method same as embodiment 1, 2, show through statistics: after adopting the sieving device screening of prior art, in the tobacco stem raw material, the long stem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com