Oyster ash silt slurry for repairing hollow drums and cracks and anchoring of mural and preparation method thereof

A hollowing and cracking technology, which is applied in the field of cracks and oyster ash powder soil slurry for anchoring and its preparation, and mural repairing hollowing, can solve the problems of mural surface cracking, mural falling off, bulging, etc., and achieve small shrinkage and final The setting time is short and the effect of ensuring the reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

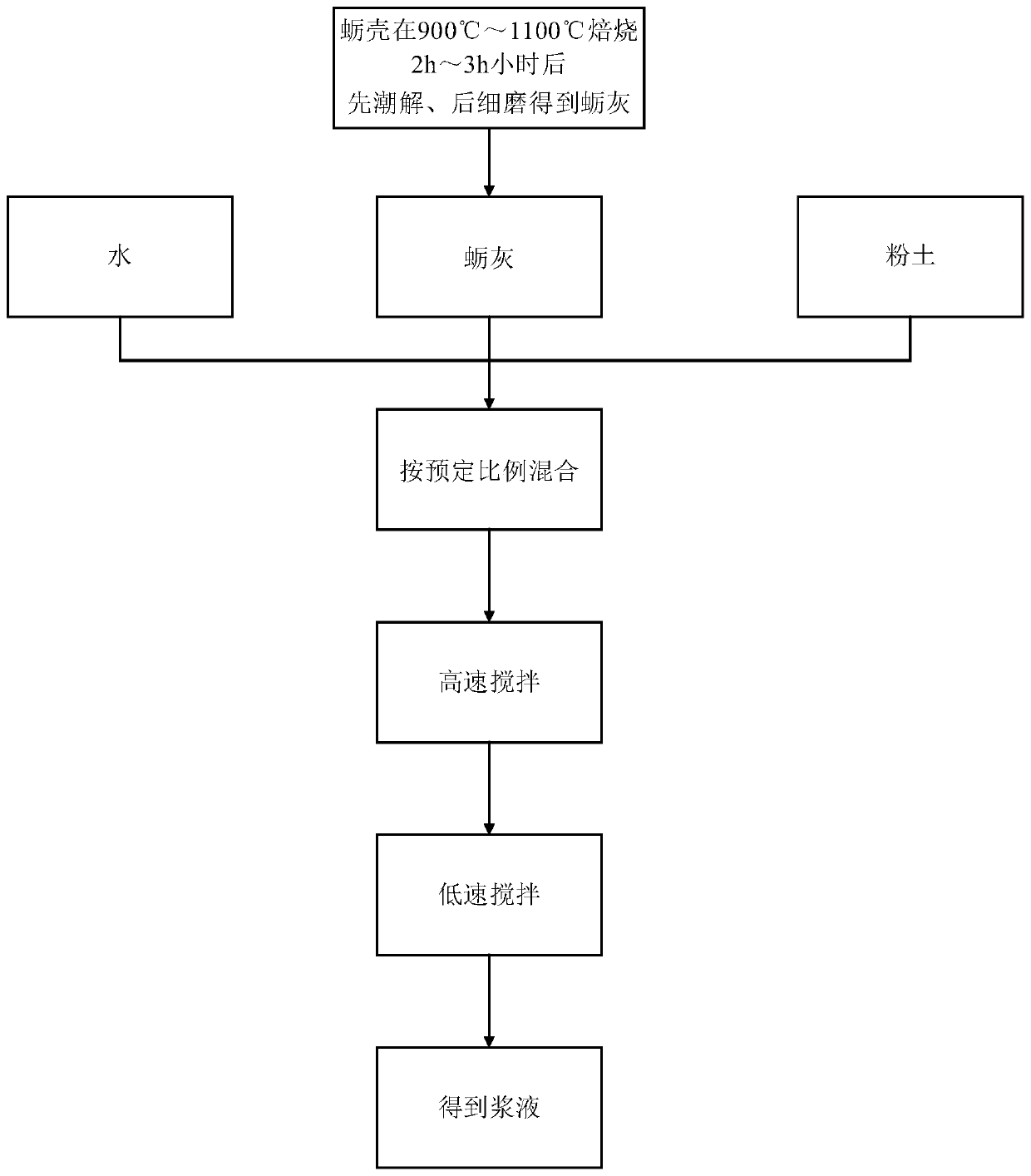

Method used

Image

Examples

Embodiment 1

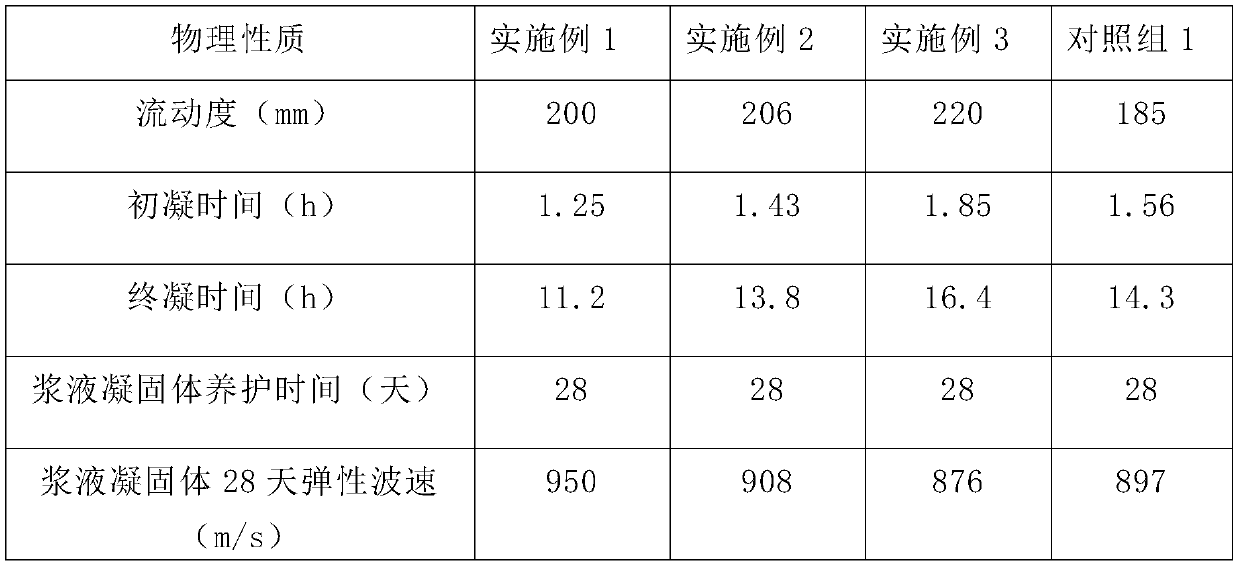

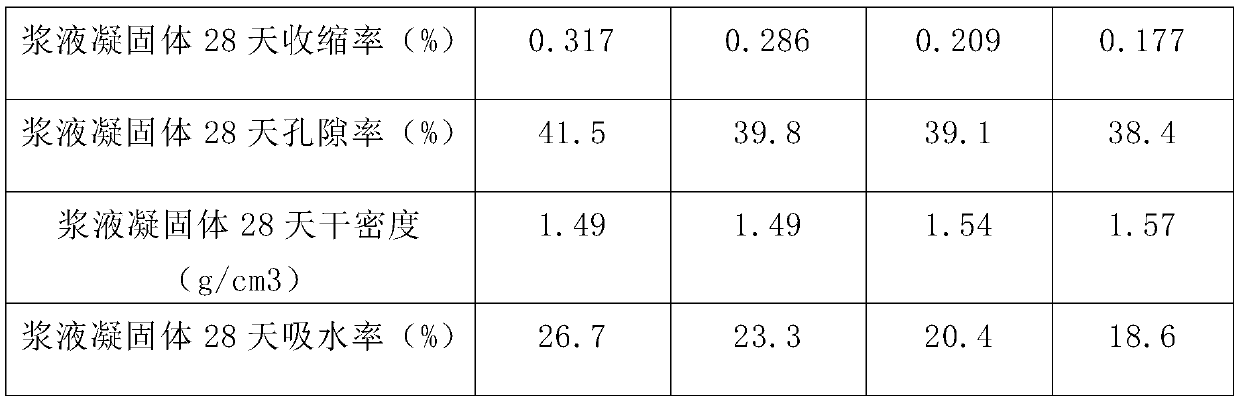

[0024] A kind of oyster ash silt slurry for repairing hollow drums, cracks and anchoring of murals, the ratio of raw materials is as follows according to the stated requirements:

[0025] 1) Oyster ash: 1 part by mass

[0026] 2) Silt: 3 parts by mass

[0027] 3) Water: 2.08 parts by mass

[0028] The fluidity of the slurry obtained by the above ratio is 200mm. The above-mentioned oyster ash is calcined at 1000°C for 2 hours, then deliquified and finely ground into ash by dry method. Its hydraulic component β-type calcium silicate β- The CS content is 6.2%, the air-hardening component calcium oxide CaO content is 92.8% (mass percentage), the other content is 1.0%, and the particle diameter is 180-200 mesh;

[0029] The particle size of the above-mentioned silt is 80 mesh to 100 mesh, and the total soluble salt content is ≤0.5%;

Embodiment 2

[0031] A kind of oyster ash silt slurry for repairing hollow drums, cracks and anchoring of murals, the ratio of raw materials is as follows according to the stated requirements:

[0032] 1) Oyster ash: 1 part by mass

[0033] 2) Silt: 9 parts by mass

[0034] 3) Water: 4.7 parts by mass

[0035] The fluidity of the slurry obtained through the above ratio is 206mm. The above-mentioned oyster ash is roasted at 1000°C for 2 hours by the oyster shell, and then deliquified and finely ground into ash by dry method. Its hydraulic component β-type calcium silicate β- The CS content is 6.2%, the air-hardening component calcium oxide CaO content is 92.8% (mass percentage), the other content is 1.0%, and the particle diameter is 180-200 mesh;

[0036] The particle size of the above-mentioned silt is 80 mesh to 100 mesh, and the total soluble salt content is ≤0.5%;

Embodiment 3

[0038] A kind of oyster ash silt slurry for repairing hollow drums, cracks and anchoring of murals, the ratio of raw materials is as follows according to the stated requirements:

[0039] 1) Oyster ash: 1 part by mass

[0040] 2) Silt: 15 parts by mass

[0041] 3) Water: 7.04 parts by mass

[0042] The fluidity of the slurry obtained through the above ratio is 220mm. The above-mentioned oyster ash is roasted at 1000°C for 2 hours, then deliquified and finely ground into ash by dry method. Its hydraulic component β-type calcium silicate β- The CS content is 6.2%, the air-hardening component calcium oxide CaO content is 92.8% (mass percentage), the other content is 1.0%, and the particle diameter is 180-200 mesh;

[0043] The particle size of the above-mentioned silt is 80 mesh to 100 mesh, and the total soluble salt content is ≤0.5%;

[0044] Control group 1

[0045] A kind of oyster ash silt slurry for repairing hollow drums, cracks and anchoring of murals, the ratio of ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com