High and large concrete formwork reinforcing system

A formwork reinforcement and tall technology, which is applied in the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problems of poor concrete appearance quality, cold joints in concrete layers, large verticality deviation, etc. problems, achieve good reinforcement effect, save material, and ensure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

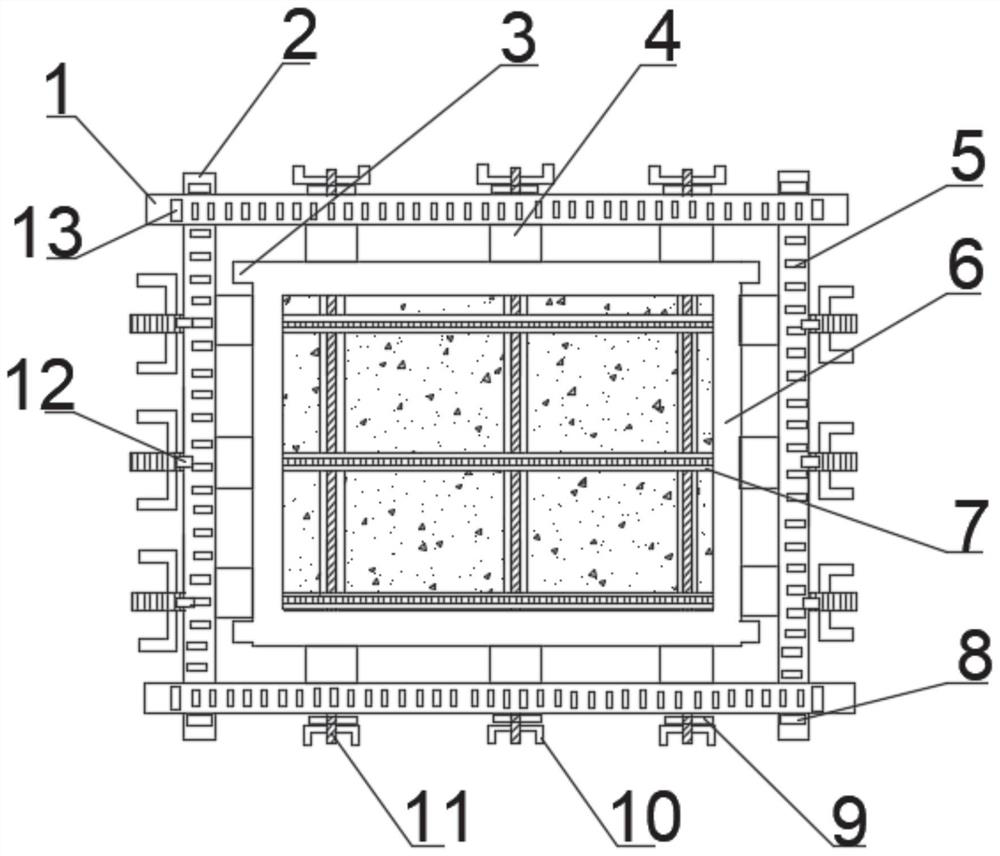

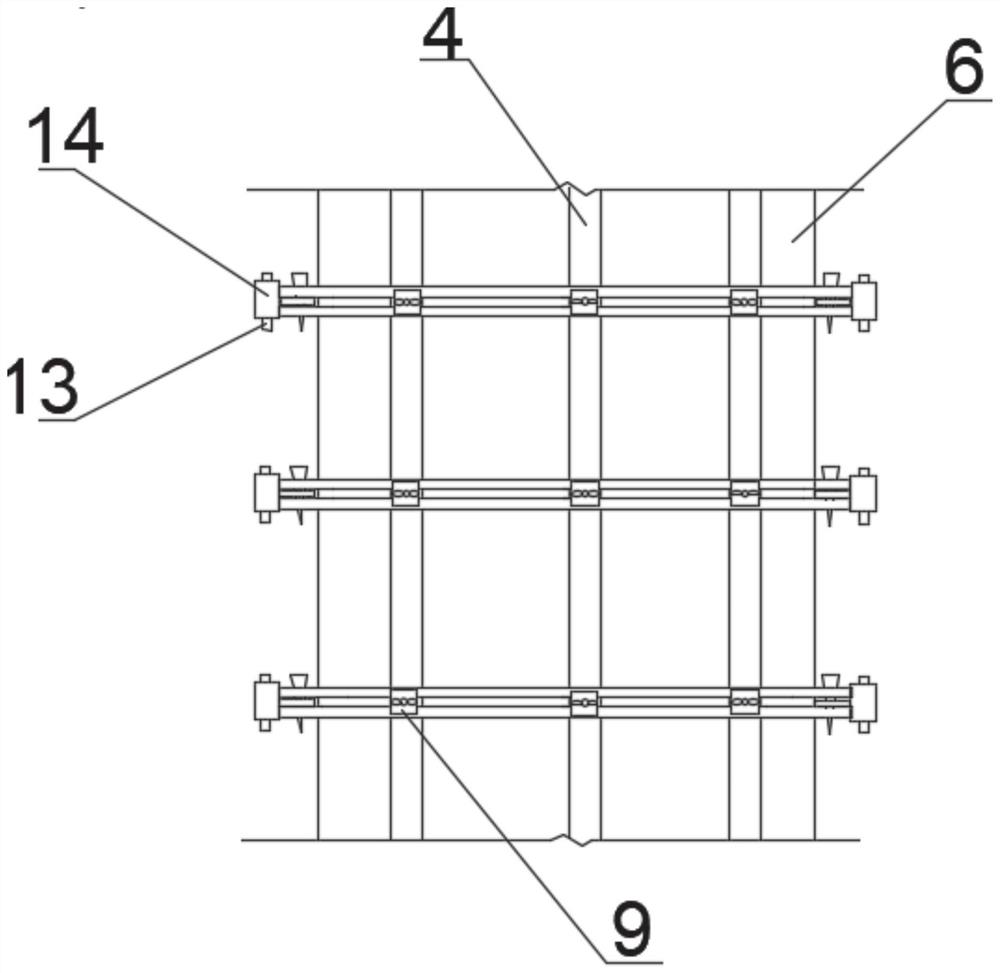

[0020] A tall concrete formwork reinforcement system, comprising a first channel steel 1, a second channel steel 2, a wooden board 4, a steel formwork 6 and a tension screw, the edge of the steel formwork 6 is provided with a reinforcement corrugated 3, and the first groove The steel 1 and the second channel steel 2 are uniformly provided with fixing holes 5, and the outer periphery of the steel formwork 6 is provided with wooden boards 4 at vertical intervals, and the opposite sides of the wooden board 4 are laterally provided with the first channel steel 1. The first channel steel 1 is provided with two, the two ends of the first channel steel 1 are wrapped by the fixing block 14, the two first channel steel 1 are fixed by the first fixing plate 15, and the periphery of the plank 4 is additionally The second channel steel 2 is arranged horizontally on both sides, and the second channel steel 2 is provided with one. The second channel steel 2 is inserted into the gap between t...

Embodiment 2

[0027] When the formwork is installed, a plurality of steel formworks 6 are required to be spliced, and the steel formworks 6 are connected by a fixed buckle, which includes a first fixed tooth 15, a support plate 16, a movable clamping block 17, a sleeve 18, a second fixed Teeth 19, the first fixed tooth 15 is fixedly connected to the side of one end of the support plate 16, the side of the support plate 16 away from the first fixed tooth 15 is provided with a turbine tooth, and the side of the sleeve 18 is fixedly connected with a second Fixed tooth 19, the side of the sleeve 18 away from the second fixed tooth 19 is provided with a movable clamping block 17, the side of the movable clamping block 17 close to the second fixed tooth 19 is provided with a protrusion, the support The plate 16 is engaged with the movable clamping block 17. During installation, the sleeve 18 is set on the support plate 16, and the first fixed tooth 15 and the second fixed tooth 19 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com