Patents

Literature

30results about How to "Strong construction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

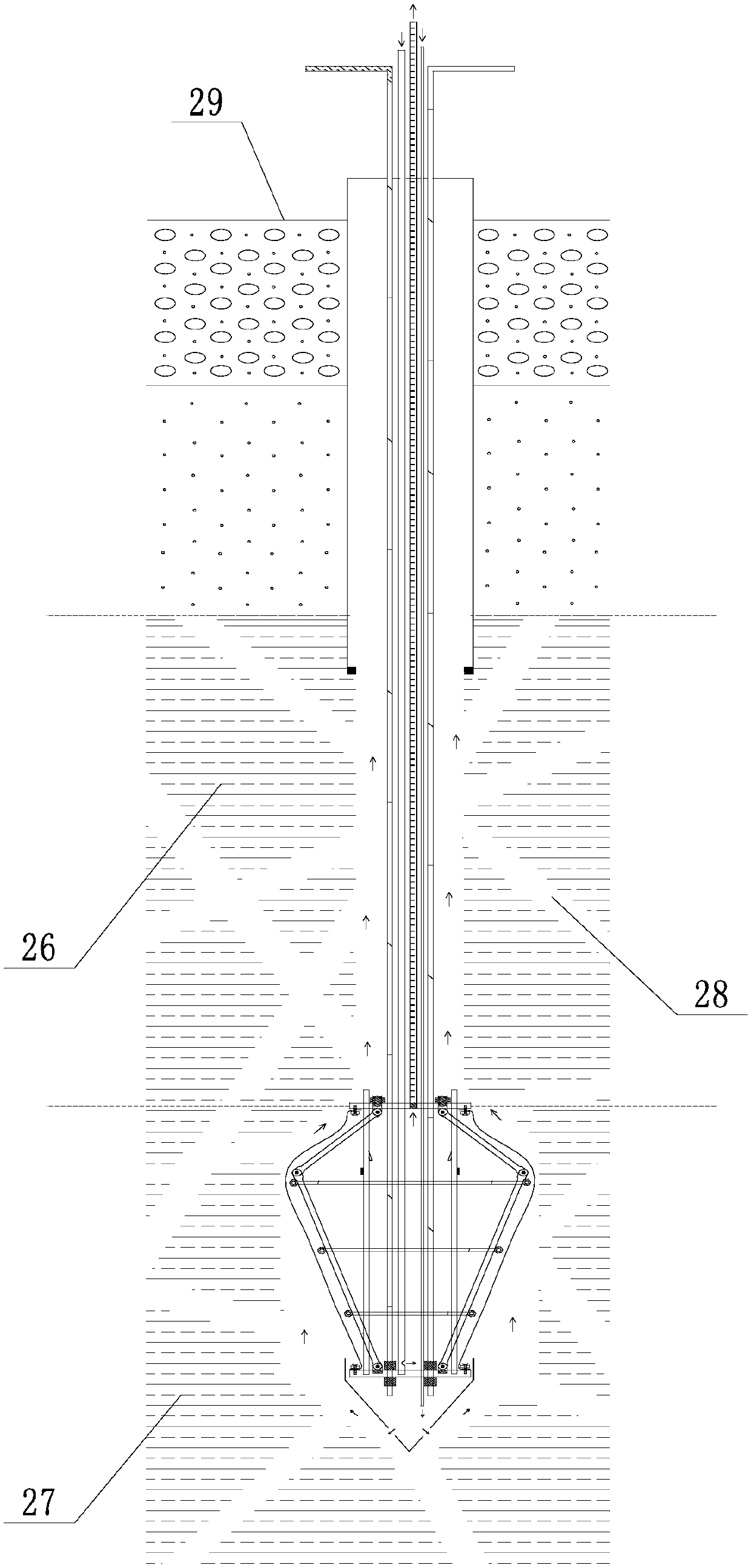

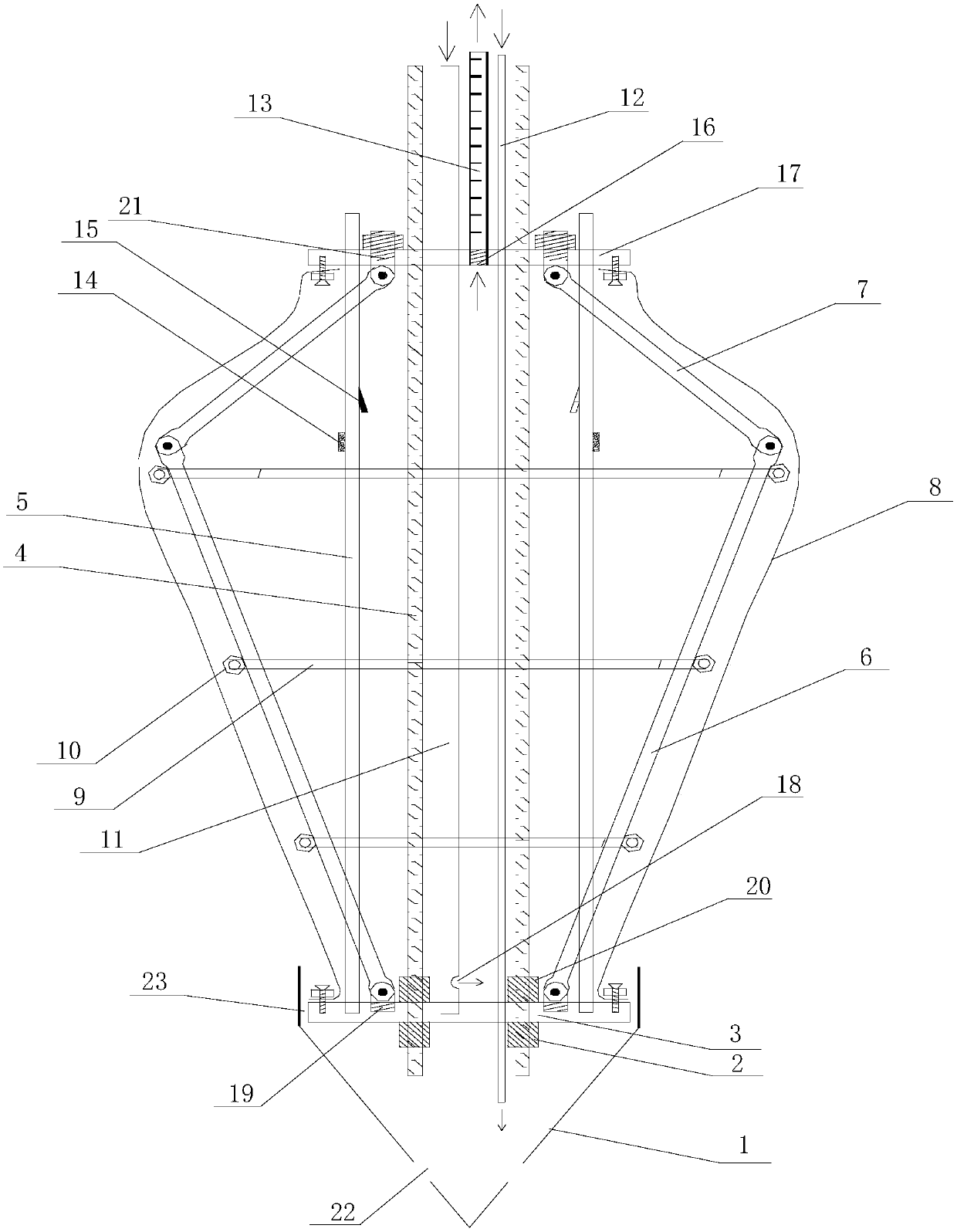

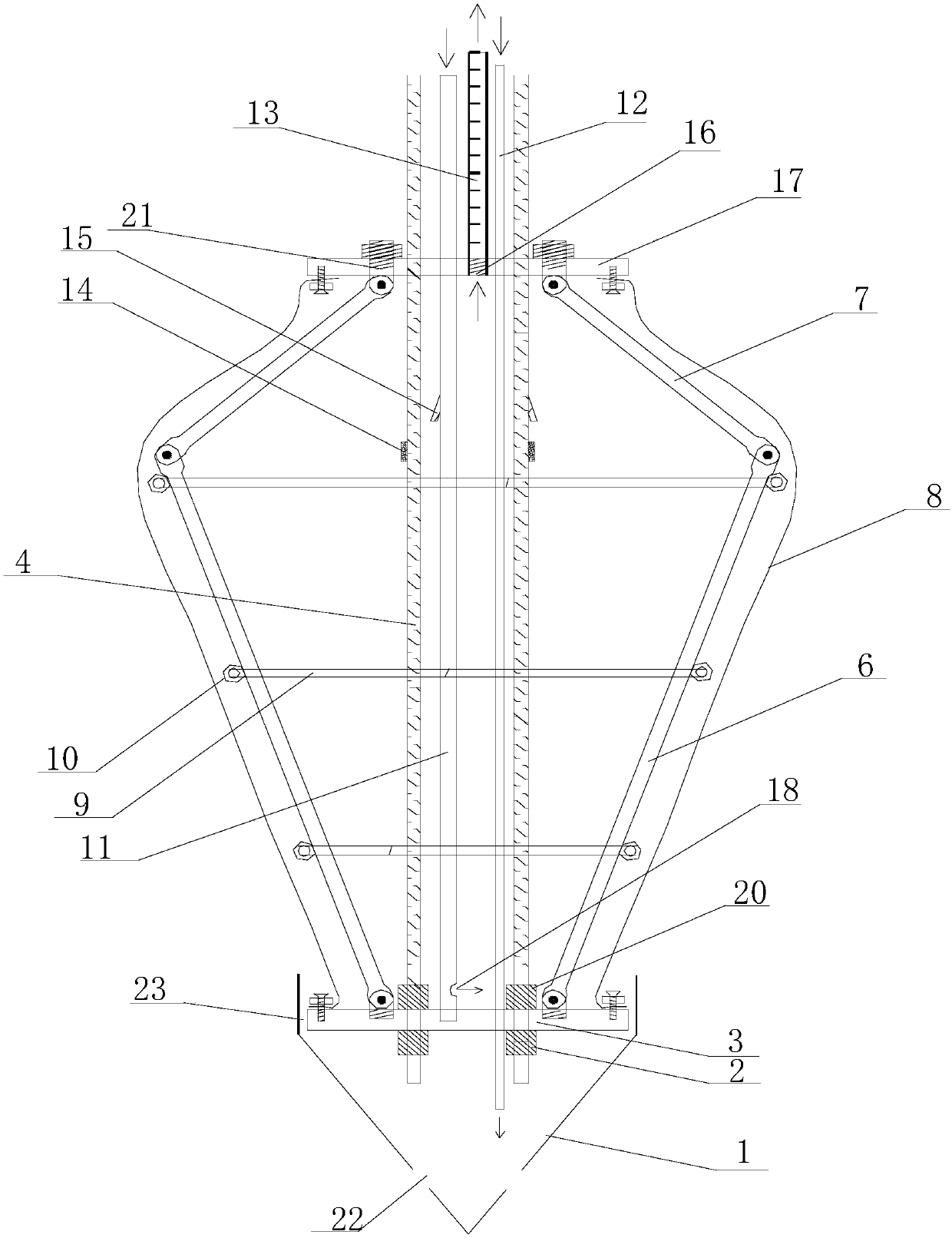

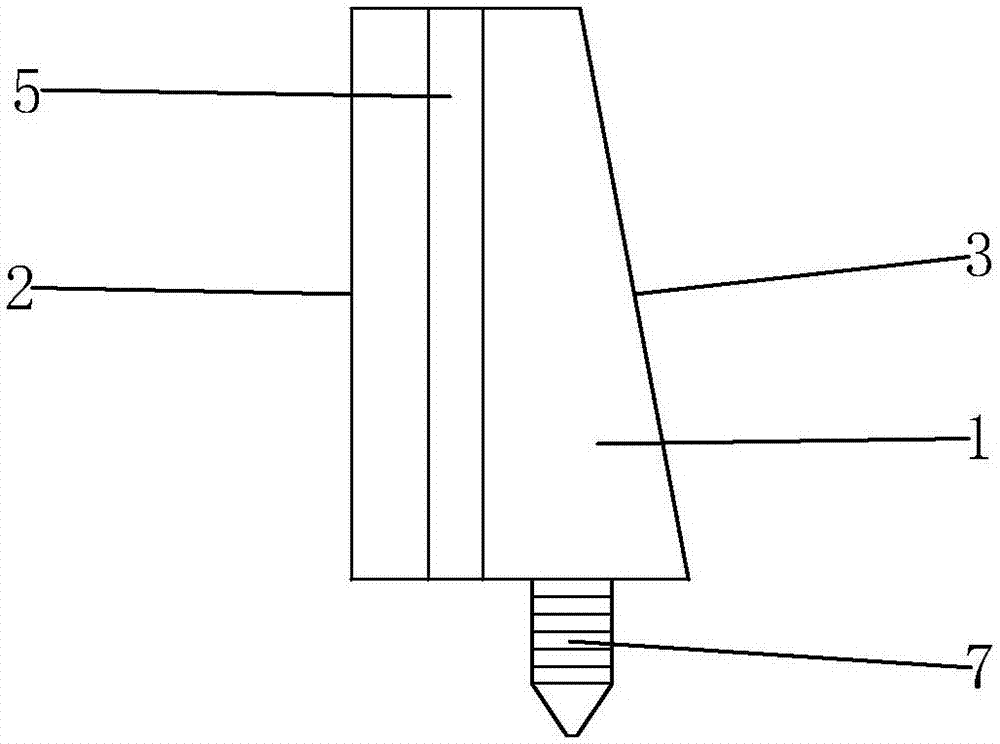

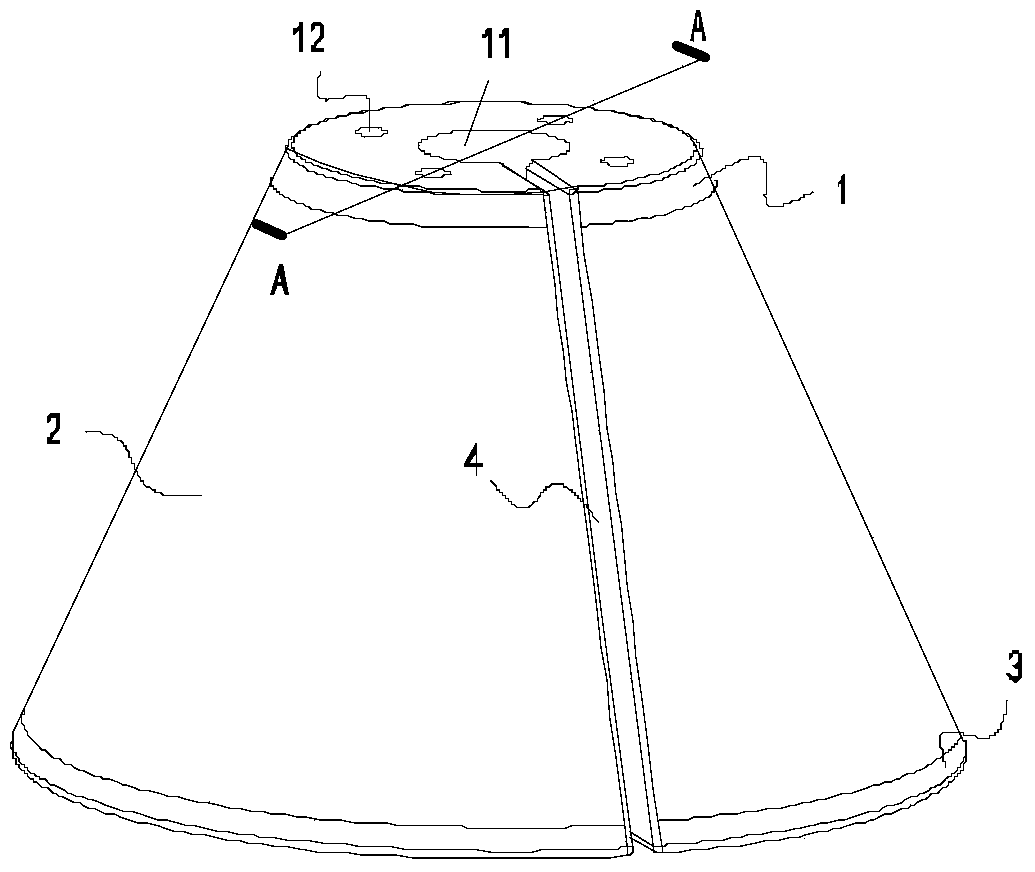

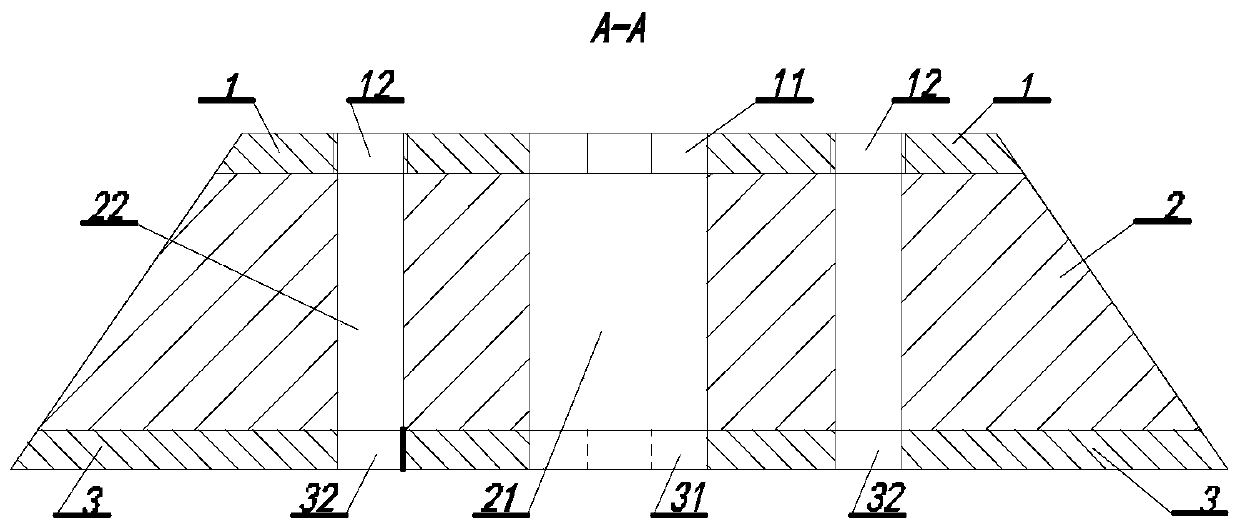

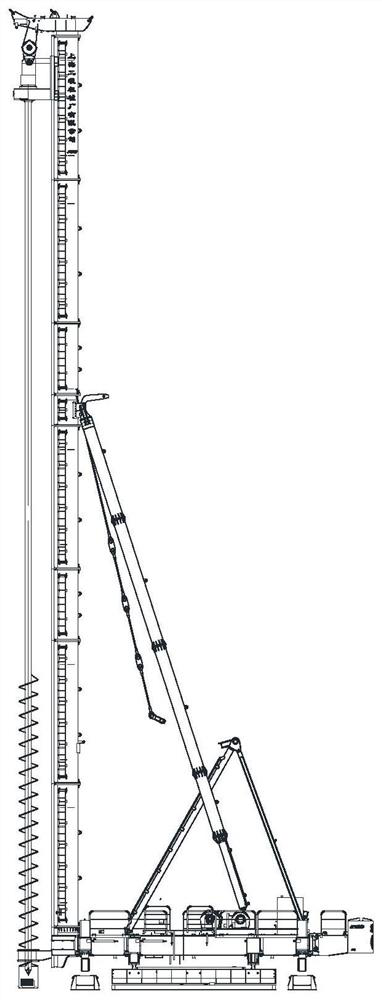

Rear-embedded film bag-type umbrella-shaped expansion tip used for pre-reaming and construction method thereof

PendingCN109518690AQuality improvementLow costExcavationsBulkheads/pilesEngineeringUltimate tensile strength

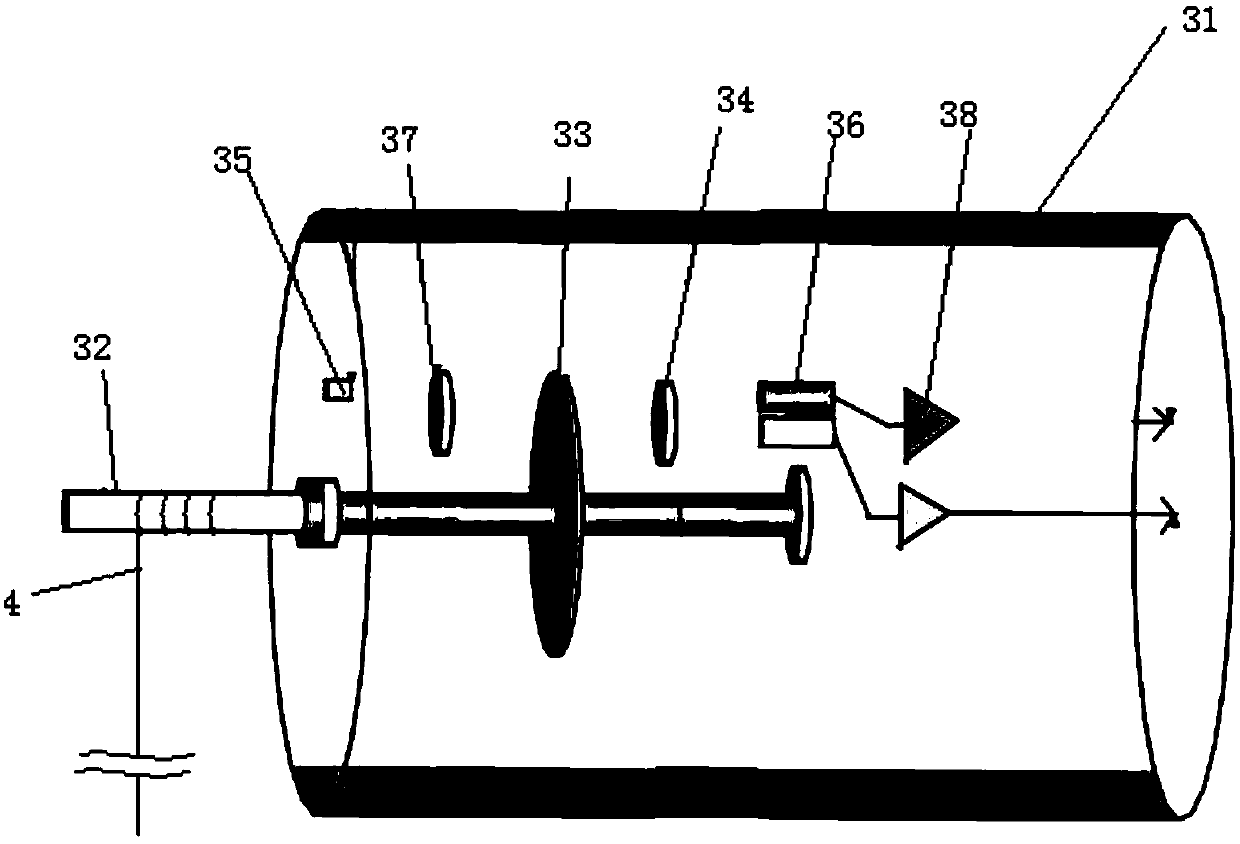

The invention discloses a rear-embedded film bag-type umbrella-shaped expansion tip used for pre-reaming and a construction method thereof. The rear-embedded film bag-type umbrella-shaped expansion tip used for pre-reaming comprises an umbrella-shaped expansion body device, a plurality of anchor bars penetrating through the umbrella-shaped expansion body device and a grouting pipe II. The umbrella-shaped expansion body device is sleeved with a film bag. A grout outlet of the grouting pipe is located in the film bag. A bar drawing disc, an umbrella-shaped folding rod set and a bar penetration disc are sequentially arranged in the umbrella-shaped expansion body device from front to back. By adoption of the rear-embedded film bag-type umbrella-shaped expansion tip used for pre-reaming and a construction method thereof, the problems that the work of rotary-jetting hole cleaning in a hard clay bed is complex and high in labor and machine consumption, mud in fractures of fracture-developed rock mass flows back into the umbrella-shaped expansion tip and consequentially affects the elements and strength of a grouting consolidated body, and the construction efficiency is reduced due to theadoption of the umbrella-shaped tip technique and the rotary jetting technique for drilling and reaming and synchronous carrying of the umbrella-shaped expansion tip are solved.

Owner:刘晓理

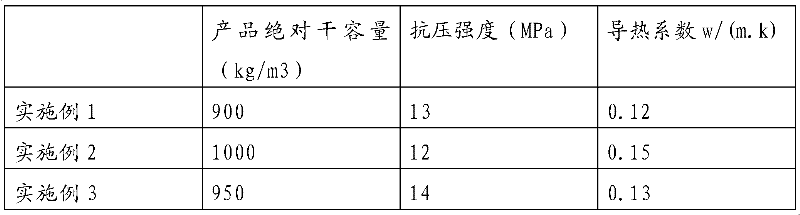

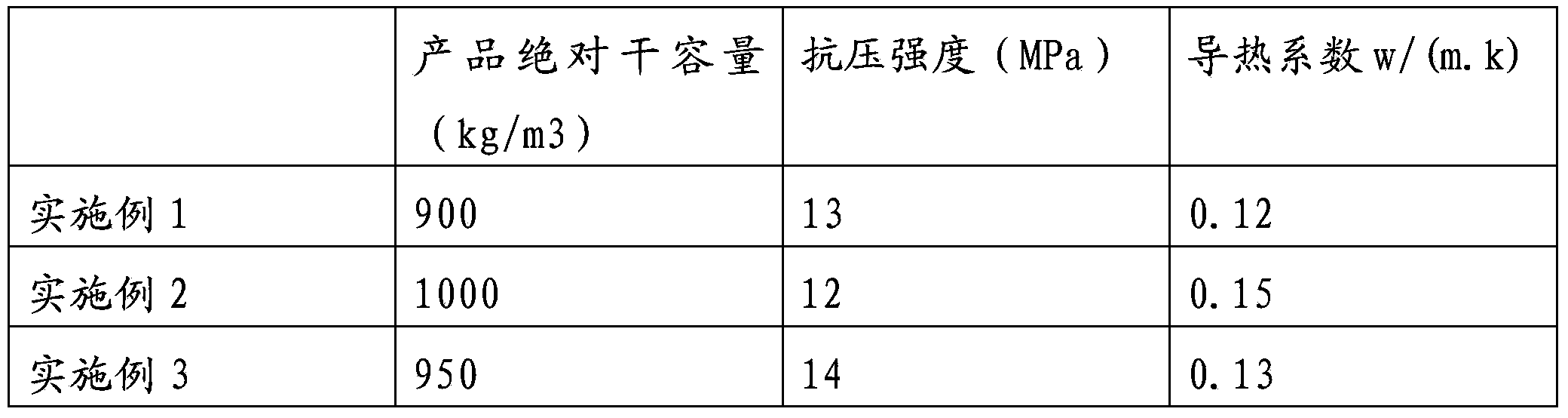

Ceramsite heat insulation brick and preparation method thereof

The invention relates to a building material and a preparation process thereof, and in particular relates to a heat insulation brick containing ceramsites and a preparation method thereof. The technical scheme of the invention is as follows: a ceramsite heat insulation brick is provided. The ceramsite heat insulation brick comprises the following raw material in parts by weight: 20-40 parts of ceramsite, 20-40 parts of steel furnace slag, 5-10 parts of fluorite tailings, 8-9 parts of coal ash, 5-10 parts of white mud and 1-3 parts of activating agent. The ceramsite heat insulation brick has the beneficial effects that 1, if the brick disclosed by the invention is used in a building to build a wall body, the self-weight of the building is reduced by about 30% as compared with the traditional clay brick, basic building cost of a foundation is reduced, and project cost is reduced; 2, compression strength is high; 3, heat insulation, heat isolation and sound isolation properties are good;4, the brick has fire-resistant and seismic performance and is good in durability; and 5, the brick does not crack and is good in frost resisting property. The heat insulation brick is strong in practicability when in use; and because the heat insulation brick is light and high in strength, construction efficiency is high, and the heat insulation brick is suitable for various building structures.

Owner:赵汝雄

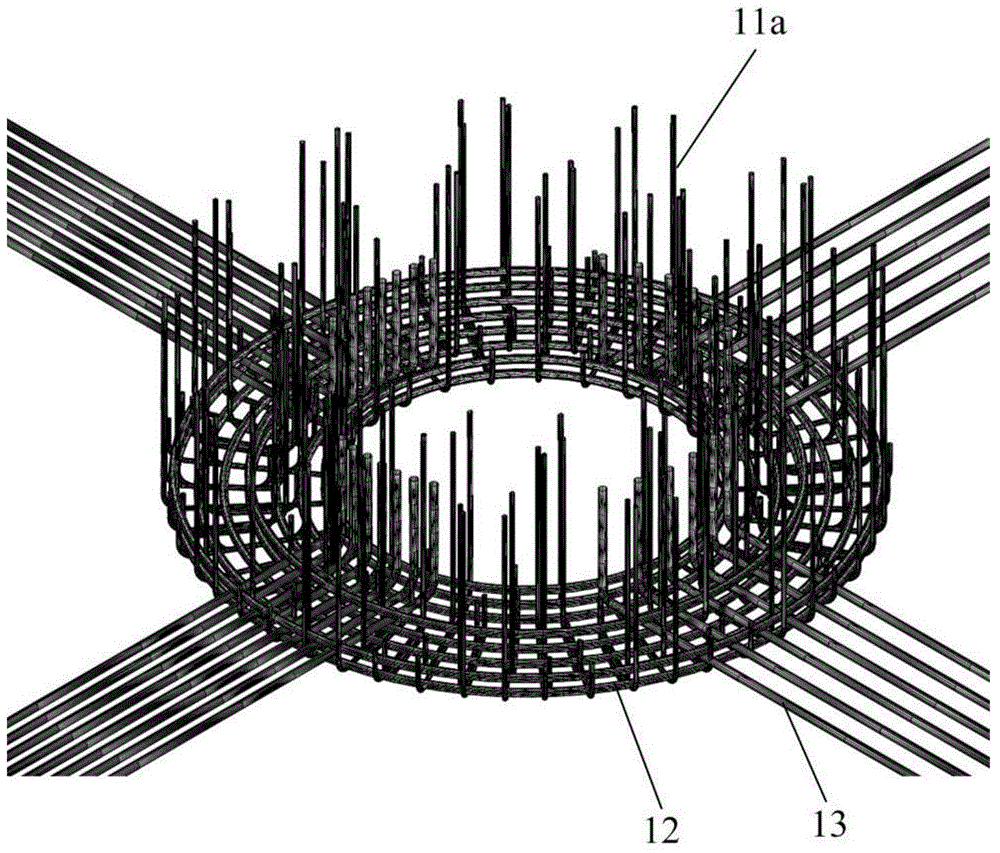

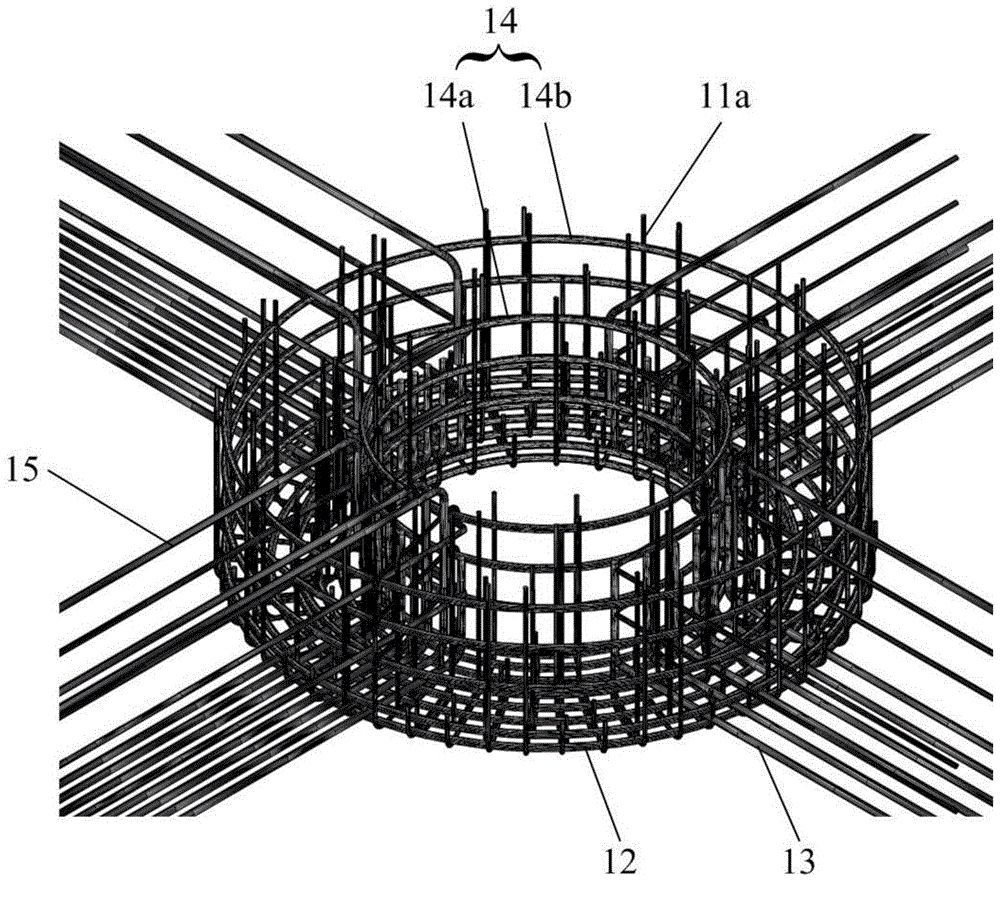

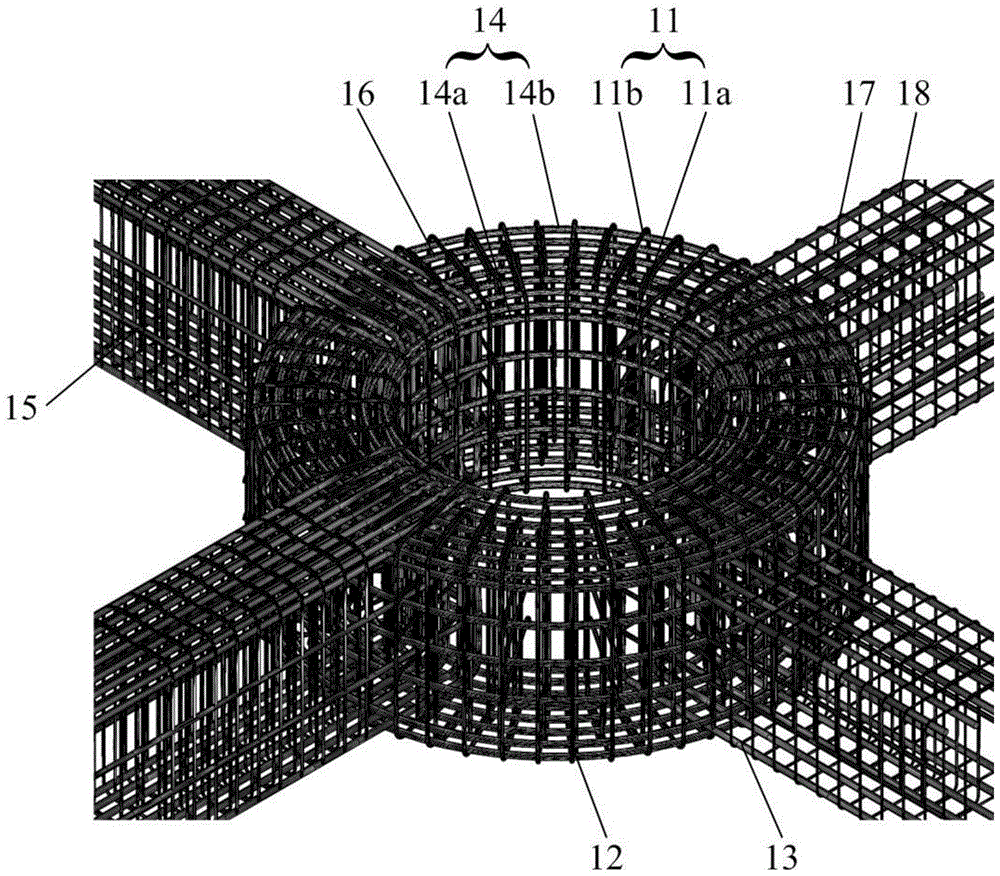

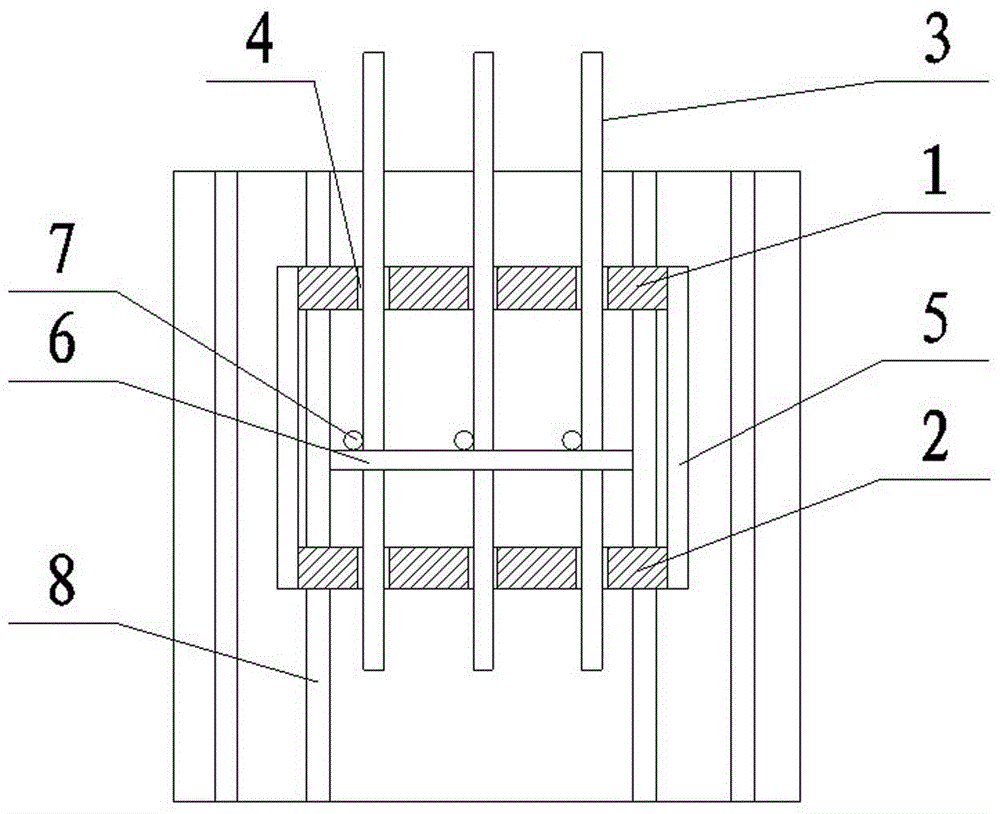

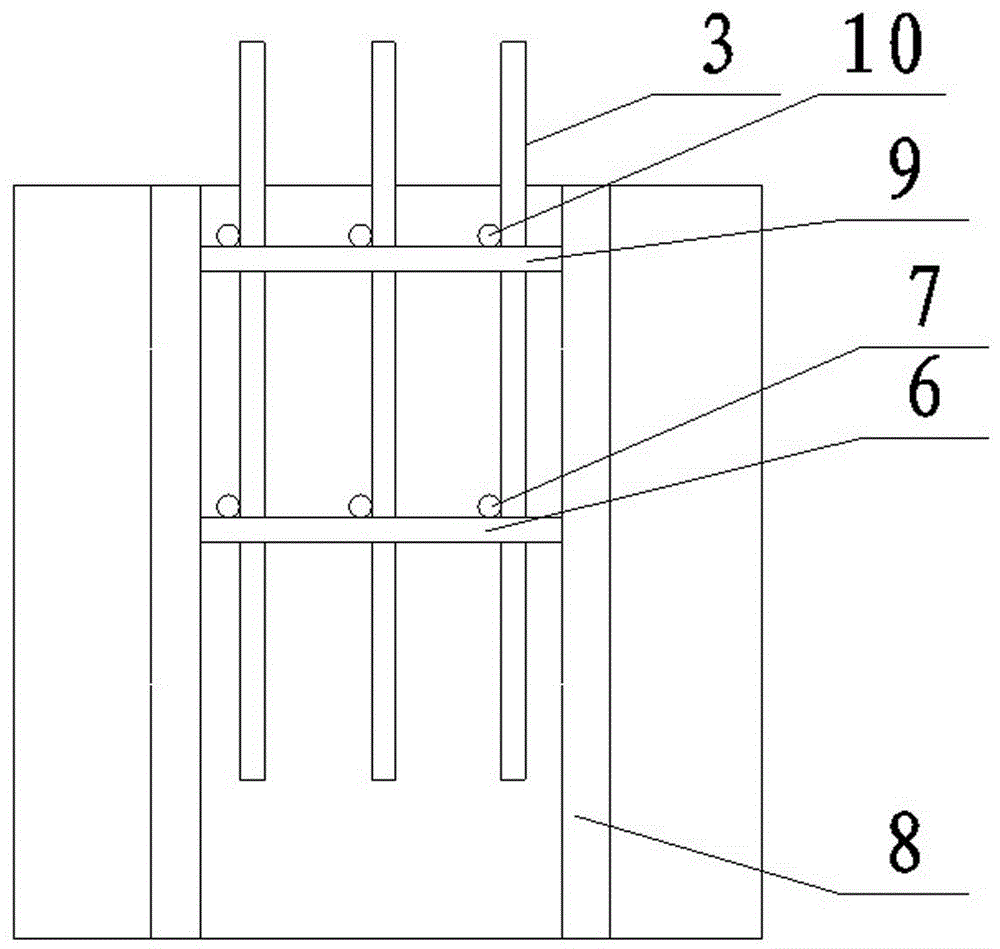

Construction method of constructing beam-column joint using ring beam

InactiveCN104947712AGuarantee the construction qualitySolve the problem of crossingArtificial islandsBuilding constructionsMultiple frameRebar

The invention discloses a construction method of constructing a beam-column joint using a ring beam, and relates to the technical filed of building construction. The construction method aims at solving the problems that the construction technology of rebar traversing in the position of the joint of the beam-column joint is complicated in an existing reverse building method, and harmful effect is caused to the joint structure when adjusting an original rebar structure on site. The construction method comprises the steps that 1 construction is conducted to form a concrete filled steel tubular column in the reverse building method, and a ring beam bottom cast is fixed to a bent surrounding the concrete filled steel tubular column; 2 multiple first U-shaped stirrups, ring beam bottom bars and lower rebars are erected in radial direction supported by the ring beam bottom cast; 3 multiple ring beam waist bars and multiple frame beam waist rebars are erected in the longitudinal direction of the axis of the concrete filled steel tubular column; 4 ring beam far bars and second U-shaped stirrups are erected, the first U-shaped stirrups and the second U-shaped stirrups can be put together and erected to form first annular stirrups, and the first annular stirrups are enclosed and fixed to the outer sides of the ring beam bottom bars, the ring beam waist bars and the ring beam face bars; fixing side formworks are installed, concreting is conducted, when a designed strength is reached, the formworks are removed, and construction of the beam-column joint is completed.

Owner:SHANGHAI NO 4 CONSTR

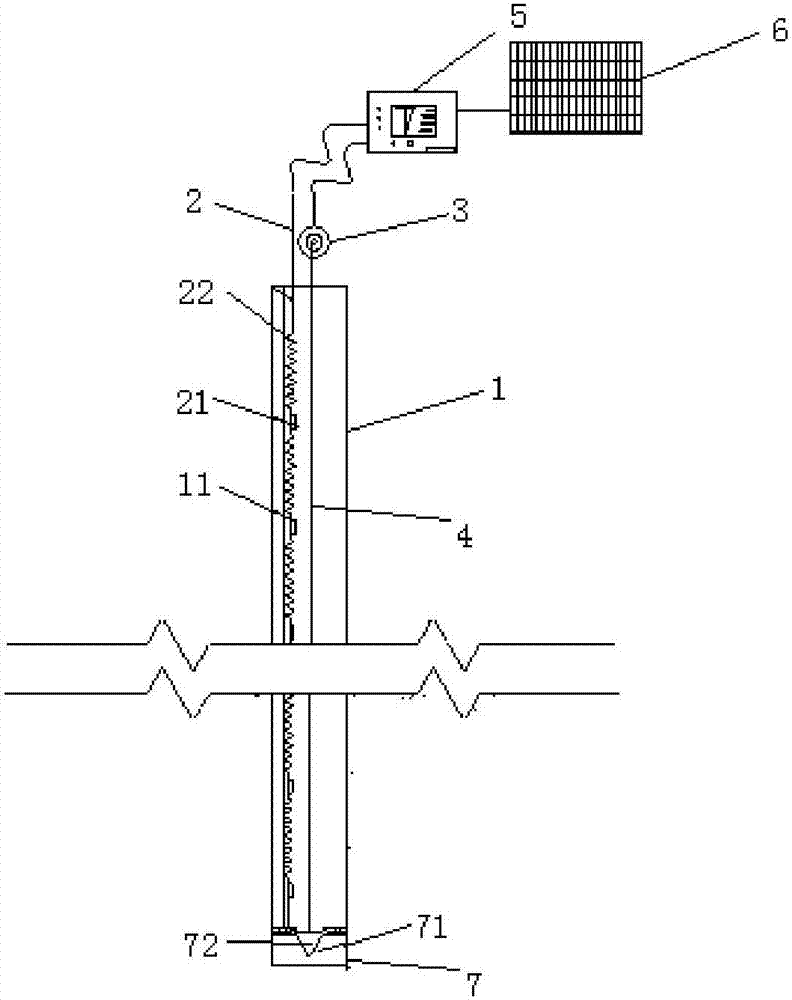

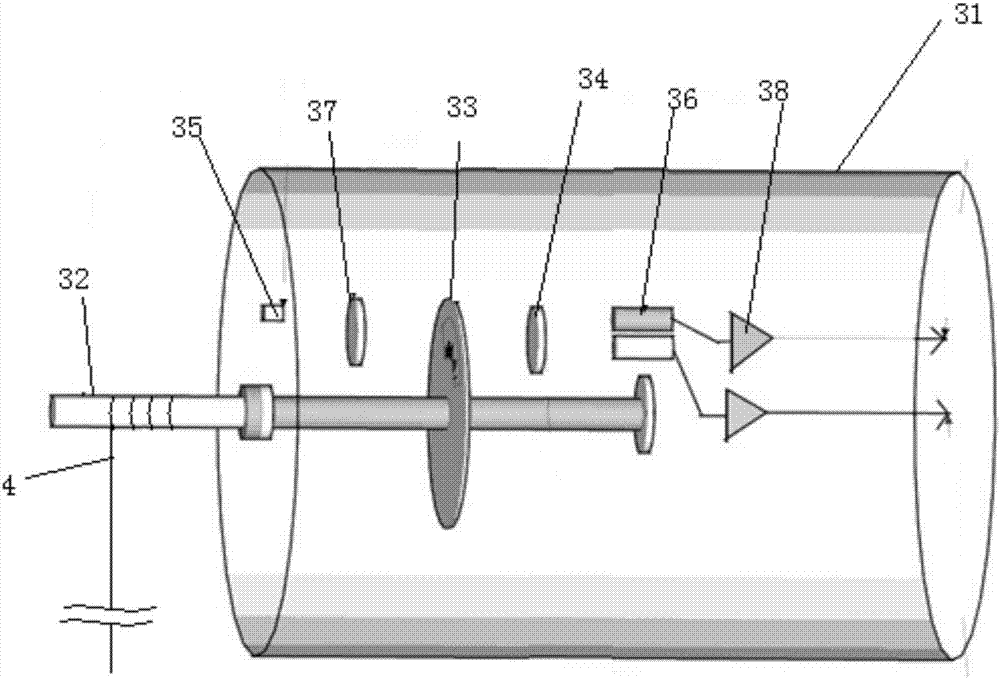

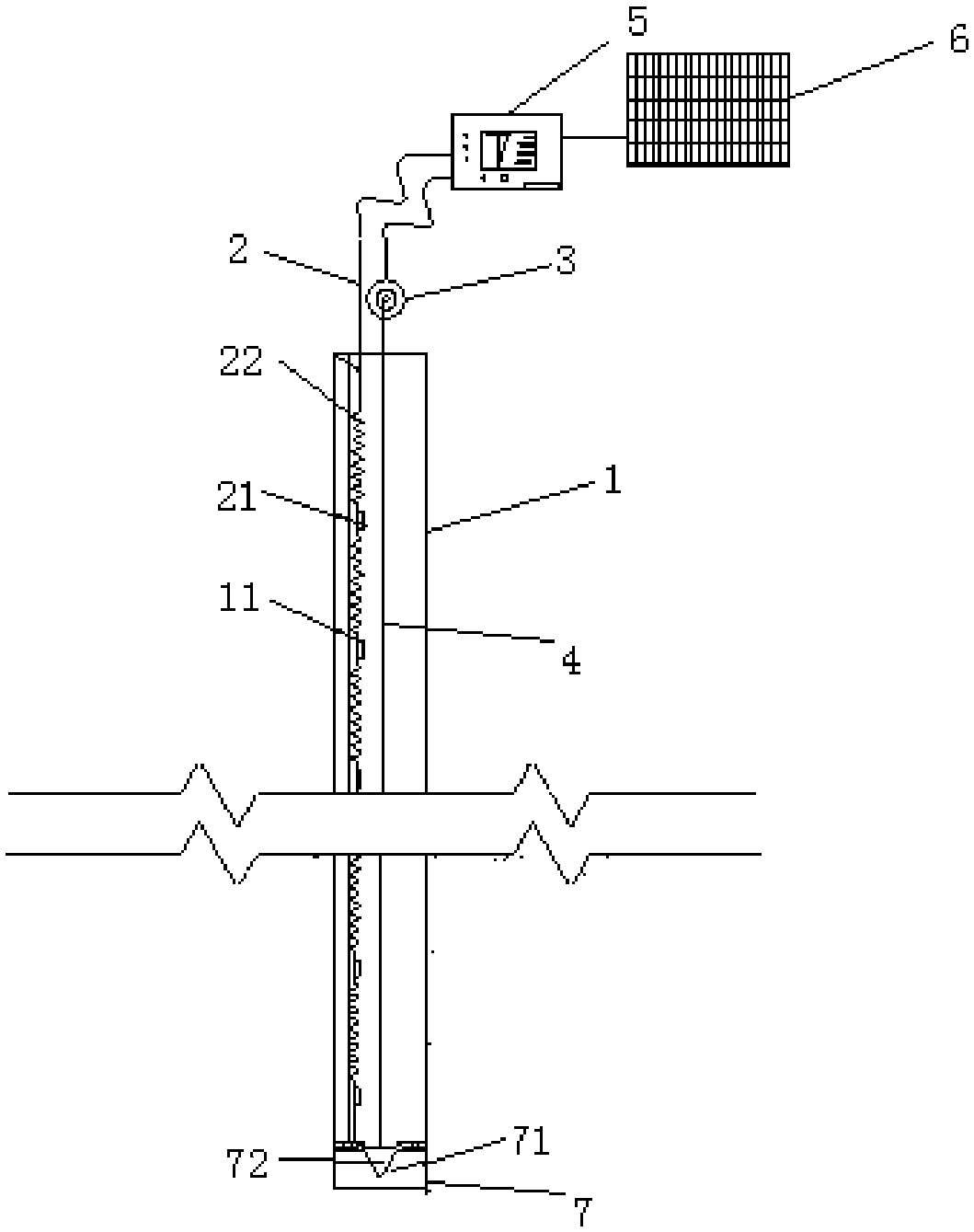

Automatic monitoring device for slope displacement, and application method of automatic monitoring device

The invention discloses an automatic monitoring device for slope displacement, and the device comprises an inclination measuring pipe, wherein the top of the inclination measuring pipe is provided with a rotary coder. The rotary coder is fixed, and is connected with a measurement line. The measurement line can extend to the bottom of the inclination measuring pipe from the top of the inclination measuring pipe. The rotary coder measures the displacement of a slope on the Z axis through the measurement line, and the rotary coder is connected with a data receiver. The displacement data measured by the rotary coder on the Z axis is transmitted to the data receiver. The invention also discloses an application method. The device can measure the deep displacement of the slope, can reflect the change condition of the displacement of the slope in a better manner, provides a better instruction for the monitoring warning, is higher in usability, and is wider in application range.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

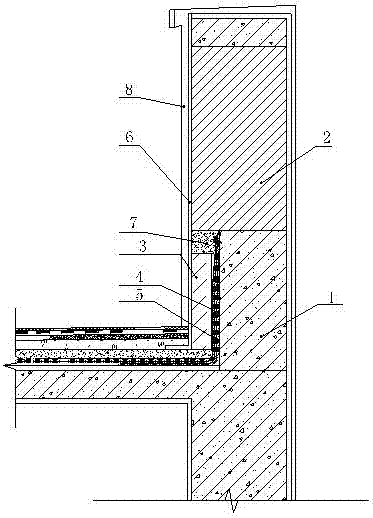

Building roof parapet wall flashing construction process

ActiveCN106906962ALow costEconomical cost, convenient operation and economicalSnow trapsBrickReinforced concrete

The invention relates to a flashing structure construction process, in particular to a building roof parapet wall flashing construction process. The building roof parapet wall flashing construction process comprises the following steps that step one, a flashing wall body of a reinforced concrete structure is poured on a building roof; step two, a waterproof roll is paved and pasted on the inner facades of the roof and the flashing wall body to form a waterproof layer, and the upper end of the waterproof roll is subjected to head retraction treatment; step three, a protective brick wall is laid on the outer facade of the waterproof layer through solid bricks, the inner facade of the protective brick wall is tightly attached to the waterproof roll, and the waterproof roll is tightly pressed on the flashing wall body, wherein the protective brick wall is no larger than the flashing wall body; and step four, a parapet wall is laid on the flashing wall body through solid bricks on the basis of the top of the flashing wall body, wherein the thickness of the wall body of the parapet wall is equal to the distance between the outer facade of the flashing wall body and the outer facade of the protective brick wall. A flashing structure built through the building roof parapet wall flashing construction process has the advantages of being resistant to cracking and falling-off and long in guarantee period and is convenient to construct and low in cost, and materials are convenient to obtain.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

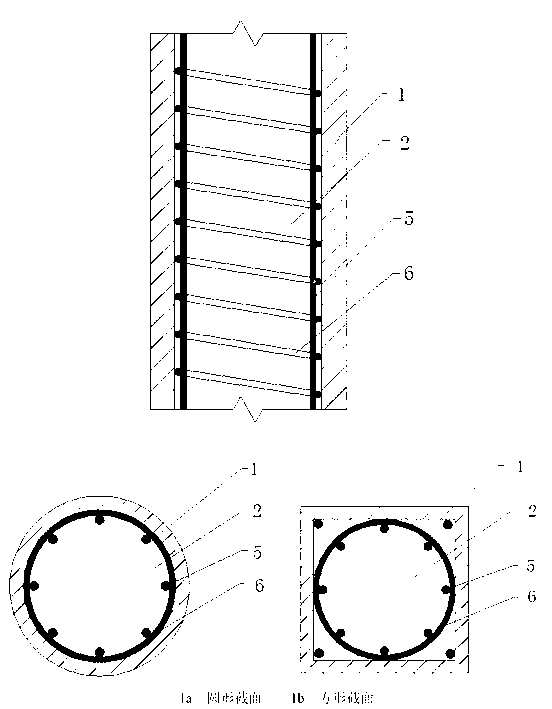

Textile reinforced concrete (TRC) tube restraining reinforced concrete column

InactiveCN103132651ASmall amount of workImprove bearing capacityStrutsBuilding reinforcementsReinforced concrete columnEngineering

The invention discloses a textile reinforced concrete (TRC) tube restraining reinforced concrete column which is characterized in that a TRC tube is prefabricated, the TRC tube is installed at a construction site, a reinforced cage is installed, concrete is poured, and the TRC tube restraining reinforced concrete column is formed. The TRC tube restraining reinforced concrete column is a novel assembled integrated type structure with the structure and a template integrated. The TRC tube restraining reinforced concrete column has the advantages that the characteristics of corrosion resistance, fire resistance and high thin wall intensity of the TRC are completely utilized, spiral stirrups are combined to increase restraint on the core concrete, and bearing capacity and anti-seismic performance of construction members are improved remarkably. The TRC tube is not only a construction template, but also a constituent part of the structure to join in work together, so that the TRC tube facilitates saving of large quantities of templates. The TRC tube restraining reinforced concrete column has the advantages of being simple in structure, convenient to construct, high in construction efficiency, low in cost, high in intensity, good in anti-seismic performance, fire-proof, durable and the like. Meanwhile, the TRC tube restraining reinforced concrete column facilitates saving of resources and energy sources and promotes development of building industrialization.

Owner:YANCHENG INST OF TECH +1

Construction method applied to reinforcement of floor handling project flood control lift

ActiveCN106930231AImprove the anti-shock performanceExtended service lifeBreakwatersQuaysOperabilityRevetment

The invention discloses a construction method applied to reinforcement of a floor handling project flood control lift. The construction method comprises the following steps of (a) construction planning, (b) earthwork filling, (c) original lift maintenance, (d) banket construction, (e) retention wall bricklaying, (f) sod revetment and (g) construction of a road at the top of the lift. The construction method has the advantages that construction time is reasonably arranged, the construction period is short, construction cost is low, operability is high, construction efficiency is high, the flood control capacity of the flood control lift is improved, and maintenance is easy.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

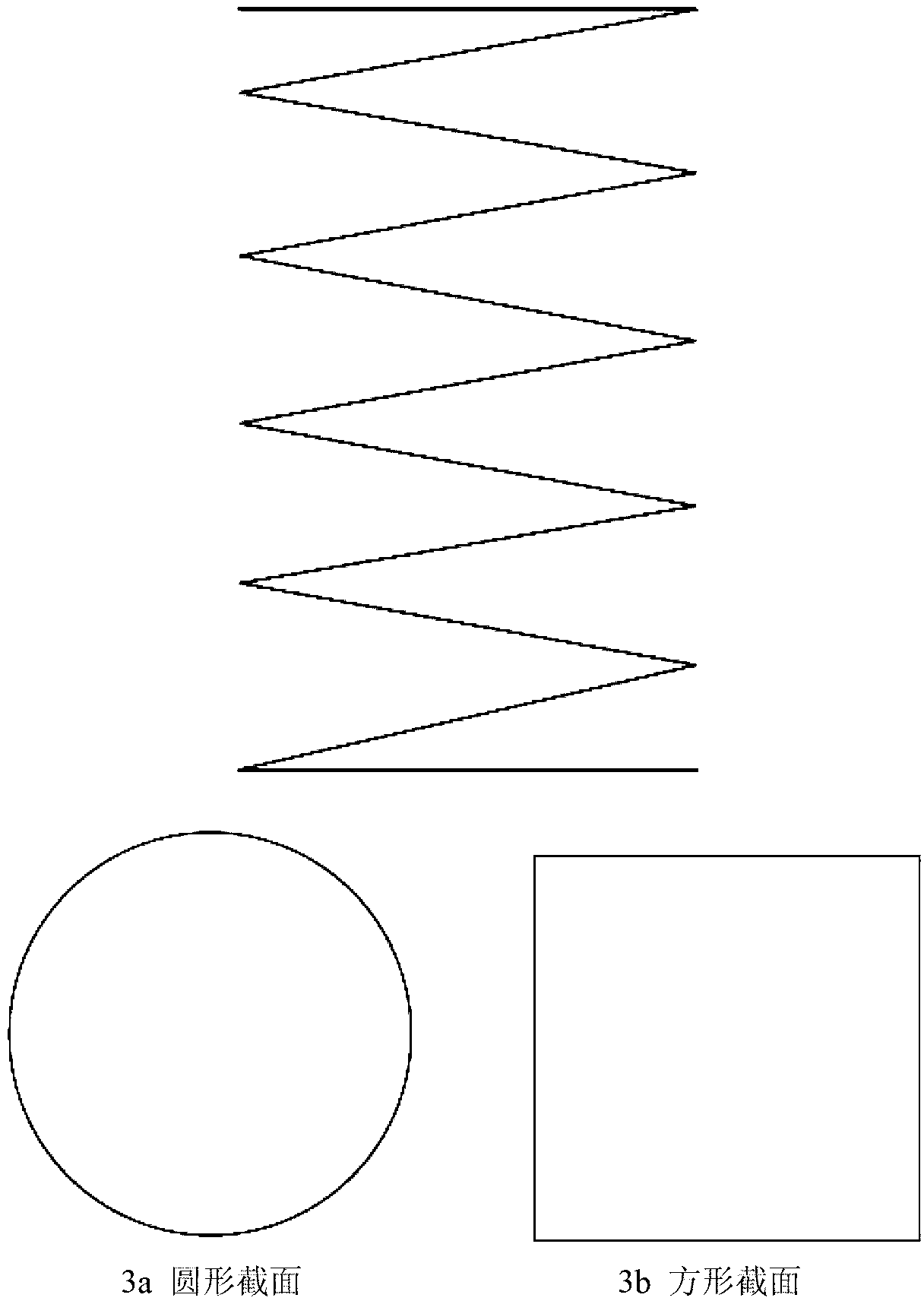

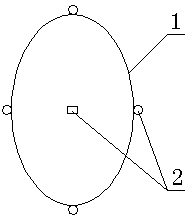

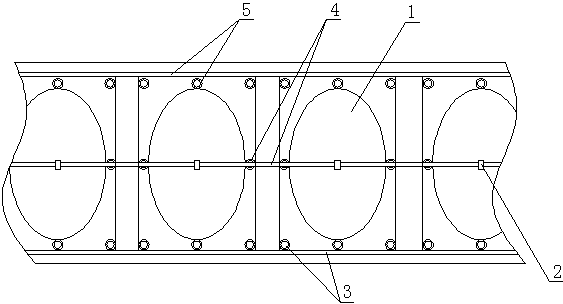

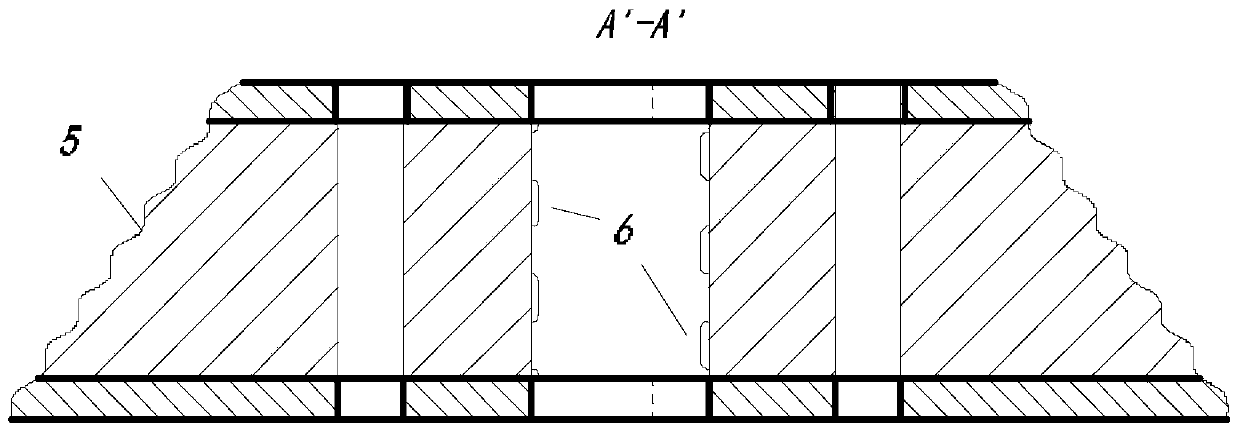

Hollow floor air bag and construction method of cast-in-place hollow floors

InactiveCN103321412AImprove pressure bearing capacityImprove impact performanceFloorsForms/shuttering/falseworksCarrying capacityEngineering

The invention discloses a hollow floor air bag and a construction method of cast-in-place hollow floors. The hollow floor air bag comprises air bag bodies in eggshell-shaped ellipsoid structures. Fixed parts are arranged on the air bag bodies, and a plurality of egg-shaped cavities are formed in the floor after concrete pouring, setting and hardening by aid of the bionic principle. The floor cavities have strong anti-pressure ability on the same pouring condition, and the loading capacity and the impact resistance of the hollow floors are greatly improved. The construction method is simple, convenient and easy to operate, the poured hollow floors have strong carrying capacity and good seismic resistance, the quality of the hollow floors is ensured, and the construction method is especially applied to the hollow floors of high-rise buildings in large-span structures.

Owner:温博为

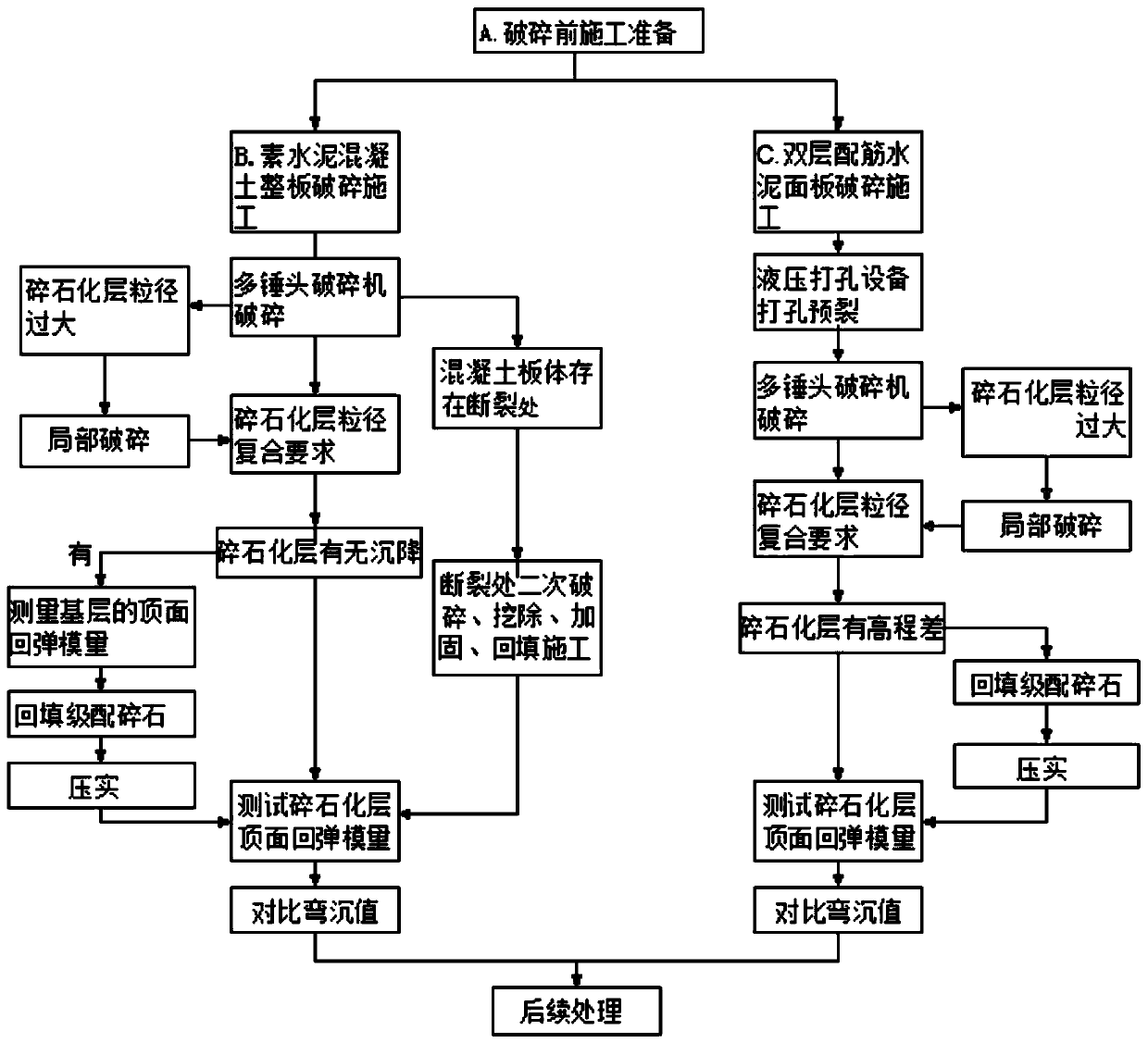

Pavement multistage rubblization construction method

InactiveCN111501512AEvenly brokenHigh strengthRoads maintainenceArchitectural engineeringCrushed stone

The invention discloses a pavement multistage rubblization construction method. The method comprises the following steps: preparing before crushing construction; crushing the plain cement concrete panel, and integrally crushing the pavement; locally crushing local large concrete blocks on the surface of the rubblization layer; conducting breaking construction on the breaking position of the plaincement concrete slab body; backfilling graded broken stones and compacting; testing the rebound modulus of the top surface of the rubblization layer; comparing deflection average values before and after crushing; conducting crushing construction on the double-layer reinforced cement panel, and conducting punching presplitting through hydraulic punching equipment; integrally crushing the pavement;locally crushing local large concrete blocks on the surface of the rubblization layer; backfilling graded broken stones and compacting; testing the rebound modulus of the top surface of the rubblization layer; comparing deflection average values before and after crushing; and carrying out final subsequent processing. The construction process is suitable for the transformation process of most of old concrete pavements, the construction speed is high, the construction efficiency is high, important joints are subjected to strength reinforcement, and the overall construction cost is low.

Owner:ZHENJIANG PORT GRP CO LTD

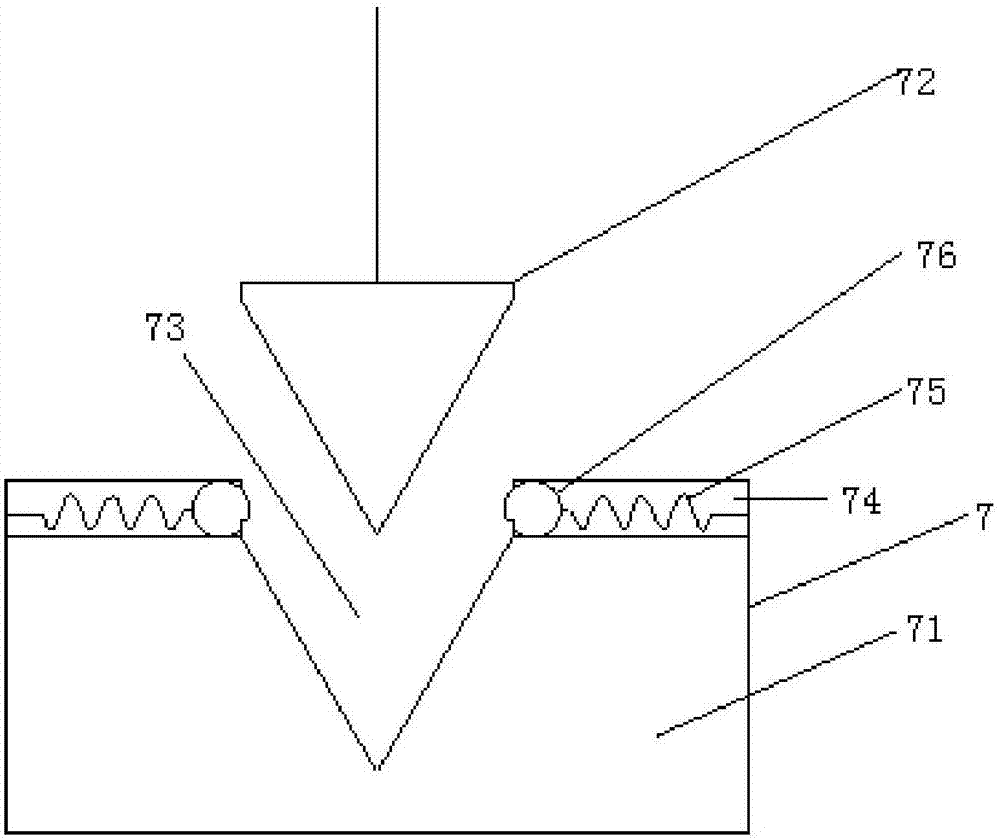

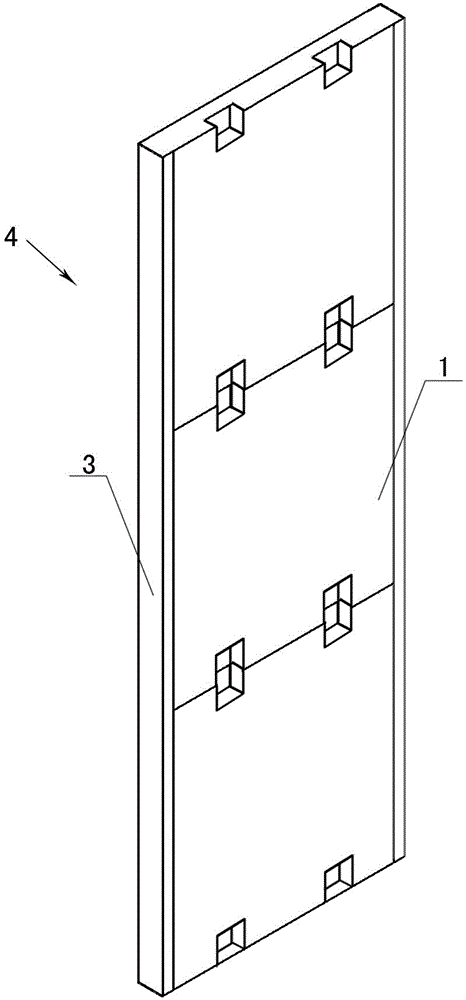

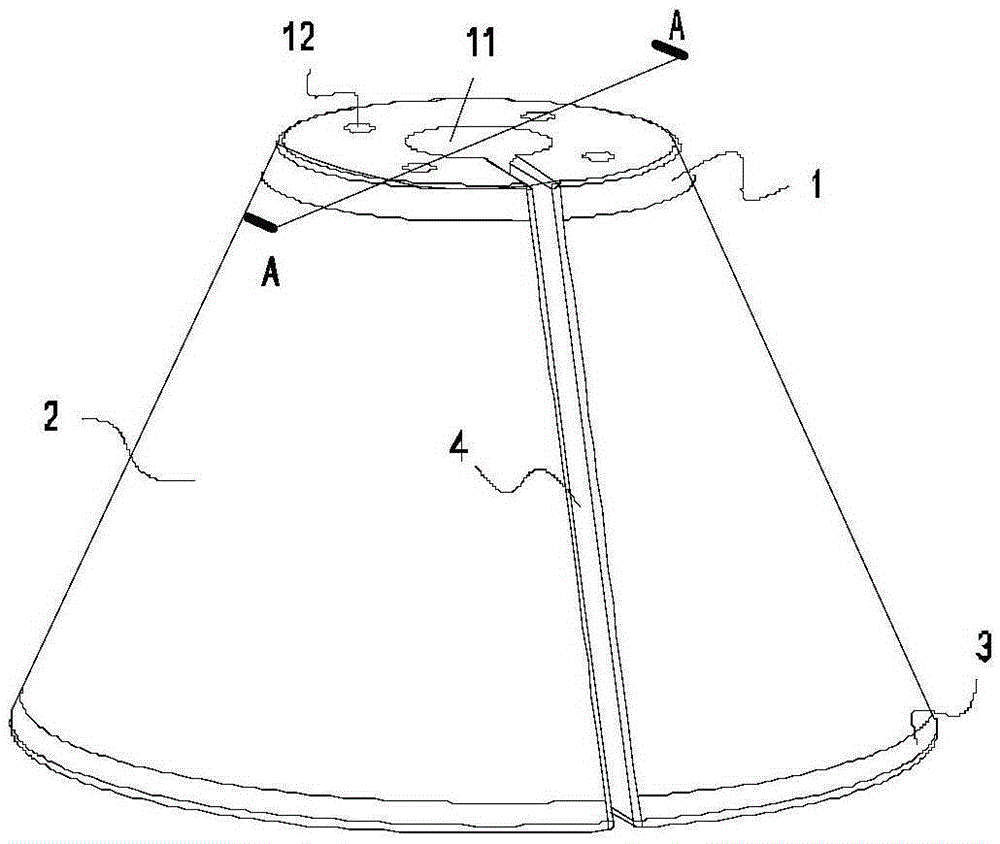

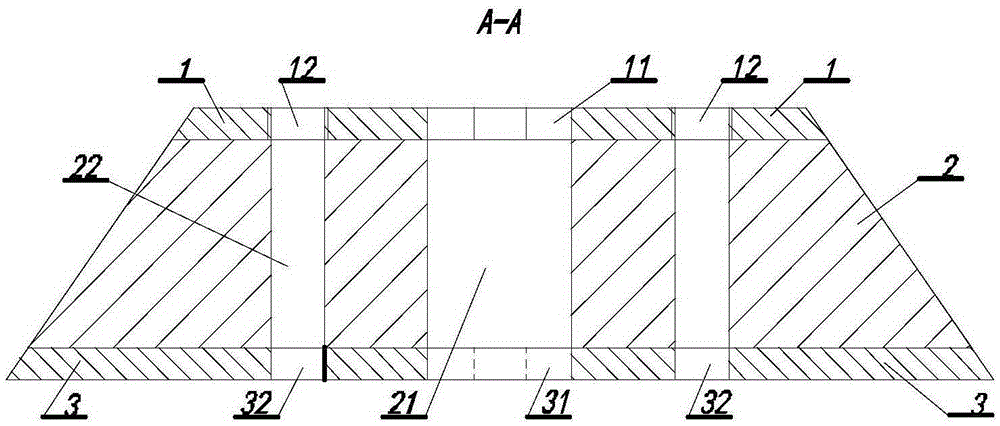

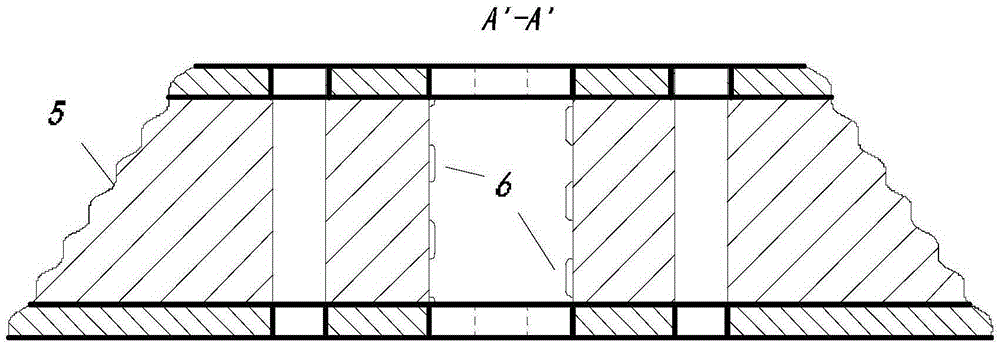

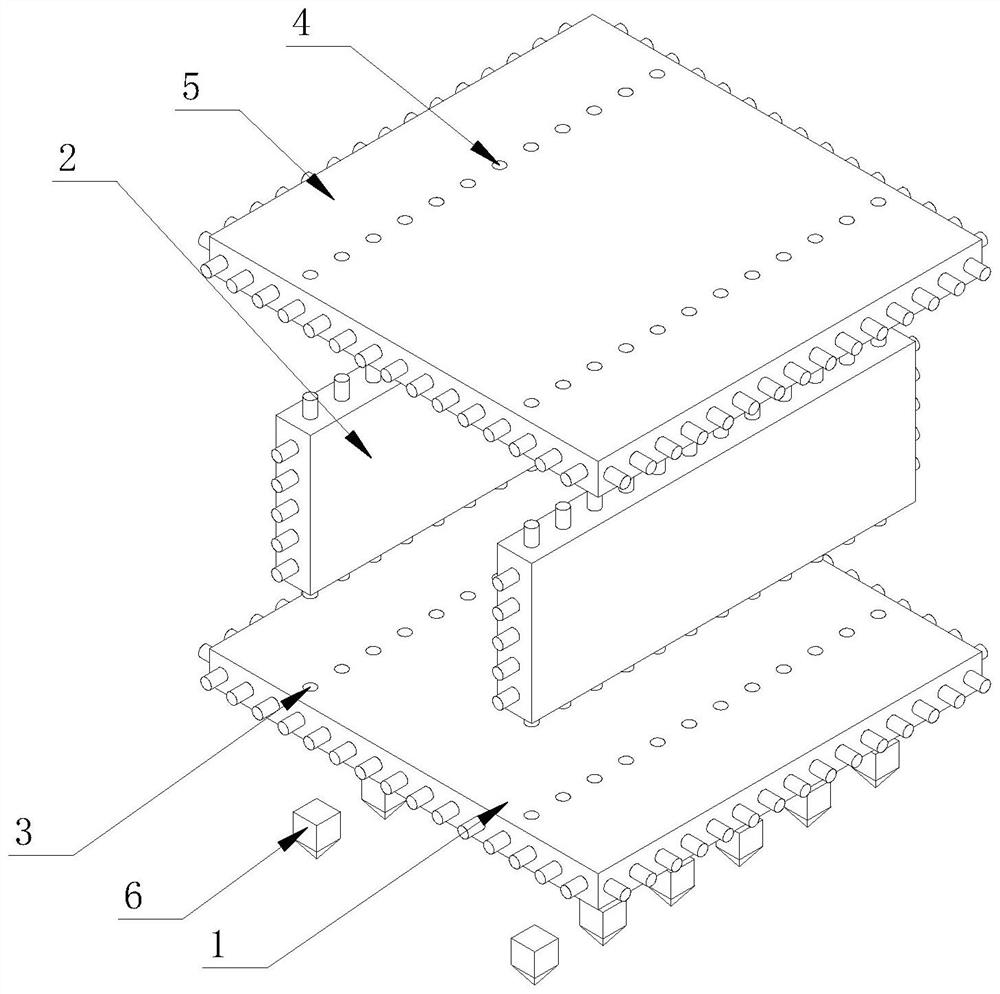

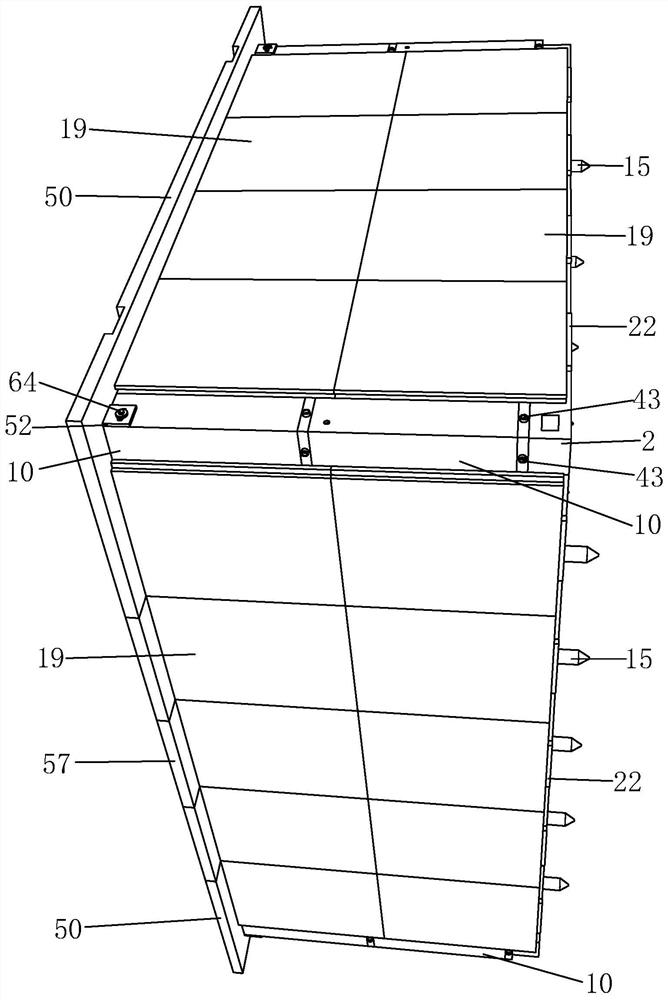

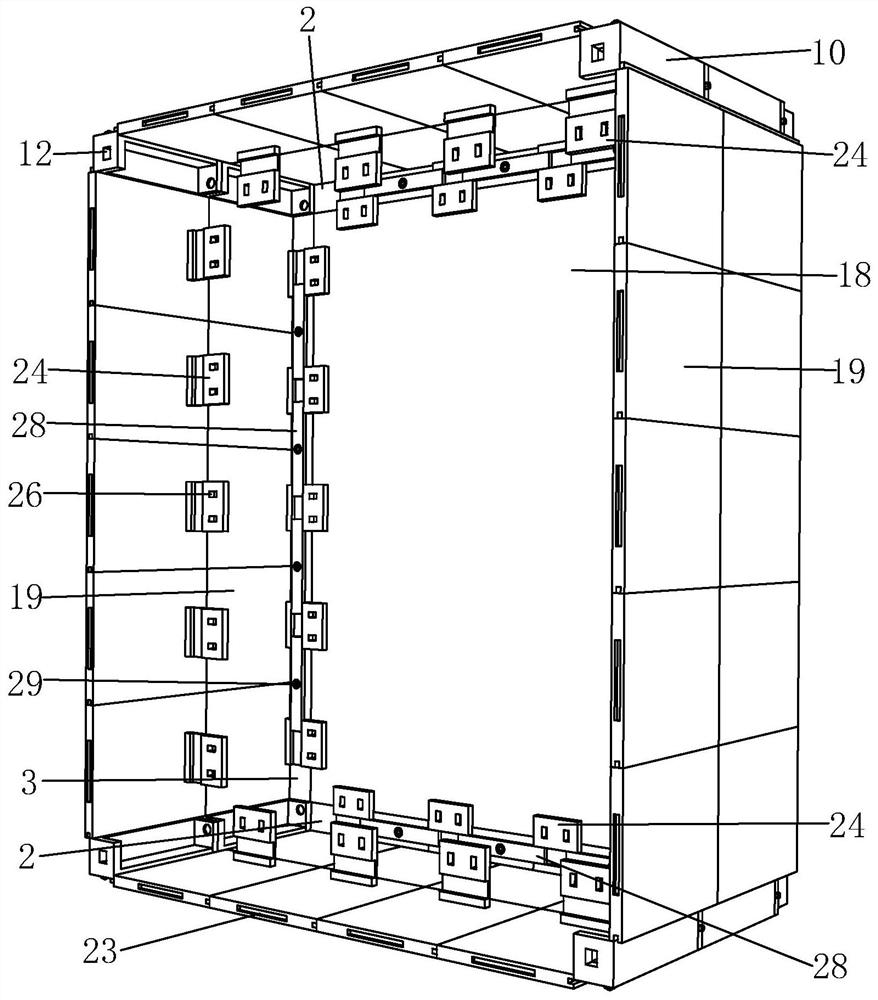

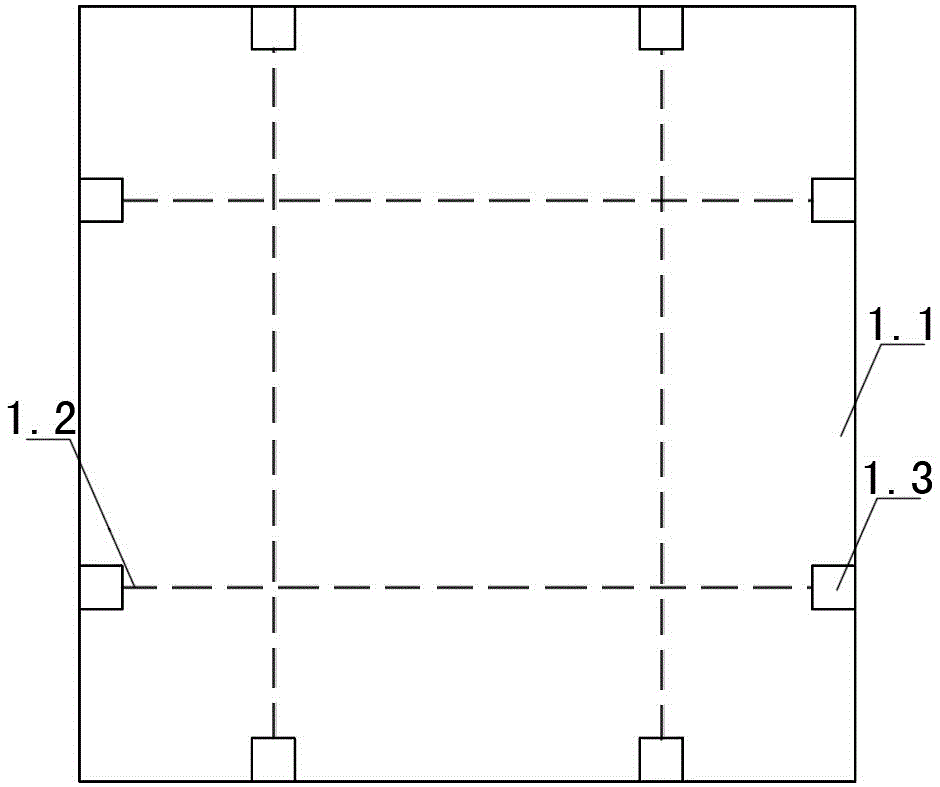

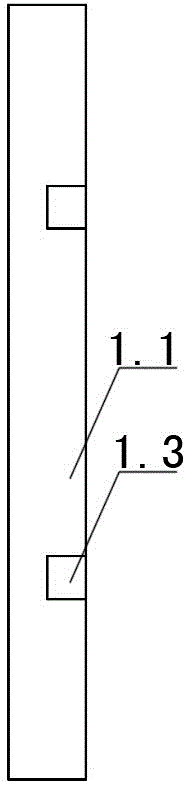

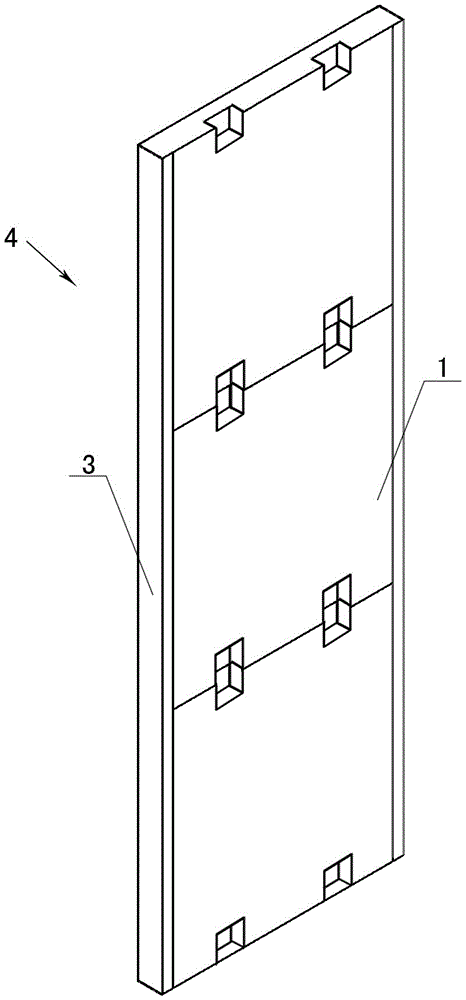

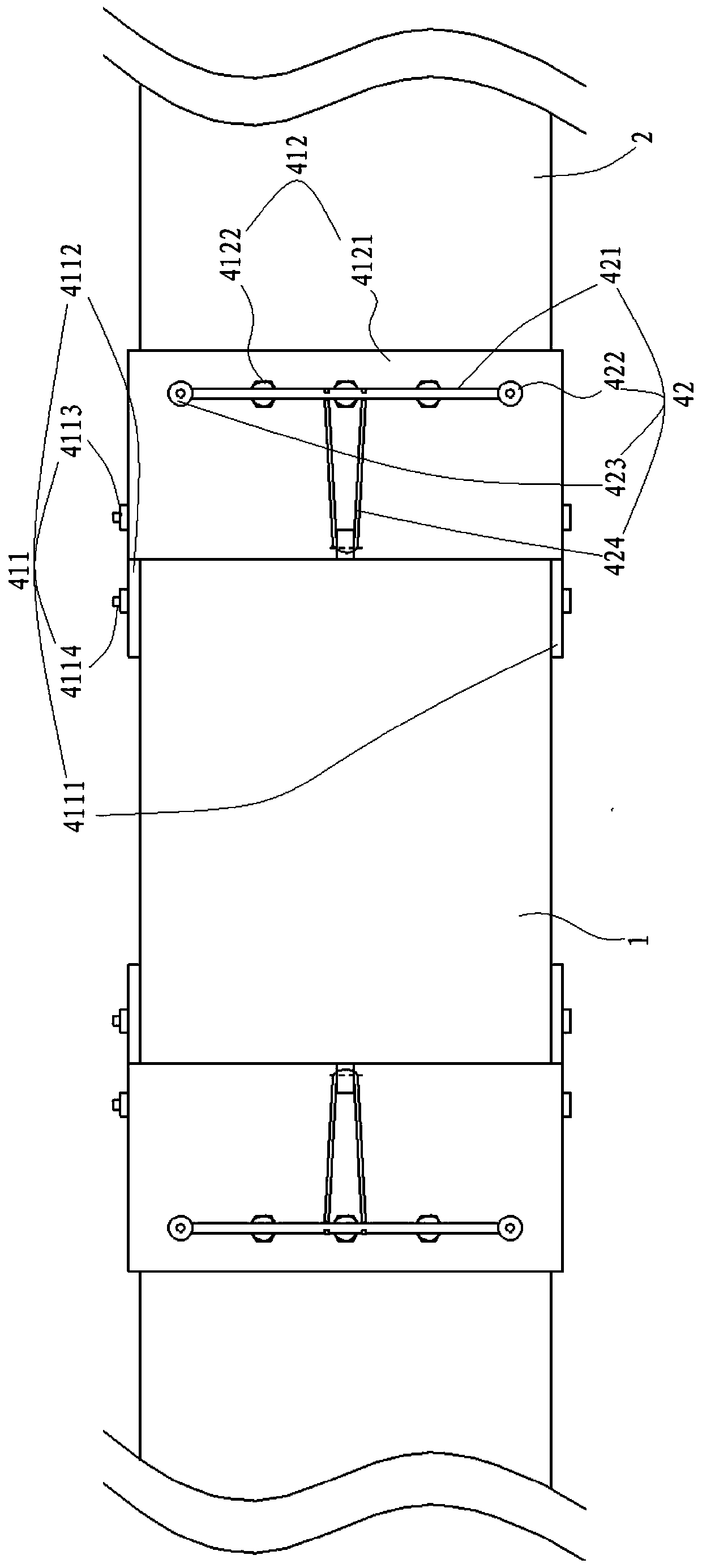

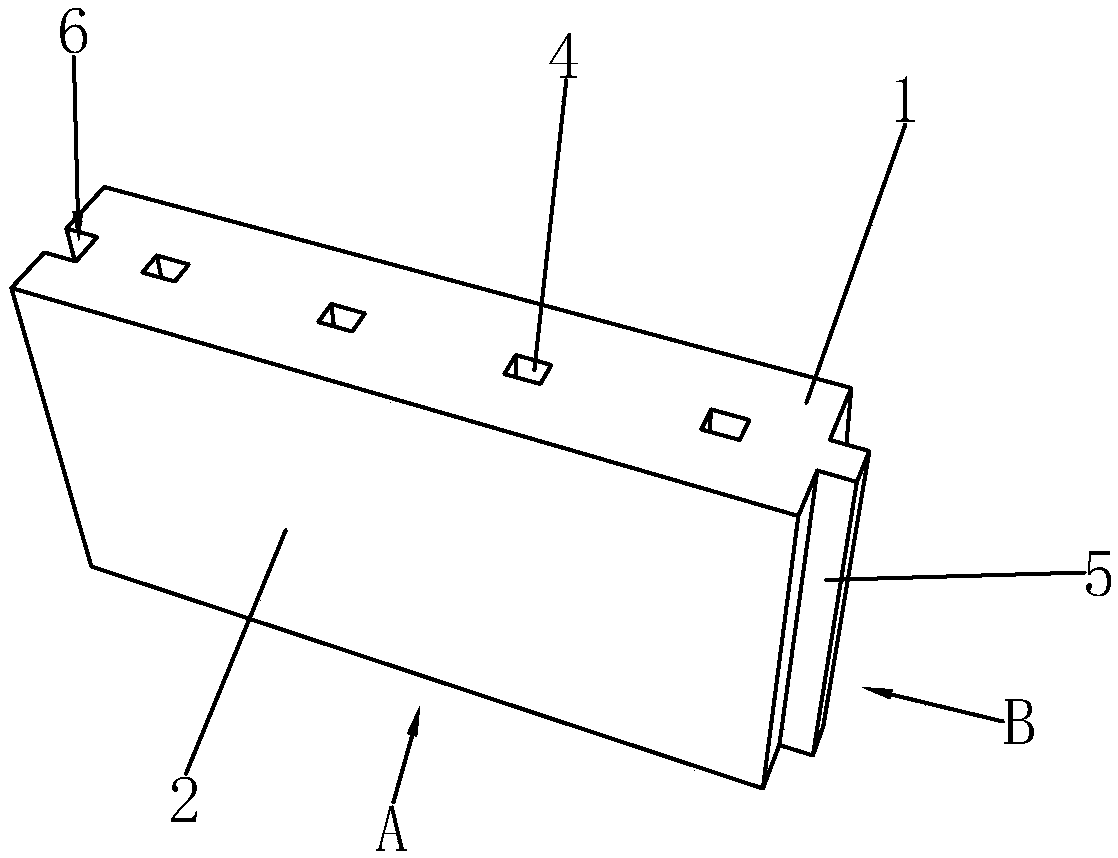

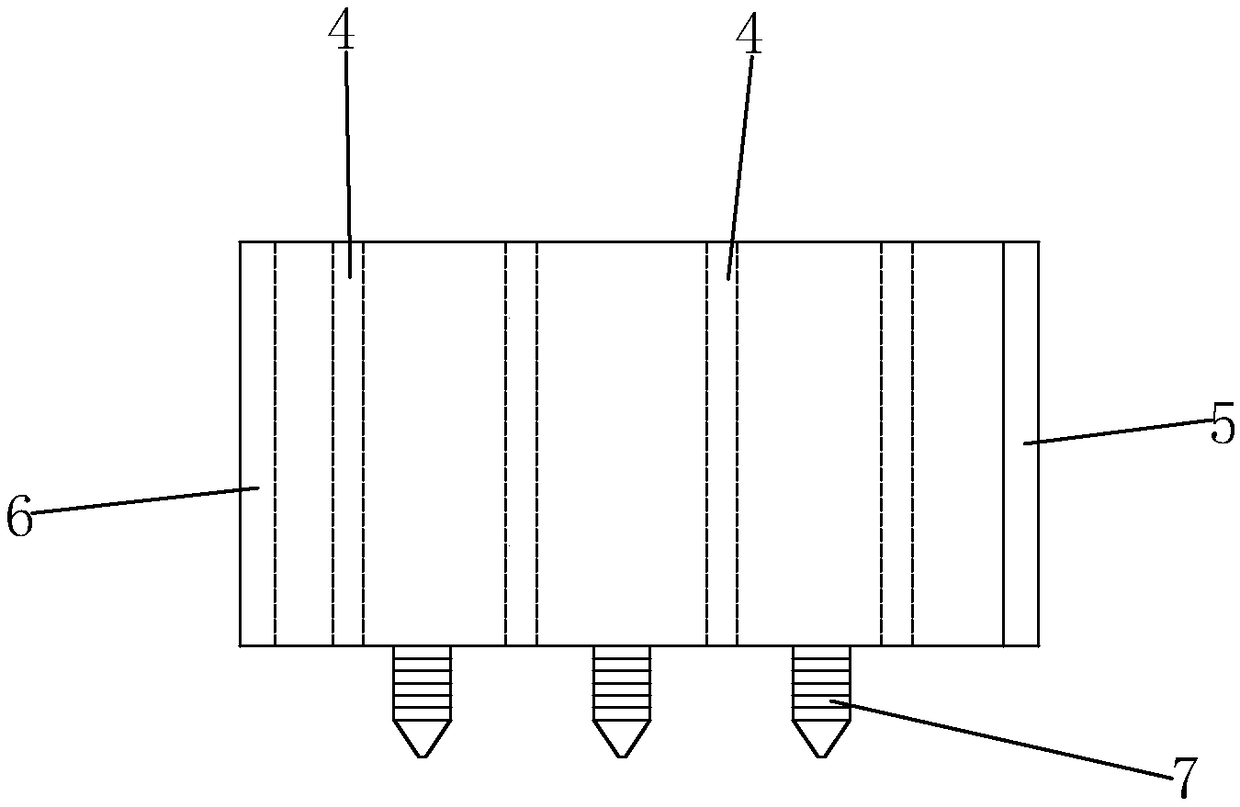

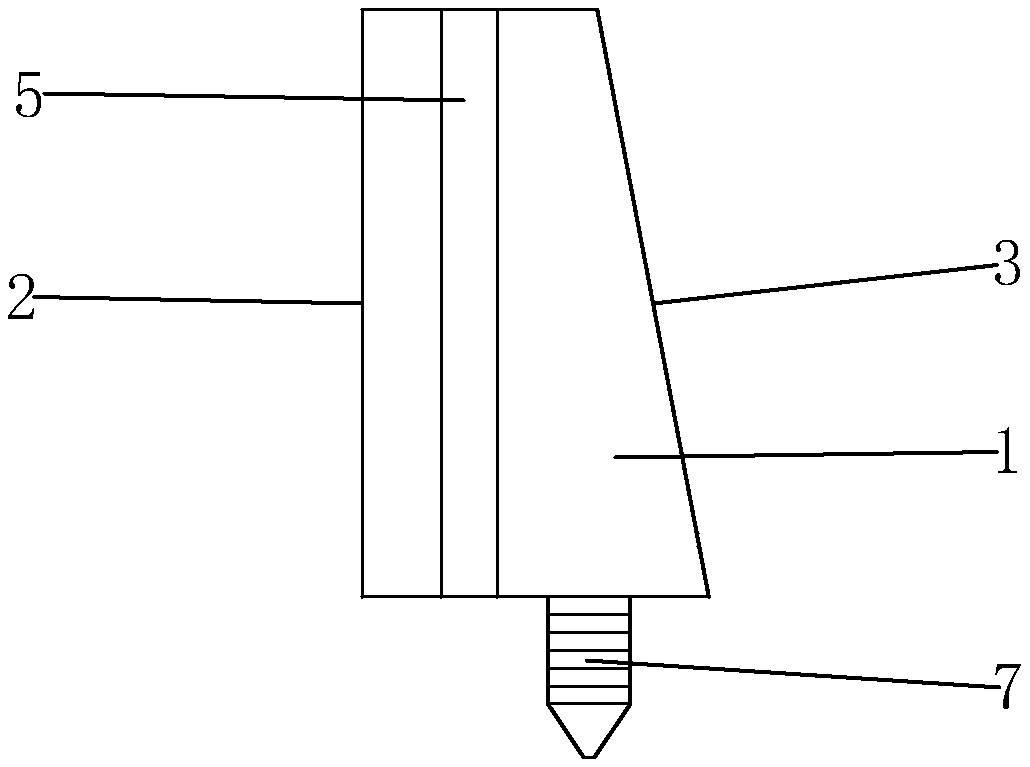

Unit type lightweight ribbed partition and construction method thereof

ActiveCN104594531ALightweight insulationMeet functional requirementsWallsThermal insulationUnit type

The invention discloses a unit type lightweight ribbed partition and a construction method thereof. The partition is connected between a roof and a ground and is composed of at least one partition board; an upper end of the partition board is fixedly connected to the roof through at least two F-shaped clips, and a lower end of the partition board is fixedly connected to the ground through at least two U-shaped clips; the F-shaped clips are horizontally arranged, the straight tail parts of the F-shaped clips are fixed with the roof through bolts, and the head ends thereof with clip slots are clamped at the two sides of the end side of the partition board; the U-shaped clips are vertically arranged, and the openings of the slots of the U-shaped clips are upward; the bottom parts of the U-shaped clips are connected to the ground through bolts, the slots of the U-shaped clips are clamped at the two sides of the end side of the partition board; the single partition board is formed by splicing three partition units to achieve the effects of light weight, heat preservation, thermal insulation and sound insulation. During construction, splicing the prefabricated partition board units into the complete partition or an infilled wall is only needed, thus, the construction speed is obvious faster than that of the traditional partitions, the construction is simple and convenient, the efficiency is high, and the quality control on site is benefited.

Owner:北京振利节能环保科技股份有限公司

Plugging device for cable hole

Owner:GUANGZHOU PANYU CABLE WORKS

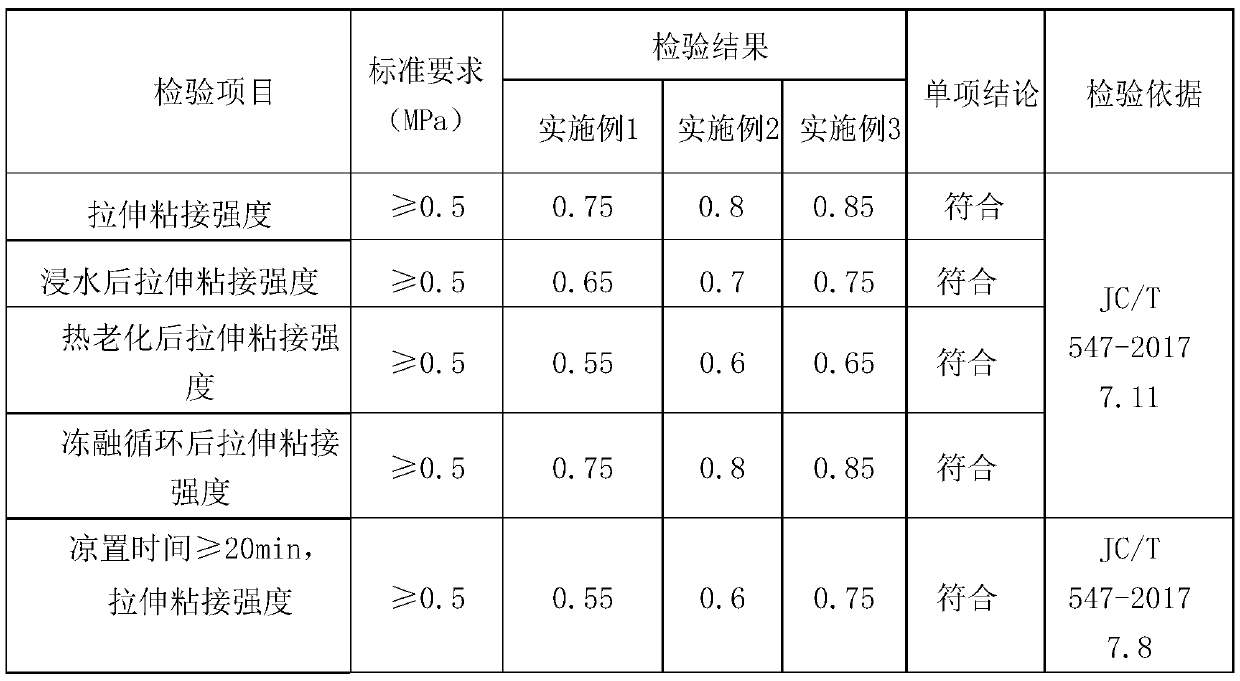

Ceramic tile binder, preparation method and using method

InactiveCN110054449AImprove general performanceGood flexibilityBuilding constructionsCelluloseMaterial consumption

The invention discloses a ceramic tile binder which comprises, by weight, 30-35 parts of high-quality cement, 65-70 parts of filler, 0.15-0.35 part of cellulose ether and 0.5-1 part of redispersible adhesive powder. The ceramic tile binder is a nontoxic, odorless, pollution-free and environment-friendly product which emerges as development of building ceramic tiles require, and has the characteristics of being ultrastrong in binding, high in universality and flexibility, lasting in performance, supportive of fa ade construction, needless to fix, supportive of premixing and environment-friendlyin use; the ceramic tile binder has the advantages of being high in binding strength and construction efficiency and saving in material consumption when in use, and the defects of weak binding force,poor durability, easiness in falling and high construction material consumption when cement is directly used for binding are overcome thoroughly.

Owner:曹磊

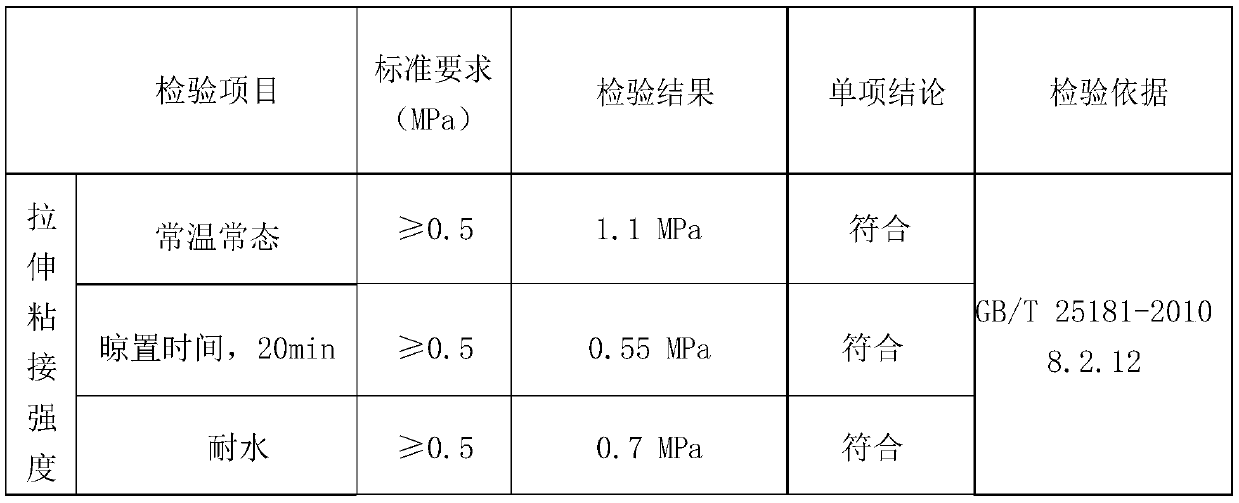

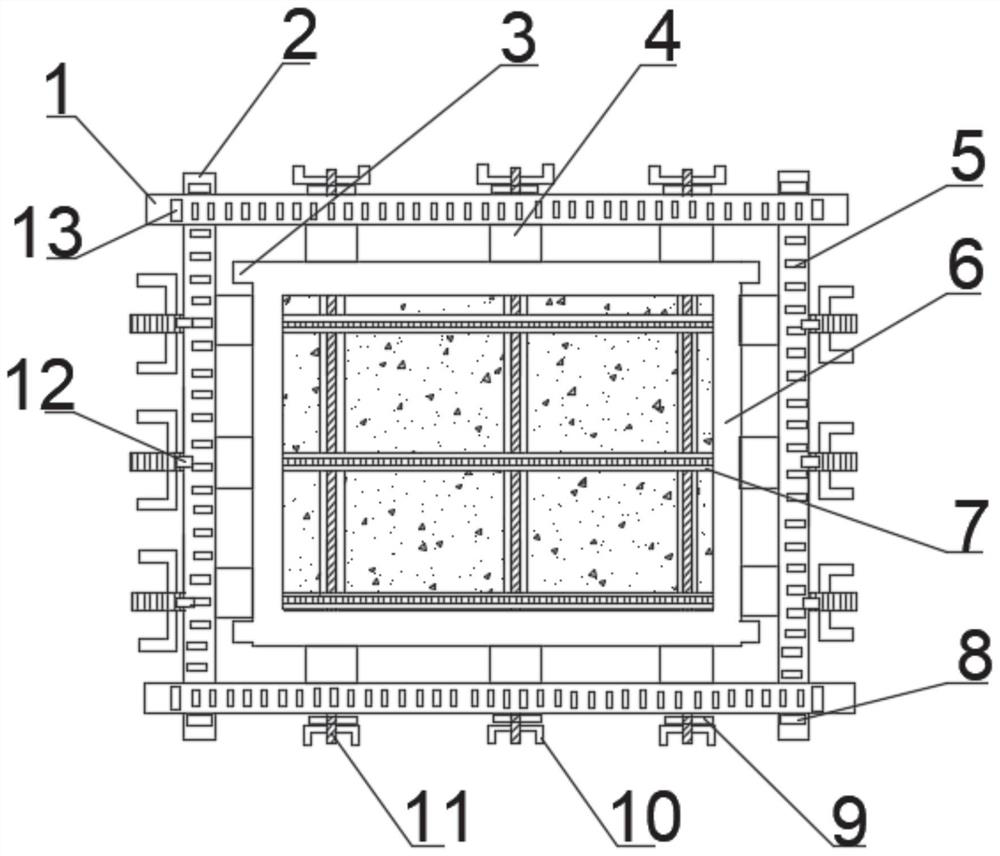

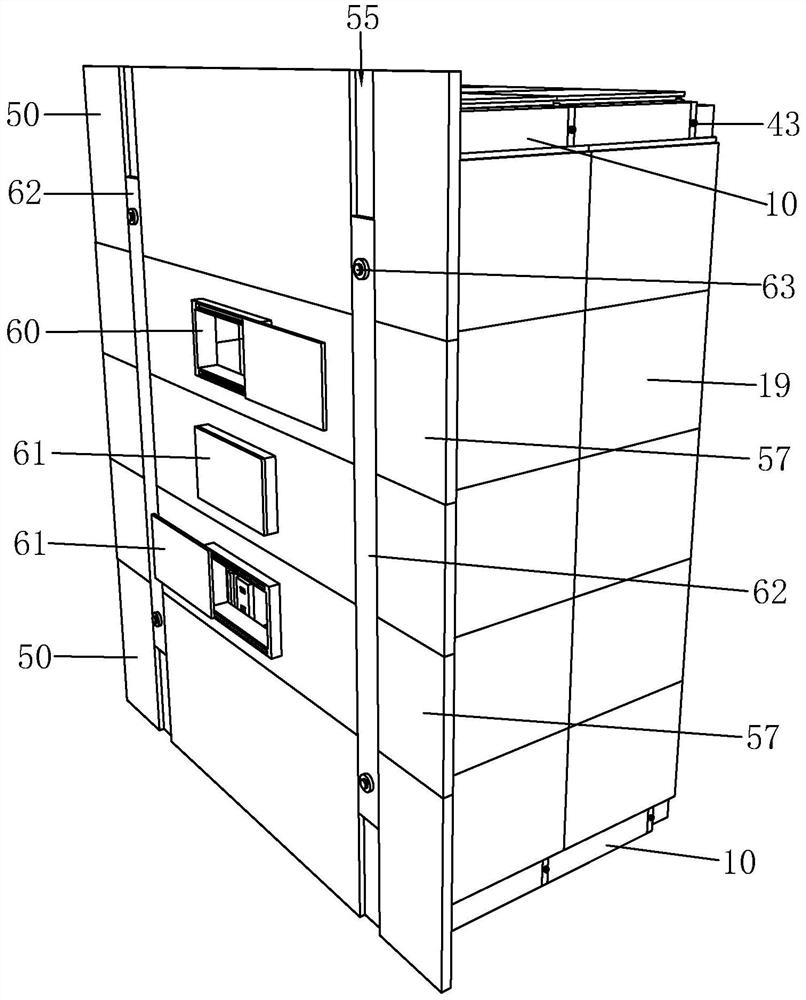

High and large concrete formwork reinforcing system

InactiveCN111779270AAvoid cold seamsAvoid wrong stationAuxillary members of forms/shuttering/falseworksWood plankSteel casting

The invention discloses a high and large concrete formwork reinforcing system. The high and large concrete formwork reinforcing system comprises two first channel steels, second channel steels, woodenboards, a steel formwork and split bolts. The edge portion of the steel formwork is provided with reinforced edges. The wooden boards are vertically arranged on the periphery of the steel formwork atintervals. The two opposite sides of the periphery of the wooden boards are transversely provided with the two first channel steels. The two ends of the two first channel steels are wrapped through fixed blocks. The two first channel steels are fixed through first fixed plates. The second channel steels are transversely arranged on the other two sides of the periphery of the wooden boards. The second channel steels are inserted in the gap between the two first channel steels. The second channel steels are fixed through second fixed plates. The corresponding positions of the wooden boards arefurther reinforced through split bolts. Each split bolt comprises gaskets, a cast steel nut and a screw rod, wherein the gaskets include the first gasket and the second gasket; the first gasket is square, and the second gasket is arc-shaped. The first gaskets are arranged on the corresponding sides of the first channel steels, and the second gaskets are arranged on the corresponding sides of the second channel steels. The high and large concrete formwork reinforcing system effectively improves the appearance quality and has high practicality.

Owner:SHANDONG WATER CONSERVANCY CONSTR ENG CO LTD

High strength and toughness magnesium alloy material construction template and preparation method thereof

InactiveCN111979460AGuaranteed mechanical propertiesReduce iron contentForming/stuttering elementsSolution treatmentUltimate tensile strength

The invention discloses a high strength and toughness magnesium alloy material construction template and a preparation method thereof. The high strength and toughness magnesium alloy material construction template includes: by mass, 6.6%-7.4% of aluminum, 1.7%-2.4% of tin, 0.15%-0.35% of manganese, less than or equal to 0.003% of iron, less than or equal to 0.02% of silicon, less than or equal to0.002% of nickel and the balance magnesium. The preparation method includes S1 sand blowing preheating, S2 smelting, S3 vacuum die-casting and S4 solid solution treatment. The magnesium alloy materialconstruction template obtained by the invention has the characteristics of high strength, good toughness, light weight, large plate surface width, integral molding without welding, convenient construction, long service life, corrosion resistance, energy saving, environmentally friendly, high turnover times, high construction quality and high construction efficiency; and the preparation method optimizes a vacuum die-casting process and a solid solution treatment process, and can effectively ensure the mechanical properties of products.

Owner:湖南云轮科技有限公司

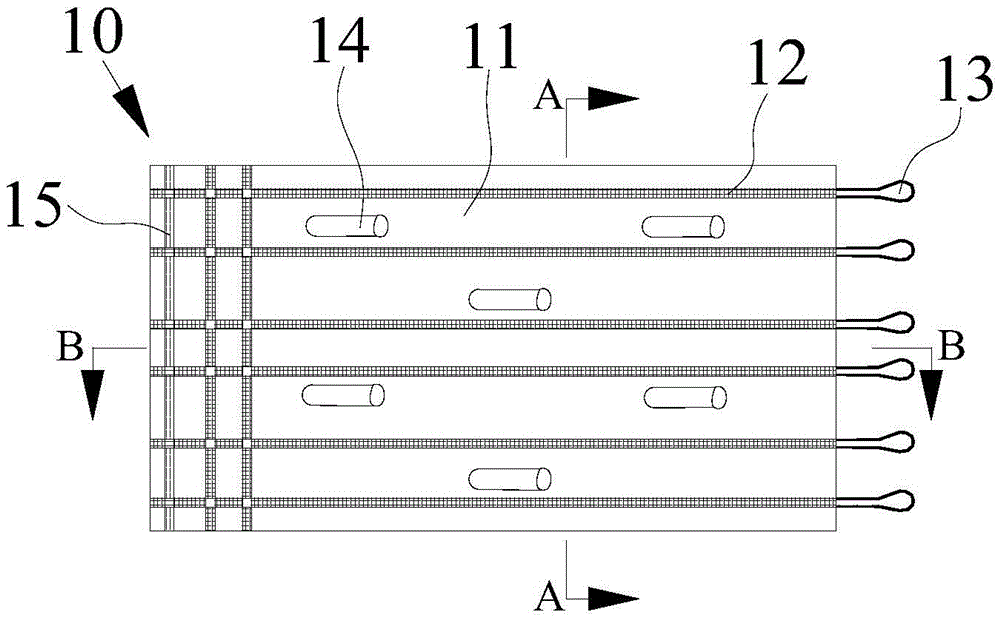

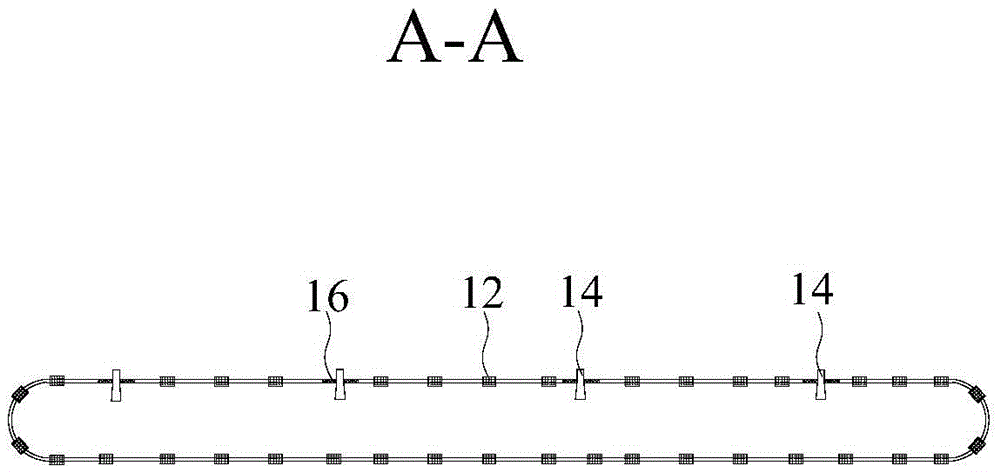

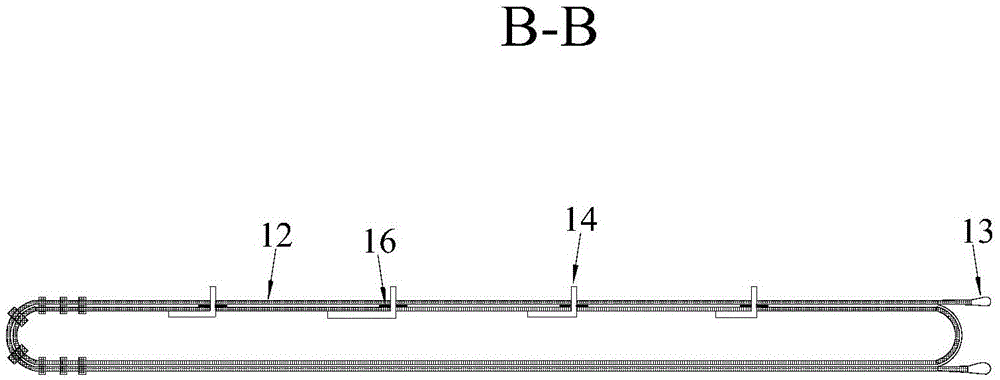

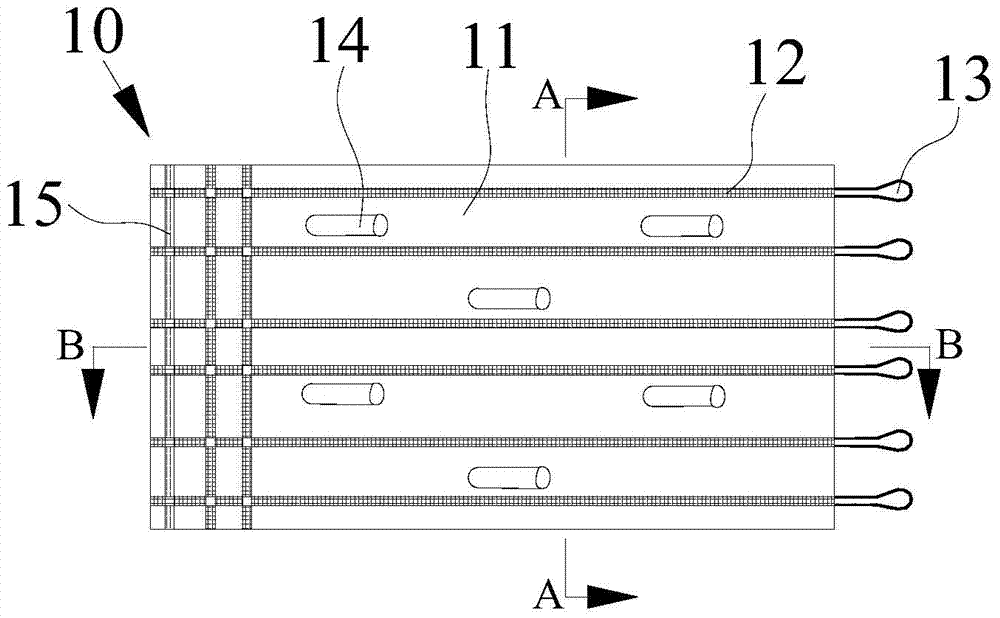

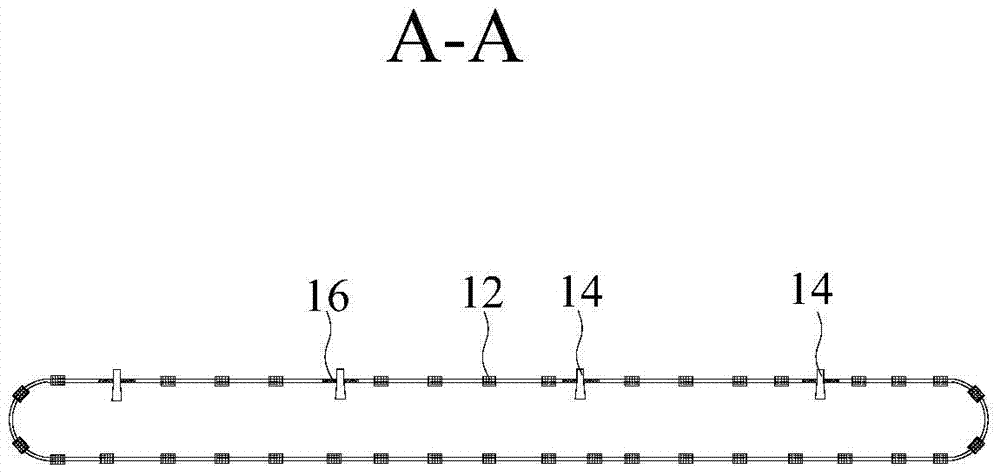

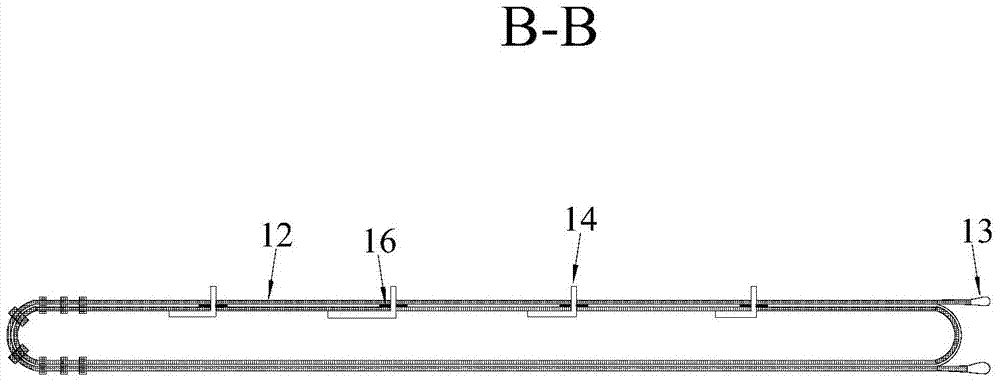

Reinforcement mud filling pipe bag

The invention discloses a reinforcement mud filling pipe bag. The reinforcement mud filling pipe bag comprises a bag body. The bag body is formed by sewing double-layer bag cloth. Reinforcement belts are evenly sewn on the bag body and located outside the bag body, and the double-layer bag cloth is connected into a whole through the reinforcement belts. A plurality of slurry inlets are distributed in the bag body and are distributed in a plum blossom manner. Slurry inlet hoses are arranged at the slurry inlets and inserted in the slurry inlets and are fixed with the double-layer bag cloth in a sewing manner. The slurry inlet hoses are in an inverted wedge shape. The outer diameter of the parts, located in the bag body, of the slurry inlet hoses is larger than that of the parts, located outside the bag body, of the slurry inlet hoses. The reserved length of the parts, in the bag body, of the slurry inlet hoses is 1.0-1.5 m, and the reserved length of the parts, outside the bag body, of the slurry inlet hoses is 0.5-1.0 m. A lantern ring is arranged at the tail of the bag body. The double-layer bag cloth is adopted in the reinforcement mud filling pipe bag, the double-layer bag cloth is connected into a whole through the reinforcement belts, the tensile strength of the whole mud filling pipe bag is improved, and the reinforcement mud filling pipe bag can be used for large arrangement ship operation. The bag laying position precision is greatly improved, the continuous work capability is high, and construction efficiency is high.

Owner:安徽水利开发有限公司

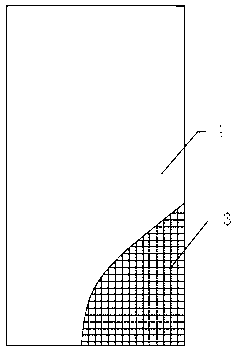

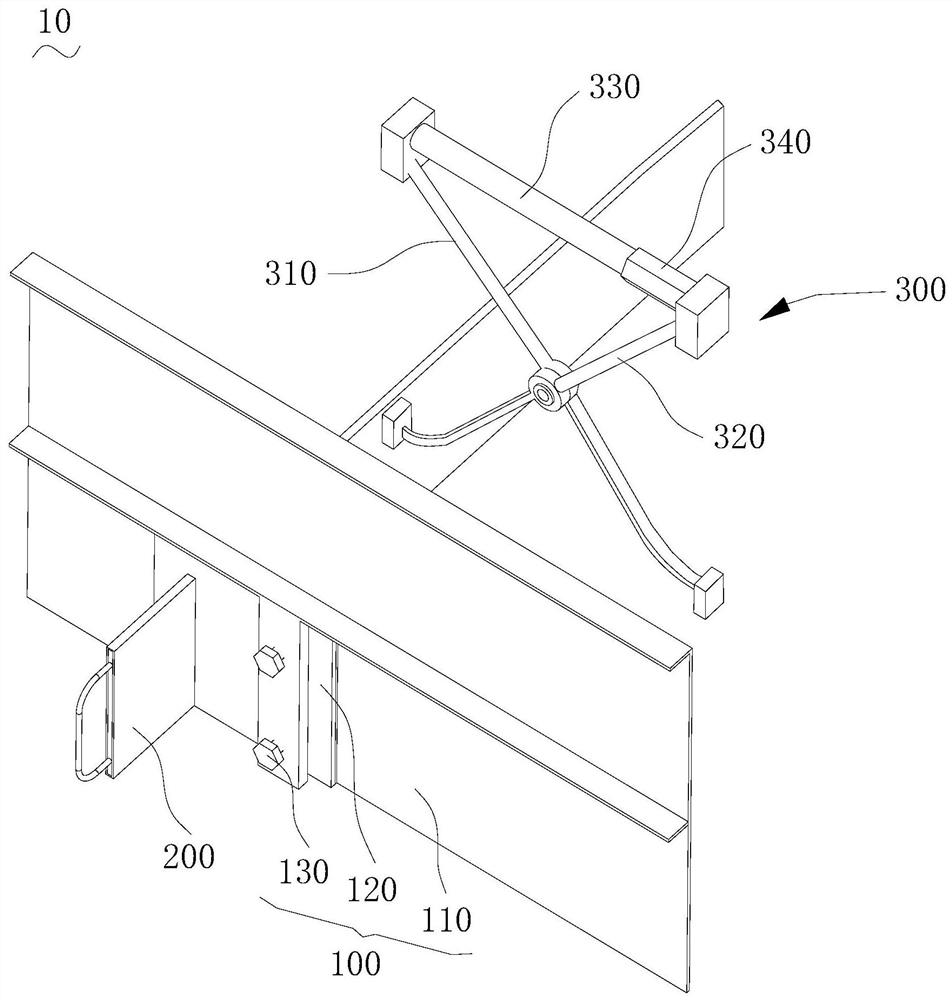

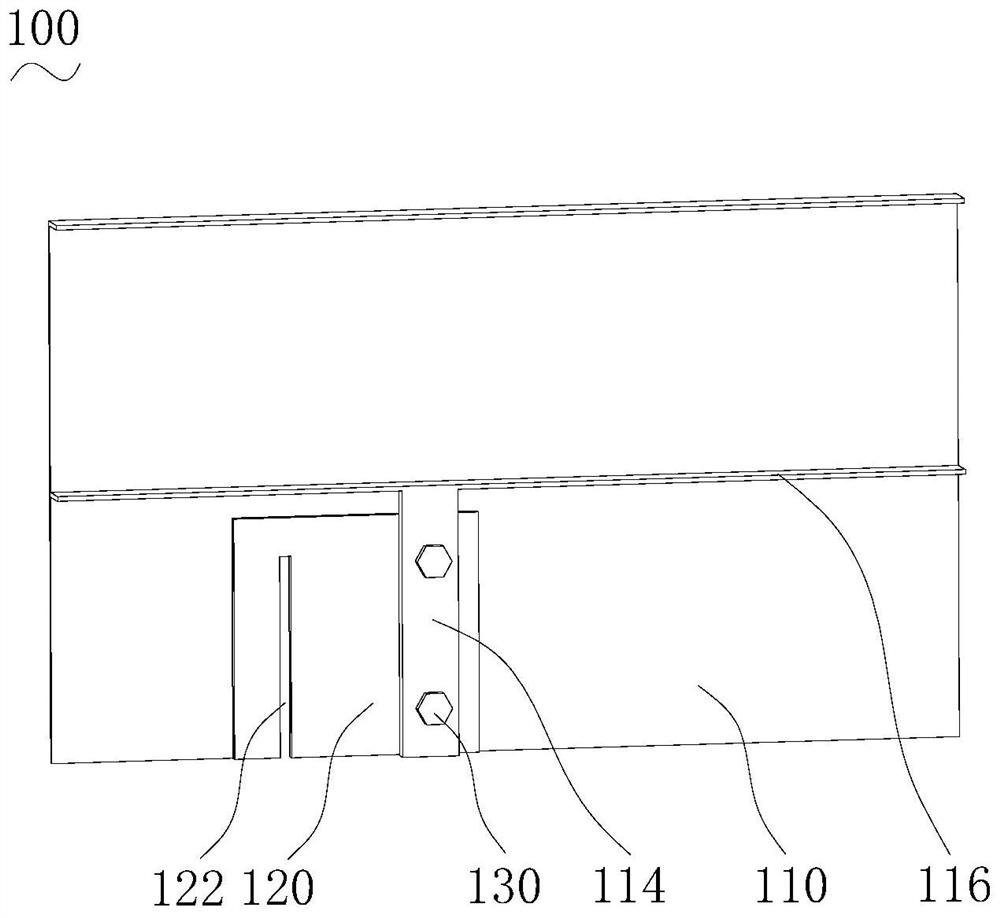

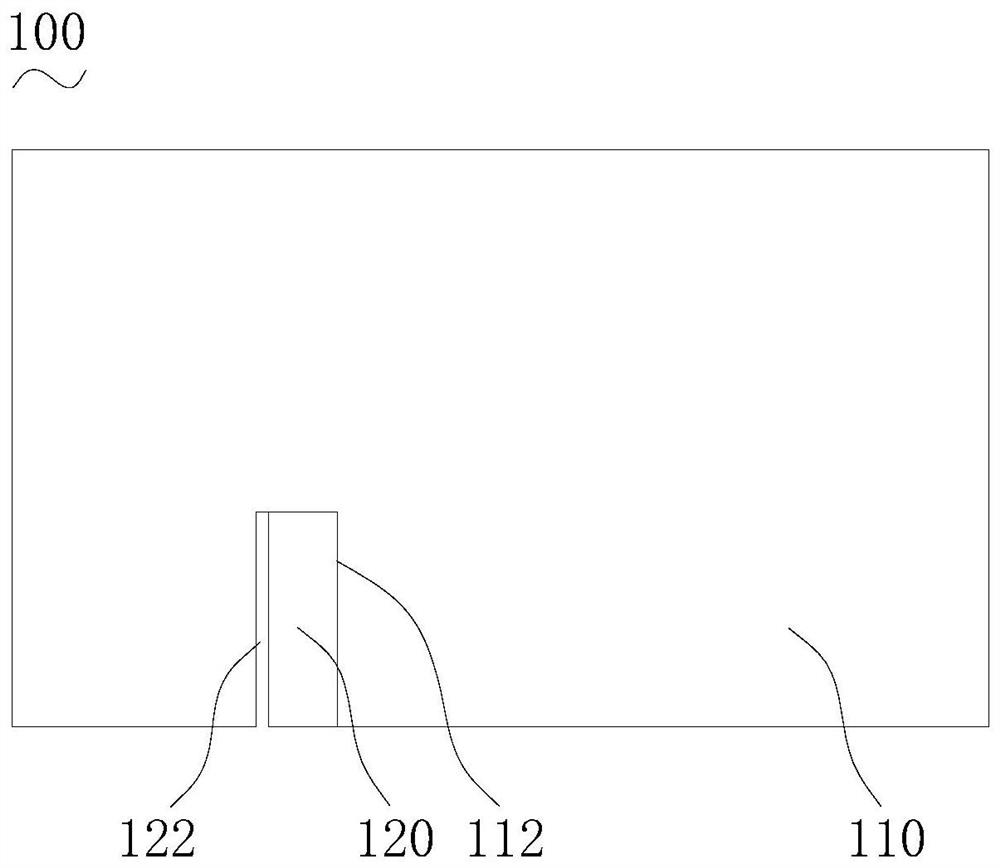

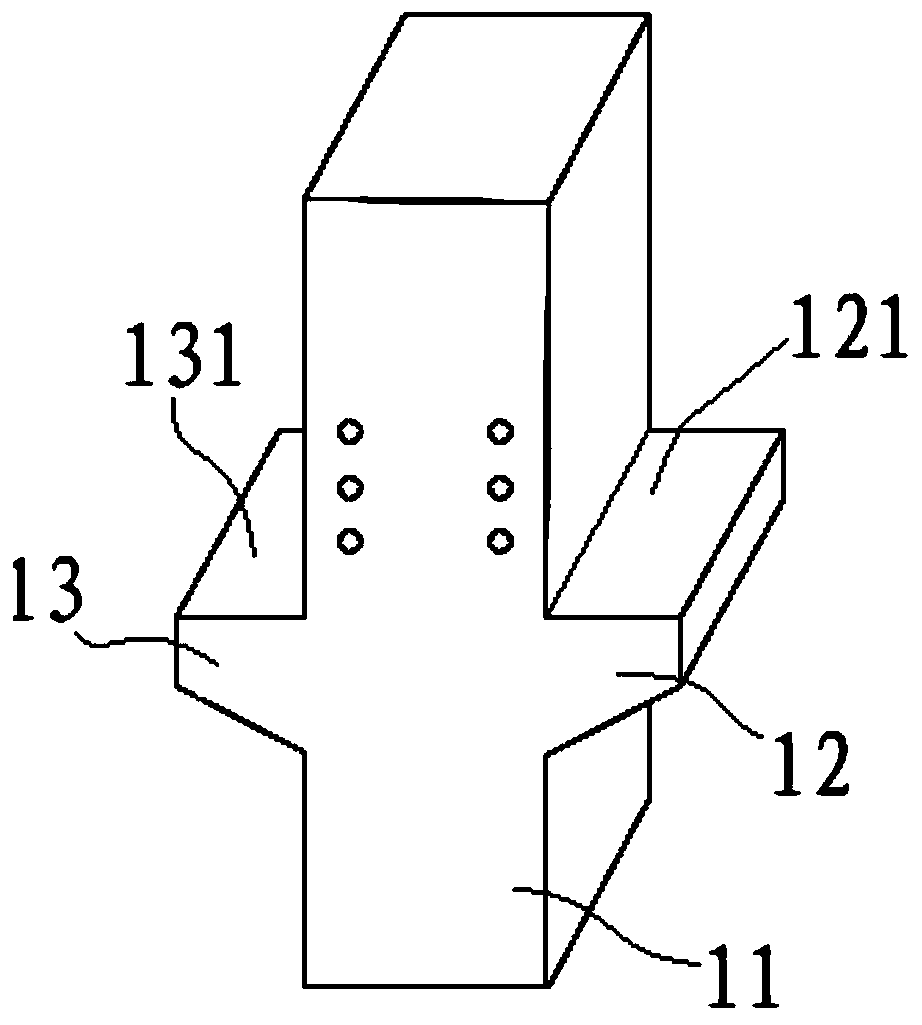

Post-cast strip pouring supporting system and post-cast strip pouring construction method

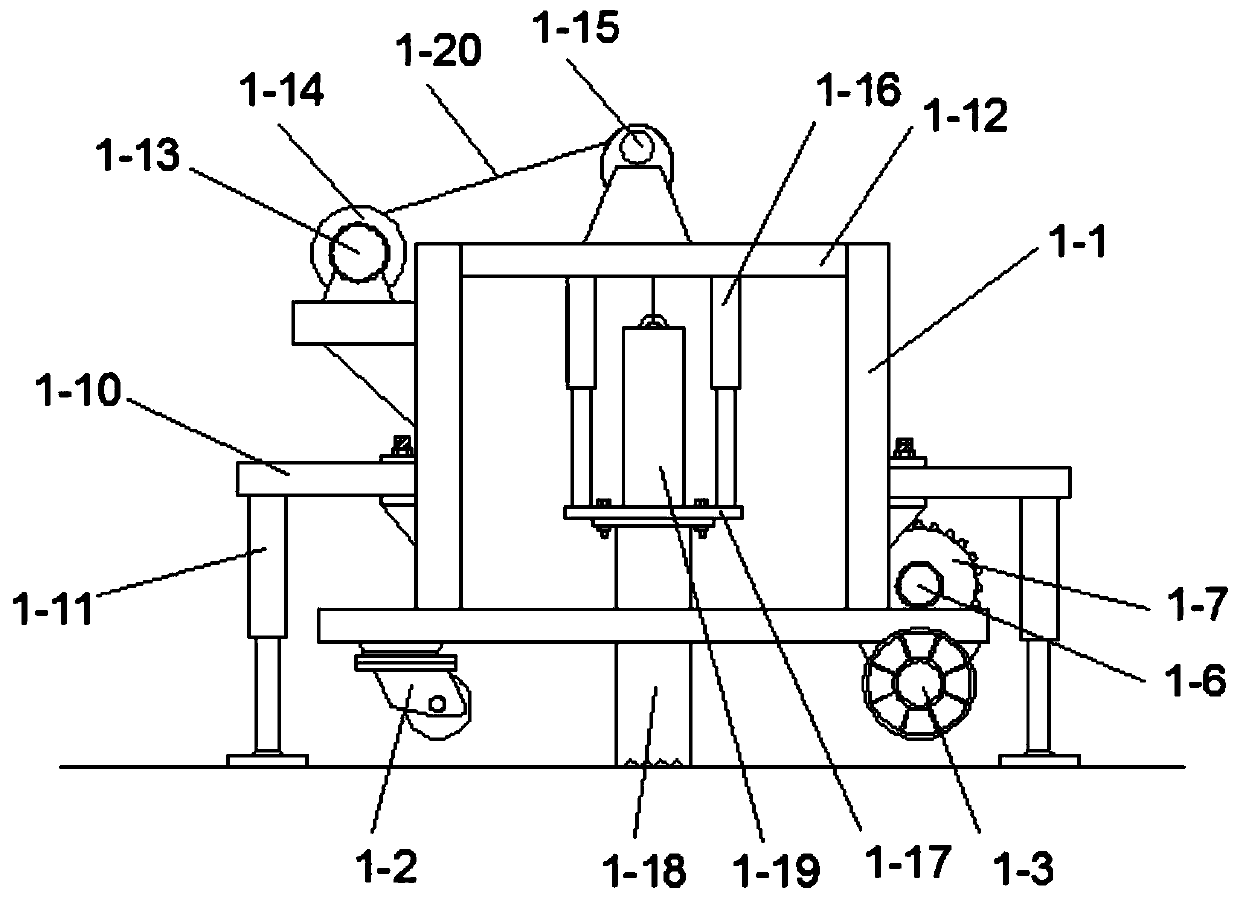

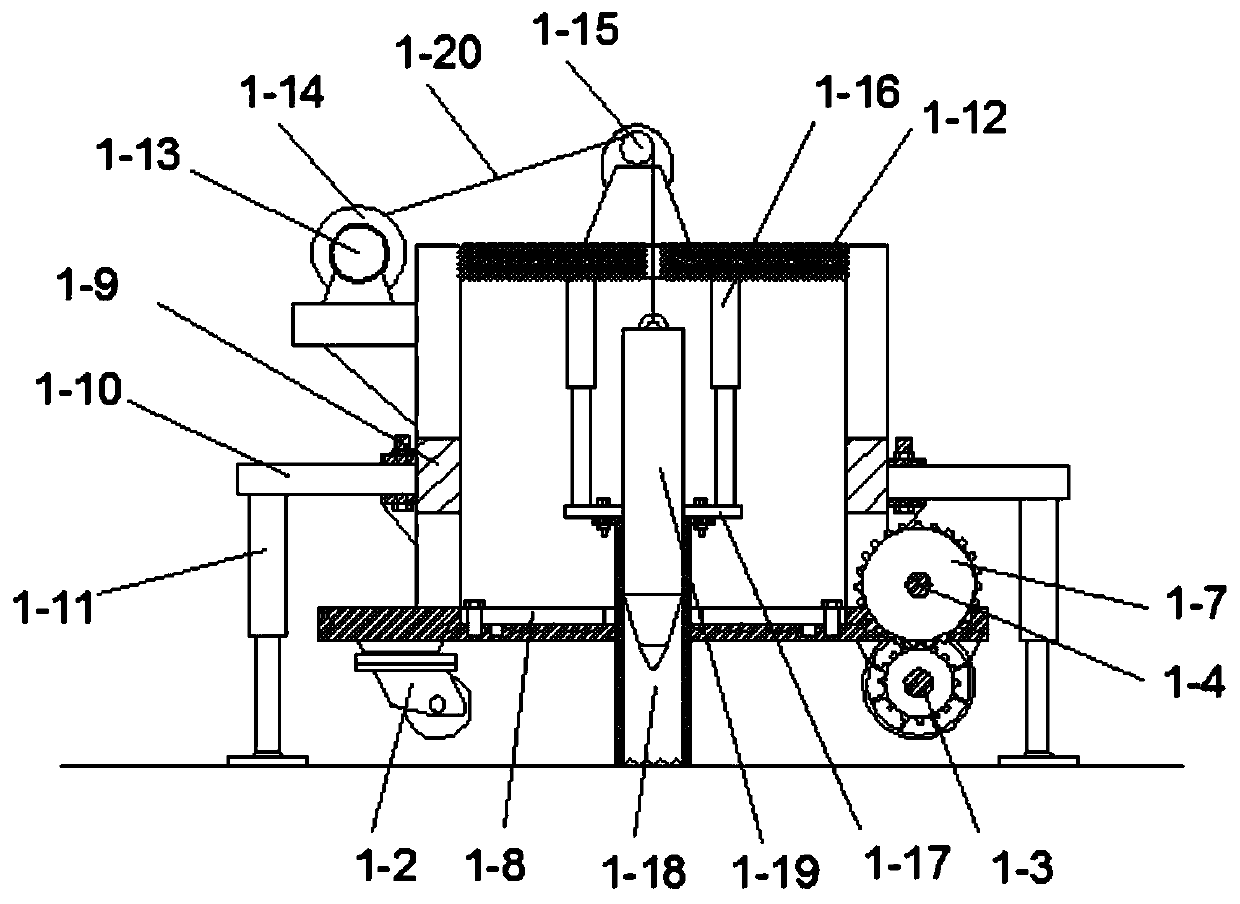

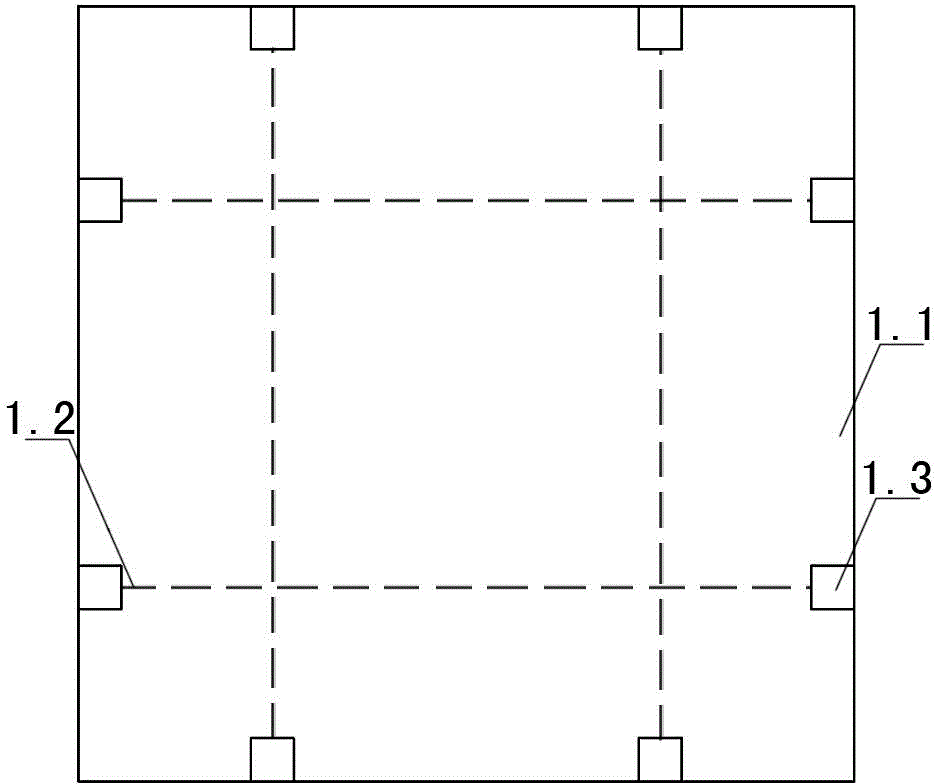

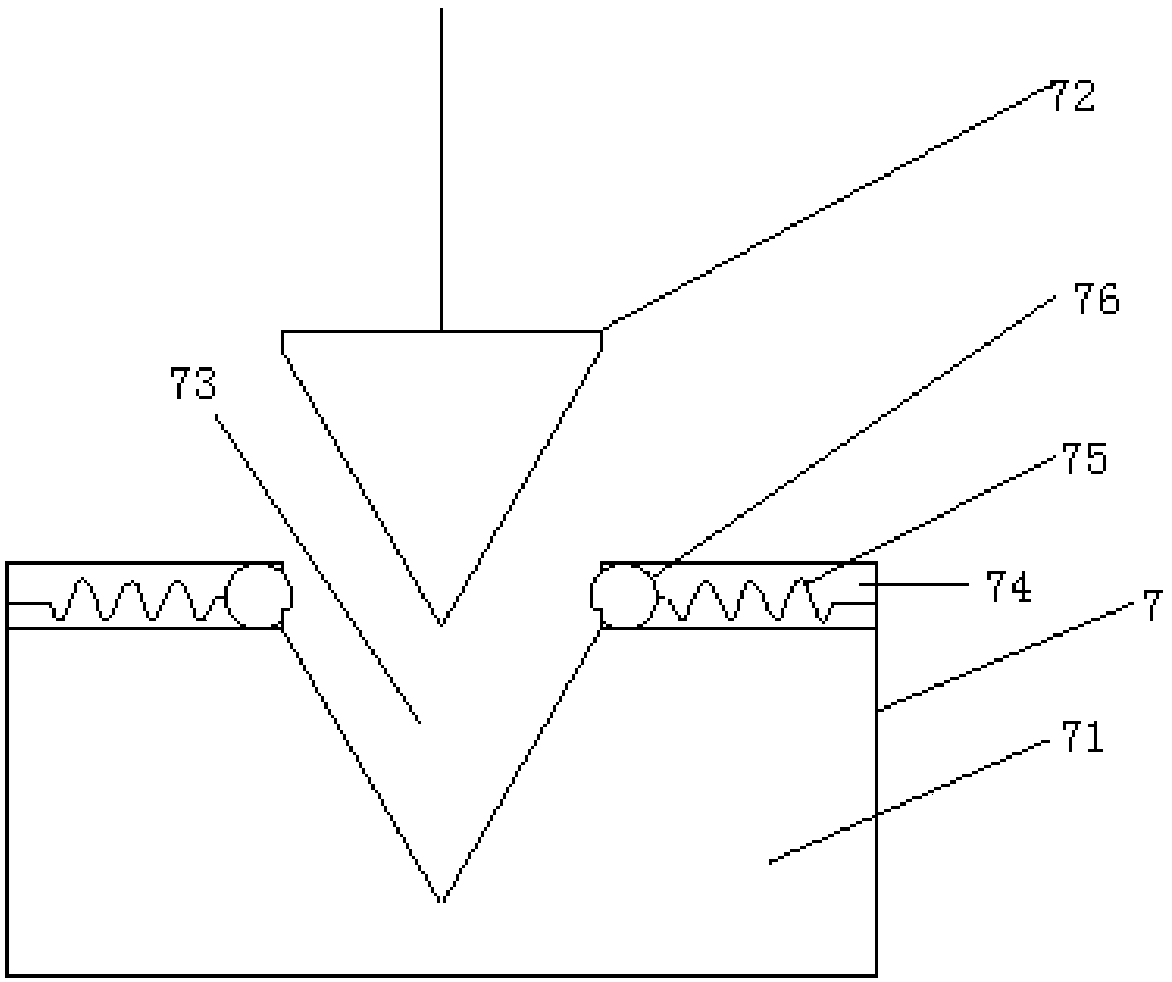

PendingCN111705565AEasy to removeStrong construction efficiencyRailway track constructionSupporting systemConstruction engineering

The invention provides a post-cast strip pouring supporting system and a post-cast strip pouring construction method, and belongs to the technical field of rail engineering. The post-cast strip pouring supporting system comprises a limiting side mold, an inserting plate and a supporting assembly. Technical effects are that: before the self-compacting concrete filling layer is poured, an insertingplate is arranged on the post-cast strip to block the previous self-compacting concrete filling layer, and the post-cast strip and the lower space of the next track plate form a communicating structure; when the post-cast strip is poured, pouring of the self-compacting concrete filling layer is synchronously achieved, pouring does not need to be conducted after the self-compacting concrete fillinglayer meets the strength requirement; the time difference between the post-cast strip and the next track plate is reduced, the construction efficiency is improved, and continuous line production canbe achieved; and meanwhile, the limiting side molds and the supporting assemblies are used for achieving position fixing and position adjusting of the inserting plates, the supporting assemblies can avoid steel bars between the adjacent track plates, the operability is high, the problem that a traditional end mold is difficult to take out is solved, the dismounting and mounting are easy and convenient, the turnover rate is high, and the construction difficulty is reduced.

Owner:中铁十七局集团第三工程有限公司

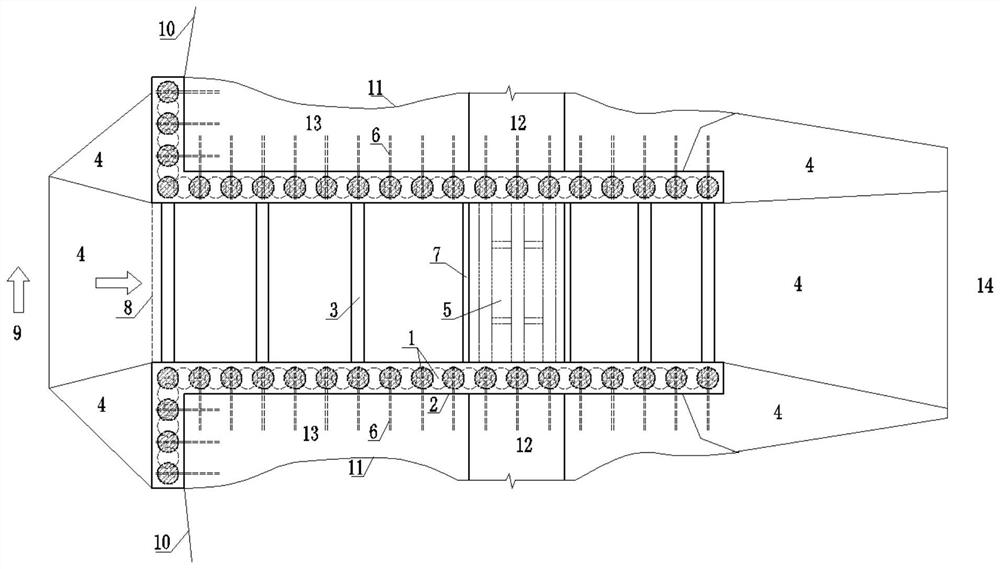

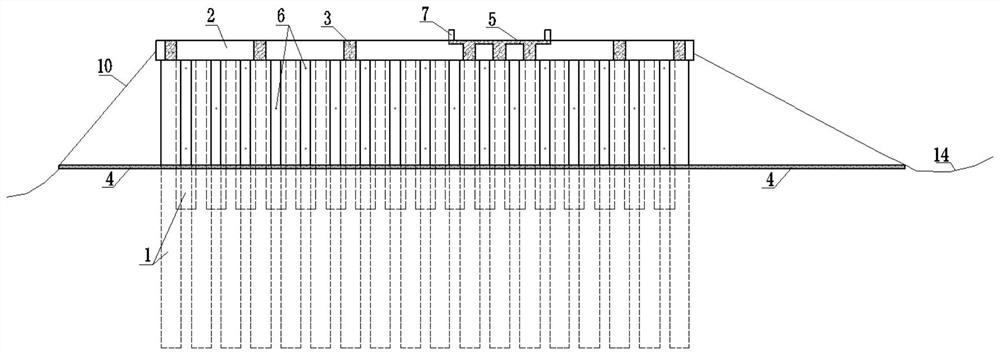

Reinforcement method of reinforced concrete box type roadbed

InactiveCN114707201AImprove structural strengthImprove integrityGeometric CADDesign optimisation/simulationReinforced concreteTrackway

The invention discloses a reinforcement method for a reinforced concrete box-type roadbed, and particularly relates to the technical field of constructional engineering. A transversely closed rectangular cavity structure is formed by a bottom plate, a vertical plate and a top plate through reserved steel bars and corresponding upper holes or lower holes; according to top plate midspan bending moment, double-rib pavement design judgment and corresponding reinforcement calculation synchronously, fixed end bending moment calculation and midspan bending moment calculation of a vertical plate are matched, and a base net counter-force design value is adaptively calculated by a bottom plate aiming at the overall upper load of the vertical plate and the top plate, so that reinforcement of the bottom plate is completed, and a cavity structure is integrally formed; the method has the advantages that the structure strength is good, the reinforcement strength is high in accuracy and reliability, the rectangular cavity structure constructed through the reinforcement method meets the bearing capacity requirement, the use function requirement and the construction requirement, and the method has the advantages of being economical, reasonable, good in integrity, high in construction efficiency and high in operability; and the engineering requirements on high-speed railway tracks in the new era are met.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Soft soil foundation diversion canal construction method for taking water from rivers

PendingCN113186878AControl deformationOptimize the amount of workArtificial water canalsBulkheads/pilesCofferdamStructure support

The invention discloses a soft soil foundation diversion canal construction method for taking water from rivers. The construction method comprises the following steps: (1) a soil retaining support structure formed by mutual occlusion of occluded cast-in-place piles is utilized; (2) the top ends of left bank cast-in-place piles and the top ends of right bank cast-in-place piles are connected into a whole through concrete top beams; (3) the left bank cast-in-place piles and the right bank cast-in-place piles are supported by using concrete diagonal supporting beams to prevent soil bodies on the two sides from moving inwards; (4) traffic bridges are arranged at the tops of the cast-in-place piles, and a frame structure type (through-road) diversion canal is formed through combination; and (5) excavation of a foundation pit between the cast-in-place piles is conducted, and finally bottom plate mold bag concrete construction is conducted. According to the construction method, the construction operation method that water is taken in the river, the occupied construction space is small, and a temporary construction cofferdam does not need to be built is achieved, the pile foundation and the traffic bridges are combined for design and construction, the construction speed is high, the construction period is shortened, the construction method is suitable for soft soil foundations, safety and reliability are achieved, and investment is saved.

Owner:CHINA WATER RESOURCES BEIFANG INVESTIGATION DESIGN & RES

Reinforced mud-filled pipe bag

The invention discloses a reinforcement mud filling pipe bag. The reinforcement mud filling pipe bag comprises a bag body. The bag body is formed by sewing double-layer bag cloth. Reinforcement belts are evenly sewn on the bag body and located outside the bag body, and the double-layer bag cloth is connected into a whole through the reinforcement belts. A plurality of slurry inlets are distributed in the bag body and are distributed in a plum blossom manner. Slurry inlet hoses are arranged at the slurry inlets and inserted in the slurry inlets and are fixed with the double-layer bag cloth in a sewing manner. The slurry inlet hoses are in an inverted wedge shape. The outer diameter of the parts, located in the bag body, of the slurry inlet hoses is larger than that of the parts, located outside the bag body, of the slurry inlet hoses. The reserved length of the parts, in the bag body, of the slurry inlet hoses is 1.0-1.5 m, and the reserved length of the parts, outside the bag body, of the slurry inlet hoses is 0.5-1.0 m. A lantern ring is arranged at the tail of the bag body. The double-layer bag cloth is adopted in the reinforcement mud filling pipe bag, the double-layer bag cloth is connected into a whole through the reinforcement belts, the tensile strength of the whole mud filling pipe bag is improved, and the reinforcement mud filling pipe bag can be used for large arrangement ship operation. The bag laying position precision is greatly improved, the continuous work capability is high, and construction efficiency is high.

Owner:安徽水利开发有限公司

A cable hole blocker

Owner:GUANGZHOU PANYU CABLE WORKS

A kind of automatic monitoring device for slope displacement and using method thereof

The invention discloses an automatic monitoring device for slope displacement, and the device comprises an inclination measuring pipe, wherein the top of the inclination measuring pipe is provided with a rotary coder. The rotary coder is fixed, and is connected with a measurement line. The measurement line can extend to the bottom of the inclination measuring pipe from the top of the inclination measuring pipe. The rotary coder measures the displacement of a slope on the Z axis through the measurement line, and the rotary coder is connected with a data receiver. The displacement data measured by the rotary coder on the Z axis is transmitted to the data receiver. The invention also discloses an application method. The device can measure the deep displacement of the slope, can reflect the change condition of the displacement of the slope in a better manner, provides a better instruction for the monitoring warning, is higher in usability, and is wider in application range.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

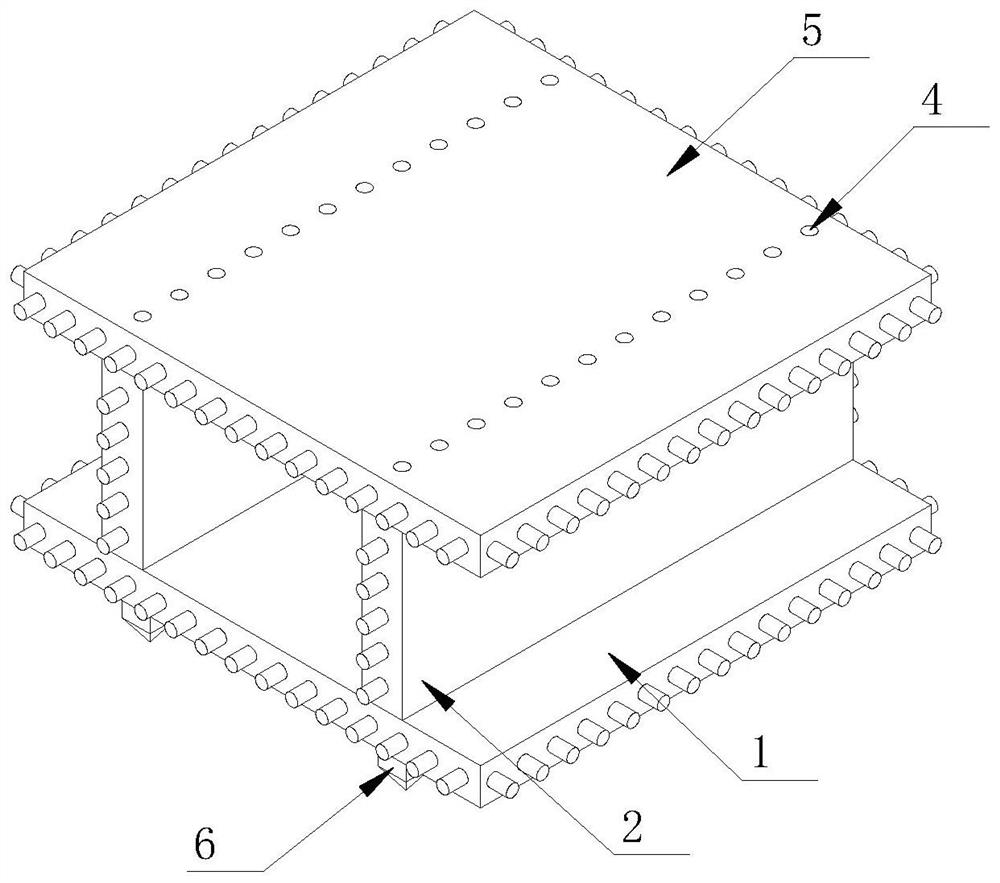

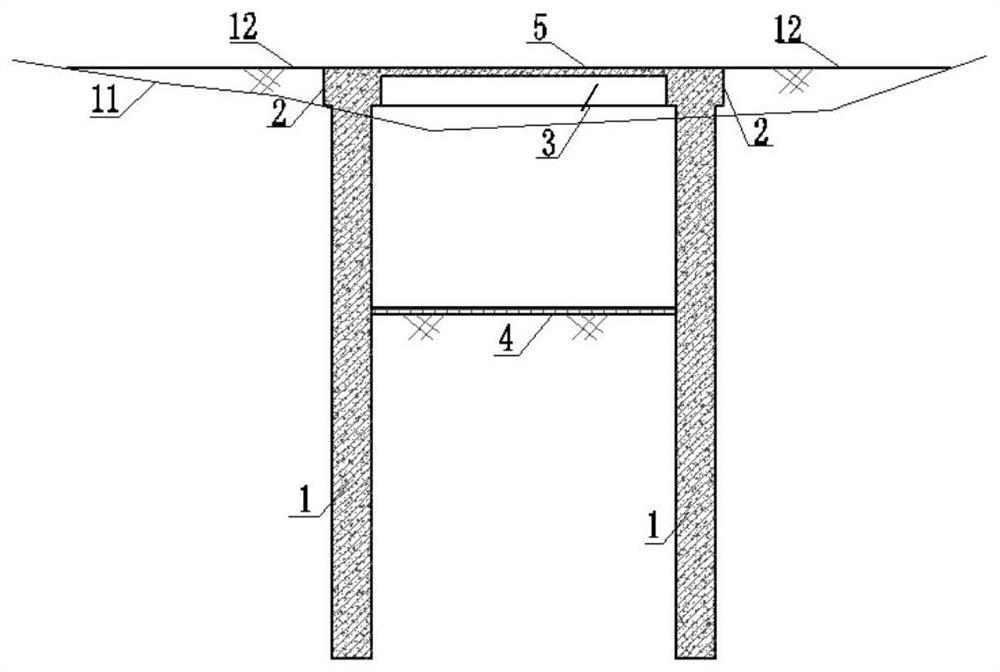

A construction method of a temporary collection station for plain river garbage

ActiveCN112761400BStable structureImprove reliabilityFatty/oily/floating substances removal devicesSewerage structuresRiver routingArchitectural engineering

The invention discloses a construction method for a temporary garbage collection station in a plain river course, which comprises the following steps: (a) building a foundation; (b) building a side wall; and (c) capping. The invention has simple process, step-by-step order, sufficient operation space, positioning operation, low construction difficulty, high construction efficiency, easy control of construction quality, low manual labor intensity, ensuring the assembly quality of the temporary garbage collection station, and the temporary collection of garbage The capacity of the station can also be flexibly adjusted according to actual needs, with strong adaptability, can be dismantled and transferred to other places for continued use, and has high resource utilization.

Owner:SINOHYDRO FOUND ENG

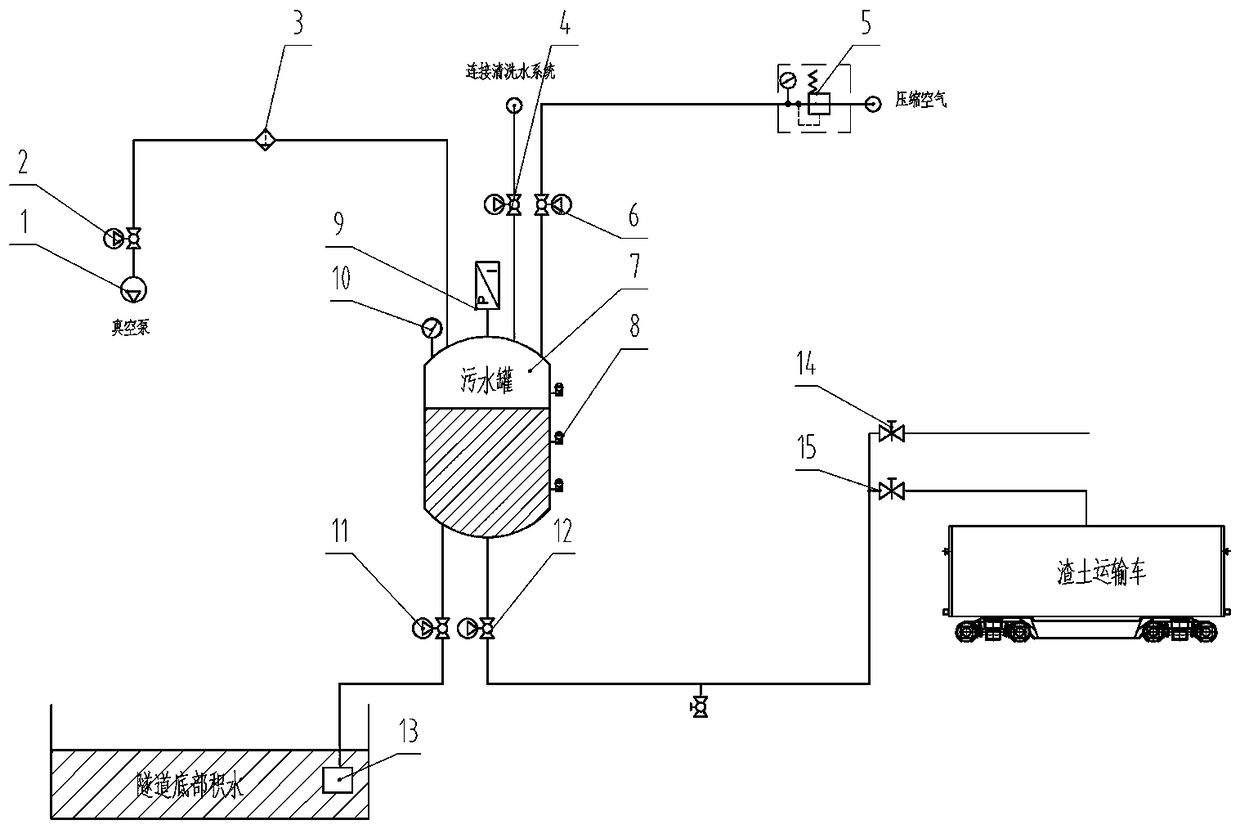

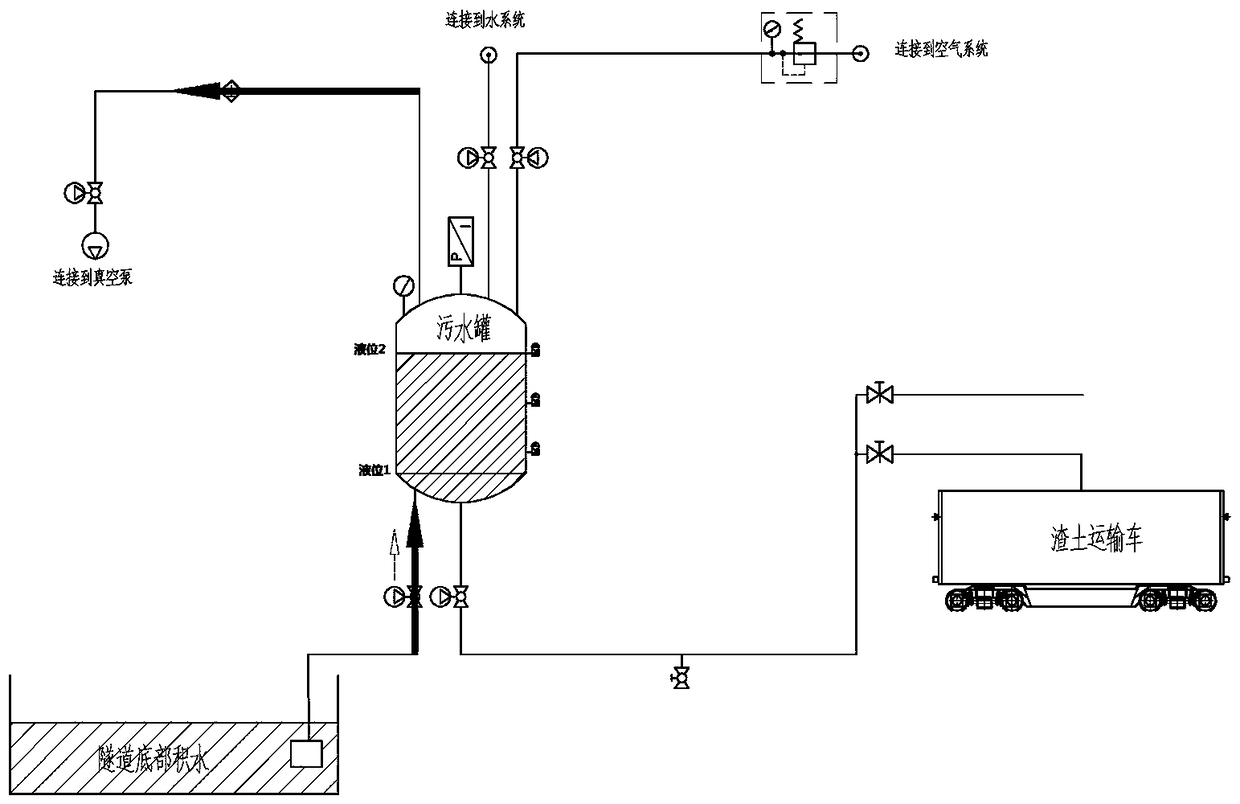

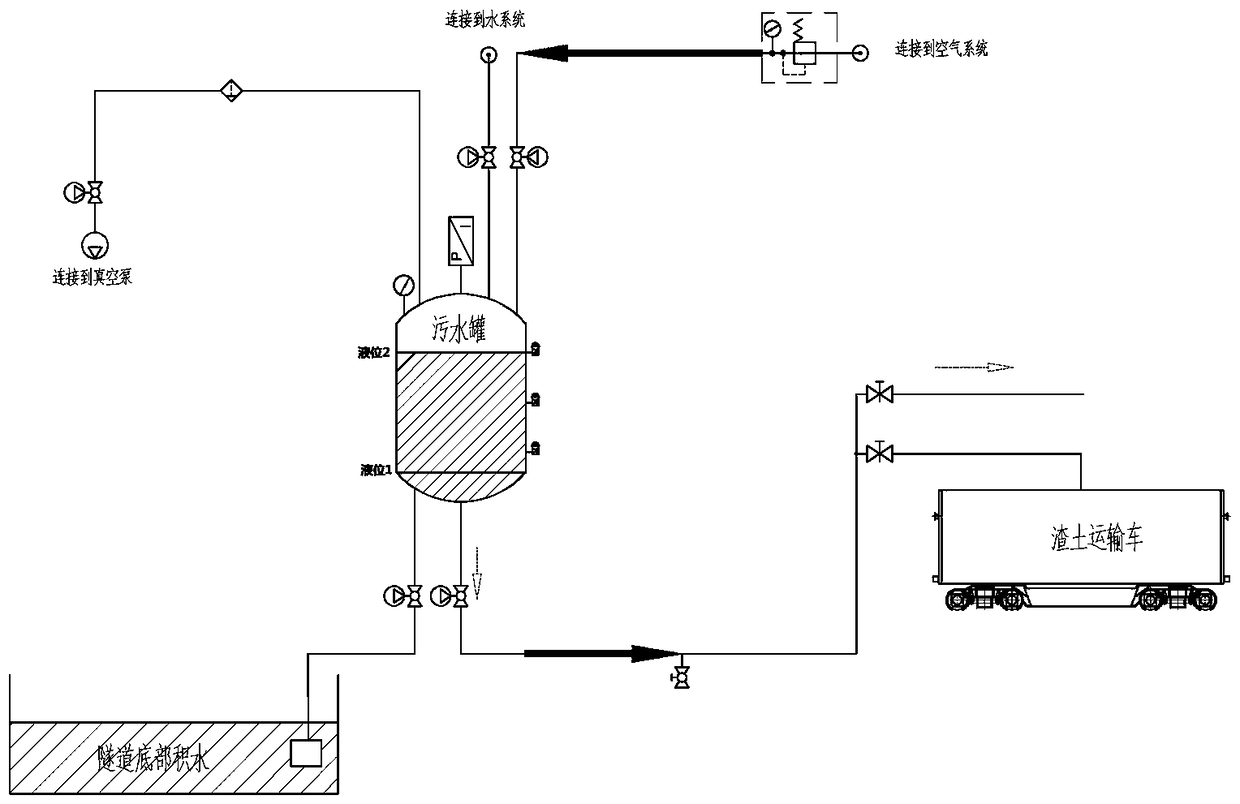

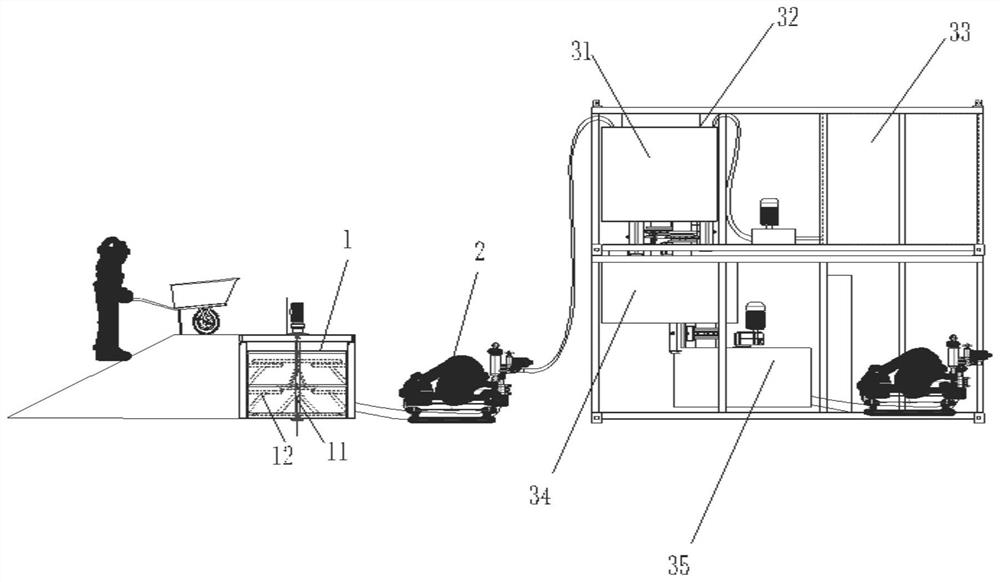

Tunnel vacuum sewage discharge system and sewage discharge method

PendingCN108589879AImprove dirt absorption capacityReduce lossSewage drainingSewer pipelinesControl systemControl valves

The invention relates to the technical field of engineering construction, in particular to a tunnel vacuum sewage discharge system and a sewage discharge method. The system comprises a suction mechanism and a sewage discharge mechanism, the sewage discharge mechanism comprises a sewage discharge tank and a pressure regulating pipeline, a vacuum port is formed in a sewage tank, and a sewage inlet and a sewage discharge port are formed in the bottom of the sewage discharge tank; the suction mechanism comprises a sewage filtering device disposed at a water accumulated position of a tunnel and a vacuum pump connected to the vacuum port through the vacuum pipeline, the sewage filtering device is communicated with the sewage inlet through a sewage treatment pipeline, a vacuum regulating valve isarranged on the vacuum pipeline, and a sewage control valve is arranged on the sewage treatment pipeline; the sewage discharge port is connected to a muck transport vehicle or an external sewage discharge pipeline through the sewage discharge pipeline, and the sewage discharge pipeline is provided with the sewage discharge valve. The system has novel and reasonable design and strong sewage absorption ability, automatically discharges sewage under the participation of a control system, reduces the loss of consumable parts, achieves rapid sewage discharge, and improves construction efficiency.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

A unitary light-weight reinforced partition wall and its construction method

ActiveCN104594531BLightweight insulationMeet functional requirementsWallsThermal insulationUnit type

The invention discloses a unit type lightweight ribbed partition and a construction method thereof. The partition is connected between a roof and a ground and is composed of at least one partition board; an upper end of the partition board is fixedly connected to the roof through at least two F-shaped clips, and a lower end of the partition board is fixedly connected to the ground through at least two U-shaped clips; the F-shaped clips are horizontally arranged, the straight tail parts of the F-shaped clips are fixed with the roof through bolts, and the head ends thereof with clip slots are clamped at the two sides of the end side of the partition board; the U-shaped clips are vertically arranged, and the openings of the slots of the U-shaped clips are upward; the bottom parts of the U-shaped clips are connected to the ground through bolts, the slots of the U-shaped clips are clamped at the two sides of the end side of the partition board; the single partition board is formed by splicing three partition units to achieve the effects of light weight, heat preservation, thermal insulation and sound insulation. During construction, splicing the prefabricated partition board units into the complete partition or an infilled wall is only needed, thus, the construction speed is obvious faster than that of the traditional partitions, the construction is simple and convenient, the efficiency is high, and the quality control on site is benefited.

Owner:北京振利节能环保科技股份有限公司

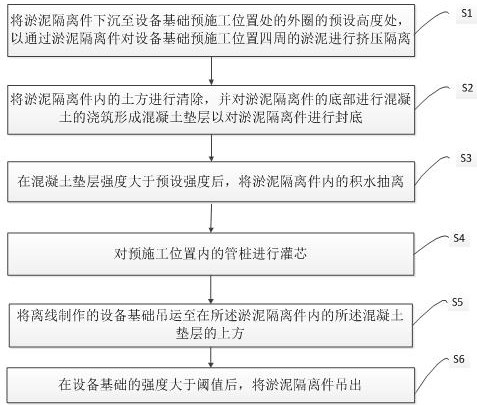

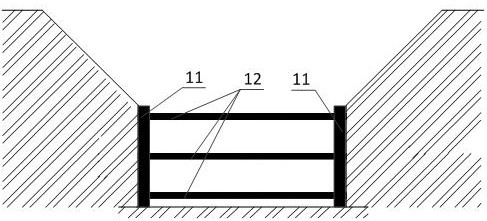

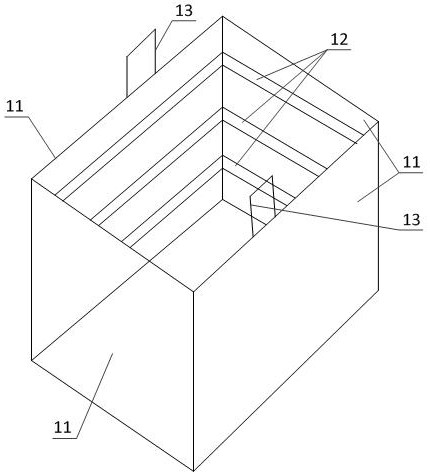

Method for carrying out equipment foundation construction by isolating sludge

The invention provides a method for carrying out equipment foundation construction by isolating sludge. The method comprises the steps of sinking a sludge isolating piece to a preset height of an outer ring at a pre-construction position of an equipment foundation so as to extrude and isolate sludge around the pre-construction position of the equipment foundation through the sludge isolating piece; removing earthwork in the sludge isolating piece, and pouring concrete at the bottom of the sludge isolating piece to form a concrete cushion layer so as to seal the bottom of the sludge isolating piece; pouring the equipment foundation on the concrete cushion layer in the sludge isolating piece; and after the strength of the equipment foundation is larger than the threshold value, hoisting outthe sludge isolating piece. Sludge is extruded and isolated through the sludge isolating piece, and the method is timely, simple, convenient, rapid, good in safety effect, capable of saving cost, highin applicability and capable of being reused after being hoisted and placed.

Owner:MCC5 GROUP CORP SHANGHAI

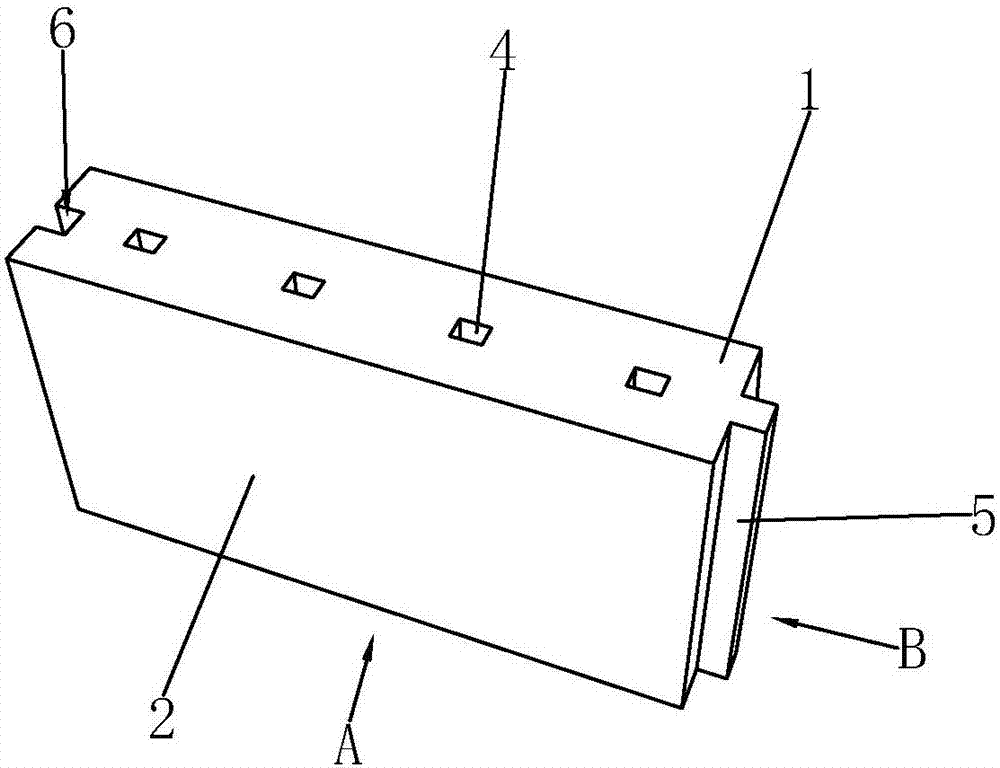

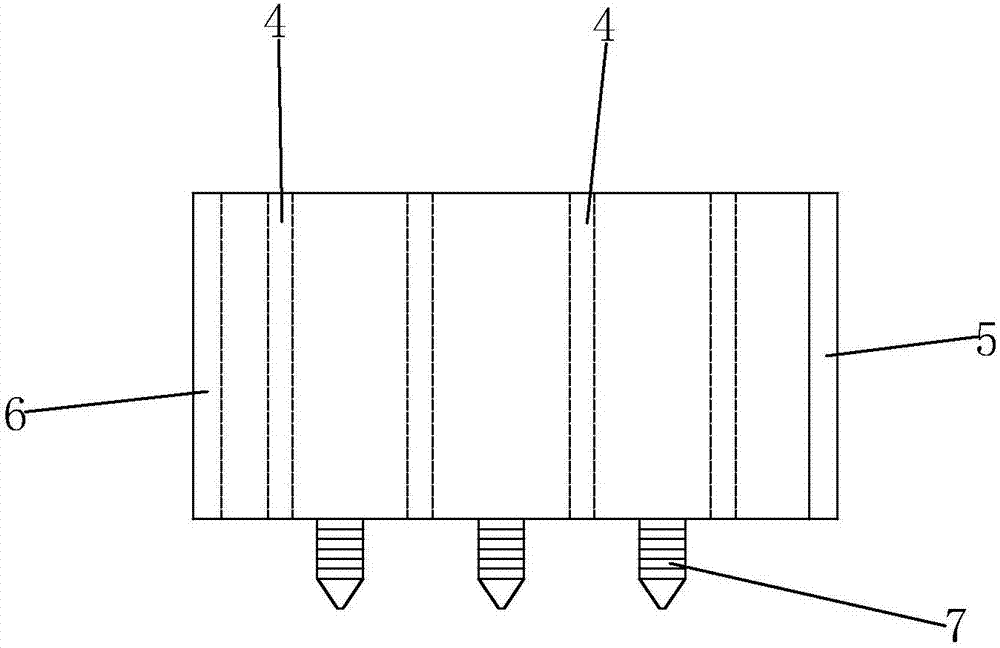

Quick Installation Method of Anchor Bolts in Steel Structure Workshop

The invention relates to a mounting method of steel structure workshop foundation bolts, in particular to a rapid mounting method of the steel structure workshop foundation bolts. The rapid mounting method solves the problem of low construction efficiency in the installation process of existing steel structure workshop foundation bolts. The rapid mounting method includes the following steps: adopting upper portion bamboo plywood and lower portion bamboo plywood, enabling all the steel structure workshop foundation bolts which are contained in a foundation upright column steel reinforcement cage to penetrate through locating holes in the upper portion bamboo plywood and the lower portion bamboo plywood, welding lower portion horizontally-fixed reinforcing steel bars to every row of foundation bolts in a perpendicular mode, welding lower portion vertically-fixed reinforcing steel bars to the middles of opposite foundation bolts in two rows of the foundation bolts in a perpendicular mode, arranging the upper portion horizontally-fixed reinforcing steel bars and the lower portion vertically-fixed reinforcing steel bars which are fixed on the foundation bolts on the upper portion bamboo plywood, then welding the upper portion horizontally-fixed reinforcing steel bars and the lower portion vertically-fixed reinforcing steel bars to main ribs in the foundation upright column steel reinforcement cage, and dismantling the upper portion bamboo plywood. The rapid mounting method is high in construction efficiency, and can be widely applied to installation of the steel structure workshop foundation bolts.

Owner:山西太行建设开发有限公司

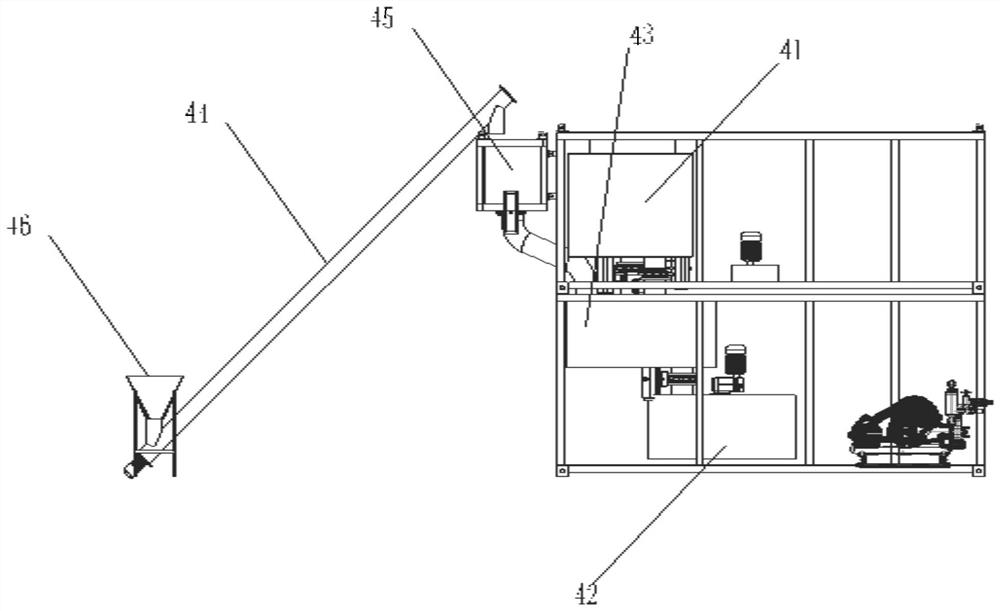

Construction method of solidified soil pile

PendingCN113073629AAdjust the clotting timeRaise the pHBulkheads/pilesSoil preservationSoil scienceSlurry

The invention provides a construction method of a solidified soil pile. The construction method comprises the following steps (1) pre-mixing solidified soil; adding water into an air hardening inorganic cementing material for dilution and blending to form initial material slurry, blending the initial material slurry with a powdery curing agent to form curing agent slurry, and mixing the curing agent slurry with soil to form on-site blended solidified soil; (2) downward drilling to form a hole; firstly drilling downwards to a designed depth, and arranging a soil sampling device on a drill rod; (3) lifting a bit, pressing and filling solidified soil; and pressing and pouring the solidified soil in the step (1) into a pile hole to form the solidified soil pile. According to the solidified soil pile constructed through the method, the air hardening inorganic cementing material is added, the solidification time of solidified soil is adjusted, and the acid-base property of the solidified soil is adjusted; and the slag is doped to reduce the cement consumption, the cost is greatly saved, the pile body strength is high, the bearing capacity is high, the construction process is simple, and the construction efficiency is high.

Owner:SHANGHAI STRONG FOUND ENG

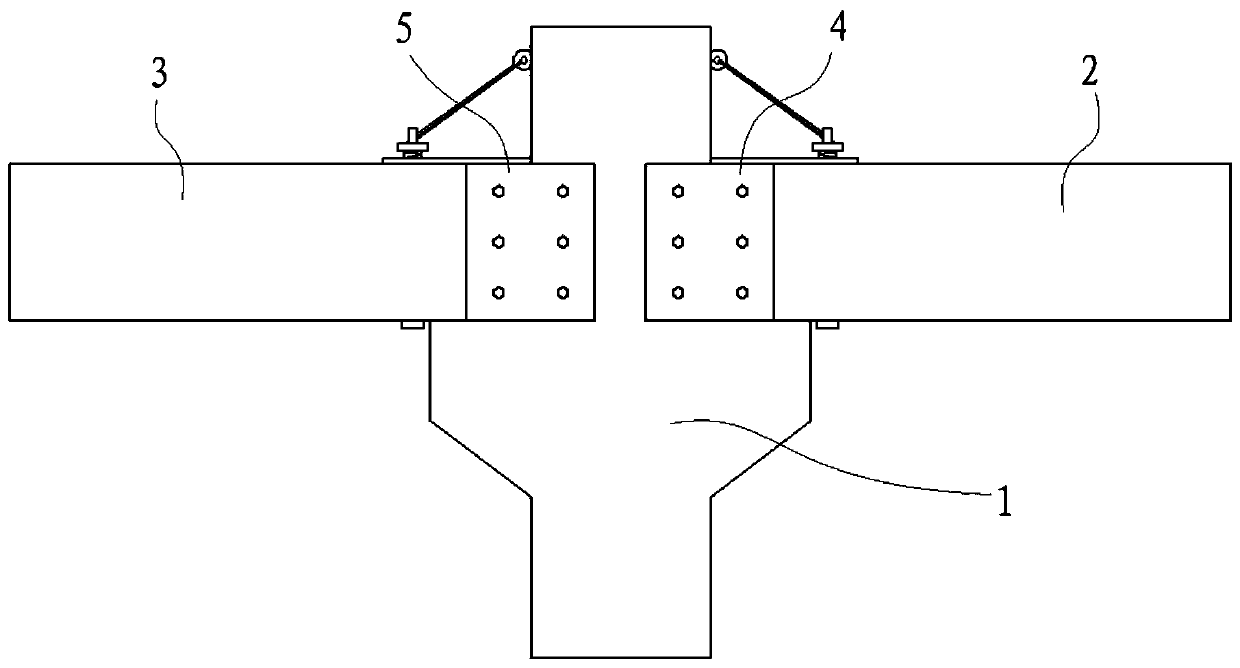

Steel plate fabricated beam-column connecting joint

PendingCN110607847AHigh strengthHigh comprehensive strength of beam-column connection jointsProtective buildings/sheltersShock proofingStructural engineeringBearing surface

The invention provides a steel plate fabricated beam-column connecting joint and belongs to the field of building beam-column connecting. The steel plate fabricated beam-column connecting joint comprises a precast corbel pillar, two precast beams and two beam-column connecting structures. The precast corbel pillar comprises a pillar body and bearing bosses located on the two sides of the pillar body. The upper end of each bearing boss is provided with a bearing surface. The pillar body and the bearing bosses are integrally formed. The two precast beams are detachably connected with the bearingbosses through the two beam-column connecting structures correspondingly and transversely arranged at the upper ends of the corresponding bearing surfaces. Each beam-column connecting structure comprises a connecting steel plate and an inhaul cable connecting assembly. Each connecting steel plate comprises a vertical part and a transverse part, the vertical part is perpendicularly connected withthe transverse part, the two ends of the vertical part are detachably connected with the pillar body and one end of the corresponding precast beam, the transverse part is located at the upper end of the corresponding precast beam and is detachably connected with the precast beam, and each inhaul cable connecting assembly is mounted between the corresponding transverse part and the pillar body andused for connecting the pillar body with the corresponding transverse part. The steel plate fabricated beam-column connecting joint is high in comprehensive strength and good in anti-seismic performance.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

A Construction Method Applied to Flood Control Embankment Reinforcement in Flood Control Project

ActiveCN106930231BImprove the anti-shock performanceExtended service lifeBreakwatersQuaysOperabilityEngineering

The invention discloses a construction method applied to reinforcement of a floor handling project flood control lift. The construction method comprises the following steps of (a) construction planning, (b) earthwork filling, (c) original lift maintenance, (d) banket construction, (e) retention wall bricklaying, (f) sod revetment and (g) construction of a road at the top of the lift. The construction method has the advantages that construction time is reasonably arranged, the construction period is short, construction cost is low, operability is high, construction efficiency is high, the flood control capacity of the flood control lift is improved, and maintenance is easy.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com