Tunnel vacuum sewage discharge system and sewage discharge method

A technology of vacuum sewage discharge and tunneling, which is applied in the direction of waterway system, sewer pipeline system, and sewage discharge, etc. It can solve the problems of taking up more time, discounting the service life of pumps, affecting construction efficiency and construction cost, etc., so as to improve construction efficiency and reduce The effect of component loss and strong promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

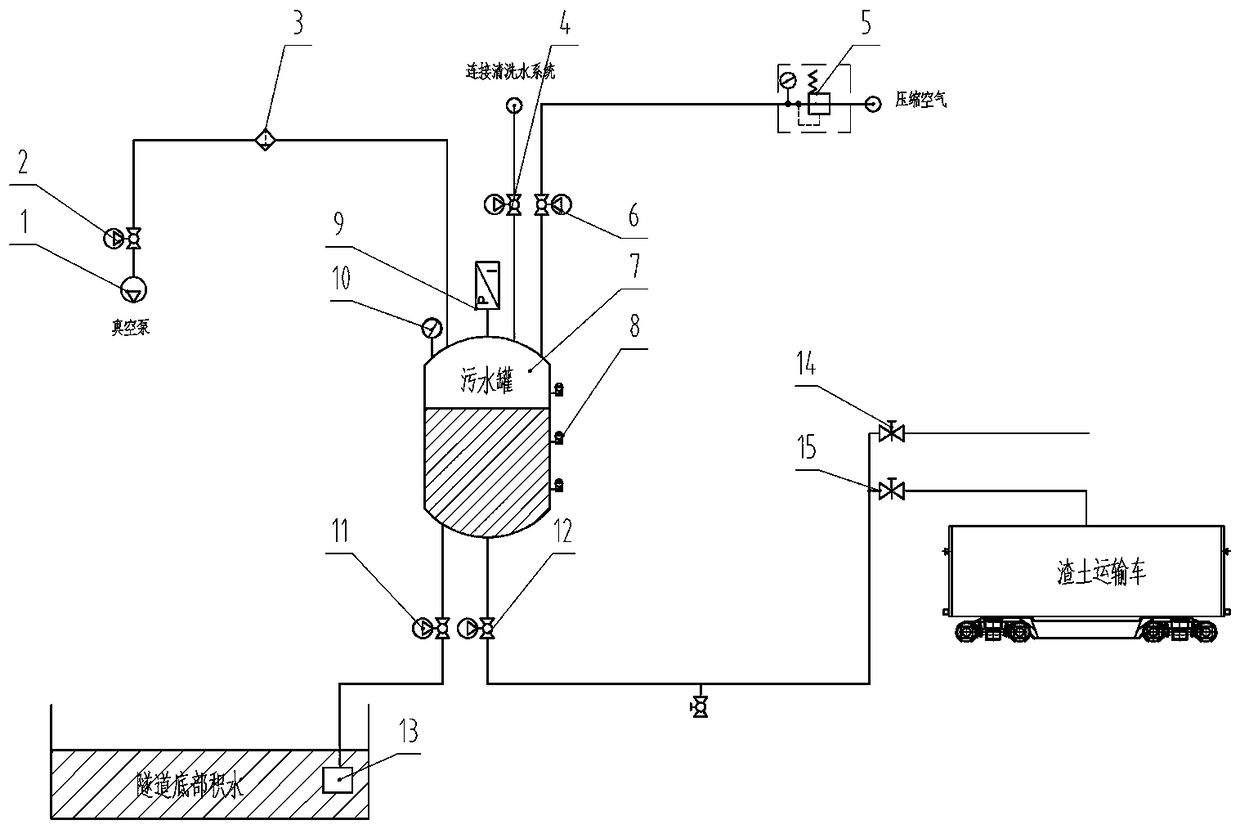

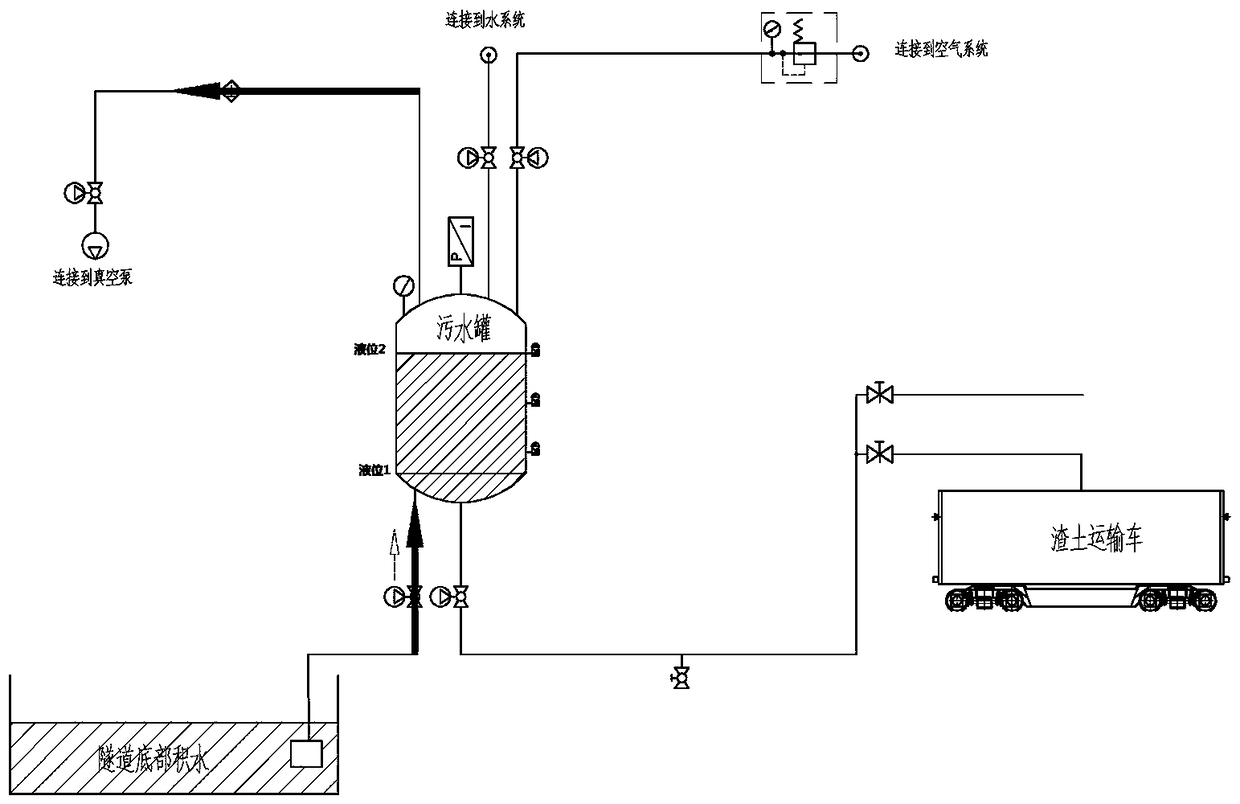

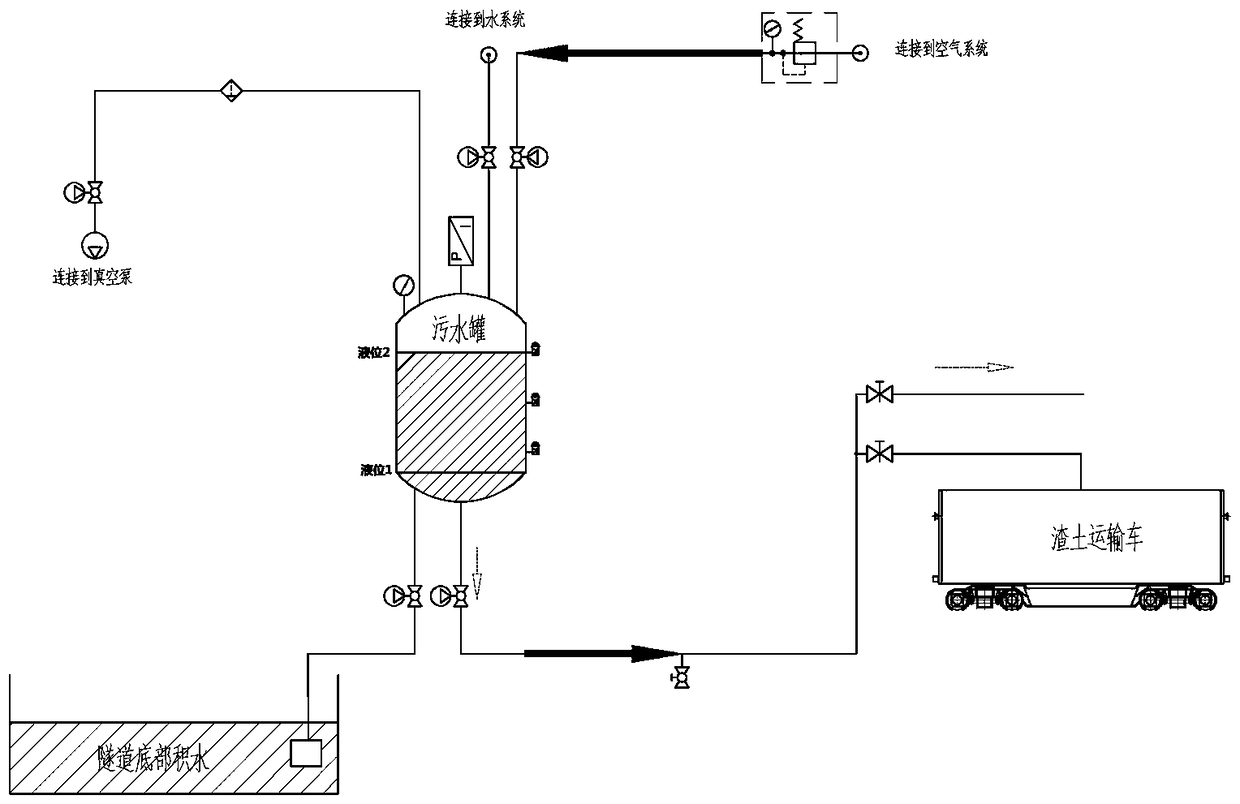

[0023] Numbers in the figure, number 1 stands for vacuum pump, number 2 stands for vacuum regulating valve, number 3 stands for vacuum dehumidification device, number 4 stands for cleaning control valve, number 5 stands for pressure regulating device, number 6 stands for compressed air valve, and number 7 stands for sewage tank , the label 8 represents the liquid level detection element, the label 9 represents the pressure gauge, the label 10 represents the pressure detection element, the label 11 represents the sewage treatment valve, the label 12, 14, 15 represents the sewage valve, and the label 13 represents the sewage filter equipment.

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and technical solutions, and the implementation of the present invention will be described in detail through preferred embodiments, but the implementation of the present invention is not limited thereto.

[0025] Aiming at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com