Rear-embedded film bag-type umbrella-shaped expansion tip used for pre-reaming and construction method thereof

An enlarging head and umbrella-shaped technology, which is applied to the pre-reaming and post-planting membrane bag-type umbrella-shaped enlarging head and its construction field, can solve the problems of lowering construction efficiency, affecting the composition and strength of grouting consolidation body, and complicated man-machine consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

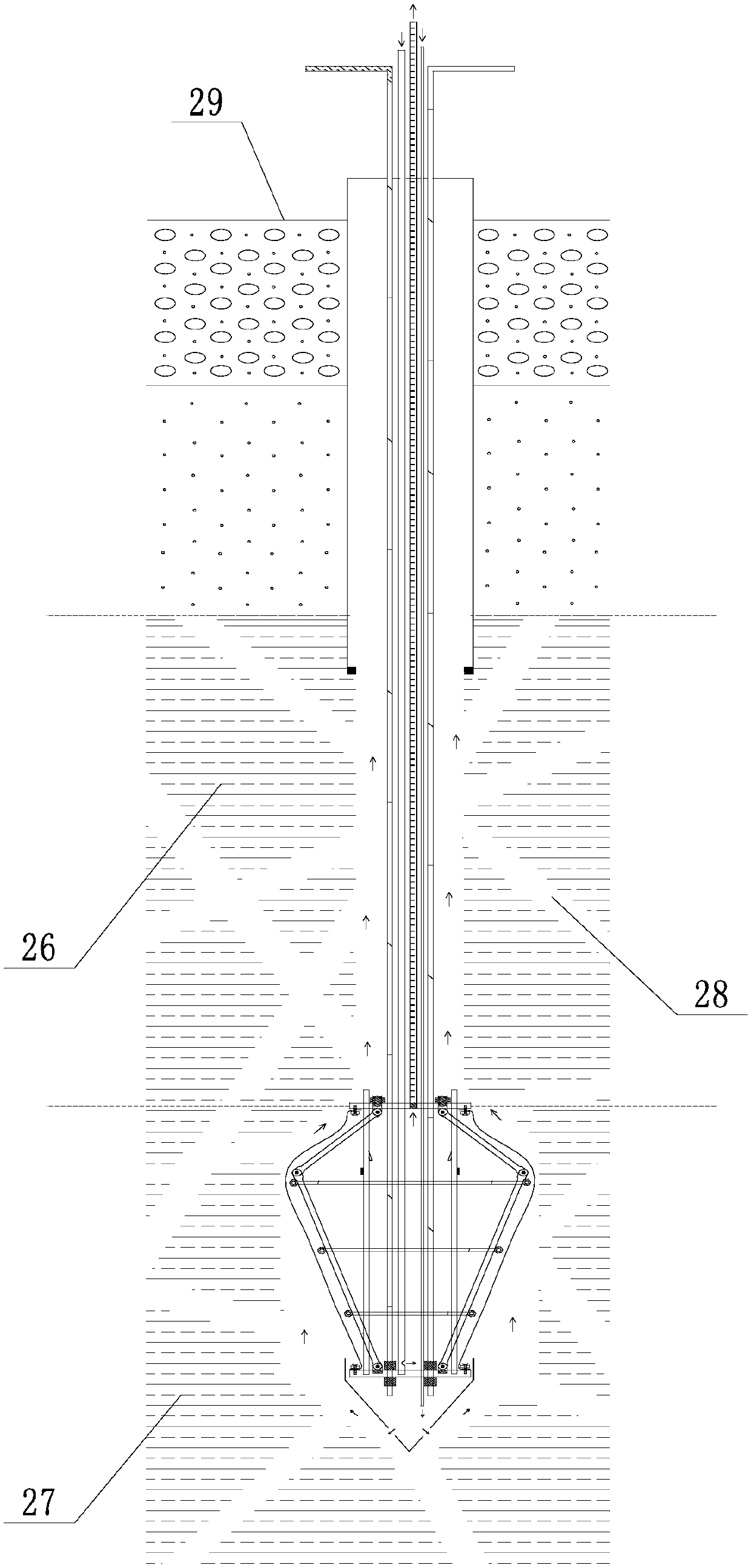

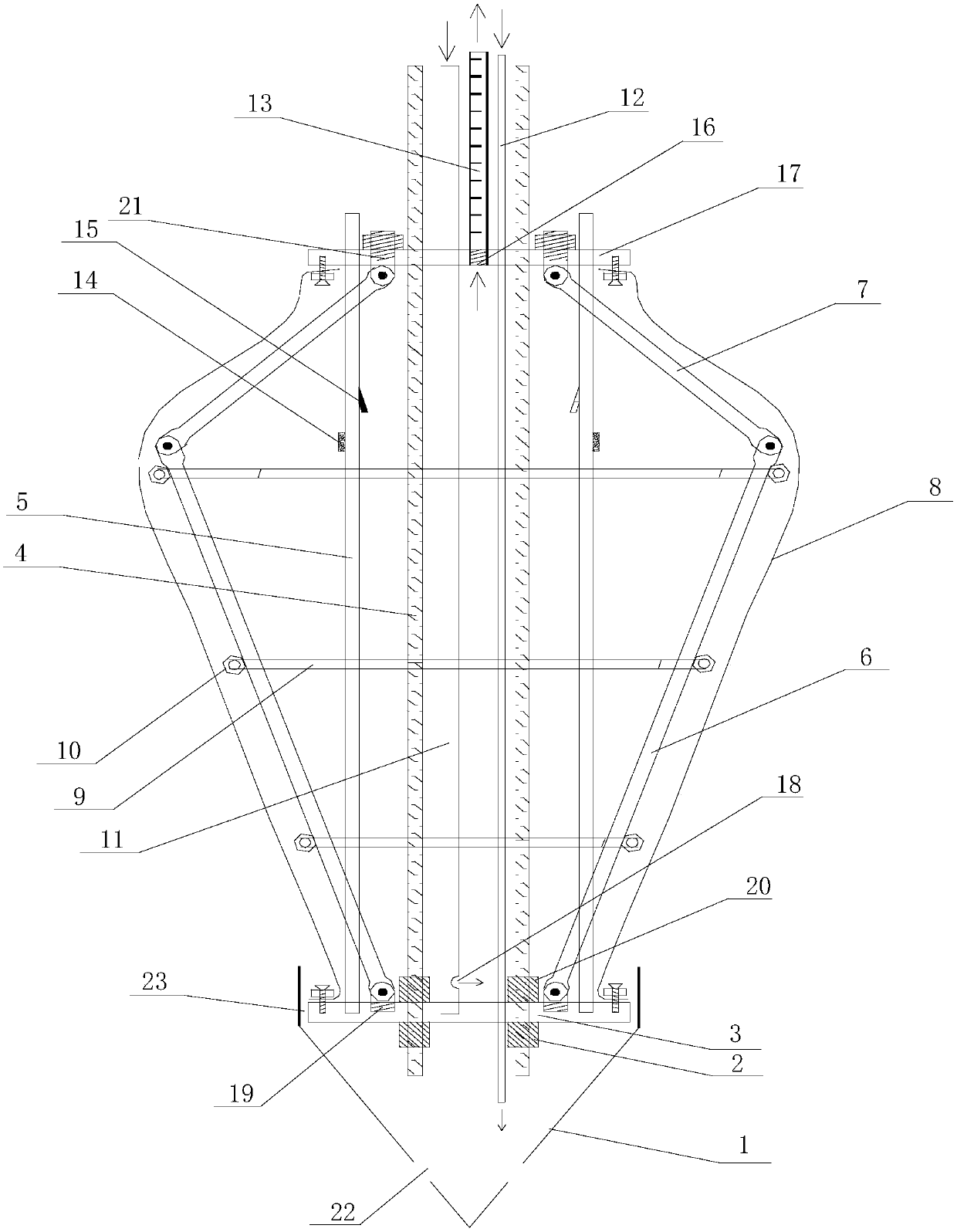

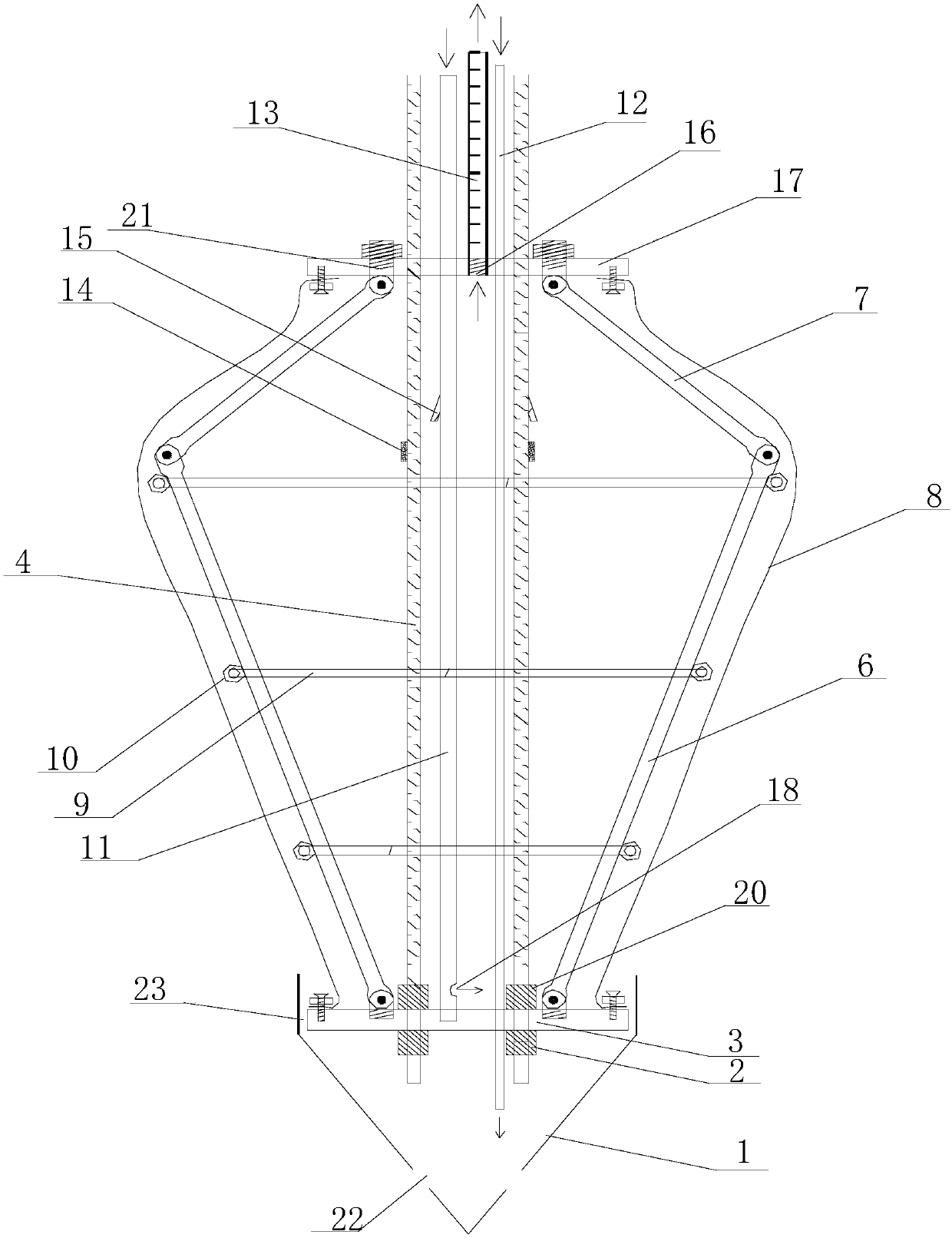

[0092] Such as figure 1 and figure 2 , Figure 10 The pre-expanded post-planted membrane bag-shaped umbrella-shaped expanding head includes an umbrella-shaped expansion device and several anchor bars 4 passing through the umbrella-shaped expansion device. It is characterized in that it also includes a grouting pipe II11. The umbrella-shaped A membrane bag 8 is arranged on the outside of the expander, and the grout outlet of the grouting pipe II11 is located inside the membrane bag 8. The inside of the umbrella-shaped expander includes a tendon disc 3, an umbrella-shaped folding rod group, and a rib-through Disk 17.

[0093] The front end of the anchor bar 4 moves through the tendon plate 3, and the rear end moves through the tendon plate 17; The contact is used to transmit the tensile force of the anchor rib 4 to the tendon disc 3; the front and rear ends of the film bag 8 are respectively connected with the tendon disc 3 and the rib disc 17.

[0094] A structural compone...

Embodiment 2

[0124] Such as image 3 As shown, this embodiment adopts a reinforced cage concrete structure without structural components, which is suitable for the case of low design bearing capacity.

Embodiment 3

[0126] Such as Figure 4 As shown, the anchor bars in this embodiment are made of pipes, such as steel pipes, glass fiber pipes, carbon fiber pipes and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com