A unitary light-weight reinforced partition wall and its construction method

A unitary, lightweight technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of high cost, complicated construction and low construction efficiency of partition walls, and achieve the effect of shortening construction period, convenient construction and strong construction adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

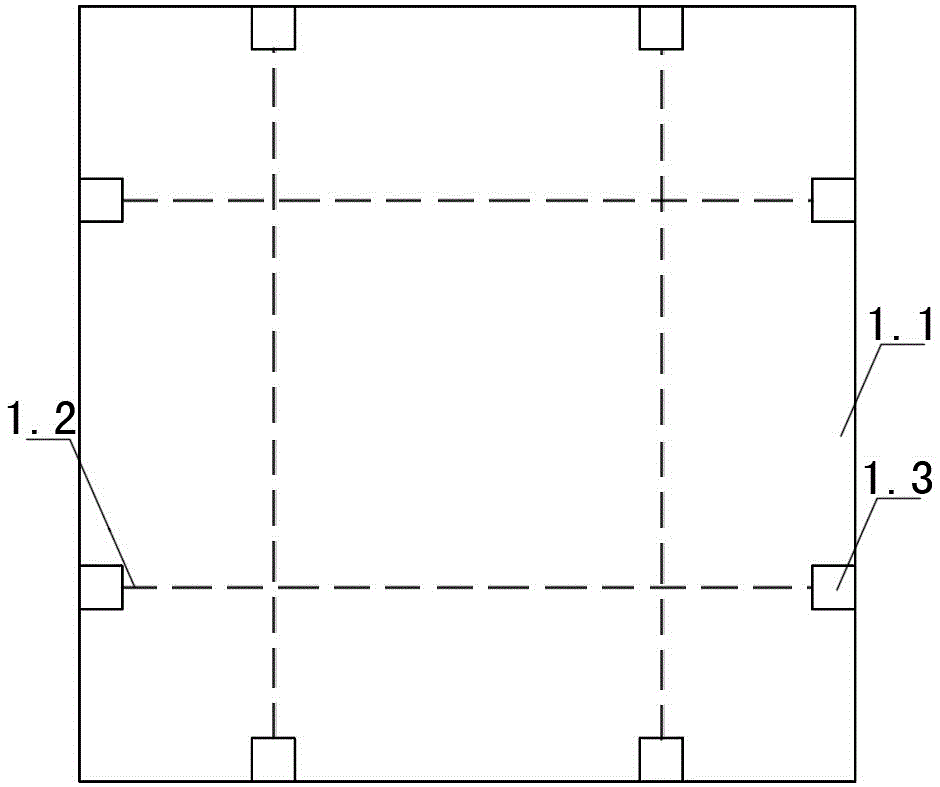

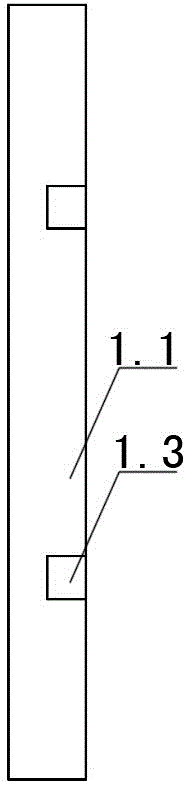

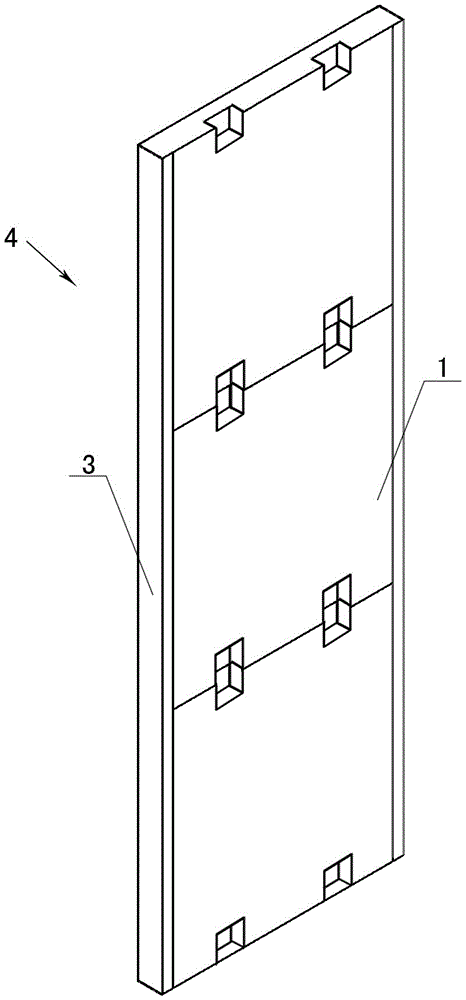

[0041] Examples see figure 1 As shown, this unitary lightweight reinforced partition wall unit includes a concrete main body 1.1 and a steel skeleton 1.2 poured inside the concrete main body 1.1. The concrete main body 1.1 is formed by pouring lightweight concrete and has connections on the surface Groove 1.3, the connection groove 1.3 is located on the same side of the concrete body 1.1 and evenly spaced on the four edges of the concrete body 1.1, each side of the concrete body 1.1 has at least two connection grooves, and the concrete body 1.1 The positions of the connecting slots on the opposite side correspond one-to-one, see figure 2 As shown, the depth of the connection groove 1.3 does not exceed half of the thickness of the concrete main body 1.1.

[0042] The lightweight concrete is polystyrene particle foam concrete, and the polystyrene particle foam concrete refers to adding polystyrene particles to ordinary foam concrete, so that the polystyrene particles are dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com