Decoration and heat preservation integrated light-weight concrete plate and production method thereof

A technology for decorative concrete and lightweight concrete, applied in building materials and other directions, can solve problems such as poor adhesion of mortar, poor durability, hollowing and falling off, and achieve the effects of good wind pressure resistance, improved performance and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

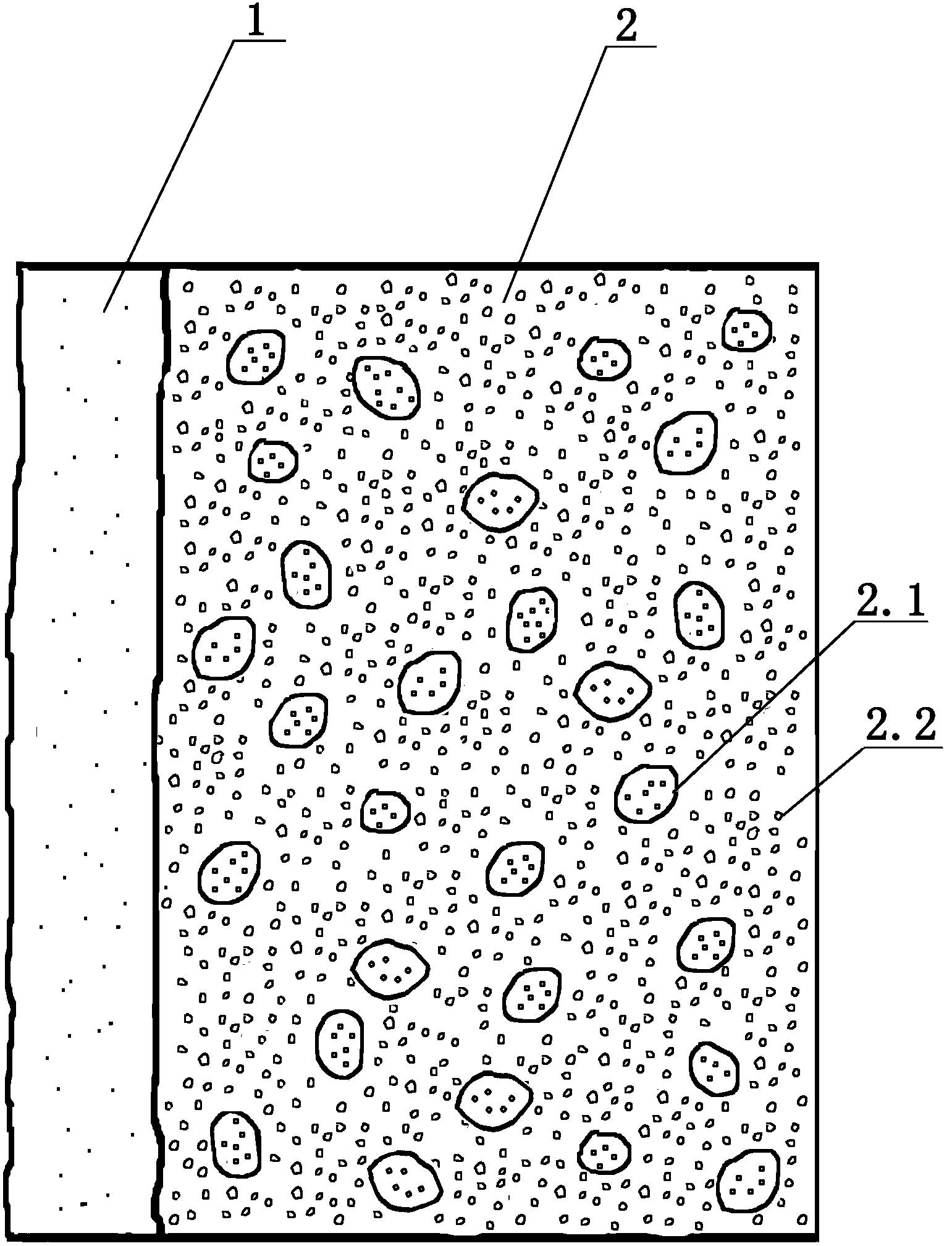

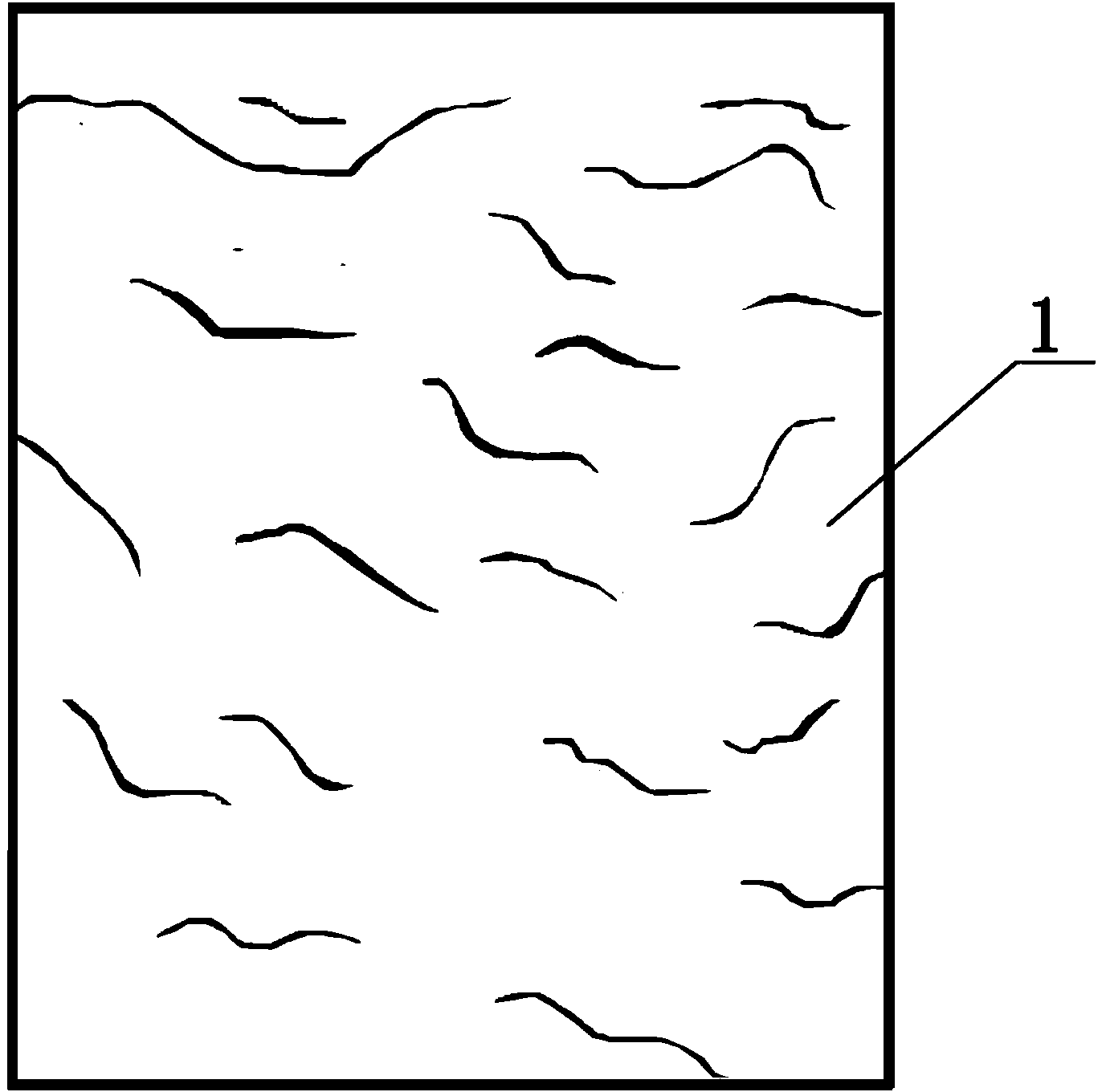

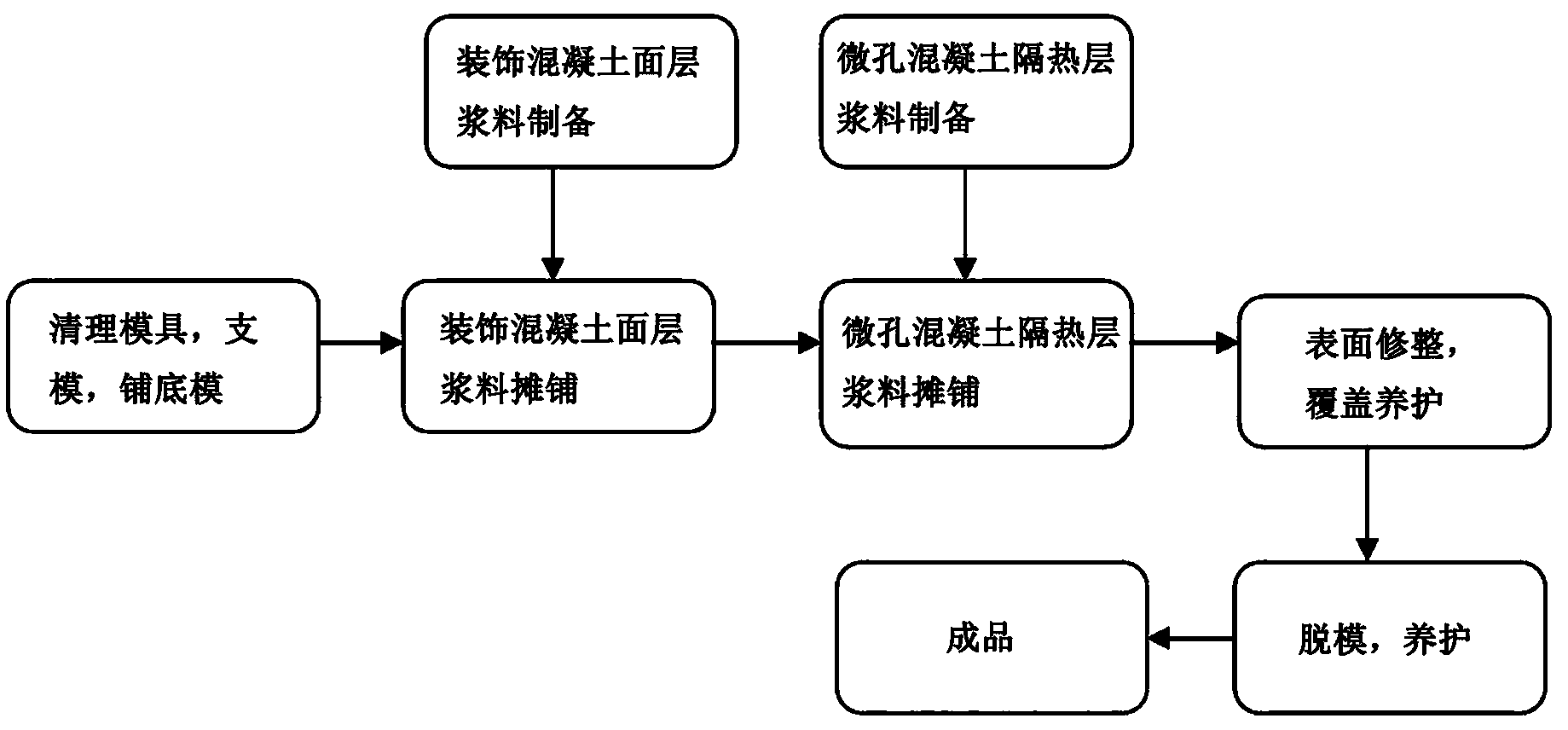

[0058] Embodiment 1, this decorative and thermally integrated lightweight concrete slab is composed of a decorative concrete surface layer 1 and a microporous concrete thermal insulation layer 2;

[0059] The raw material composition of described decorative concrete surface layer 1 is as follows according to the weight ratio of every cubic meter of concrete:

[0060] The fine aggregate 2200 kg / m 3 ;

[0061] Cement 450 kg / m 3 ;

[0062] Silica fume 40kg / m 3 ;

[0063] Admixture 90 kg / m 3 ;

[0064] Water reducer 3.9kg / m 3 ;

[0065] Tap water 145kg / m 3 ;

[0066] Inorganic pigments 2 kg / m 3 .

Embodiment 2

[0067] Embodiment 2, this decorative and thermally integrated lightweight concrete slab is composed of a decorative concrete surface layer 1 and a microporous concrete thermal insulation layer 2;

[0068] The raw material composition of described decorative concrete surface layer 1 is as follows according to the weight ratio of every cubic meter of concrete:

[0069] The fine aggregate 2100 kg / m 3 kg / m 3 ;

[0070] Cement 440 kg / m 3 kg / m 3 ;

[0071] Silica fume 30 kg / m 3 kg / m 3 ;

[0072] Admixture 60 kg / m 3 ;

[0073] Water reducer 3.4 kg / m 3 ;

[0074] Tap water 98kg / m 3 .

Embodiment 3

[0075] Embodiment 3, this decorative and thermally integrated lightweight concrete slab is composed of a decorative concrete surface layer 1 and a microporous concrete thermal insulation layer 2;

[0076] The raw material composition of described decorative concrete surface layer 1 is as follows according to the weight ratio of every cubic meter of concrete:

[0077] The fine aggregate 2400 kg / m 3 ;

[0078] Cement 520 kg / m 3 ;

[0079] Silica fume 45kg / m 3 ;

[0080] Admixture 100 kg / m 3 ;

[0081] Water reducer 3.9kg / m 3 ;

[0082] Tap water 135kg / m 3 ;

[0083] Inorganic pigments 9 kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com