A construction method of foam concrete insulation layer and foam concrete slurry pumping equipment

A technology of foam concrete and pumping equipment, which is applied to roof coverings, roof insulation materials, and roofs using sealed aggregates. It can solve the problems of complex foam concrete construction processes and achieve good waterproof effect, low cost and convenience. The effect of pouring concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

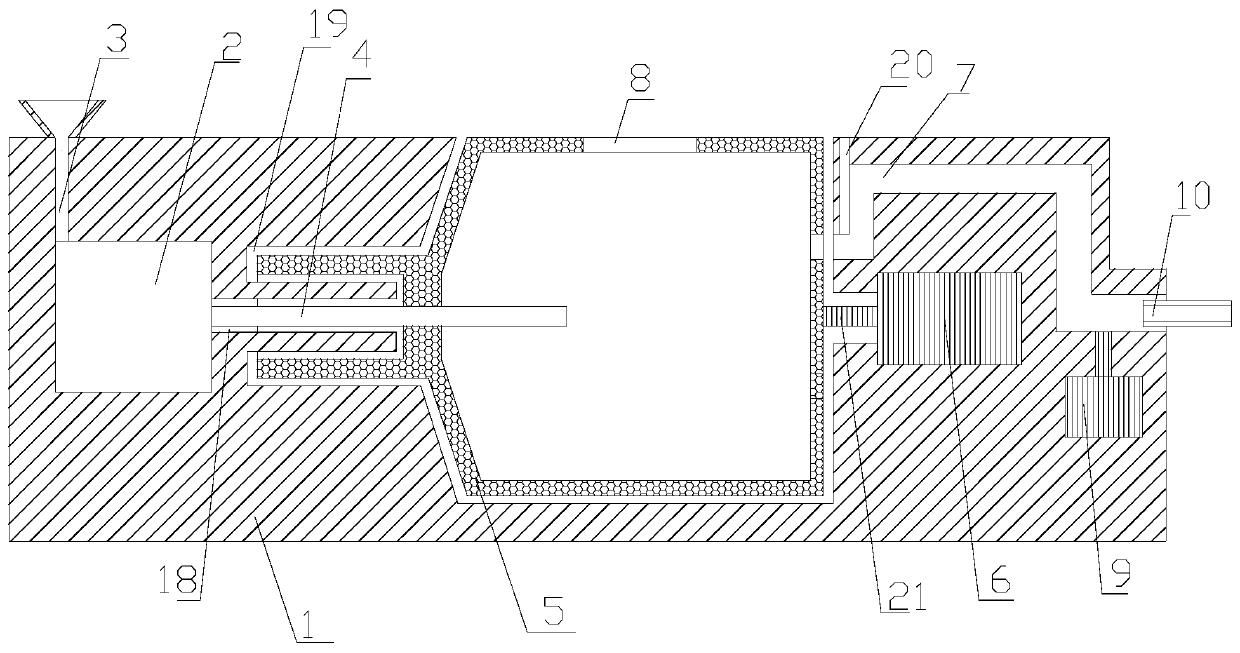

[0020] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

[0021] The present invention proposes a kind of construction method of foamed concrete insulation layer, comprises the following steps:

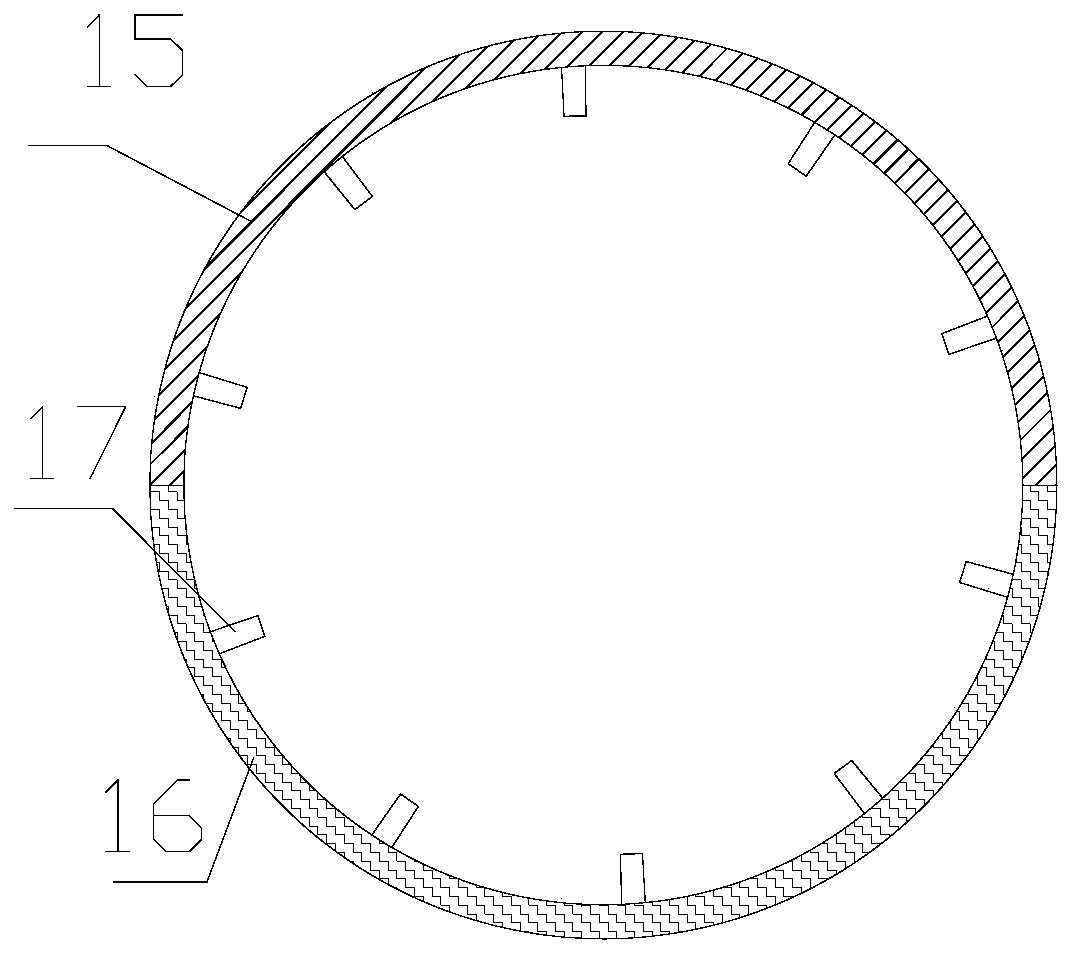

[0022] 1) Foam the foaming agent, mix the foamed foam and cement slurry evenly, and make foam concrete slurry; the raw materials of cement slurry are siliceous materials, calcium materials, water and various admixtures, etc. The final foam concrete dry density level is within 700kg / m3, the strength is greater than 0.3MPa, the thermal conductivity is less than 0.18W / M.K, and the porous concrete material meets the national roofing engineering acceptance specification;

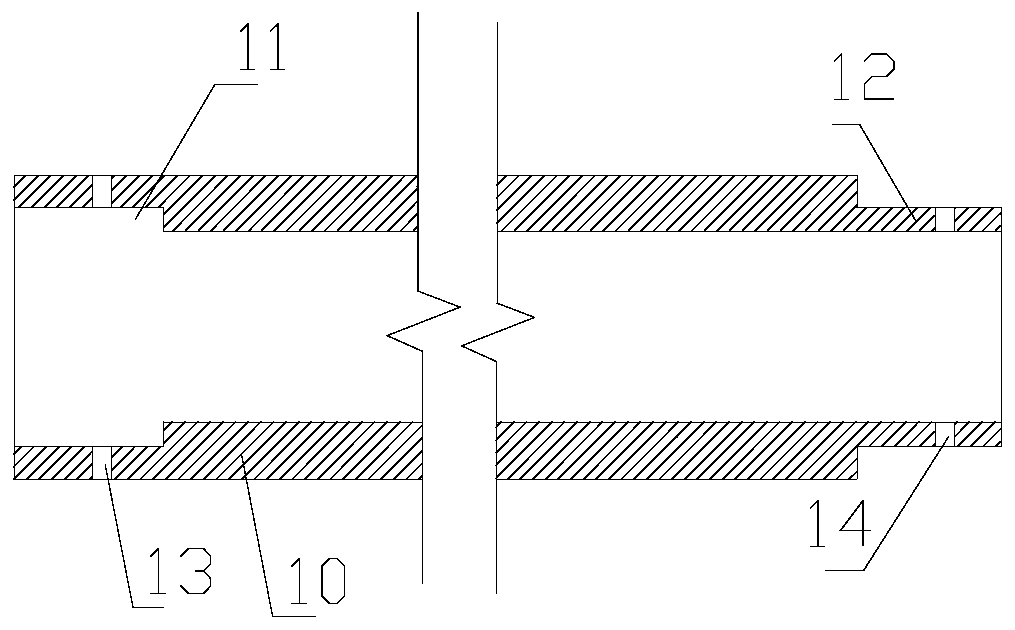

[0023] 2) The foamed concrete slurry is pumped to the flat roof or sloping roof; Set of detachable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com