Ceramsite heat insulation brick and preparation method thereof

A technology of thermal insulation bricks and ceramsite, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as difficult high strength, load bearing, difficult heat preservation, light weight, etc., to achieve improved earthquake resistance and frost resistance Good performance and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

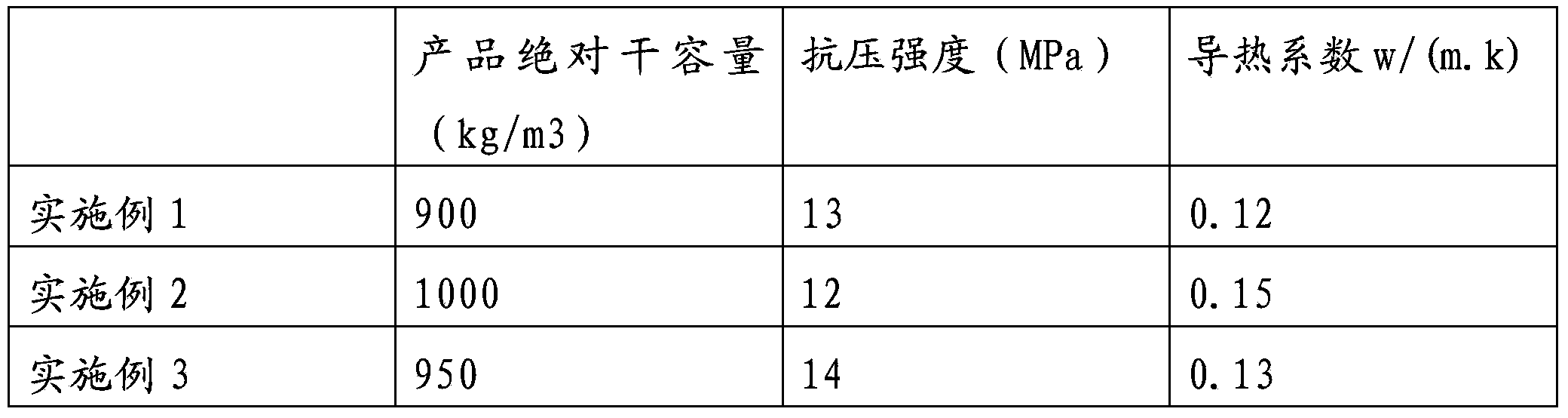

Embodiment 1

[0050] A preparation method of ceramsite insulation brick, comprising the following steps:

[0051] a. Weigh raw materials according to the following weight ratios, ceramsite: 20 parts; iron and steel slag: 20 parts; fluorite ore tailings: 20 parts; fly ash: 8 parts; lime mud: 5 parts; cement: 5 parts; Activator: 1 part;

[0052] b. First remove iron from steel slag, then mix and finely grind steel slag, fluorite ore tailings, fly ash, lime mud, cement, and activator into a mixture;

[0053] c. Stir the above-mentioned mixture and ceramsite, after stirring evenly, pour it into a mold for molding, demould after molding, and finally perform curing. The curing methods are natural curing, steam curing or curing machine curing.

Embodiment 2

[0055] A preparation method of ceramsite insulation brick, comprising the following steps:

[0056] a. Weigh raw materials according to the following weight ratios, ceramsite: 40 parts; iron and steel slag: 40 parts; fluorite ore tailings: 30 parts; fly ash: 9 parts; lime mud: 10 parts; cement: 10 parts; Activator: 3 parts;

[0057] b. First remove iron from steel slag, then mix and finely grind steel slag, fluorite ore tailings, fly ash, lime mud, cement, and activator into a mixture;

[0058] c. Stir the above-mentioned mixture and ceramsite, after stirring evenly, pour it into a mold for molding, demould after molding, and finally perform curing. The curing methods are natural curing, steam curing or curing machine curing.

Embodiment 3

[0060] A preparation method of ceramsite insulation brick, comprising the following steps:

[0061] a. Weigh raw materials according to the following weight ratios, ceramsite: 30 parts; iron and steel slag: 30 parts; fluorite ore tailings: 30 parts; fly ash: 8 parts; white mud: 8 parts; cement: 8 parts; Activator: 3 parts;

[0062] b. First remove iron from steel slag, then mix and finely grind steel slag, fluorite ore tailings, fly ash, lime mud, cement, and activator into a mixture;

[0063] c. Stir the above-mentioned mixture and ceramsite, after stirring evenly, pour it into a mold for molding, demould after molding, and finally perform curing. The curing methods are natural curing, steam curing or curing machine curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com