Pavement multistage rubblization construction method

A construction method and petrochemical technology, applied in the field of multi-stage petrochemical construction of pavement, can solve the problems of unified construction, inapplicability, poor effect, etc., and achieve the effect of short construction period, strong adaptability, and uniform crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

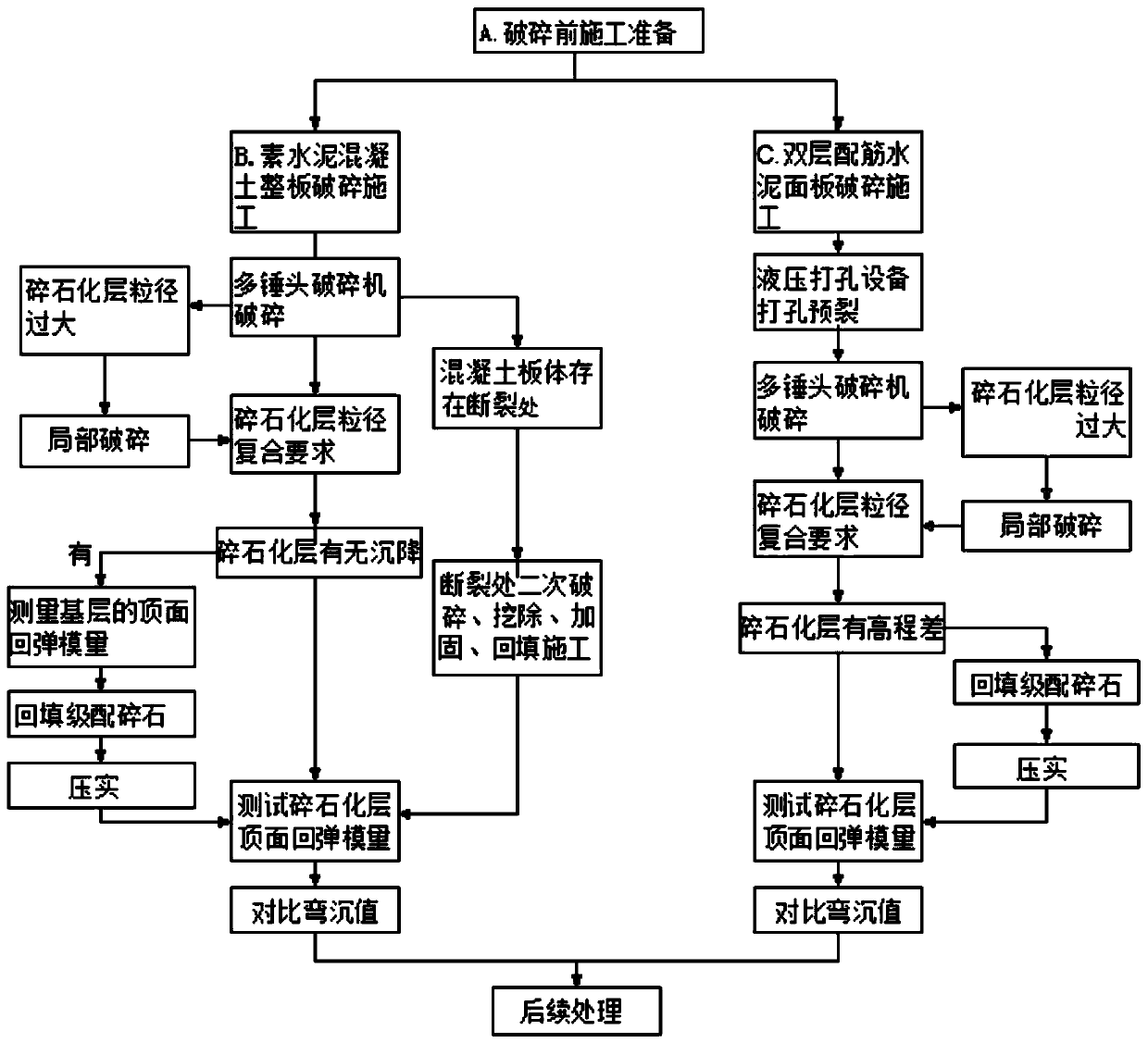

[0064] A multi-stage crushing construction method for pavement, including crushing the whole slab of plain cement concrete, including the steps of:

[0065] A. Preparation before crushing construction;

[0066] (1) There are no hidden structures such as culverts, passages, and underground pipelines;

[0067] (2) The length of a single plain cement concrete panel is 5m, the width is 4m, and the panel thickness is 25cm; the average deflection value of a single panel on the old pavement is 0.163mm, and the rebound modulus of the top surface of the base is 21.0MPa;

[0068] B. Crushing construction of plain cement concrete panels;

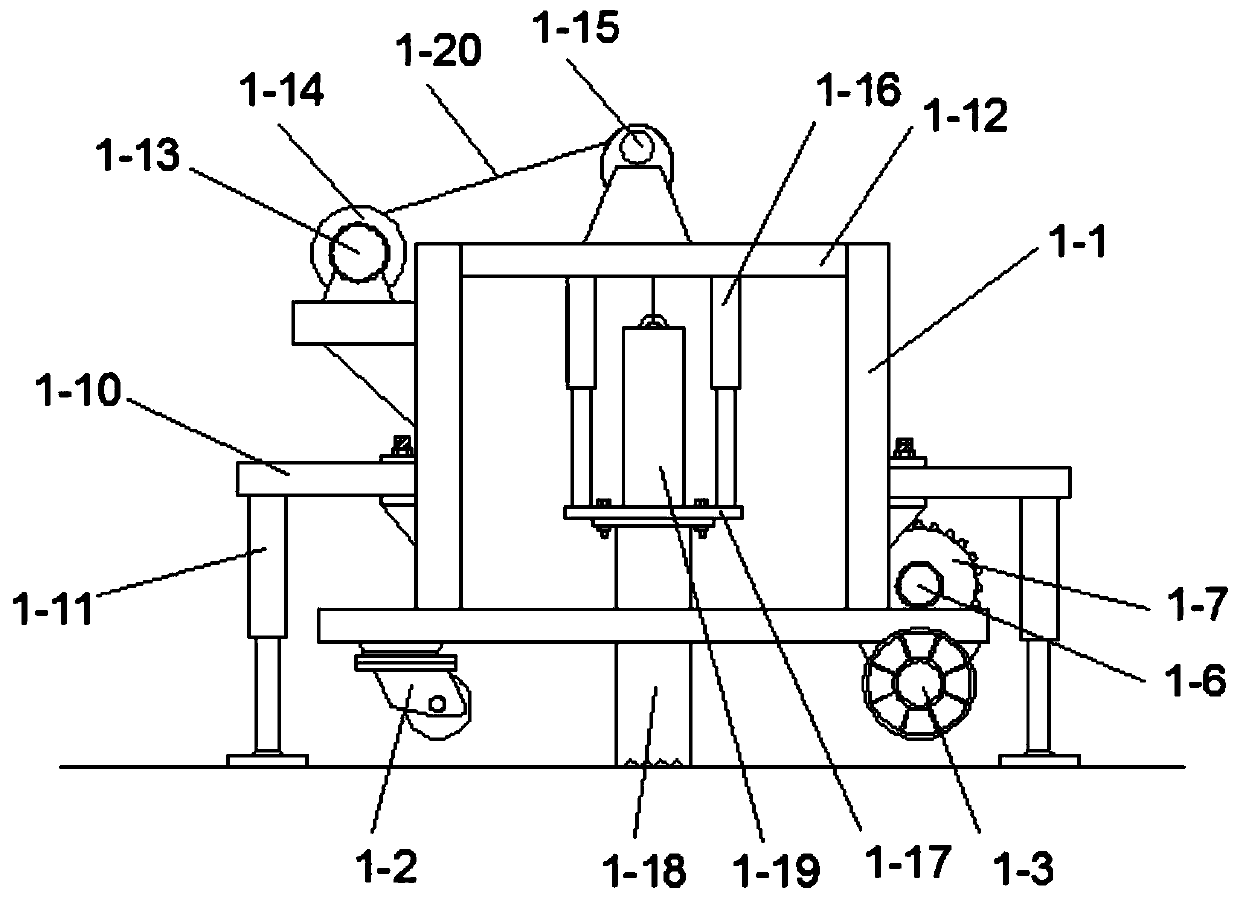

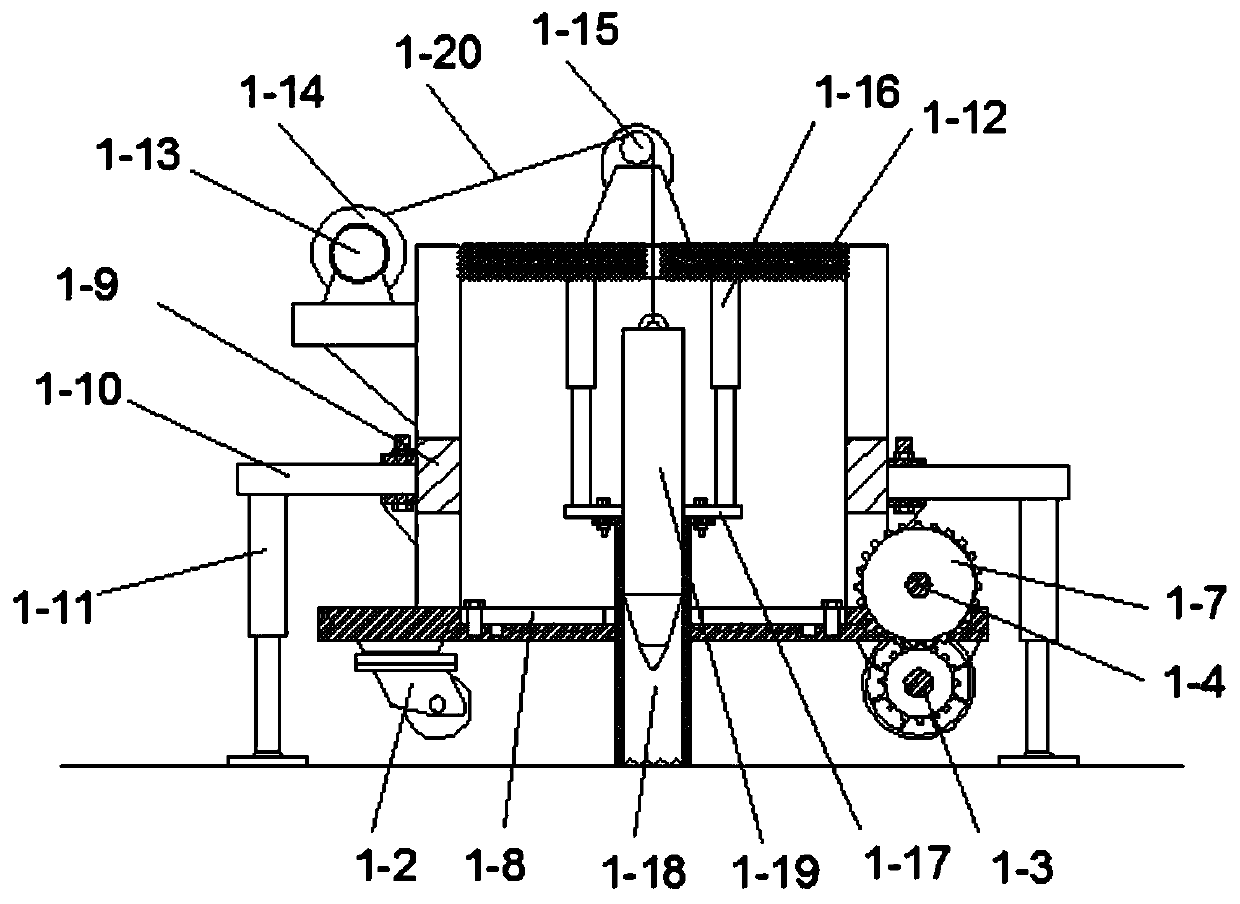

[0069] (1) Use multi-hammer crushing equipment to crush the road as a whole; adjust the parameters of the multi-hammer crushing equipment, the height of the hammer drop is 2200ms, and the frequency of the hammer drop is 18 times / min;

[0070] (2) observe that the crushed layer of the plain cement concrete whole slab has subsidence; the crushed layer ...

Embodiment 2

[0081] A multi-stage crushing construction method for pavement, including crushing the whole slab of plain cement concrete, including the steps of:

[0082] A. Preparation before crushing construction;

[0083] (1) There are no hidden structures such as culverts, passages, and underground pipelines;

[0084] (2) The length of a single plain cement concrete panel is 5m, the width is 4m, and the panel thickness is 25cm; the average deflection value of a single panel on the old pavement is 0.12mm, and the rebound modulus of the top surface of the base is 15.1MPa;

[0085] B. Crushing construction of plain cement concrete panels;

[0086] (1) Use multi-hammer crushing equipment to crush the road as a whole; adjust the parameters of the multi-hammer crushing equipment, the height of the hammer drop is 2200ms, and the frequency of the hammer drop is 18 times / min;

[0087] (2) Observe that the crushed layer of the plain cement concrete whole slab is broken and has settlement, and t...

Embodiment 3

[0096] A multi-stage crushing construction method for pavement, including the crushing of plain cement concrete slabs, including the steps of:

[0097] A. Preparation before crushing construction;

[0098] (1) There are no hidden structures such as culverts, passages, and underground pipelines;

[0099] (2) The length of a single plain cement concrete panel is 5m, the width is 4m, and the panel thickness is 25cm; the average deflection value of a single panel on the old pavement is 0.179mm, and the rebound modulus of the top surface of the base is 22.1MPa;

[0100] B. Crushing construction of plain cement concrete panels;

[0101] (1) Use multi-hammer crushing equipment to crush the road as a whole; adjust the parameters of the multi-hammer crushing equipment, the height of the hammer drop is 2200ms, and the frequency of the hammer drop is 18 times / min;

[0102] (2) Observe that the crushed layer of the plain cement concrete whole slab is broken and has settlement, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com