Patents

Literature

64results about How to "Avoid wrong station" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

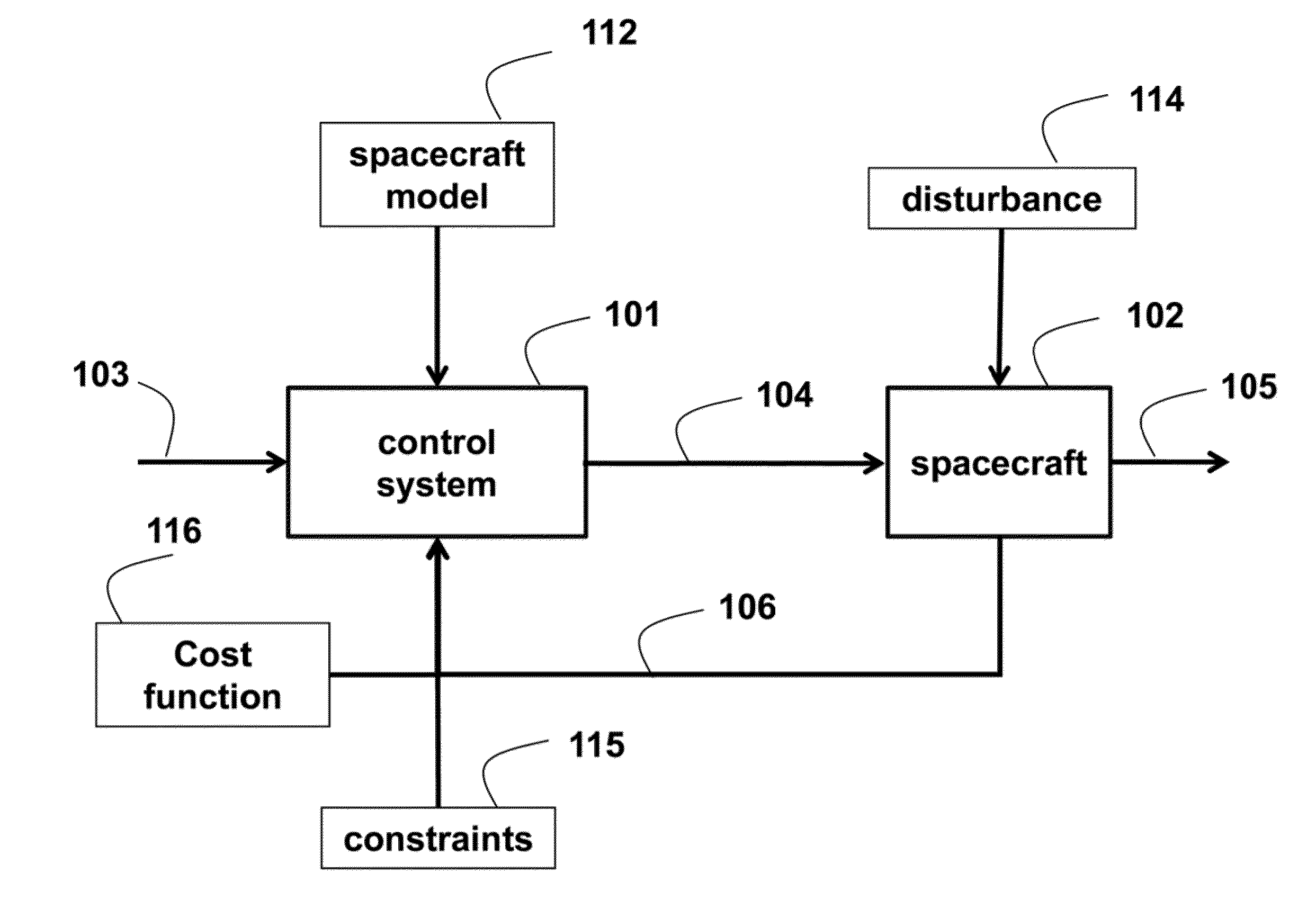

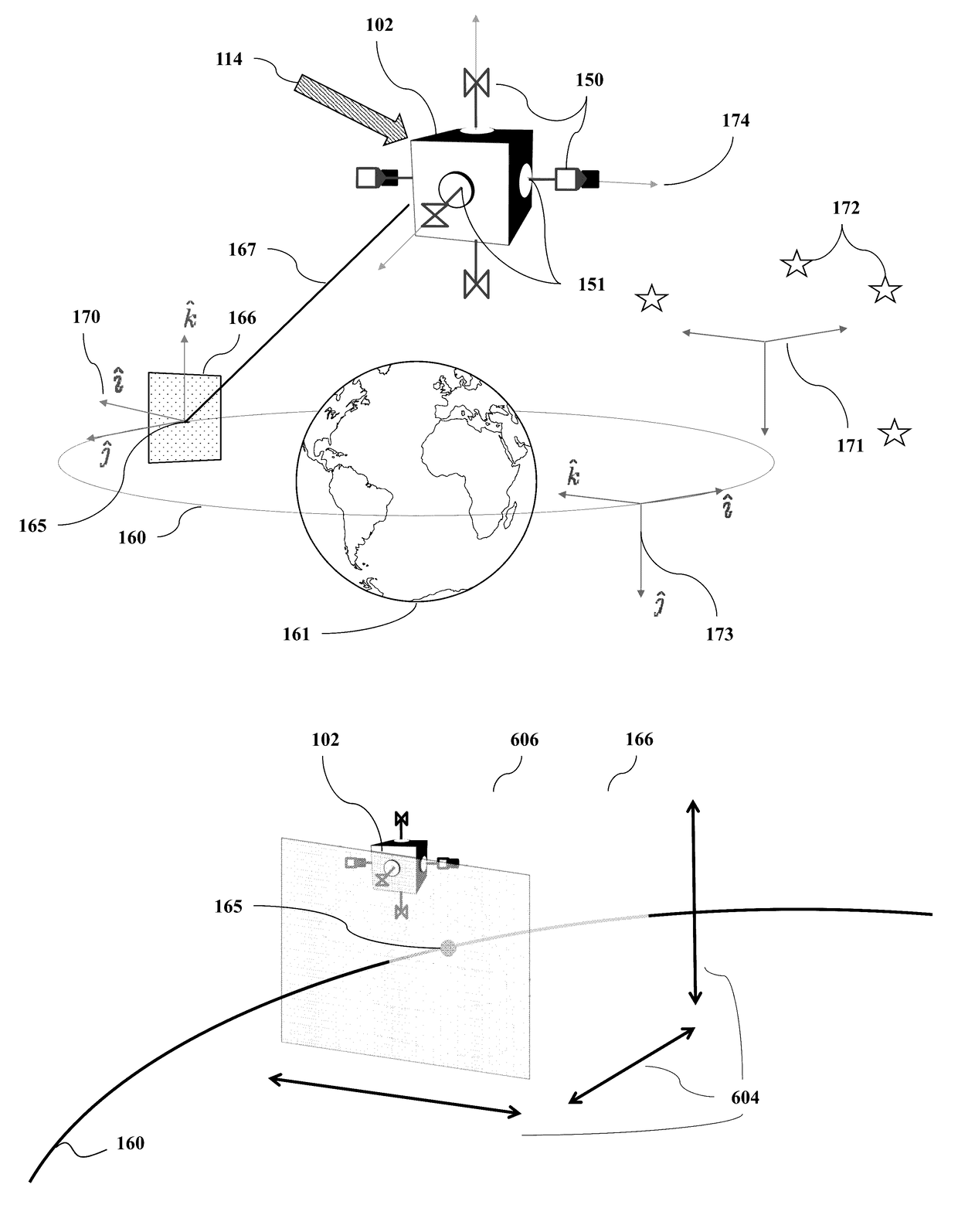

Model Predictive Control of Spacecraft

ActiveUS20160194095A1Tighter and accurate station keepingTighter and accurate and momentum unloadingCosmonautic vehiclesDigital data processing detailsHorizonMomentum

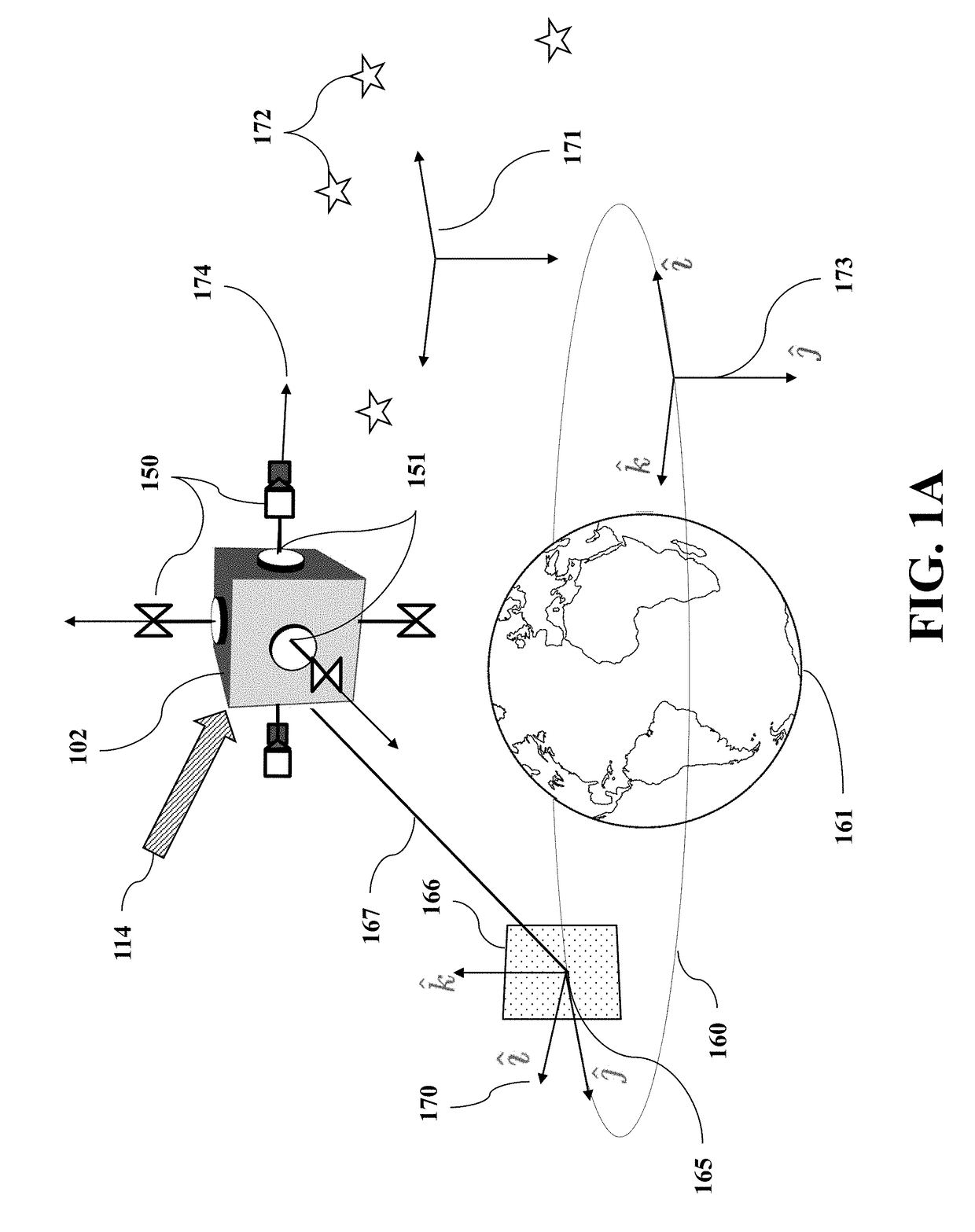

A method controls an operation of a spacecraft according to a model of the spacecraft. The method determines control inputs for controlling concurrently thrusters of the spacecraft and momentum exchange devices of the spacecraft using an optimization of a cost function over a receding horizon subject to constraints on a pose of the spacecraft and constraints on inputs to the thrusters. The cost function includes components for controlling the pose of the spacecraft and a momentum stored by the momentum exchange devices. The method generates a command to control concurrently the thrusters and the momentum exchange devices according to at least a portion of the control inputs.

Owner:MITSUBISHI ELECTRIC RES LAB INC

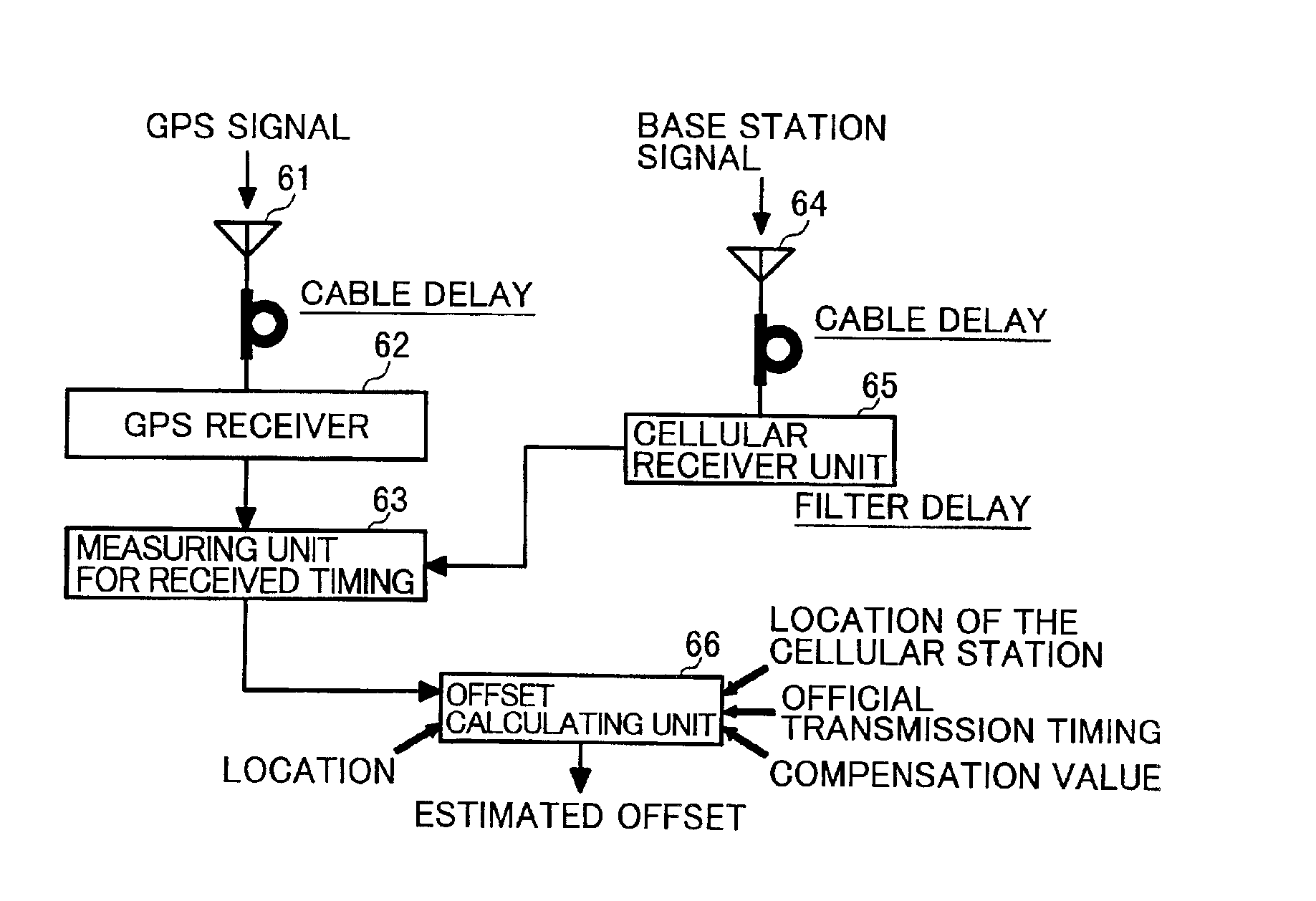

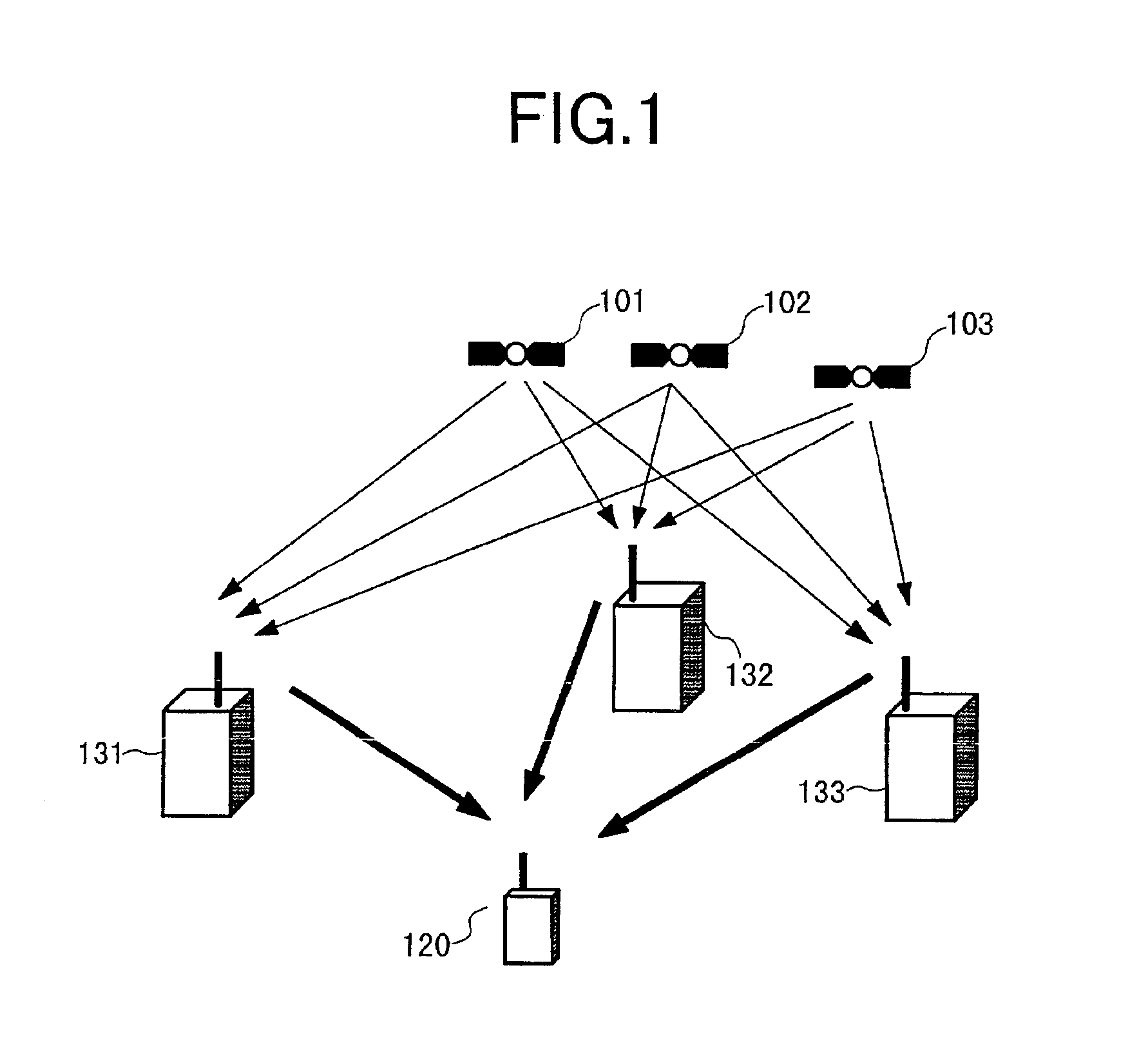

Method and apparatus for measuring transmitting time offset of a base station

InactiveUS6889051B2High measurement accuracyAvoid wrong stationSynchronisation arrangementSpatial transmit diversityObservation pointRadio Base Station

An offset measuring method according to the present invention accurately measures a transmitting time offset of a base station. The offset measuring method for receiving signals from the radio base station and measuring the transmitting time offset of the radio base station includes the steps of calculating estimated values of transmitting time offset based on signals received at a plurality of observation points and selecting a minimum from the estimated offsets to determine the selected minimum value as transmitting time offset of the radio base station.

Owner:HITACHI LTD

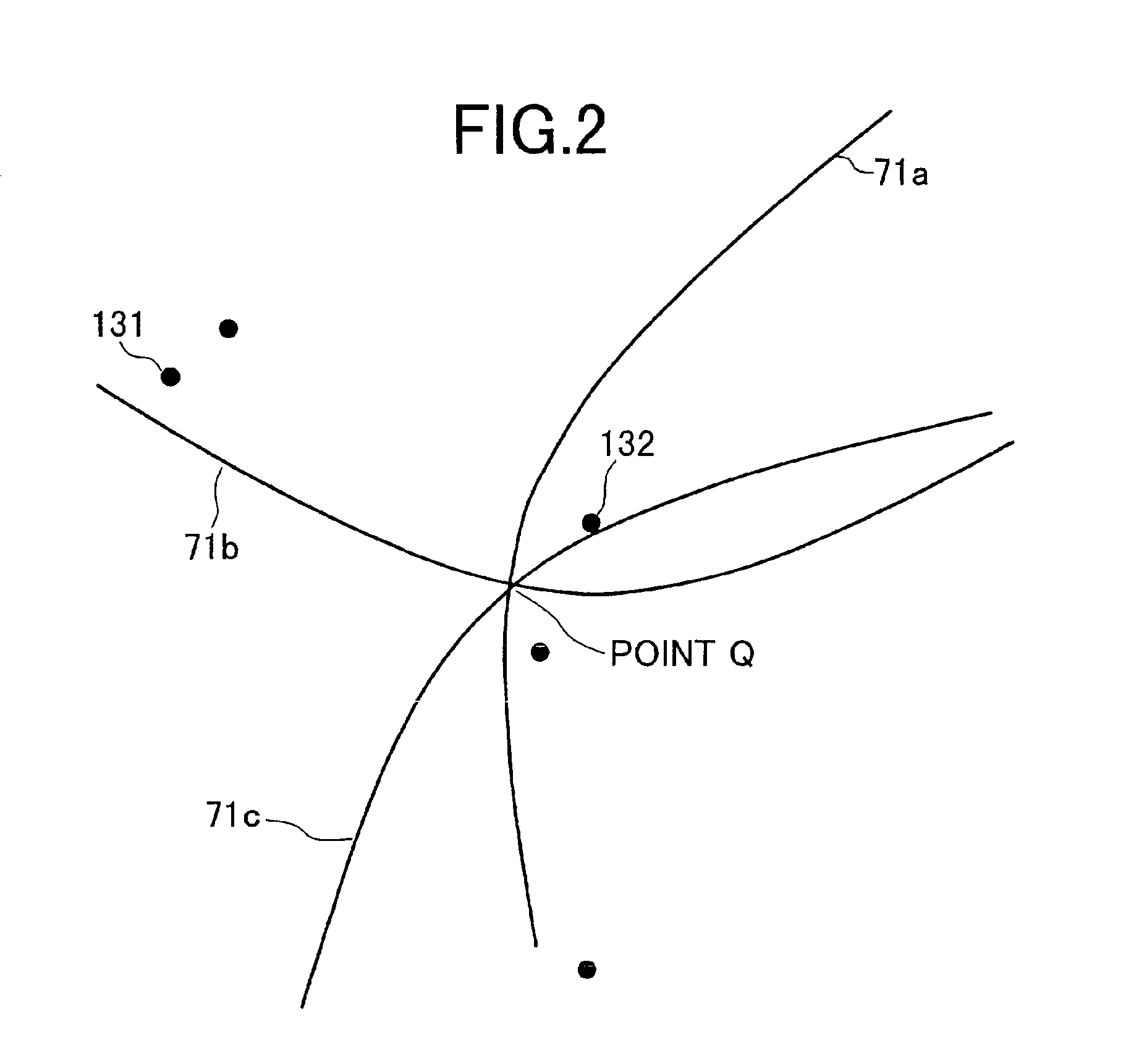

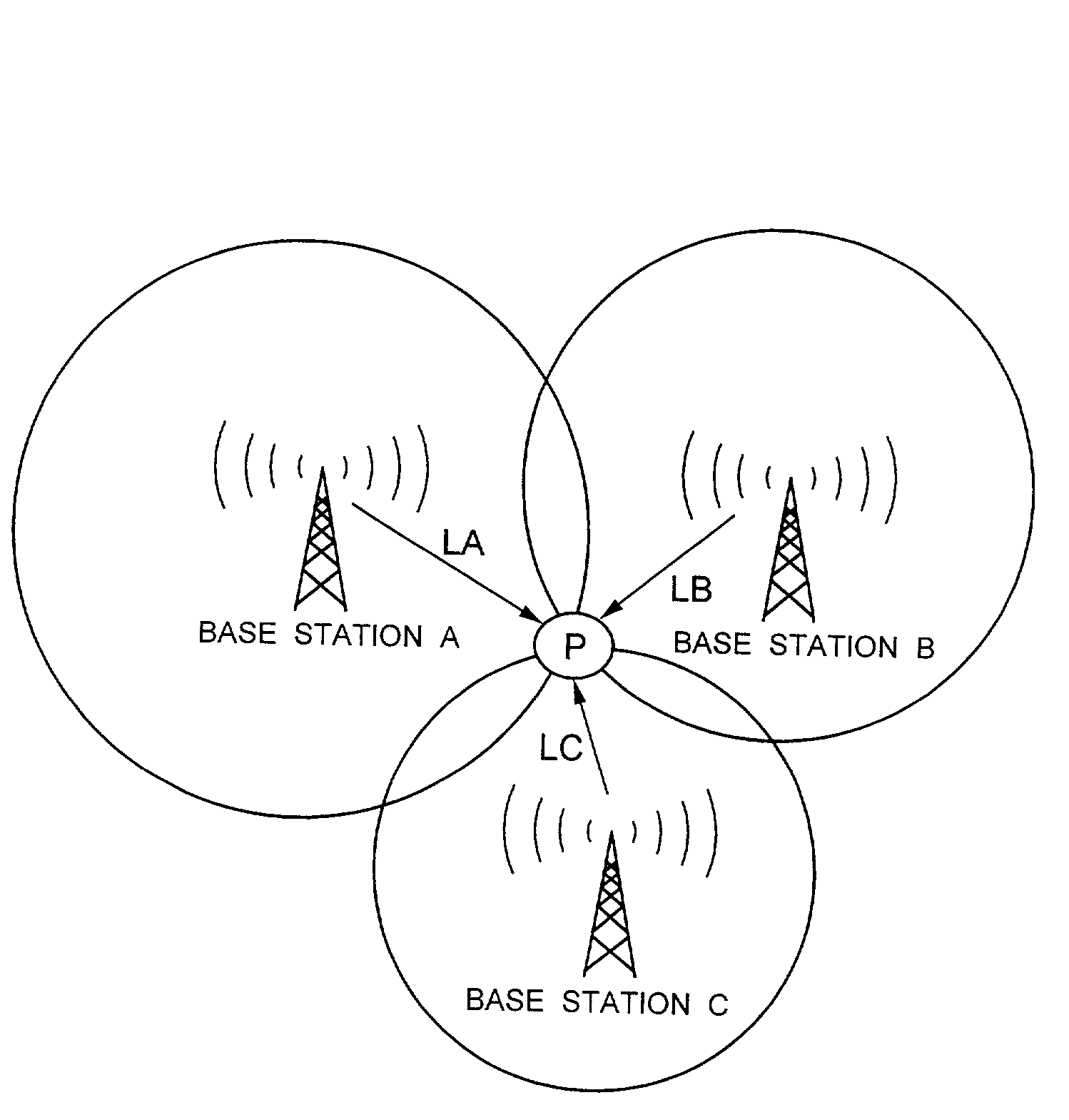

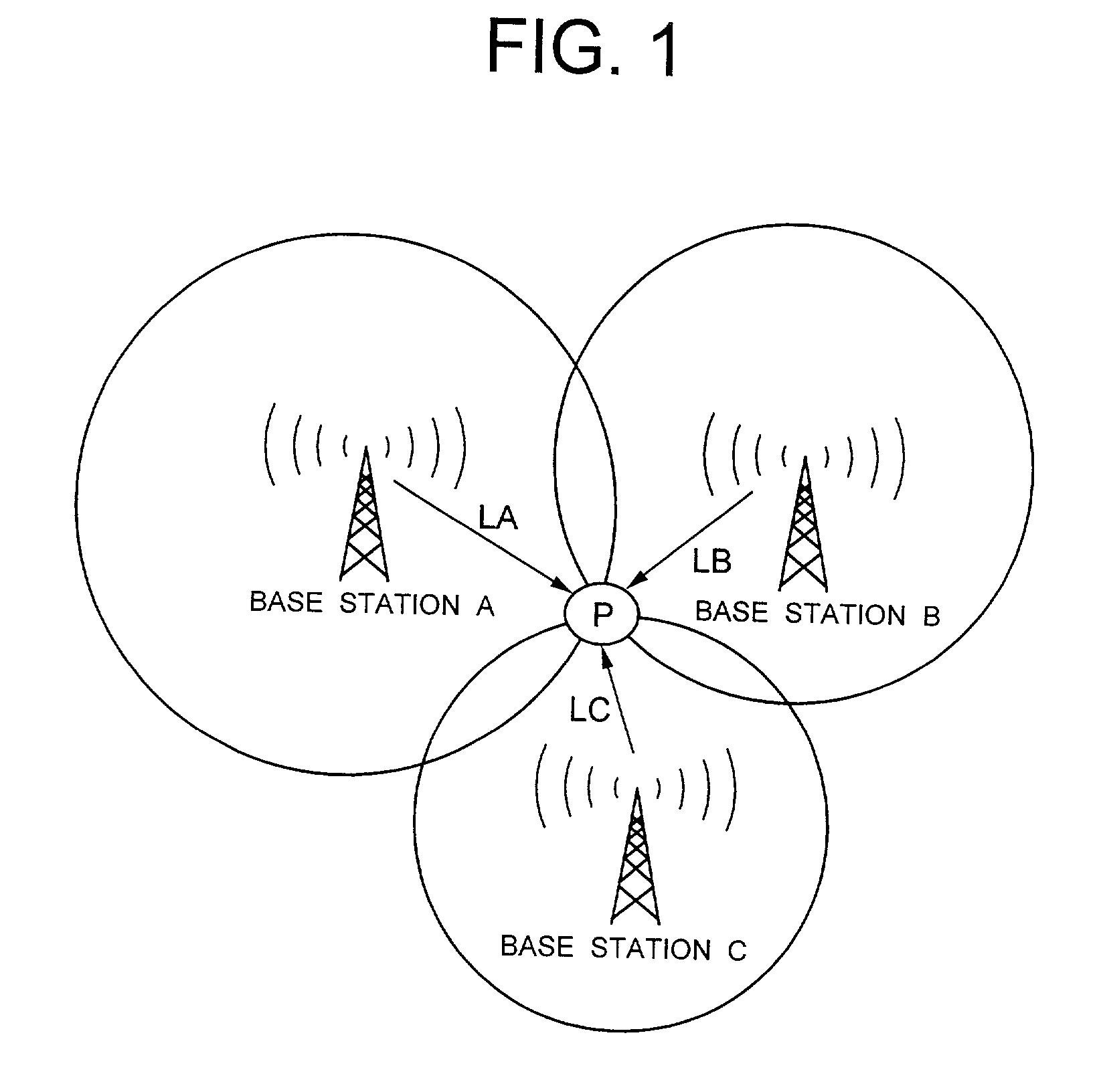

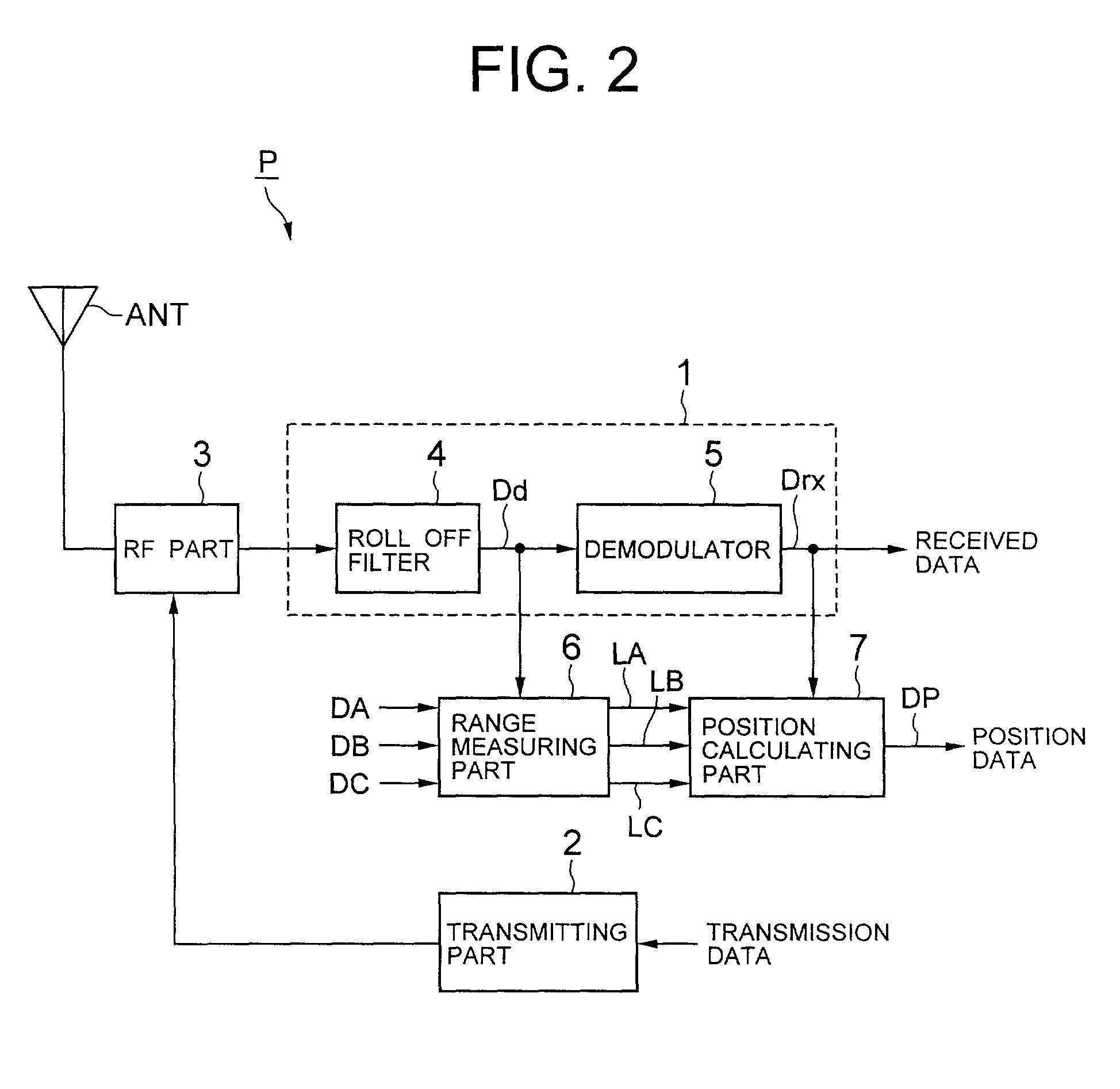

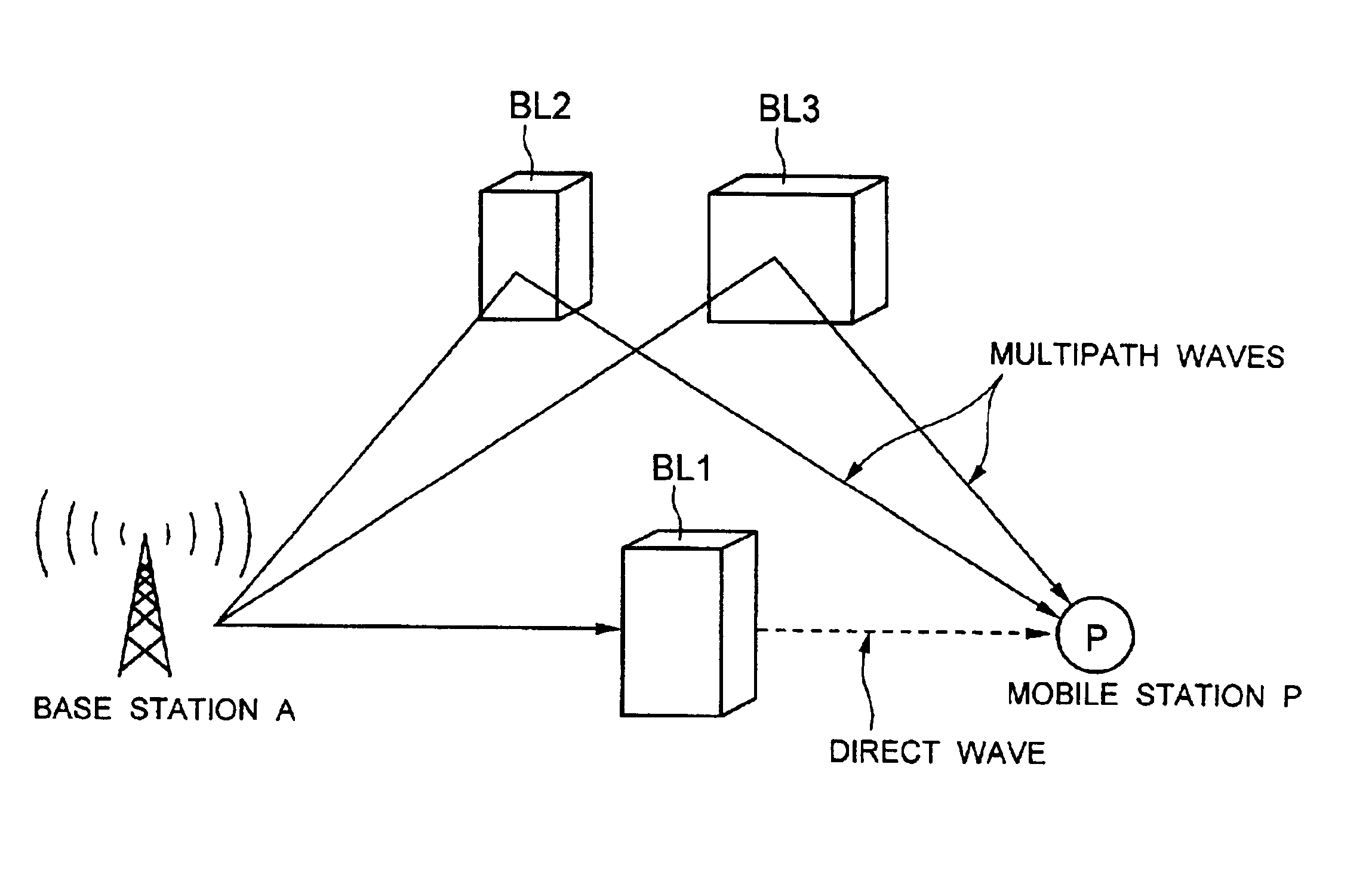

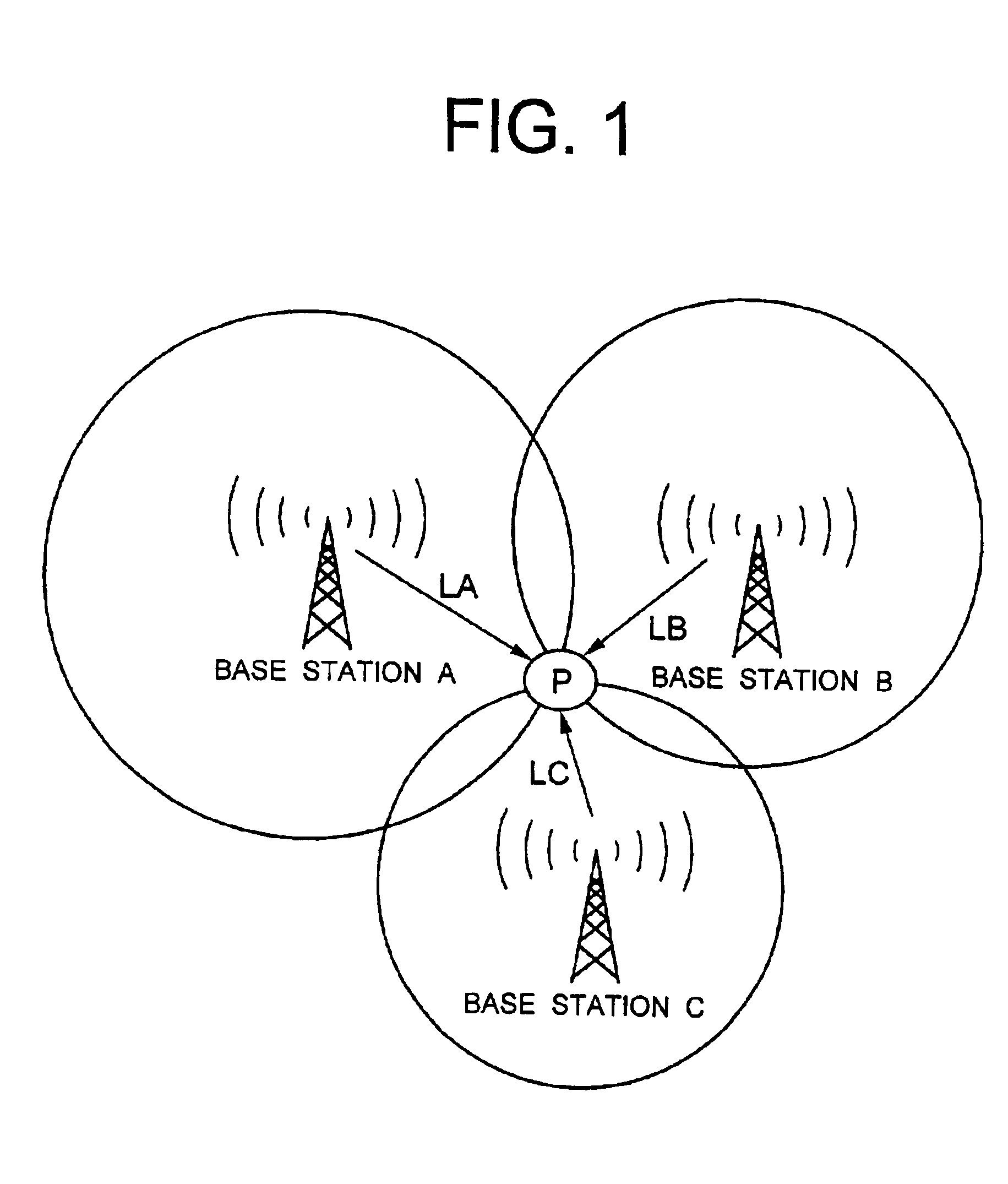

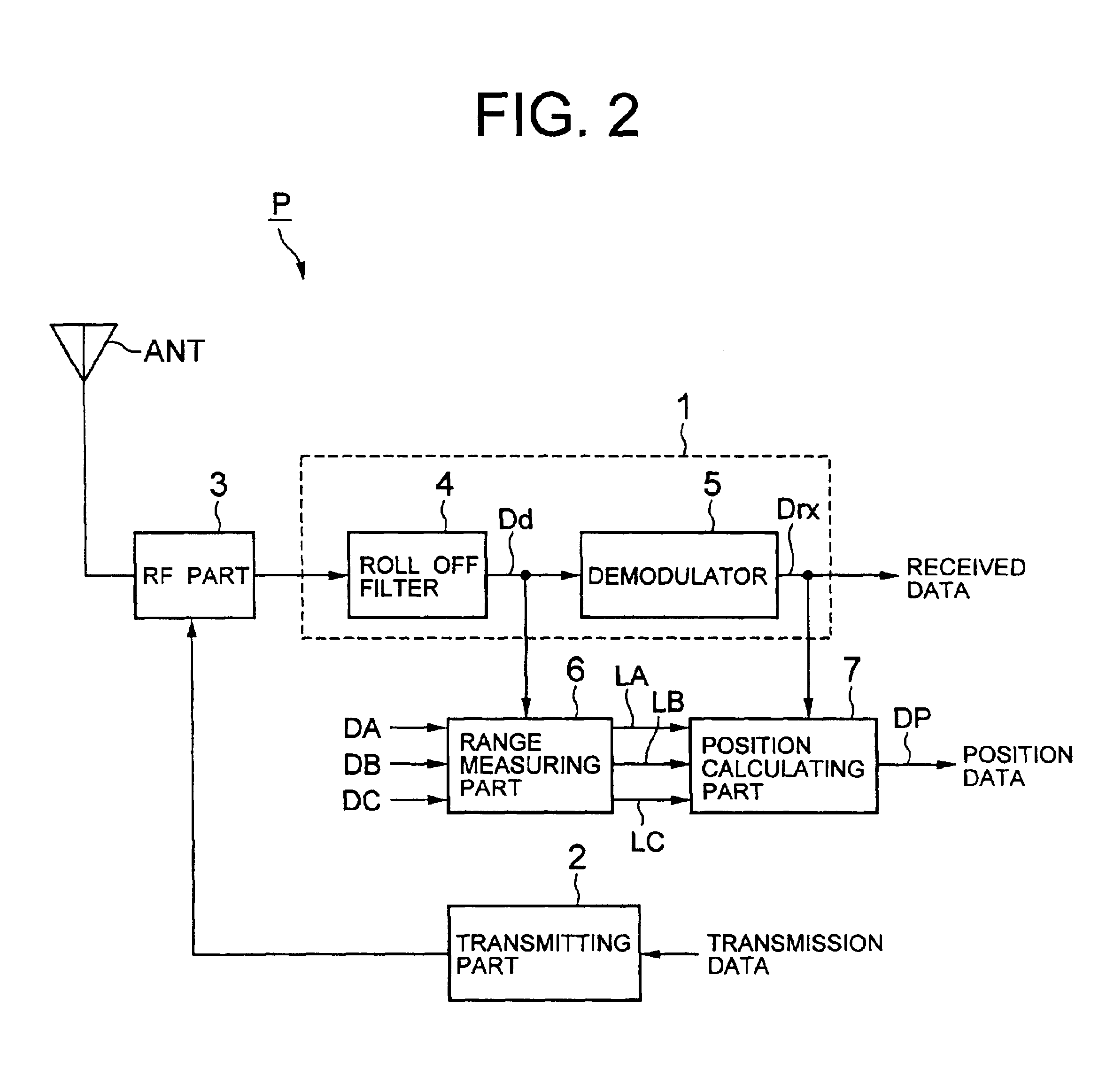

Method and apparatus for positioning a mobile station

InactiveUS20020183071A1Avoid wrong stationDirection finders using radio wavesSpecial service for subscribersRadio waveEngineering

A positioning apparatus and method for accurately determining a current position of a mobile station. The current position of the mobile station is determined utilizing radio waves arriving from a plurality of base stations installed in a communication area. For calculating a propagation range of a radio wave arriving from each base station, error correction processing is performed using a predetermined error correction coefficient previously calculated by measuring a radio wave propagation situation around each base station to estimate a propagation range of a direct wave within incoming radio waves. The current position of the mobile station is determined using the estimated propagation range and the positions of the respective base station.

Owner:PIONEER CORP

Method and apparatus for positioning a mobile station

InactiveUS6853847B2Avoid wrong stationDirection finders using radio wavesBeacon systems using radio wavesEngineeringMobile station

A positioning apparatus and method for accurately determining a current position of a mobile station. The current position of the mobile station is determined utilizing radio waves arriving from a plurality of base stations installed in a communication area. For calculating a propagation range of a radio wave arriving from each base station, error correction processing is performed using a predetermined error correction coefficient previously calculated by measuring a radio wave propagation situation around each base station to estimate a propagation range of a direct wave within incoming radio waves. The current position of the mobile station is determined using the estimated propagation range and the positions of the respective base station.

Owner:PIONEER CORP

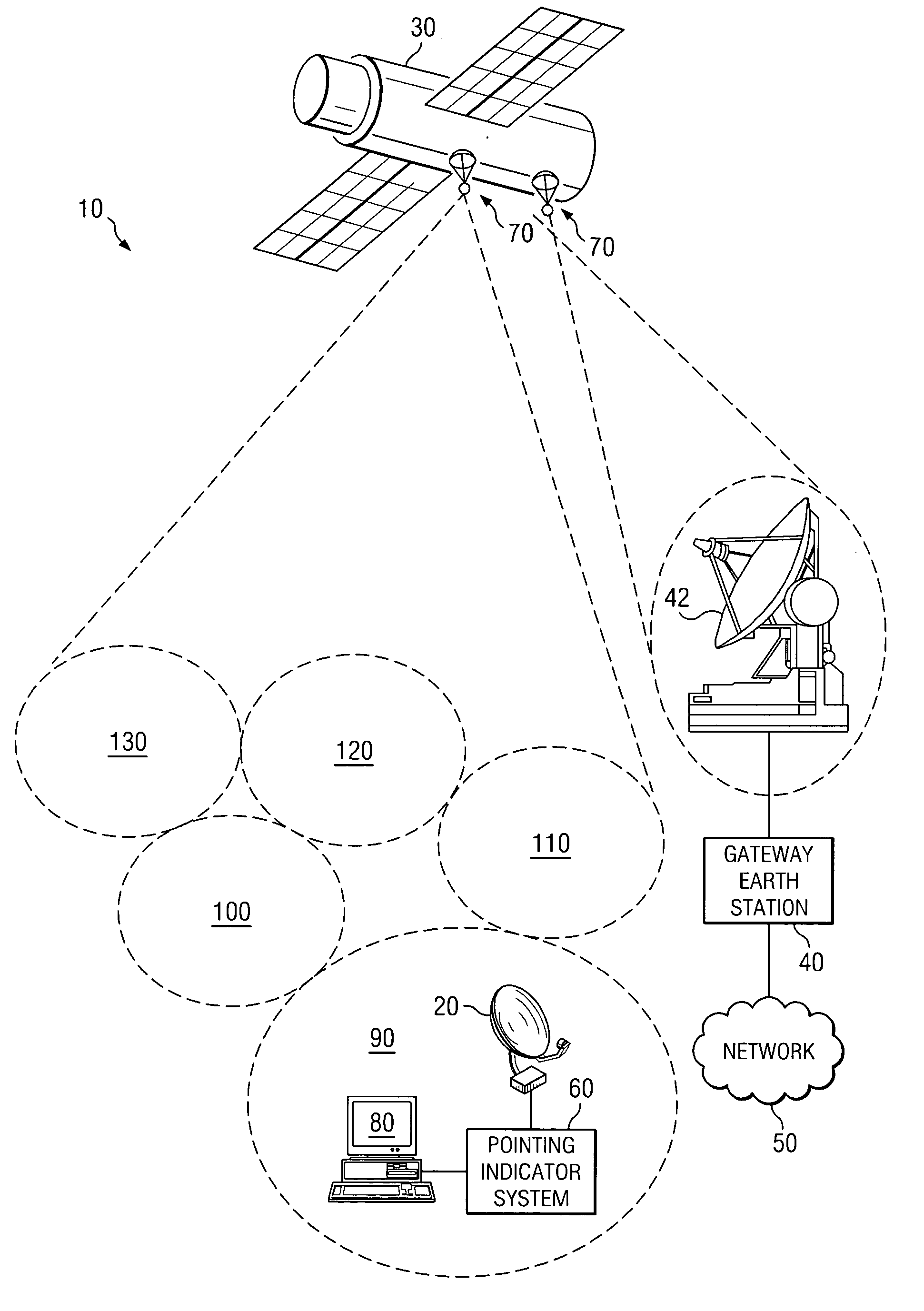

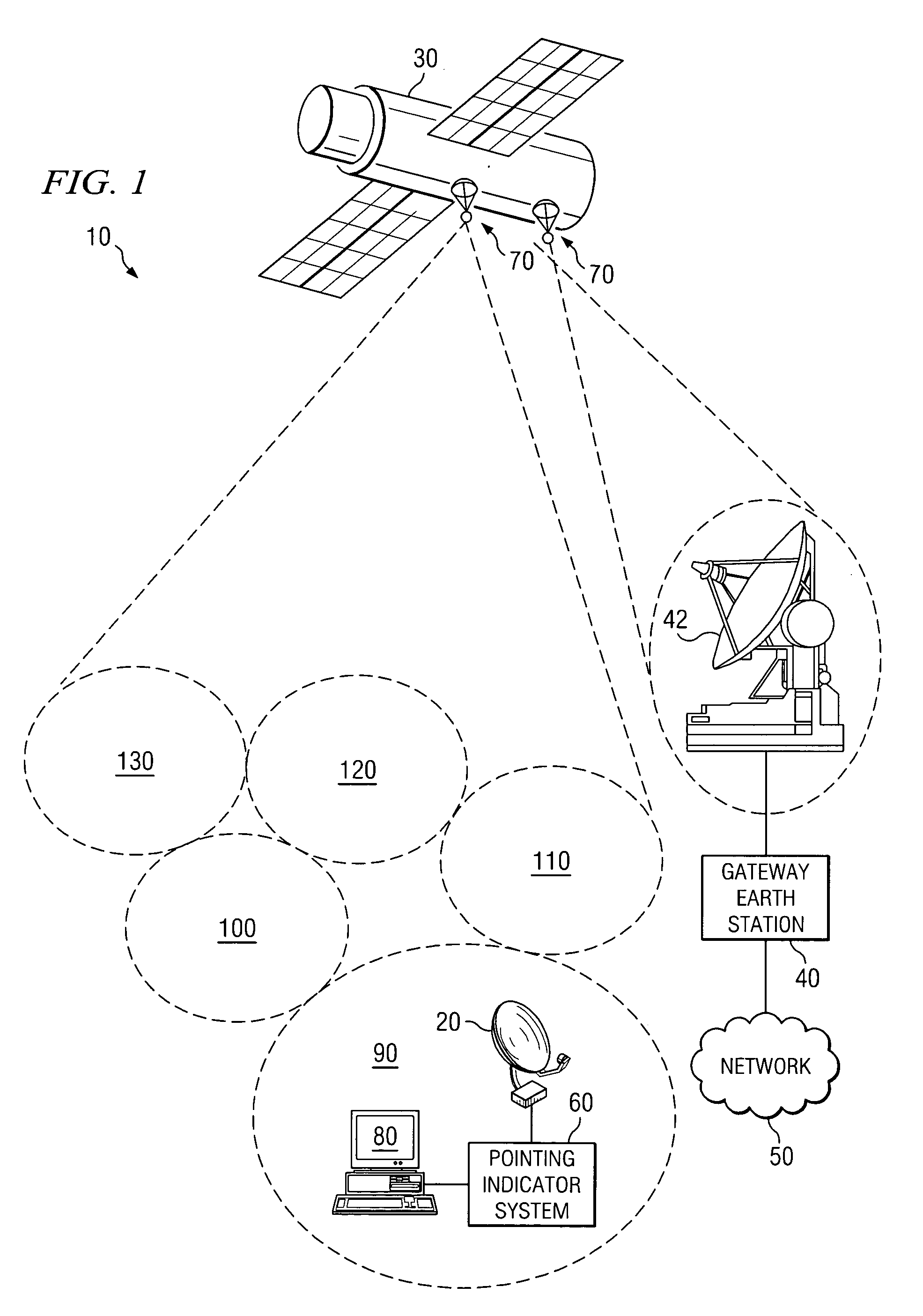

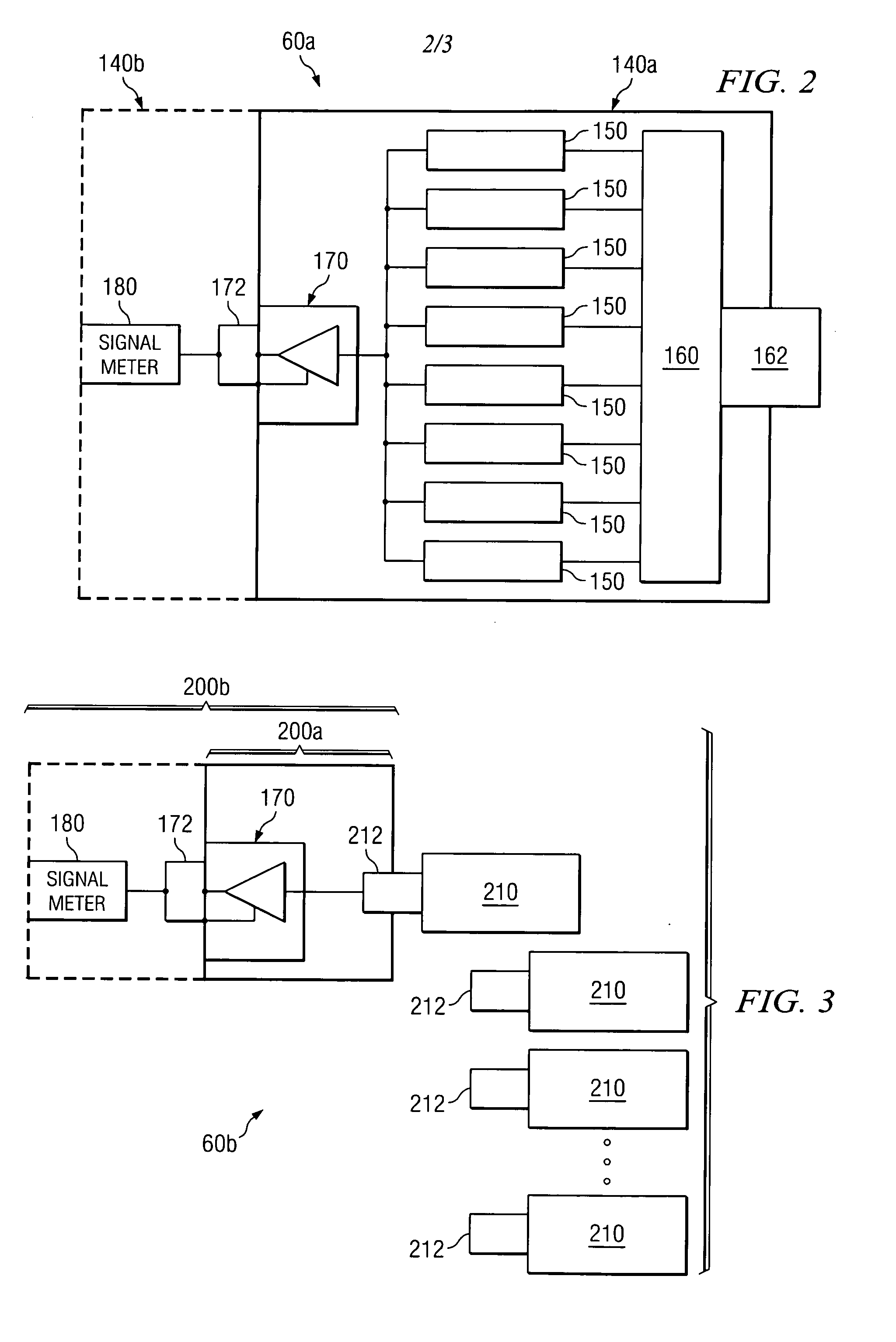

Method and device for accurately pointing a satellite earth station antenna

ActiveUS20060181455A1Easy to reconfigureEasy to updateAntenna detailsRadio wave reradiation/reflectionAudio power amplifierEngineering

A device for measuring the received signal strength at an Earth station antenna has the capability to provide an accurate pointing indication when the frequency bands and other key characteristics of the satellite signals are not uniform over the coverage area. The device has an input port, a plurality of passive or active signal filters, a filter selector and an output port. The device may further contain a signal amplifier with automatic or manual gain control. A plurality of filters is provided which may be coupled singularly or in combination between the input port and the output port. Each filter or combination of filters is associated with a particular geographic area and capable of allowing the satellite signal assigned to that geographic area to pass while attenuating or blocking other signals, noise and interference. The filter selector is used to connect the appropriate filter or combination of filters between the input port and the output port. A signal amplifier with manual or automatic gain control may be included to provide an output signal at the desired signal level. The output port may be connected to a power measuring unit, antenna pointing meter or other similar device to provide an accurate antenna pointing indication in the particular geographic area corresponding to the filter or filter combination selected.

Owner:VIASAT INC

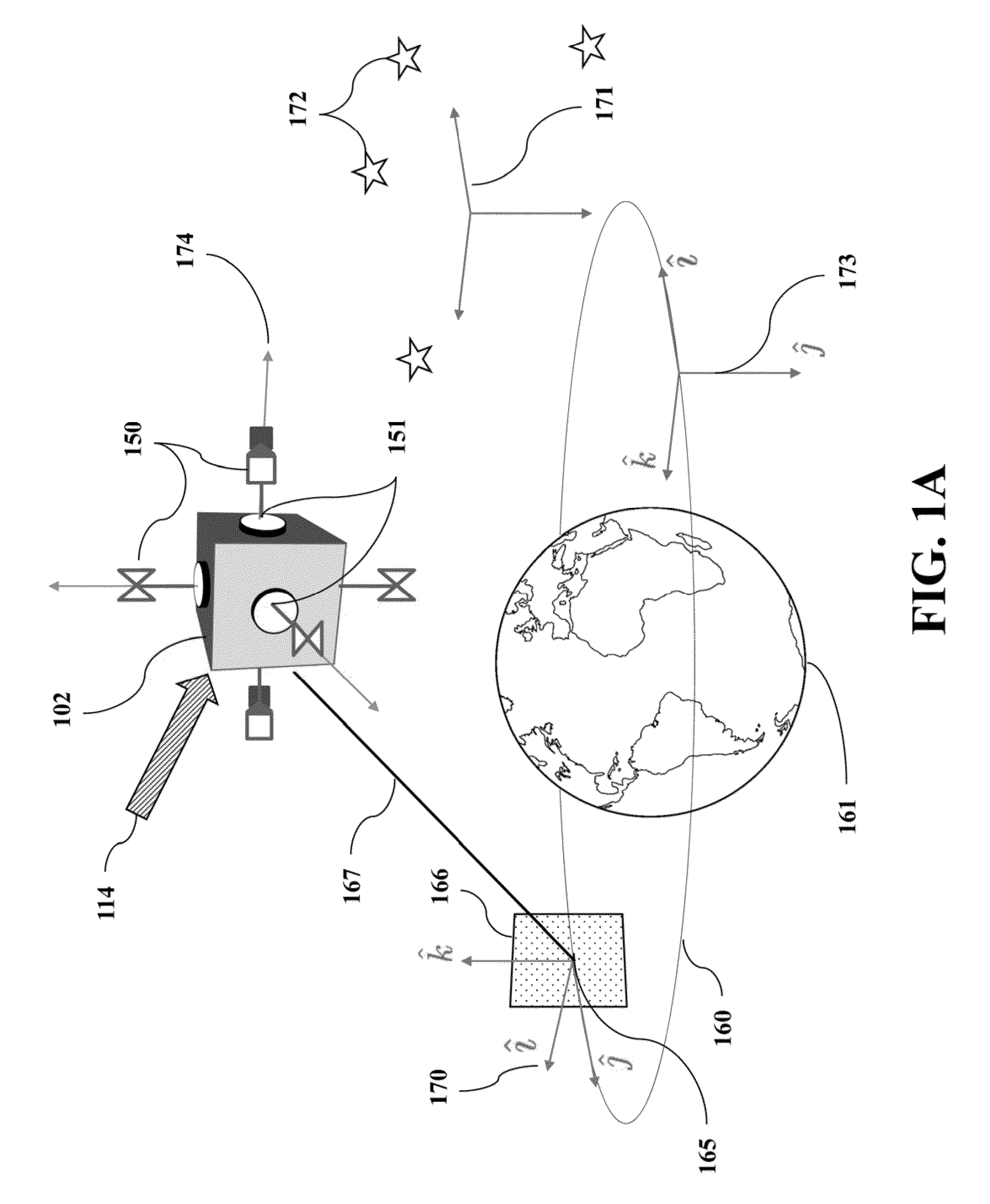

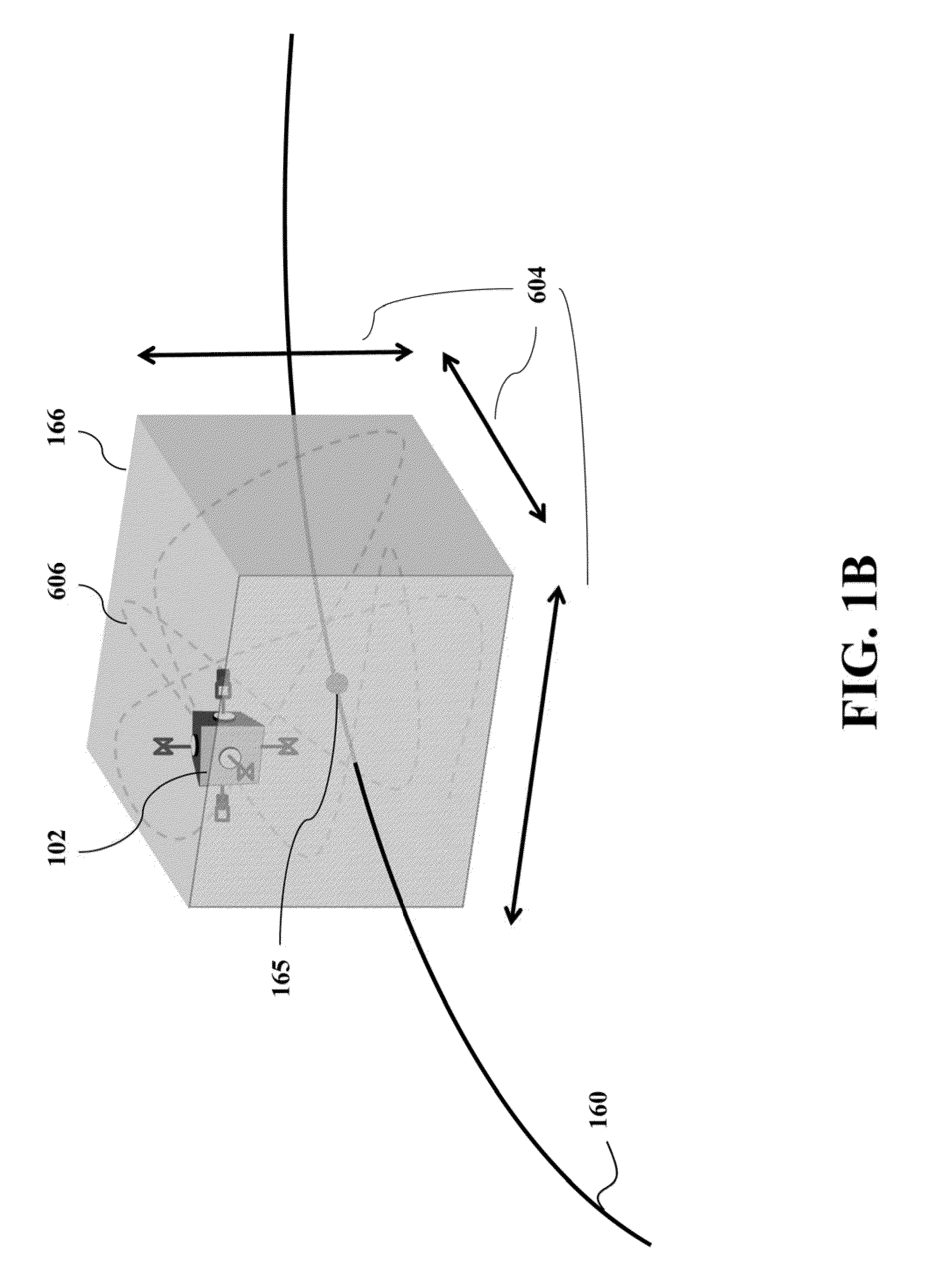

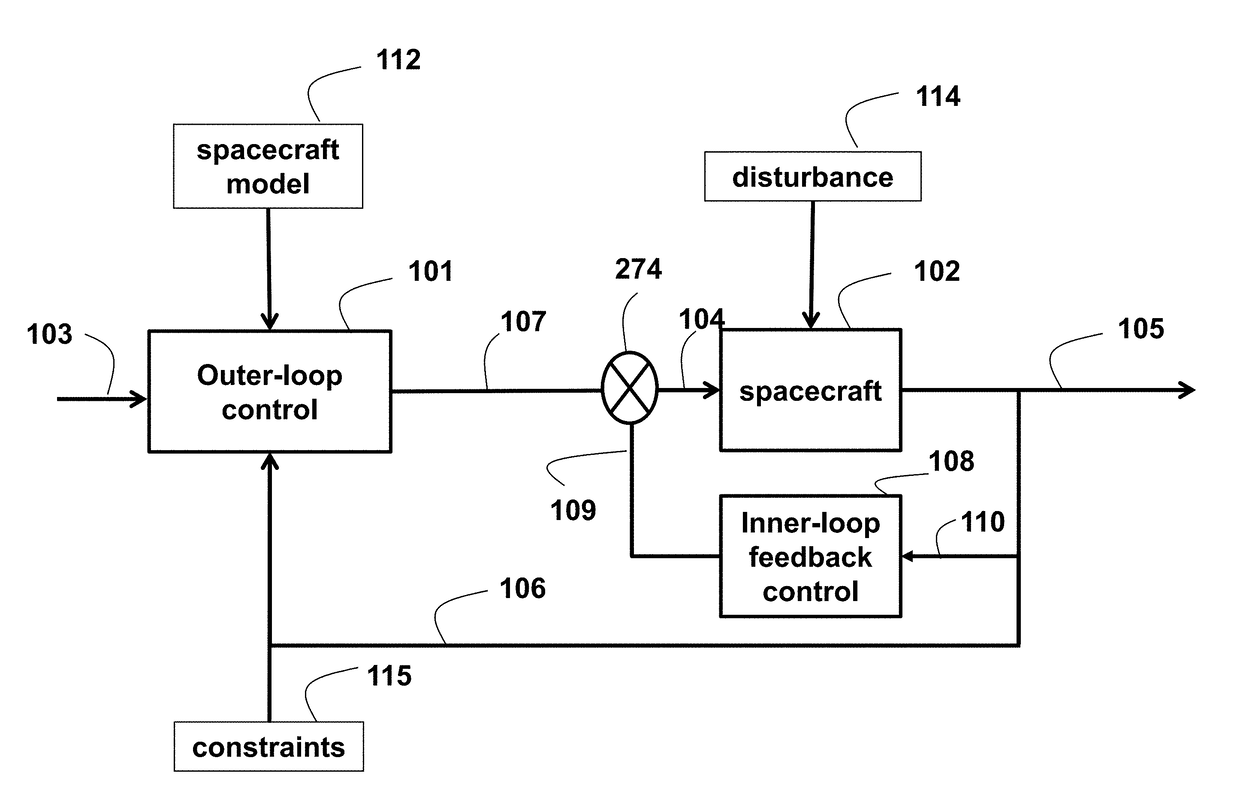

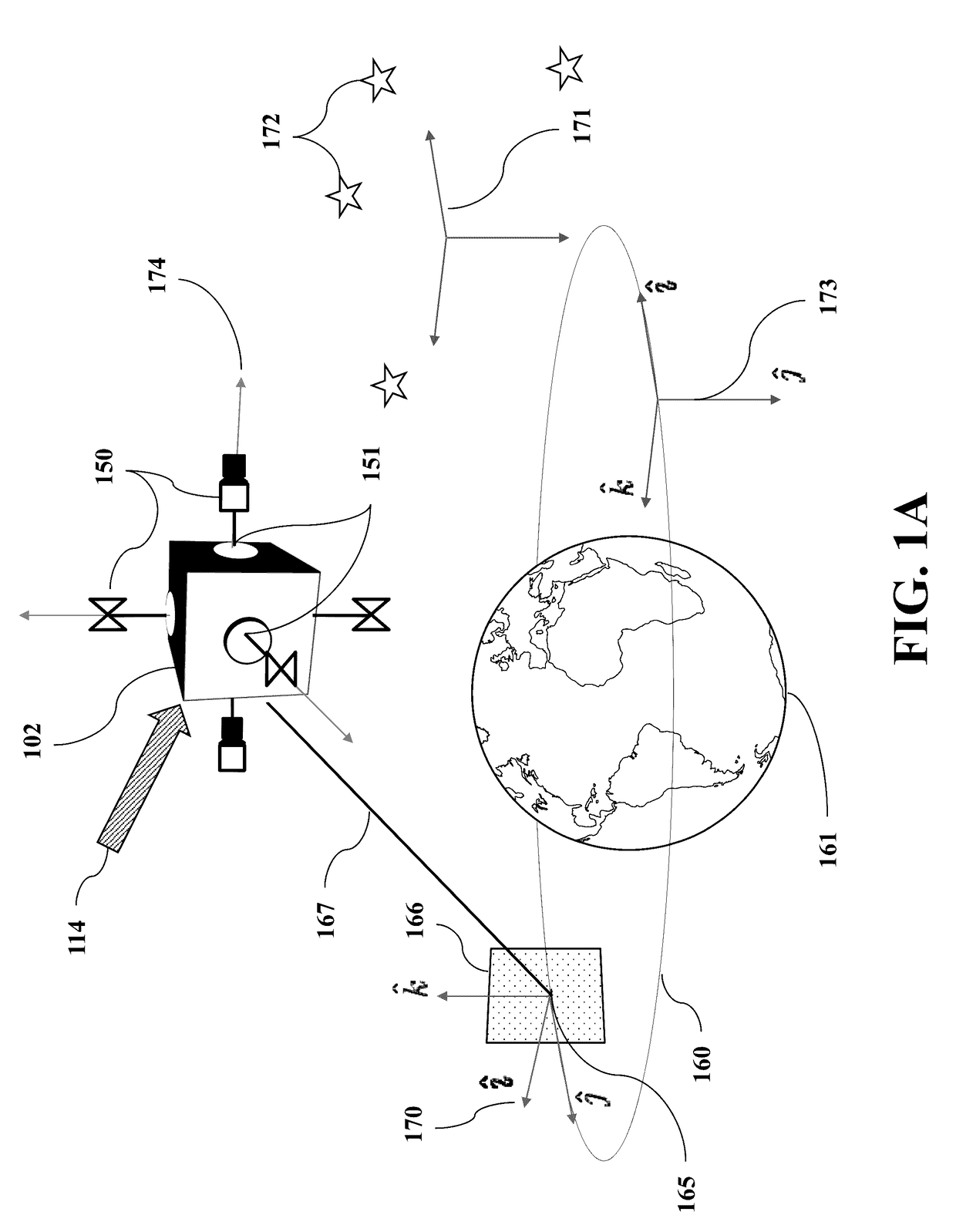

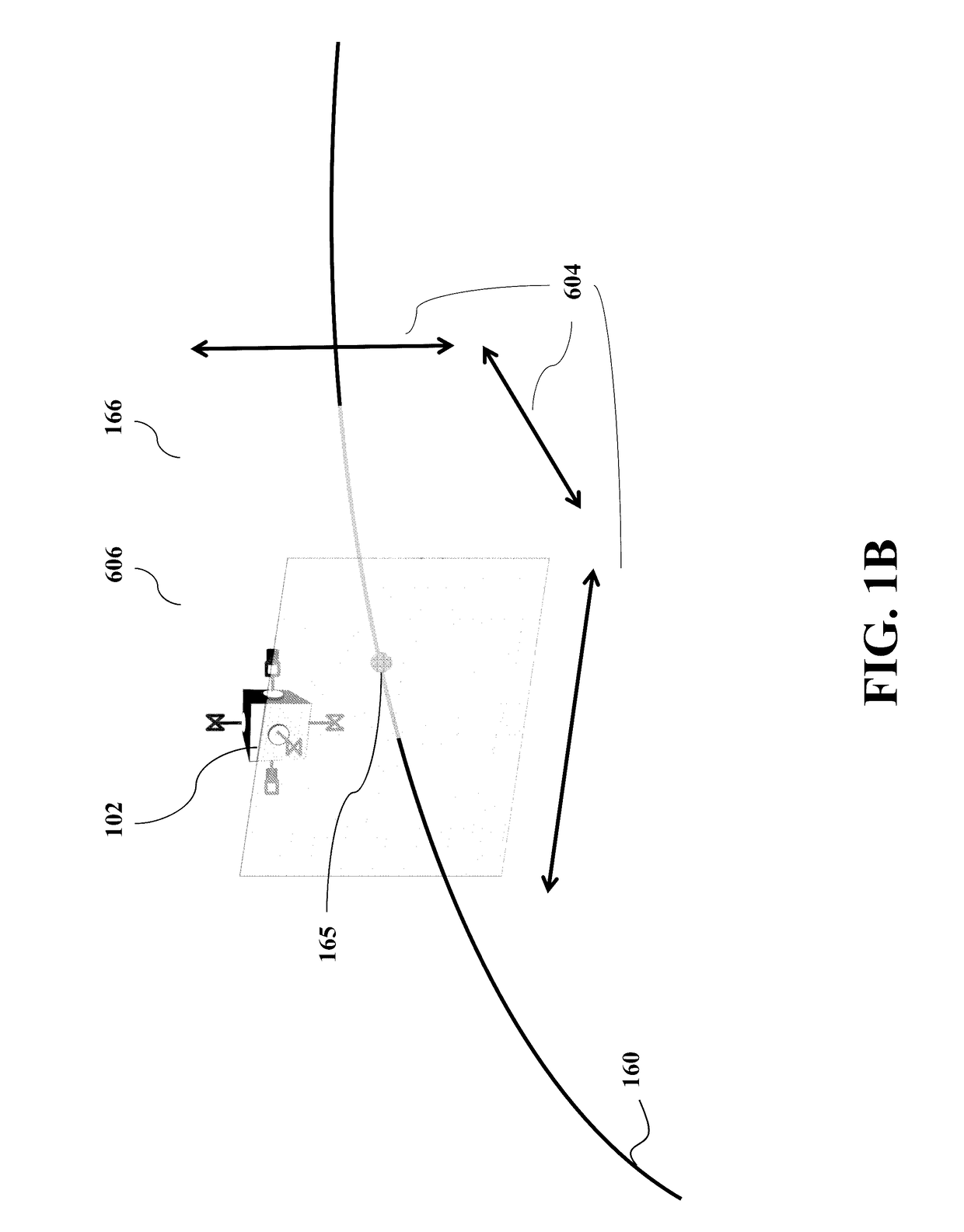

Concurrent Station Keeping, Attitude Control, and Momentum Management of Spacecraft

ActiveUS20170269610A1Tighter and accurate station keepingTighter and accurate and attitude controlCosmonautic vehiclesCosmonautic propulsion system apparatusInner loopAttitude control

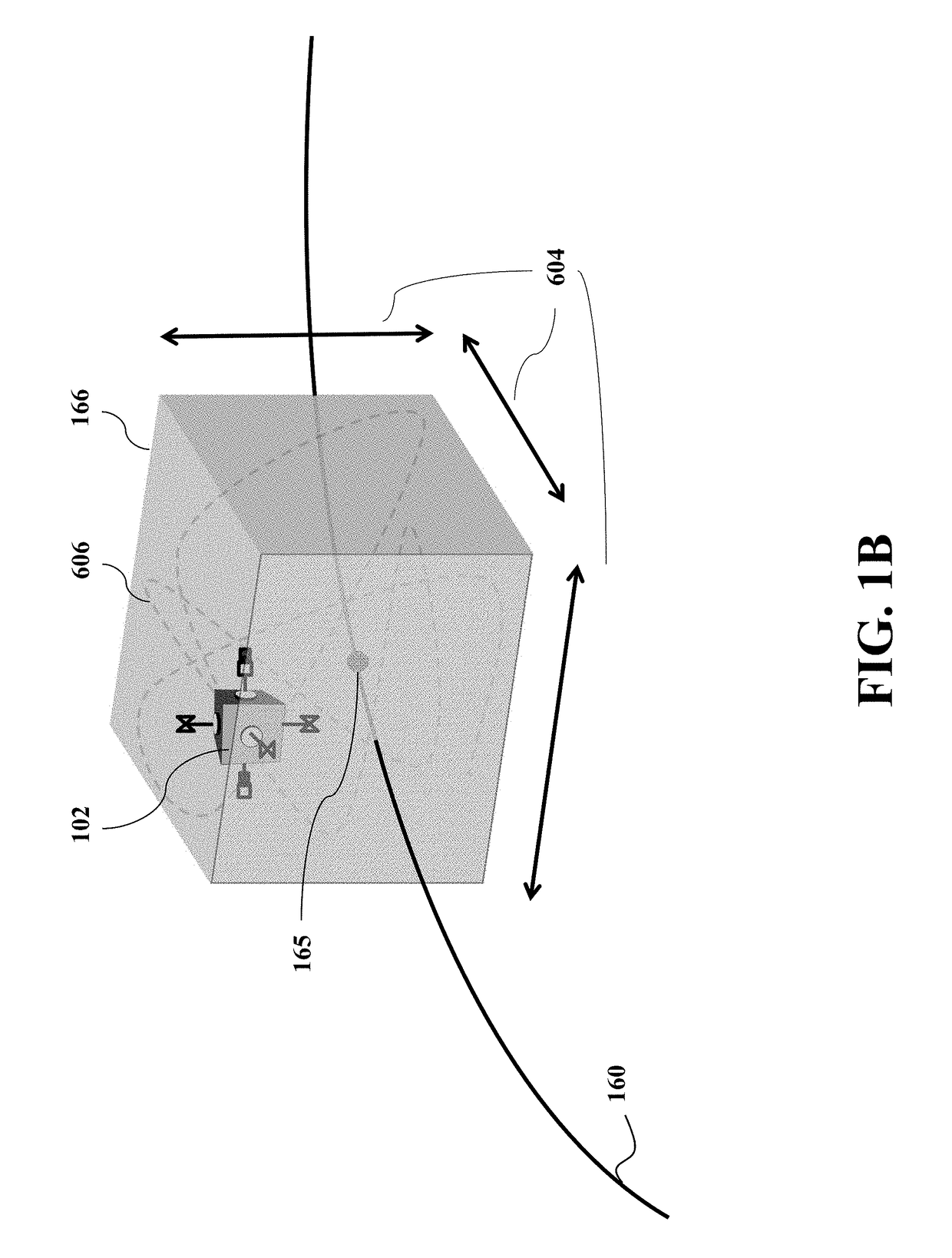

An operation of a spacecraft is controlled using an inner-loop control determining first control inputs for momentum exchange devices to control an orientation of the spacecraft and an outer-loop control determining second control inputs for thrusters of the spacecraft to concurrently control a pose of the spacecraft and a momentum stored by the momentum exchange devices of the spacecraft. The outer-loop control determines the second control inputs using a model of dynamics of the spacecraft including dynamics of the inner-loop control, such that the outer-loop control accounts for effects of actuation of the momentum exchange devices according to the first control inputs determined by the inner-loop control. The thrusters and the momentum exchange devices are controlled according to at least a portion of the first and the second control inputs.

Owner:MITSUBISHI ELECTRIC RES LAB INC

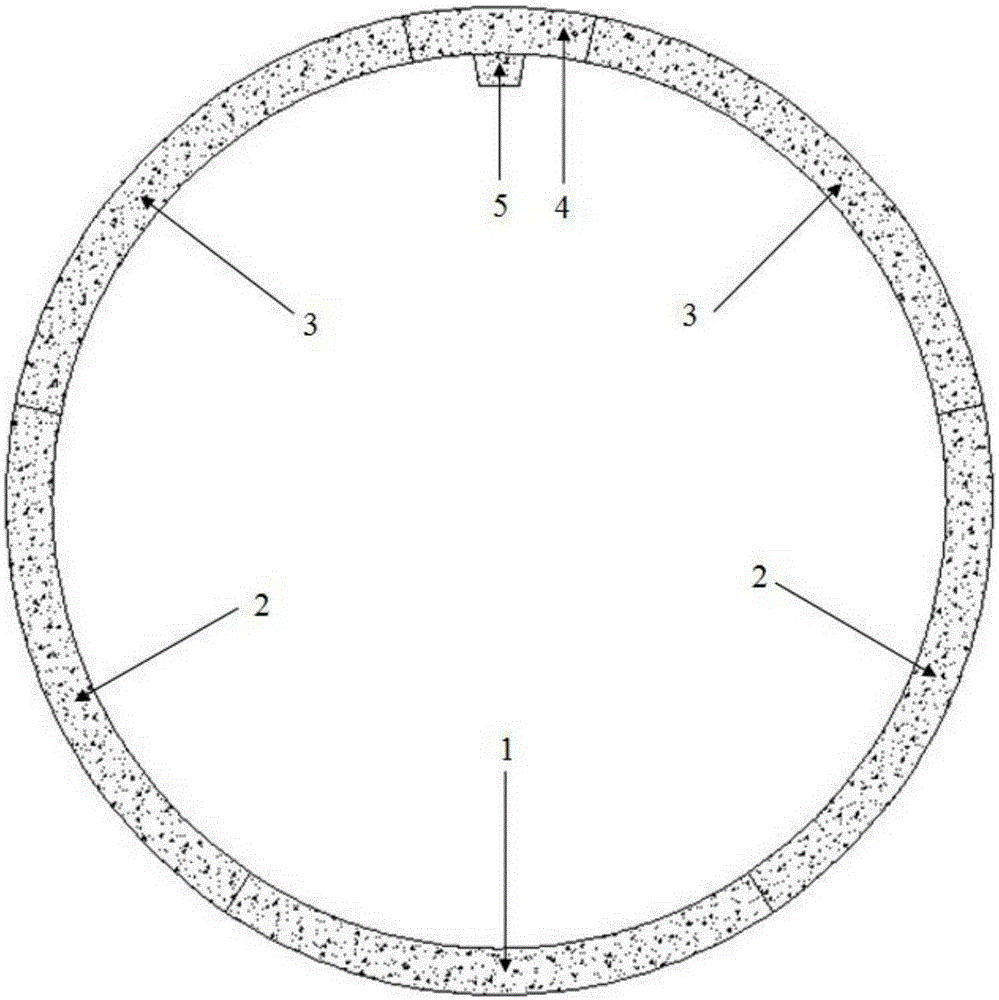

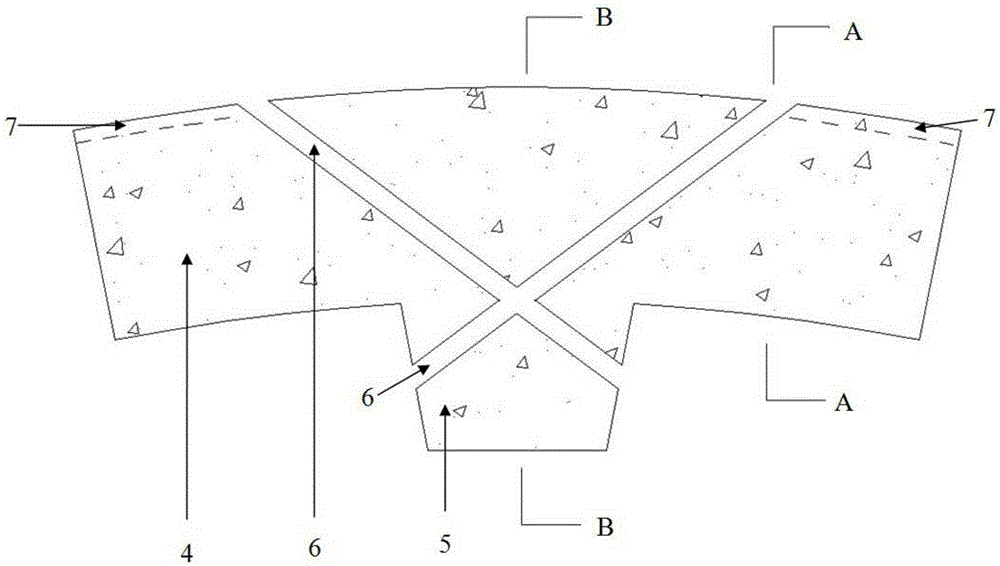

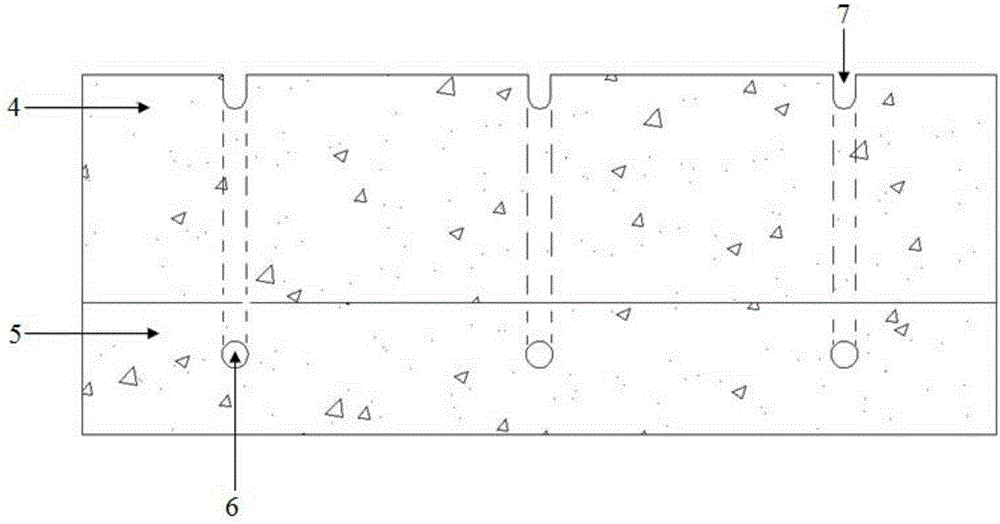

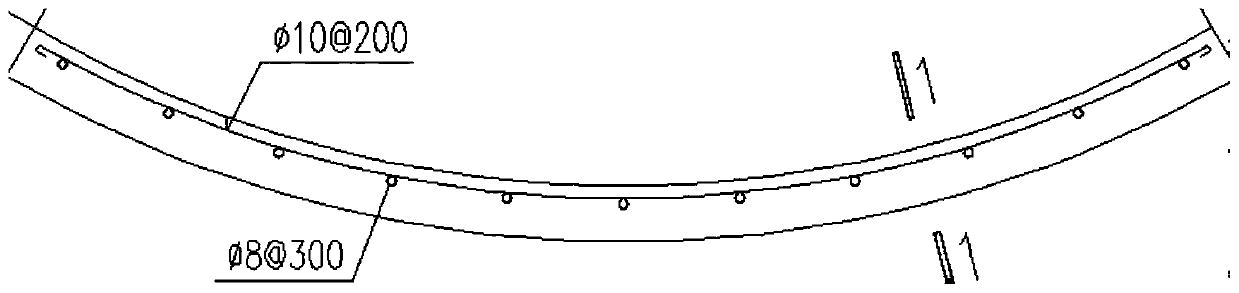

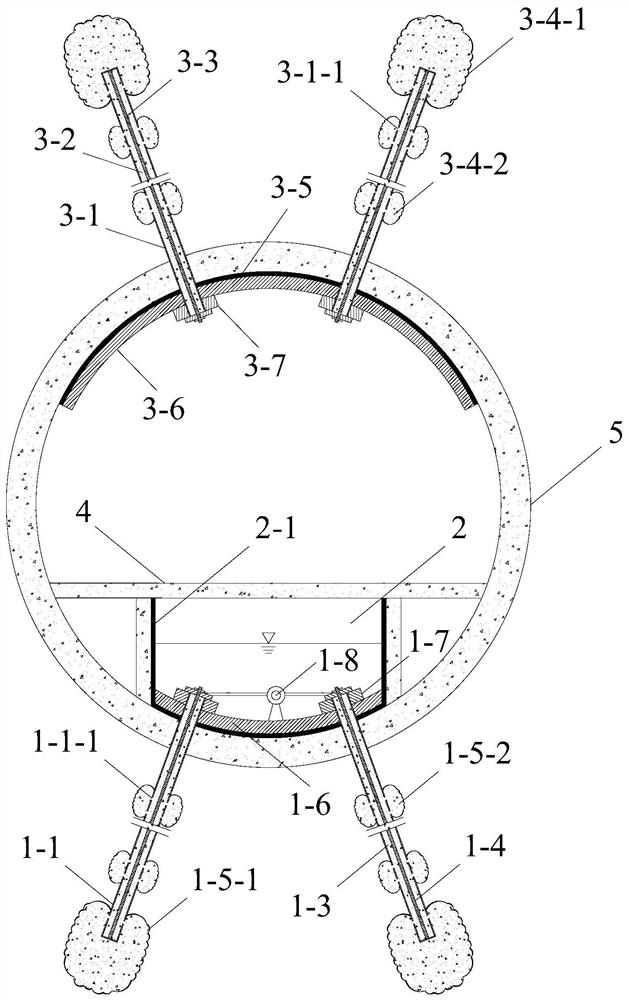

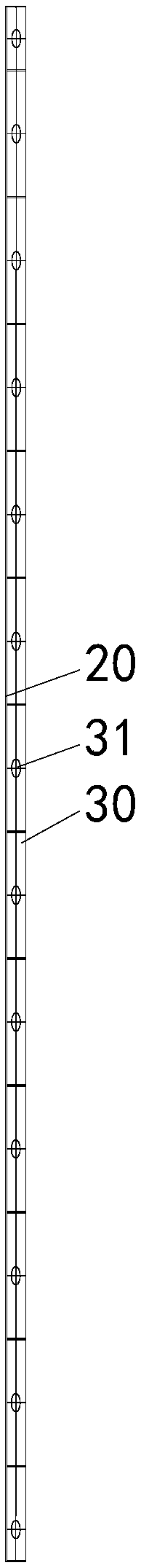

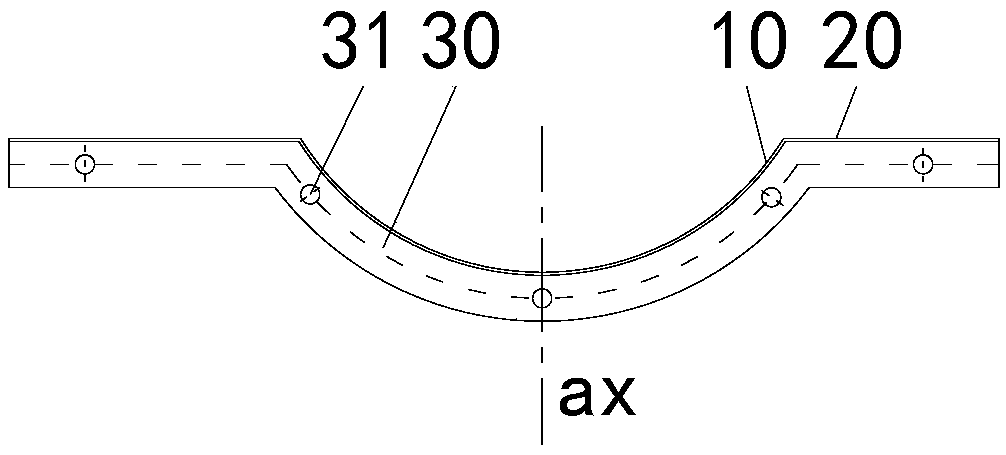

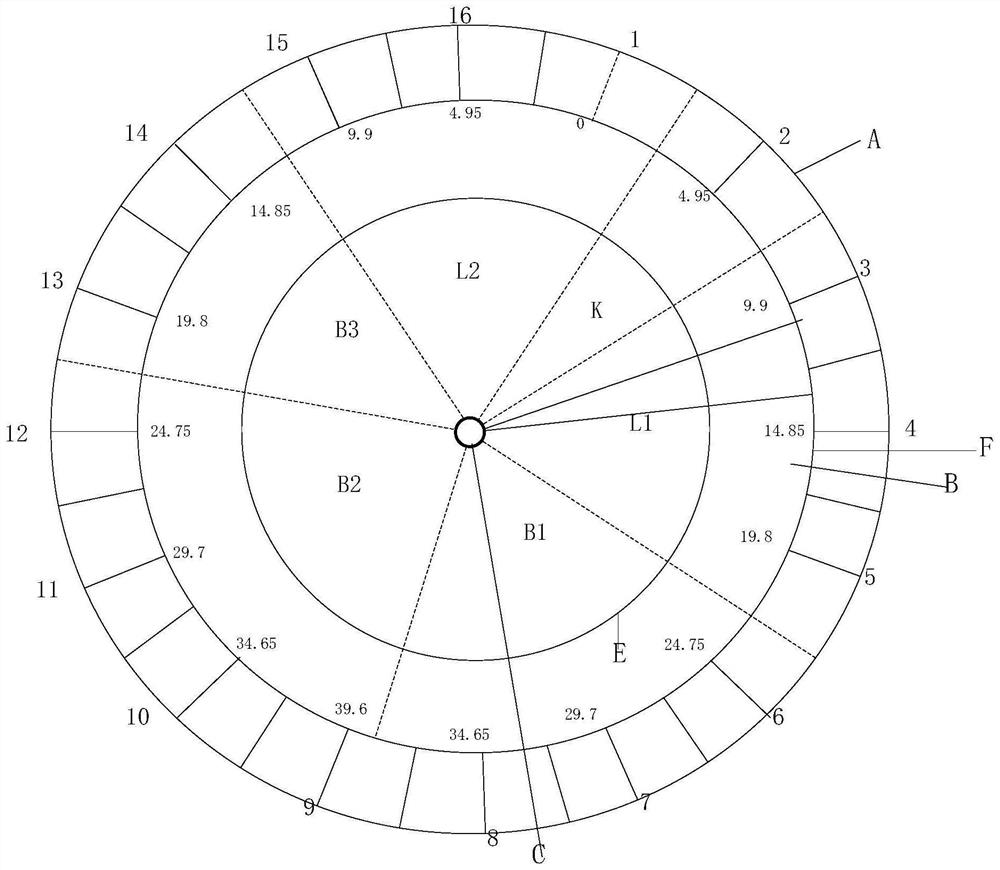

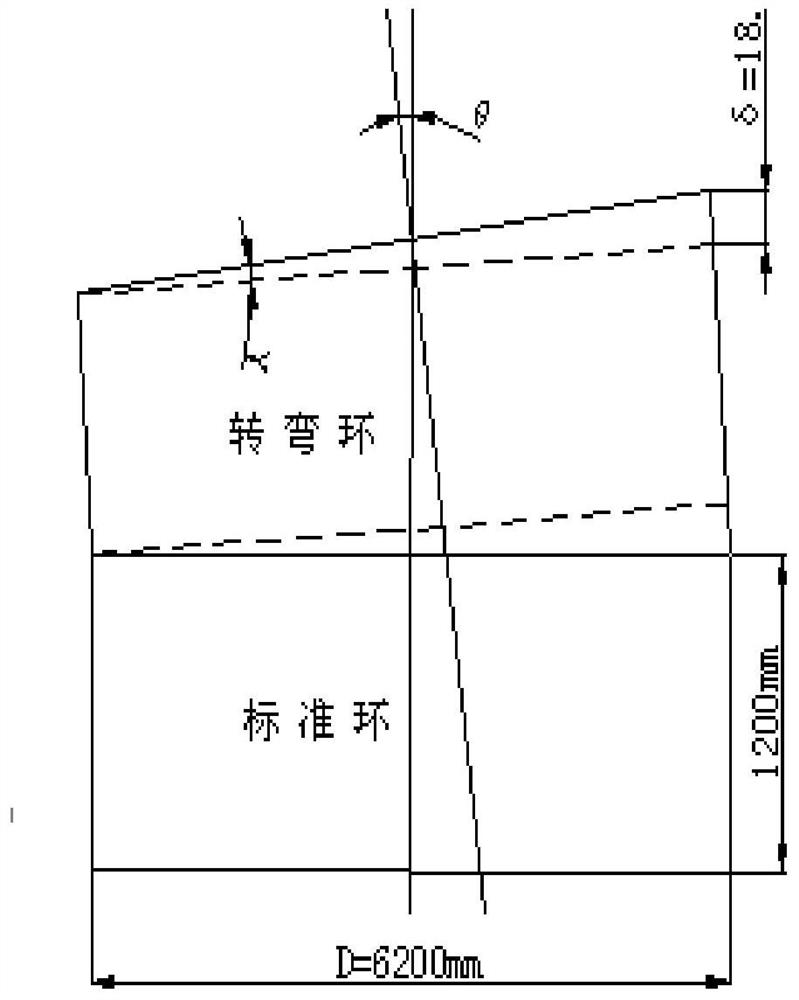

Circumferential prestress strengthening tunnel segment and manufacturing method

ActiveCN105178983AGuaranteed stressPrevent openingUnderground chambersTunnel liningPre stressEngineering

The invention relates to a circumferential prestress strengthening tunnel segment and a manufacturing method. A tunnel segment part mainly comprises an arch bottom block, wherein one adjacent block is arranged at each of two ends of the arch bottom block; a connection block clings to the end part of each adjacent block; a top sealing block is arranged between the two connection blocks; reserved grooves are formed in the outer side of the arch bottom block, the outer sides of the adjacent blocks, the outer sides of the connection blocks and the outer side of the top sealing block; reserved channels are formed in the inner part of the top sealing block; after steel strands pre-tighten the arch bottom block, the adjacent blocks, the connection blocks and the top sealing block through the reserved grooves, the end parts of the steel strands penetrate through the top sealing block and protrude out of the sealing block; each steel strand protruding out of the top sealing block is fixed by a lockset, so that the prestress application is realized; the arch bottom block, the adjacent blocks, the connection blocks and the top sealing block together form a closed cylindrical structure. Through the adoption of the tunnel segment provided by the invention, the integrality of the segment and the capability of resisting surrounding rock pressure can be effectively improved, and the manufacturing method is time-saving and material-saving.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Model Predictive Control of Spacecraft

ActiveUS20170139427A1Accurate momentumAvoid wrong stationCosmonautic vehiclesAttitude controlMomentumHorizon

A method controls an operation of a spacecraft according to a model of the spacecraft. The method determines control inputs for controlling concurrently thrusters of the spacecraft and momentum exchange devices of the spacecraft using an optimization of a cost function over a receding horizon subject to constraints on a pose of the spacecraft and constraints on inputs to the thrusters. The cost function includes components for controlling the pose of the spacecraft and a momentum stored by the momentum exchange devices. The method generates a command to control concurrently the thrusters and the momentum exchange devices according to at least a portion of the control inputs.

Owner:MITSUBISHI ELECTRIC RES LAB INC

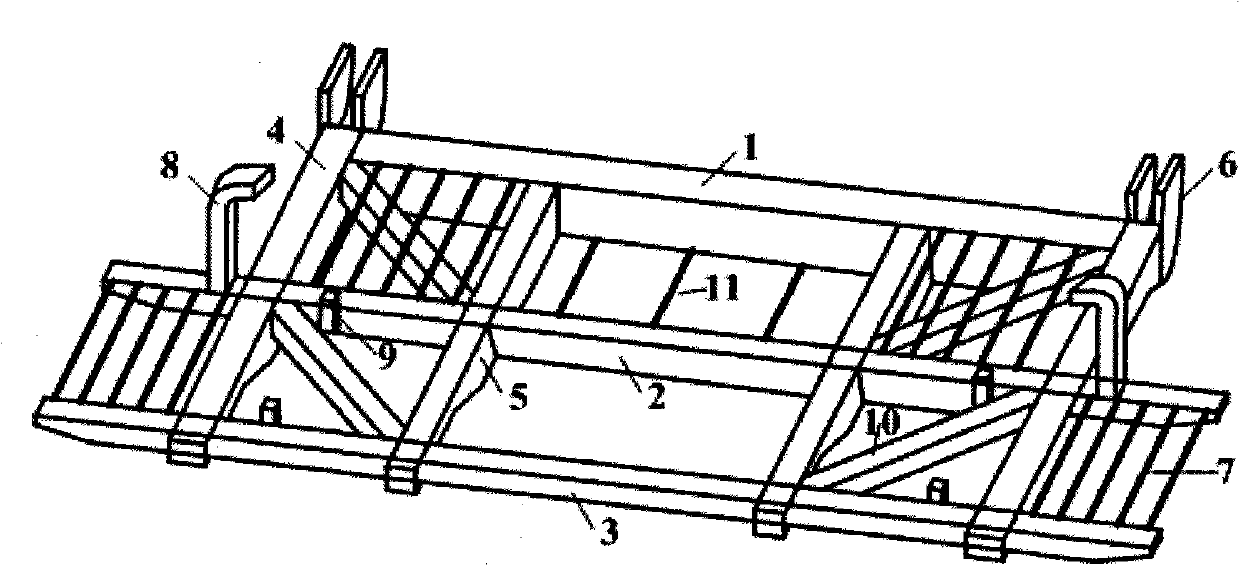

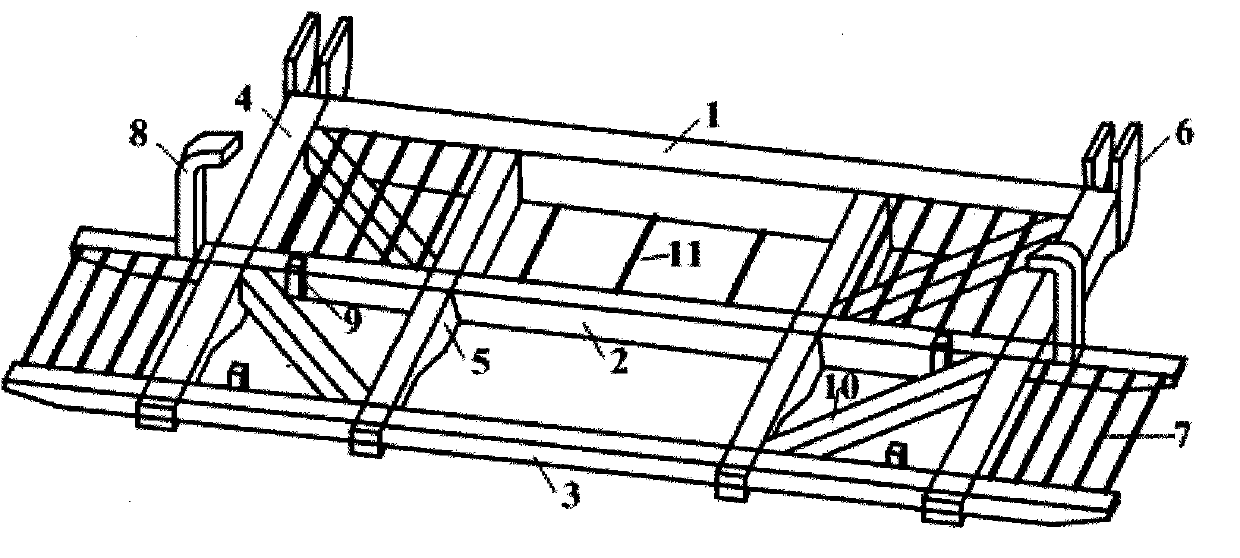

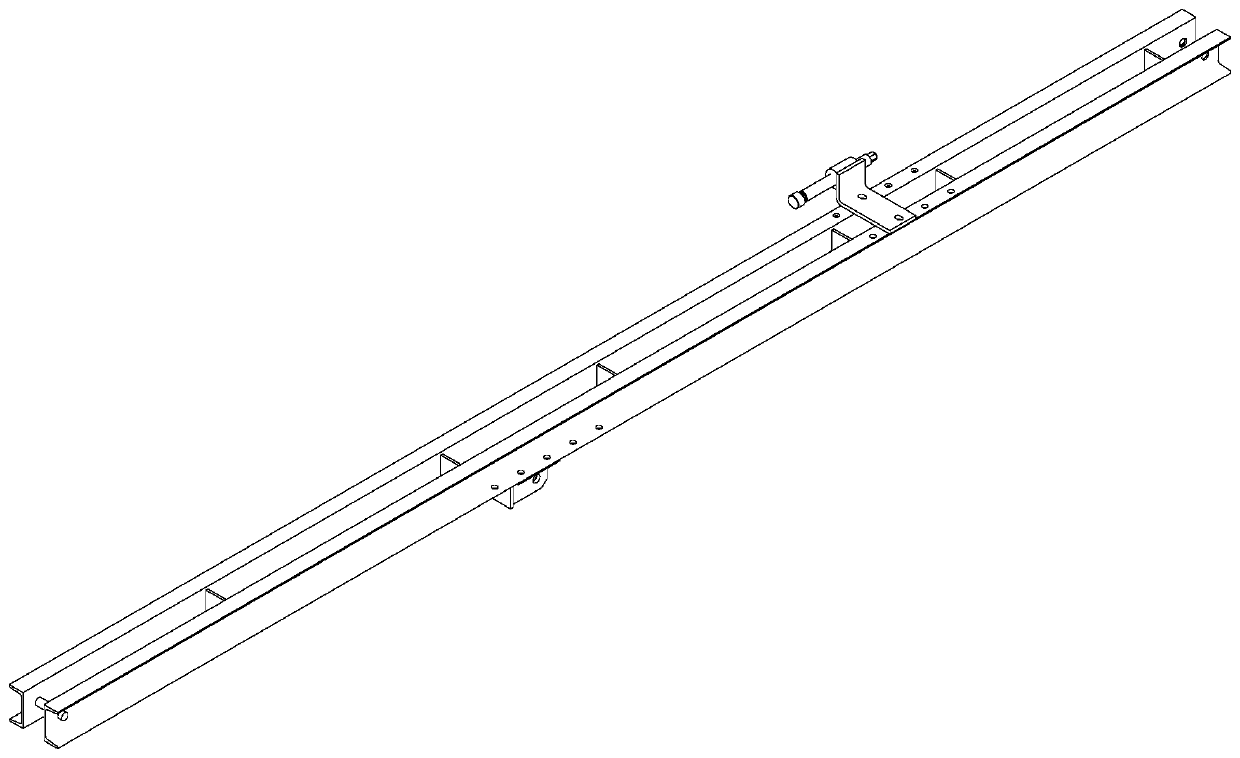

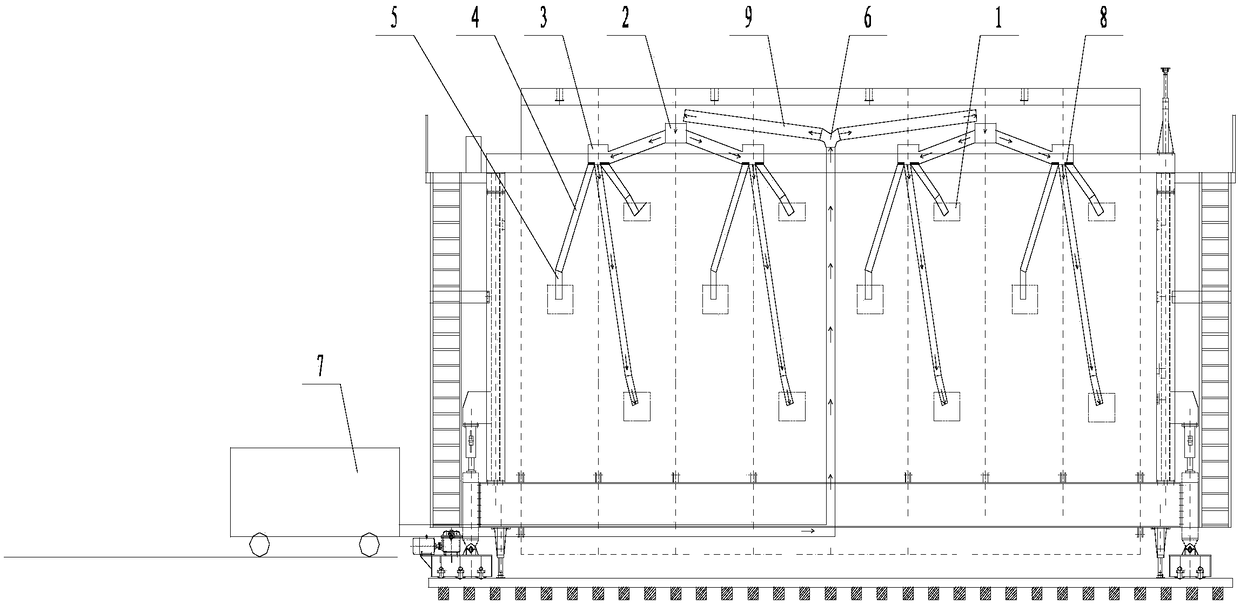

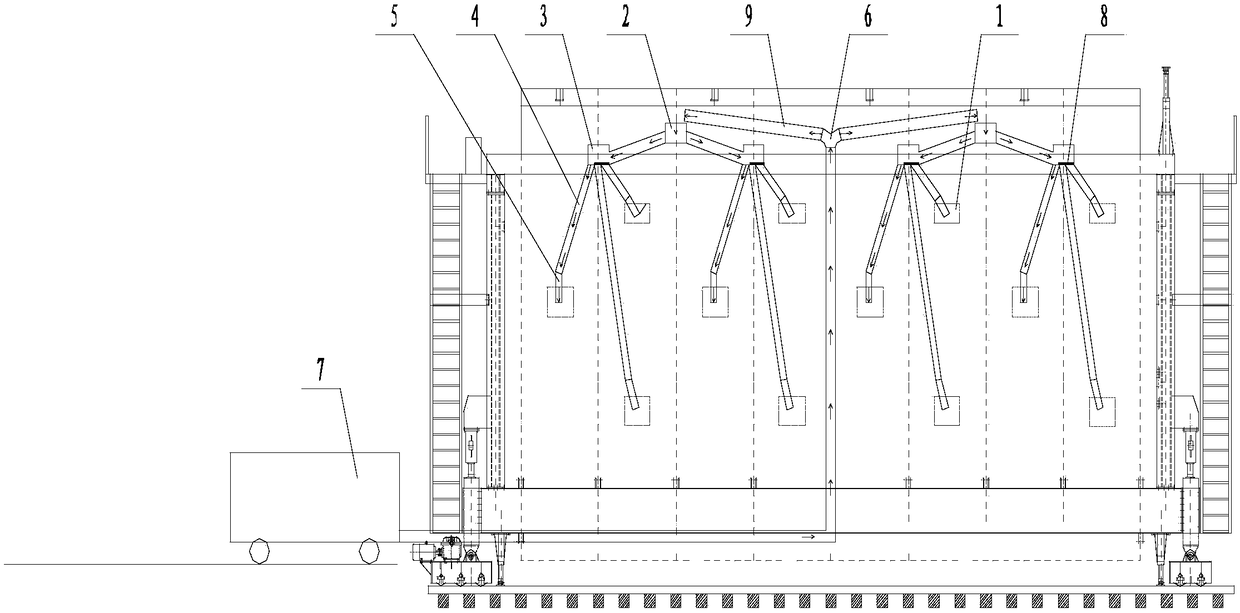

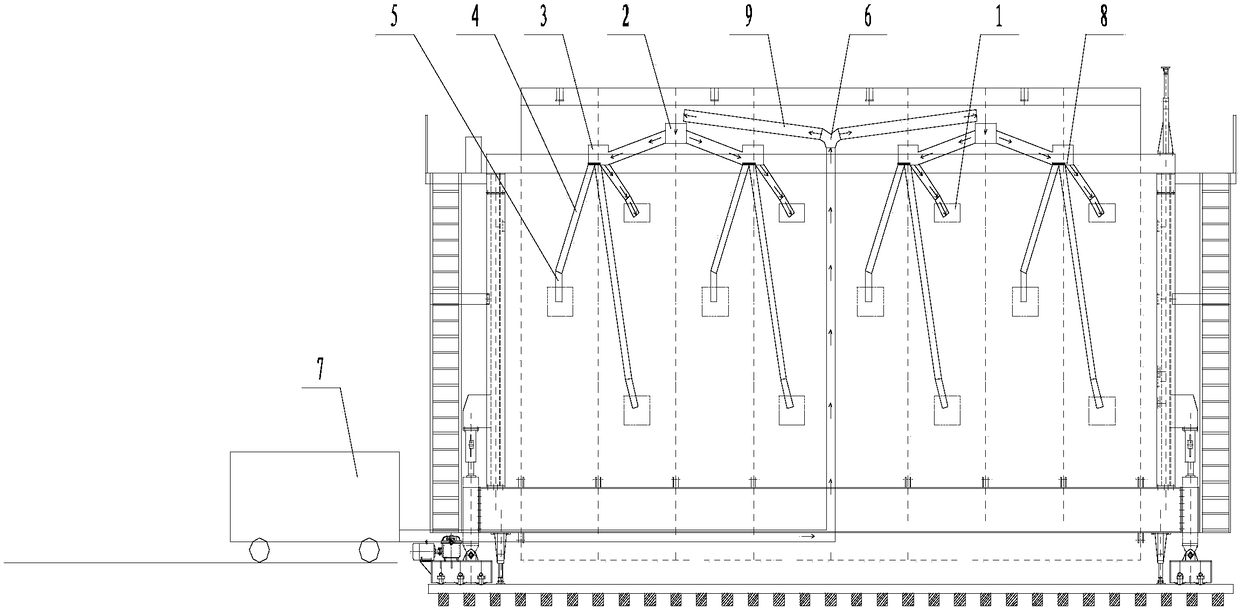

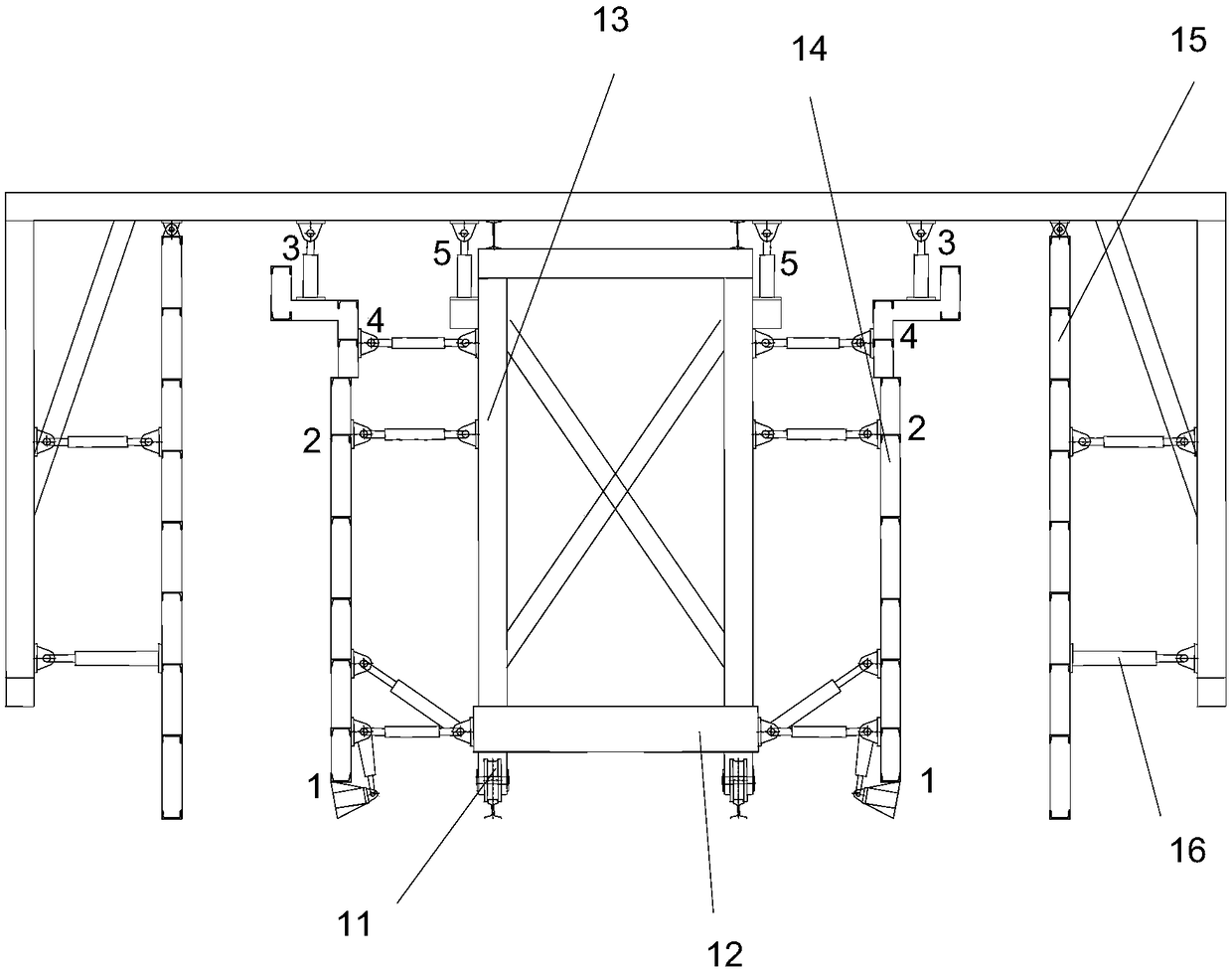

Simultaneous construction type wide-flanged guyed traveler

InactiveCN102002912AShorten construction timeImprove ergonomicsCable-stayed bridgeBridge erection/assemblyArchitectural engineeringStringer

Owner:THE SECOND CONSTR OF CTCE GROUP

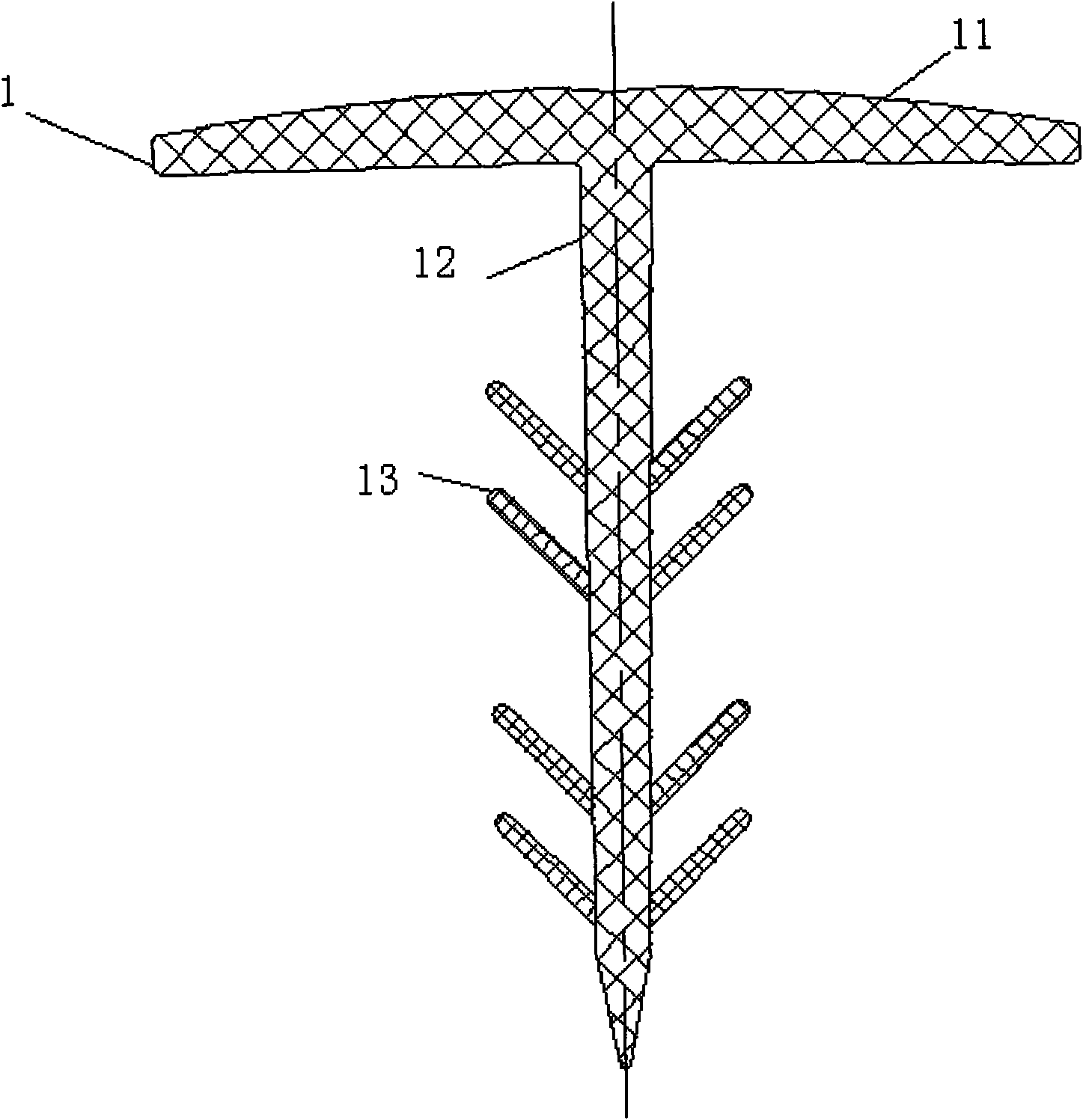

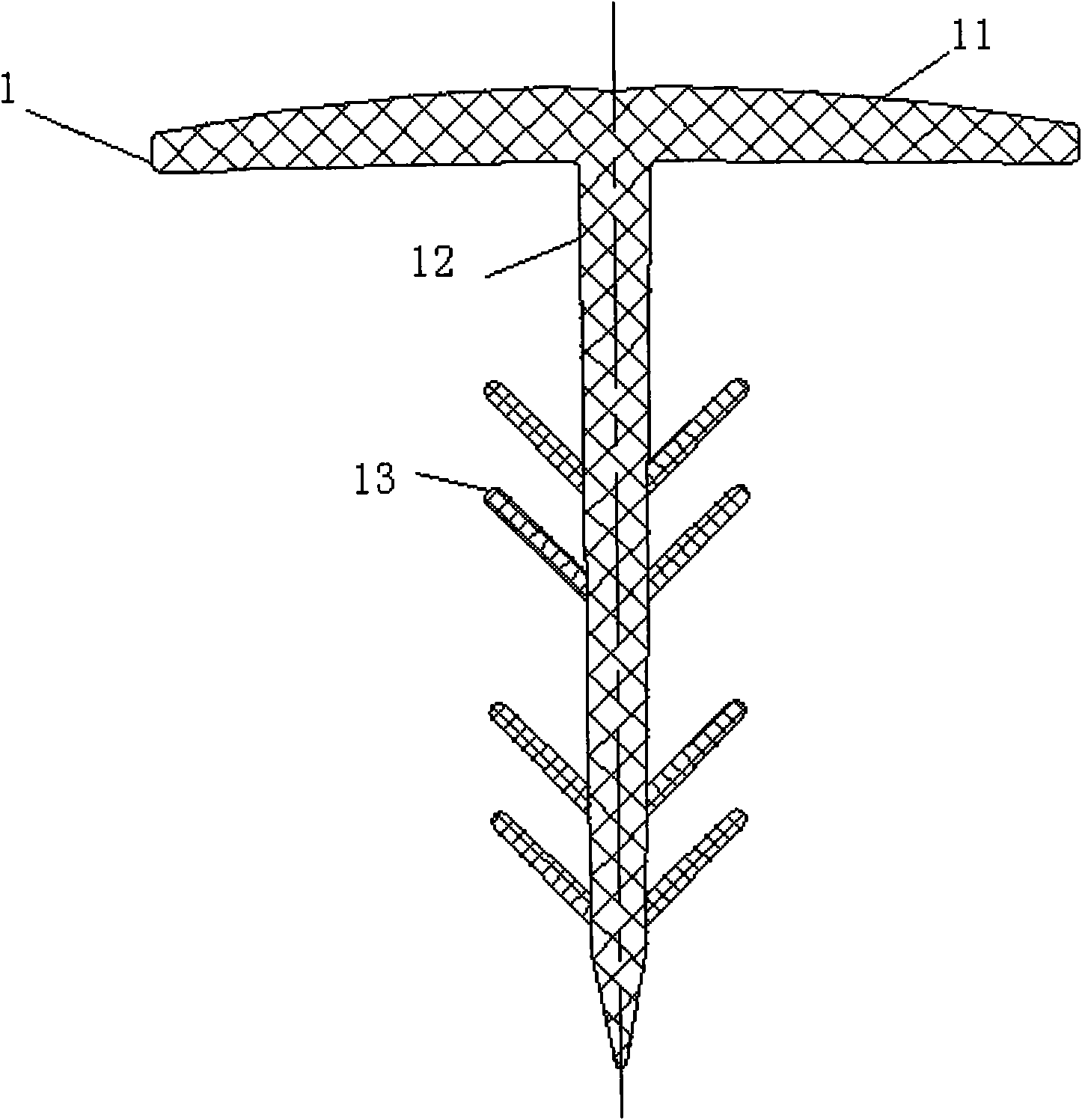

Slurry leakage preventing seal device of building templates

InactiveCN101906876AEasy to removeEasy to cleanAuxillary members of forms/shuttering/falseworksSection planeArchitectural engineering

The invention relates to a slurry leakage preventing seal device of building templates, which comprises a body having equal length with a left building template and a right building template; the transverse section of the body is in a T-shaped structure; a T-shaped transverse part covers the left building template and the right building template; a vertical T-shaped part is inserted between the left building template and the right building template; and the left side and the right side of the vertical part are respectively provided with at least one barb mortar blocking soft strip. By using the seal device, the leakage of cement slurry in concrete can be effectively improved in the concrete pouring process and the original proportion of the concrete is fully ensured; the invention has simple and rapid assembly and disassembly with the templates and convenient cleaning and can effectively prevent staggered and concave-convex phenomena formed by the height differences of various templates so that the moulded concrete is regular and attractive.

Owner:上海捷超脚手架有限公司

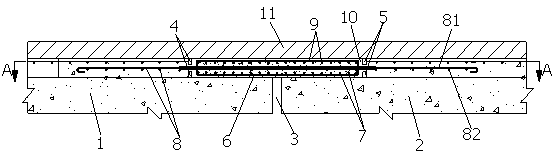

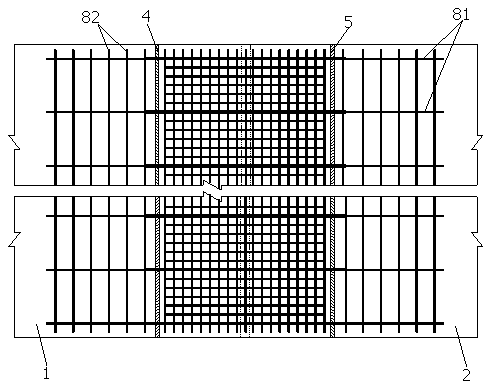

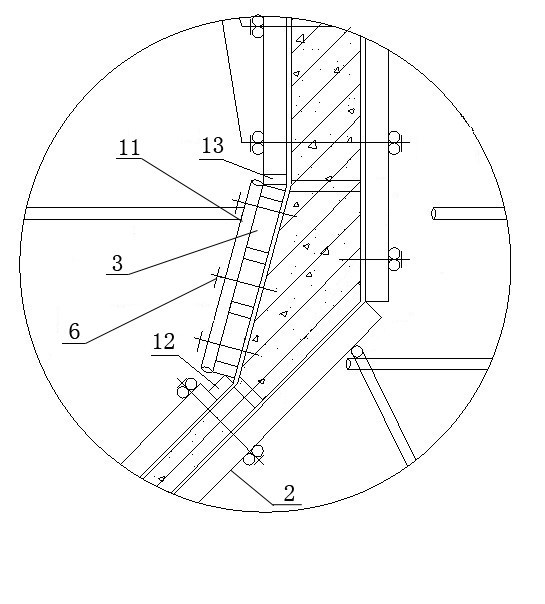

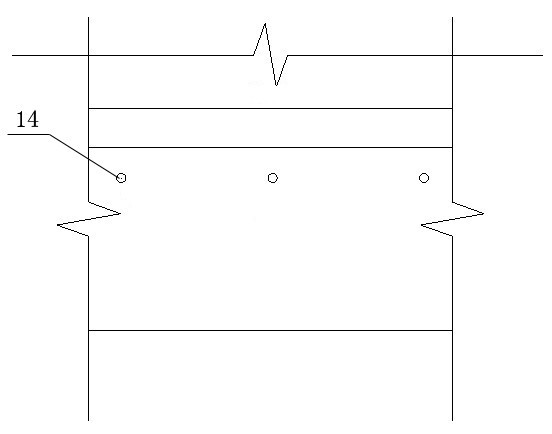

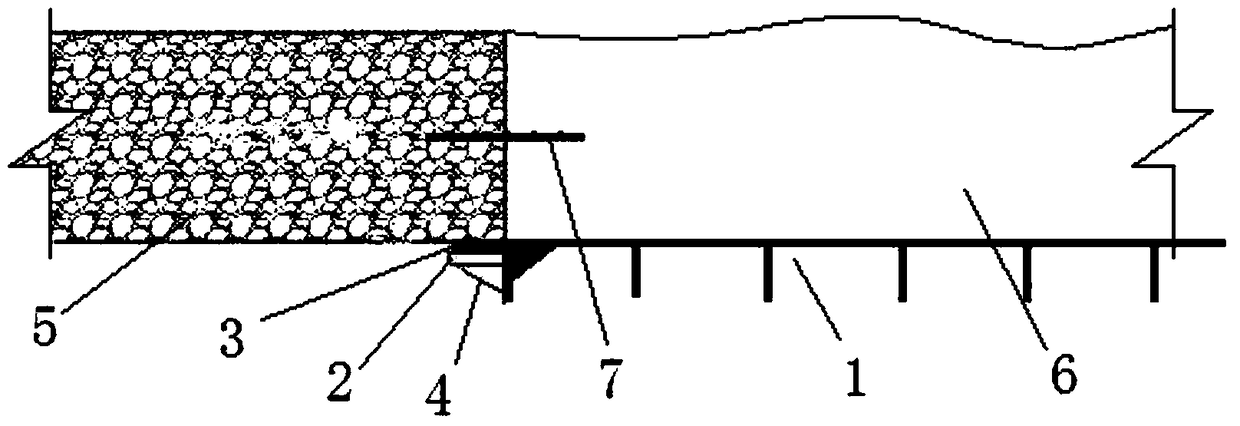

Impervious face slab anti-seismic structure of concrete rock-fill dam and construction method thereof

Provided is an impervious face slab anti-seismic structure of a concrete rock-fill dam and a construction method of the impervious face slab anti-seismic structure of the concrete rock-fill dam. The impervious face slab anti-seismic structure of the concrete rock-fill dam is characterized in that a permanent horizontal seam is arranged on an impervious face slab which is placed on 70-85 percentages of the height of a concrete rock-fill dam body, and the permanent horizontal seam is vertical to the slope direction of the impervious face slab of the concrete rock-fill dam body; a steel bar in the impervious face slab does not pass through the permanent horizontal seam; tiepiece construction members are buried in the concrete rock-fill dam body which is arranged on the upper side and lower side of the permanent horizontal seam, and one ends of the tiepiece construction members are fixed in the impervious face slab; the distance between first tiepiece construction members of each side of the permanent horizontal seam and the permanent horizontal seam is 0.5 m, and distances of other adjacent tiepiece construction members increases progressively in a geometric progression and taking 2 as common ratio mode. By giving range, number and structural type of the permanent horizontal seam additionally arranged on a local place, dislocation of the face slab can be effectively prevented from generating under the influence of seismic ground motion. The impervious face slab anti-seismic structure of the concrete rock-fill dam and the construction method of the impervious face slab anti-seismic structure of the concrete rock-fill dam can greatly improve atress condition of the face slab under the influence of the seismic ground motion, and prevents the face slab from being cracked to cause leakage.

Owner:DALIAN UNIV OF TECH

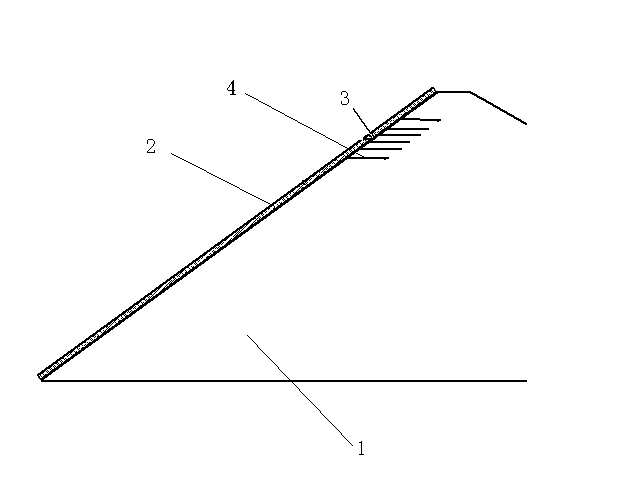

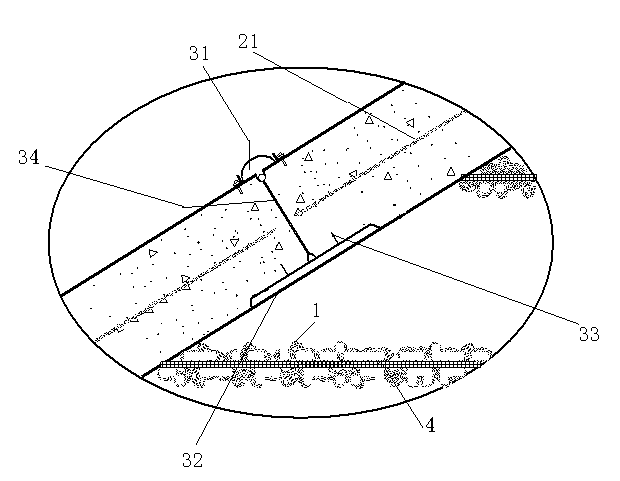

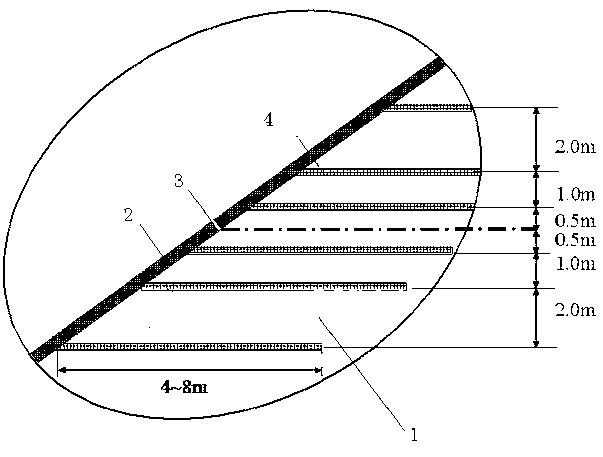

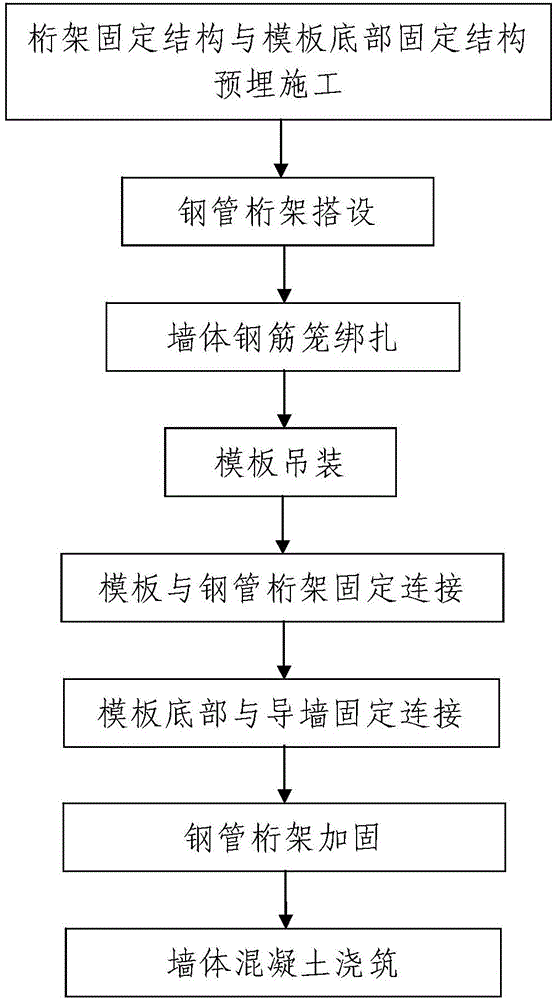

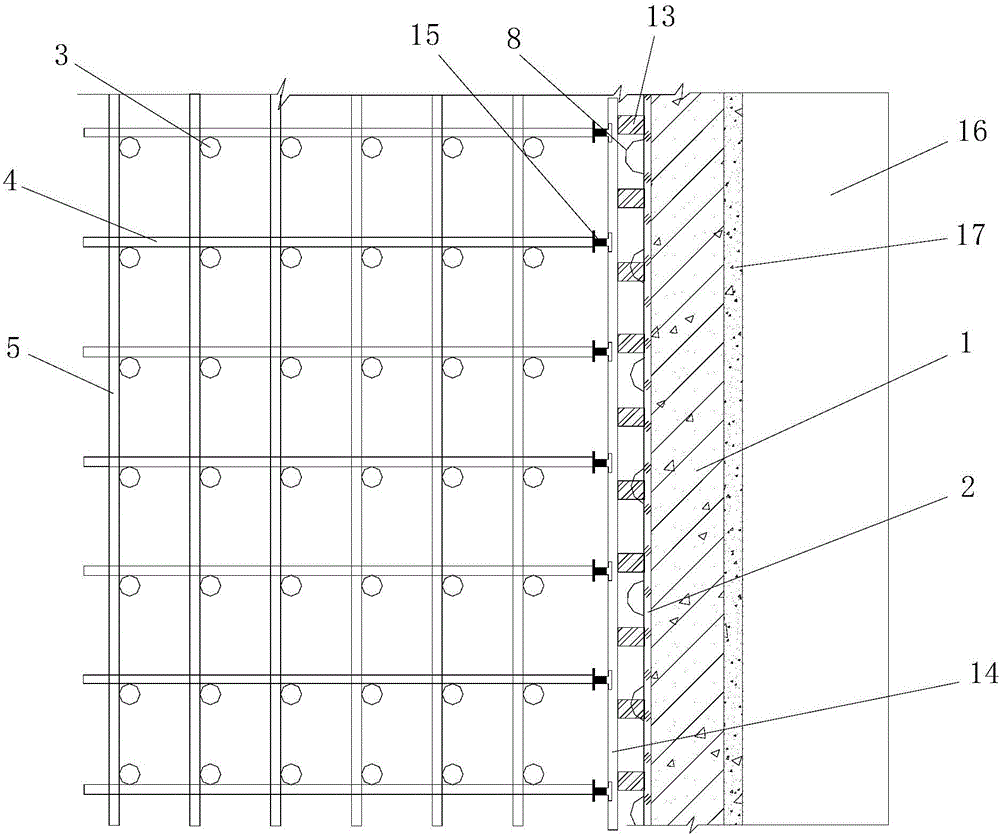

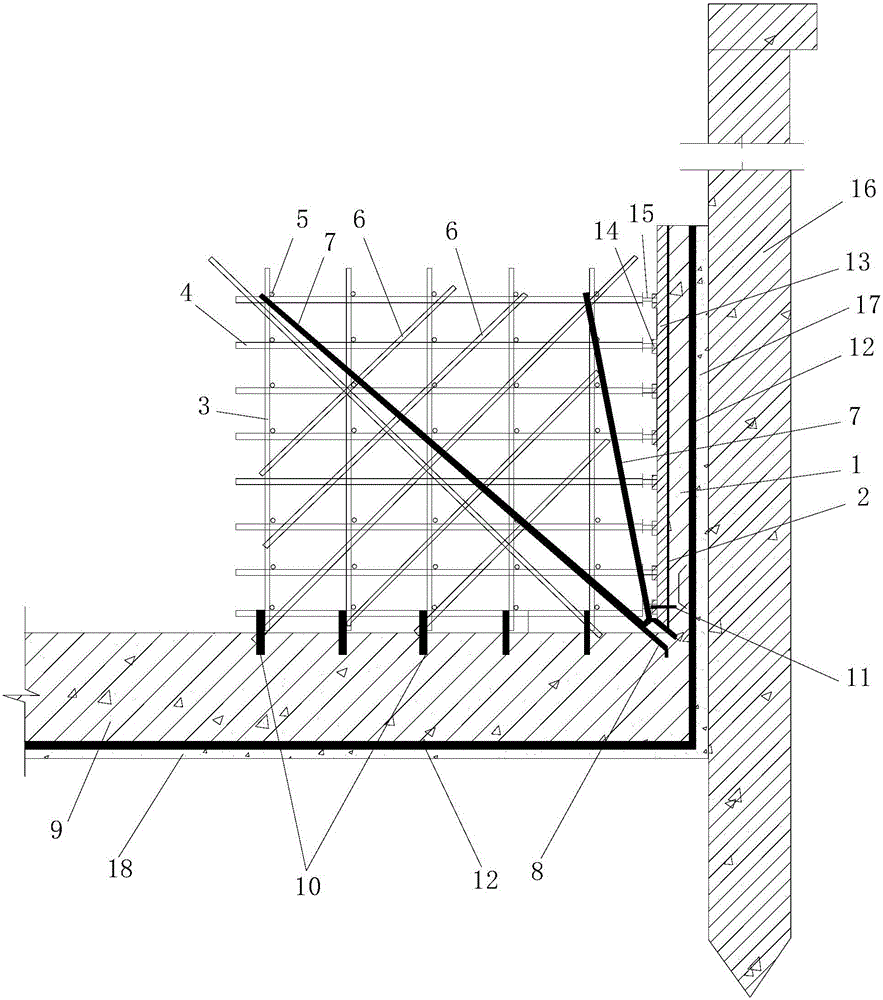

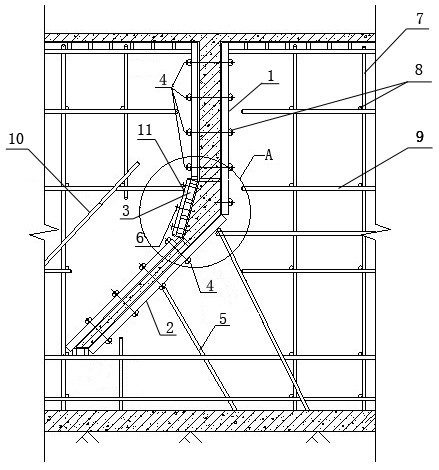

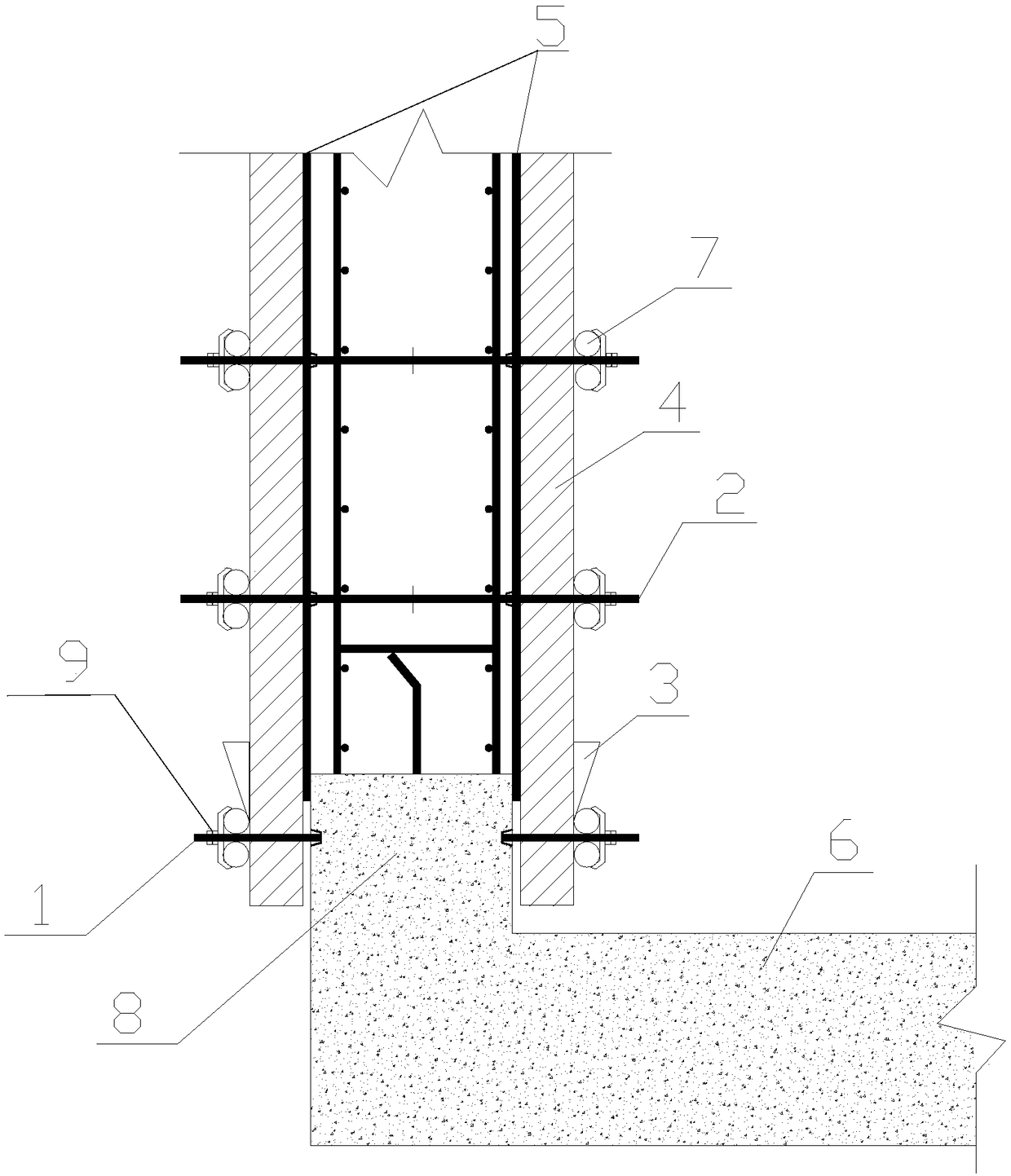

Unilateral formwork supporting construction method for basement exterior wall on basis of steel pipe truss

ActiveCN106245678AThe method steps are simpleEasy to implementArtificial islandsWallsSteel tubeBasement

The invention discloses a unilateral formwork supporting construction method for a basement exterior wall on the basis of a steel pipe truss. The method includes the steps of 1, carrying out embedment construction of a truss fixing structure and a formwork bottom fixing structure, specifically embedding the truss fixing structure for fixing the steel pipe truss into a supporting foundation and embedding the formwork bottom fixing structure for fixing a formwork into a guide wall; 2, erecting the steel pipe truss on the supporting foundation; 3, binding reinforcement cages of a wall body; 4, hoisting the formwork; 5, fixedly connecting the formwork to the steel pipe truss; 6, fixedly connecting the bottom of the formwork to the guide wall and specifically fixing the bottom of the formwork to the guide wall in a fastened mode through the formwork bottom fixing structure; 7 reinforcing the steel pipe truss; and 8, carrying out concrete pouring. The method has the advantages that the steps are simple, the design is reasonable, the construction is simple and convenient, and the use effect is good; and the steel pipe truss serves as a supporting structure, the truss fixing structure and the formwork bottom fixing structure realize the dual reinforcement effect, and therefore the unilateral formwork supporting effect of the basement exterior wall can be effectively improved.

Owner:陕西建总安装工程有限公司

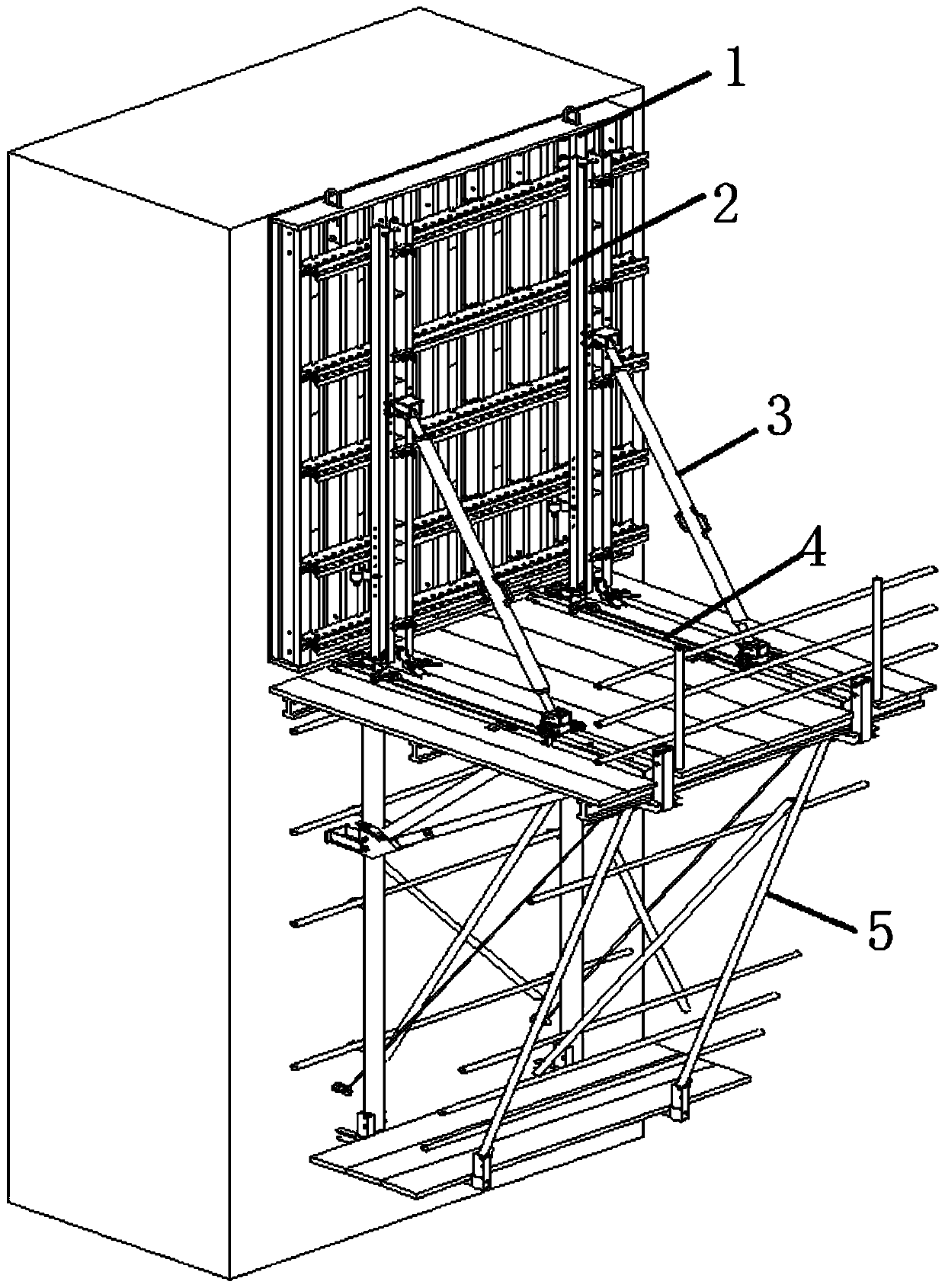

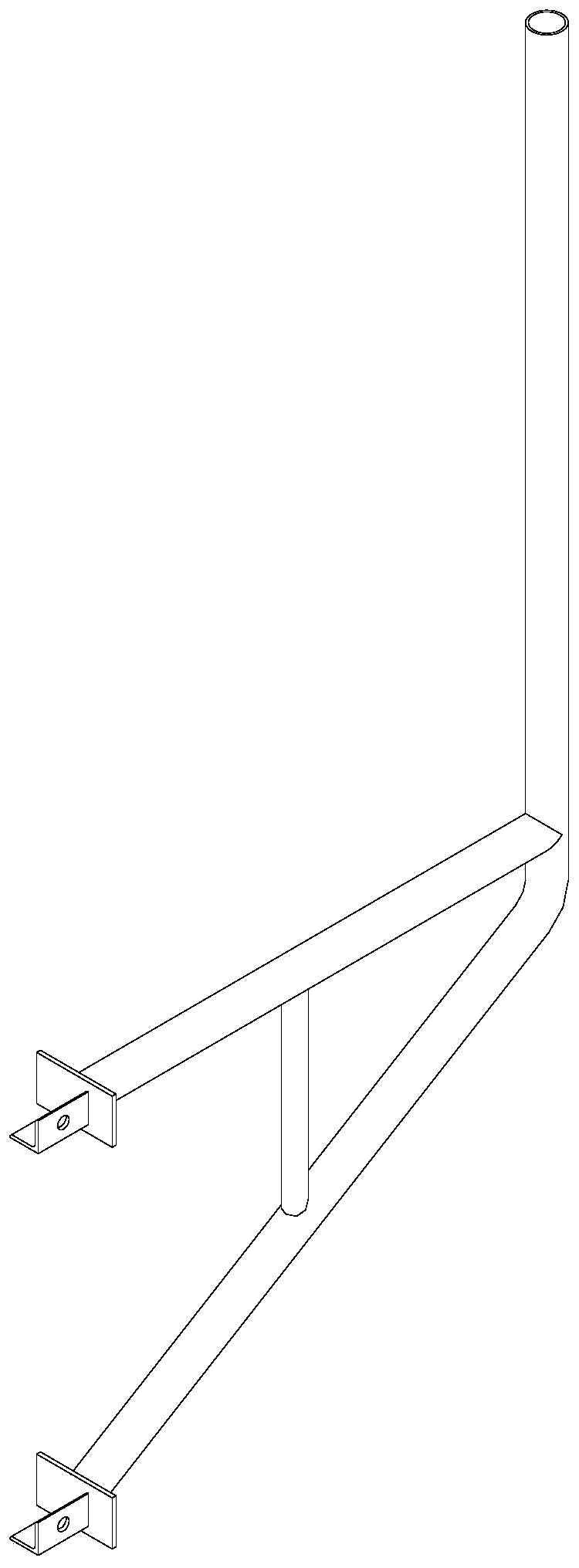

Cantilever formwork for concrete construction and construction method thereof

InactiveCN109989348AEasy constructionFast constructionBridge erection/assemblySurface finishFalsework

The invention discloses a cantilever formwork for concrete construction and a construction method thereof, and belongs to the technical field of bridge construction. The problems that construction iscomplicated, cost is high and concrete surface smoothness is low when the outer surfaces of all supporting columns of a bridge are constructed are solved. The cantilever formwork comprises a cantilever formwork support, an anchoring assembly and a planar formwork and is a single-sided wall body climbing formwork used for formwork construction of concrete linings and other structures of dams, piers, concrete retaining walls, tunnels and underground plants, the formwork is easy and rapid to construct and economical, the concrete surface is smooth, the support, the formwork and construction loadsare all borne by an embedded piece assembly, no scaffold needs to be additionally erected, and the formwork is suitable for aloft operation; by means of an anchoring device, the formwork is closely attached to a concrete wall surface, and mortar leakage and slab end faulting are prevented; an inclined strut is arranged on the cantilever support, and the perpendicularity of the formwork can be conveniently adjusted; all connectors are standard, universality is high, and a hanging platform is arranged at the lower portion of the formwork and can be used for assembling and disassembling embeddedpieces and processing the concrete surface.

Owner:中交中南工程局有限公司 +1

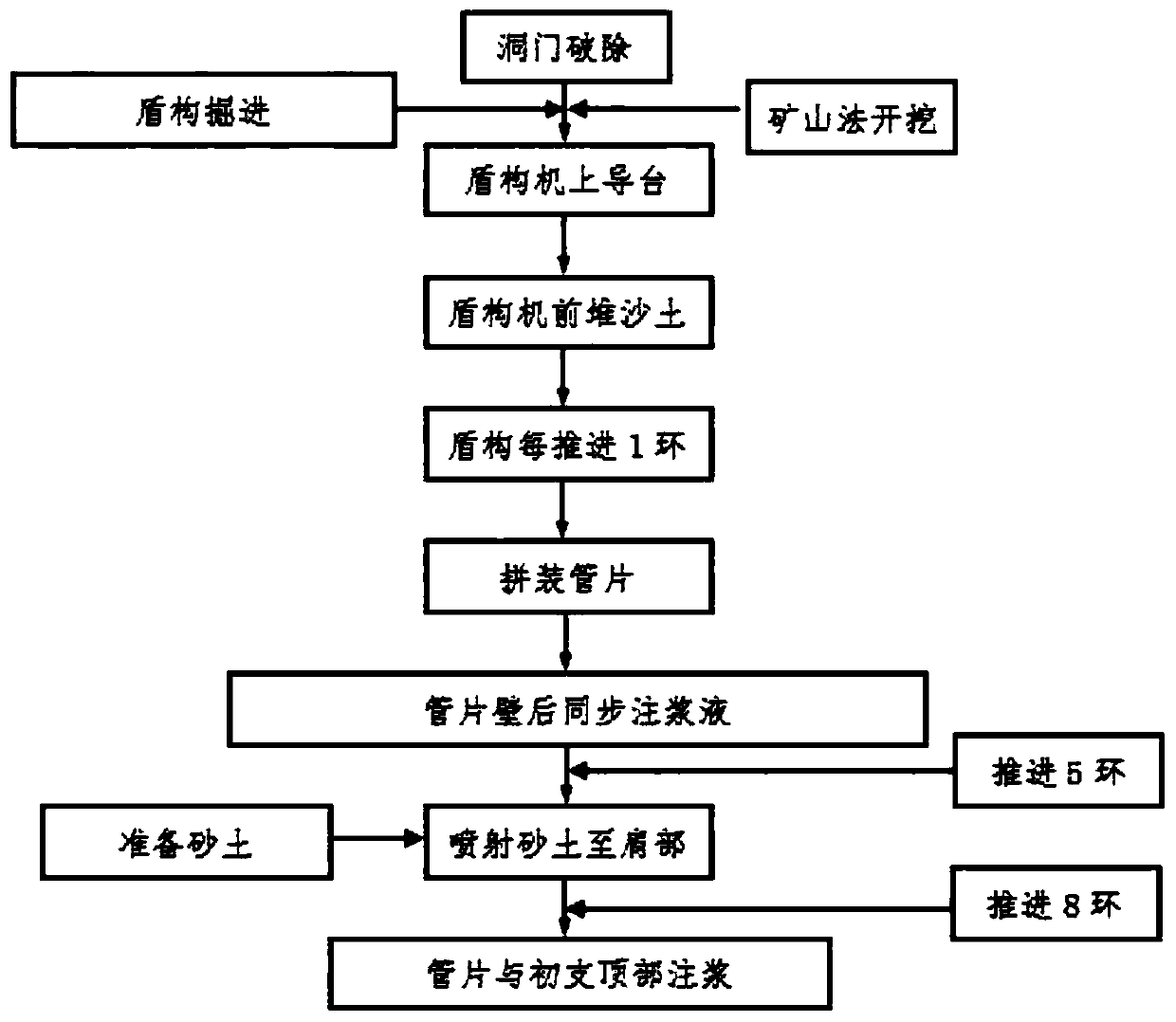

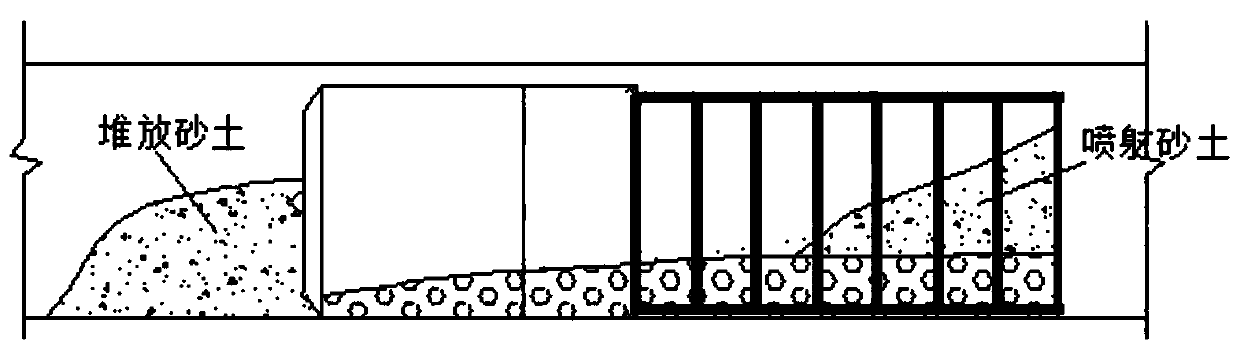

Construction method for splicing duct pieces in shield idling manner

InactiveCN110080789AImprove construction progressPrevent floatingUnderground chambersTunnel liningSocial benefitsEconomic benefits

The invention discloses a construction method for splicing duct pieces in shield idling manner. The method comprises the following steps of: respectively dividing shield and mining method constructionlengths according to the length of a shield remaining segment, while a shield machine continues the forward tunneling, carrying out opposite mining method excavation from a hoisting-out well to the direction of the shield machine, enabling an excavation section to be larger than a cutterhead of the shield machine, and strengthening primary supporting measures; after mining method excavation is completed according to task division, blocking a joint end wall, and constructing a shield tunneling guide table in a mining method section; and after the shield tunneling machine reaches the end wall and walks into the guide table, conducting segment splicing in an idling mode to pass through the mining method tunnel, and meanwhile conducting segment back backfilling and grouting till the shield tunneling machine reaches the hoisting-out well. The method is suitable for long and large shield tunnels of which the shield segment receiving ends are high in rock strength and have more developed rock cracks and which are complex in geological condition, thus need construction period optimization or need to be connected with a shield machine and are suitable for mining construction, the construction progress can be greatly improved, and good economic benefits and social benefits are achieved.

Owner:周霄

Construction method of secondary-lining trolley separated window pouring and pouring structure thereof

InactiveCN108661672AAvoid wrong stationReduce consumption costUnderground chambersTunnel liningHoneycombMaterial distribution

The invention discloses a construction method of secondary-lining trolley separated window pouring and a pouring structure thereof. A traditional secondary-lining pouring method is abandoned, and pumppipe joints do not need to be frequently disassembled and installed; and the labor consumption and labor cost are reduced, the pipe blocking risk is reduced, and construction safety is improved. Since sub-feed troughs and fixed sliding grooves can be pre-set in advance, reconnection does not need to be carried out in the construction process, and no more cases of which site workers choose only asmall amount of windows for material distribution or concrete sequence-method pouring for convenient construction is achieved, so the appearance quality defects such as material aggregating nests, honeycomb and scale, construction cold joints and gable slopes are well prevented, the workload of post-repair is reduced, and labor costs and construction period and material costs of the post-repair are greatly reduced. Since each row of pouring windows is poured at the same time, the problem that a trolley offsets to form faulting of slab ends caused by the uneven force due to uneven feeding of the secondary-lining trolley is further effectively avoided, and a secondary-lining profile is ensured to be not beyond limit.

Owner:RANKEN RAILWAY CONSTR GROUP

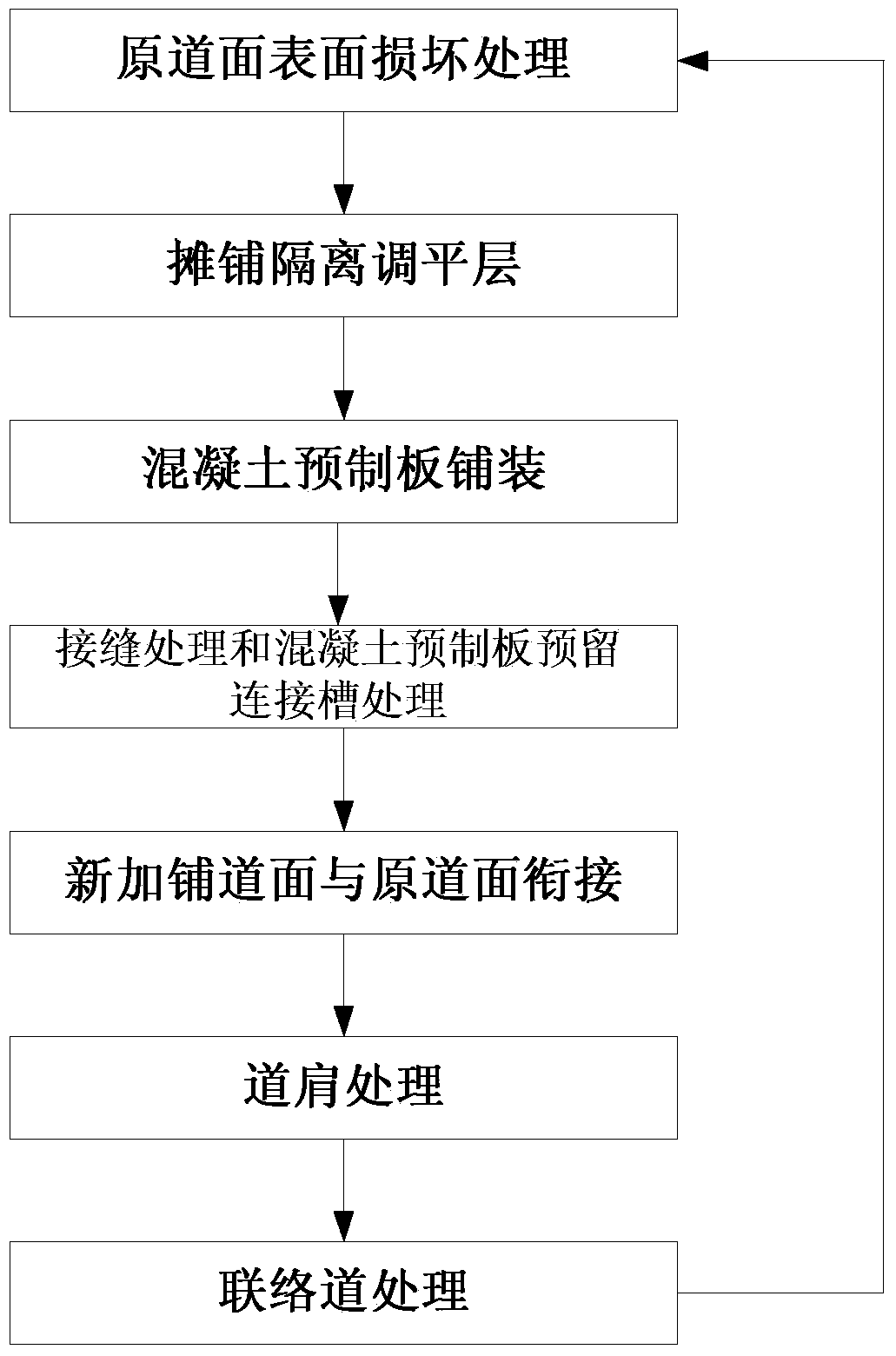

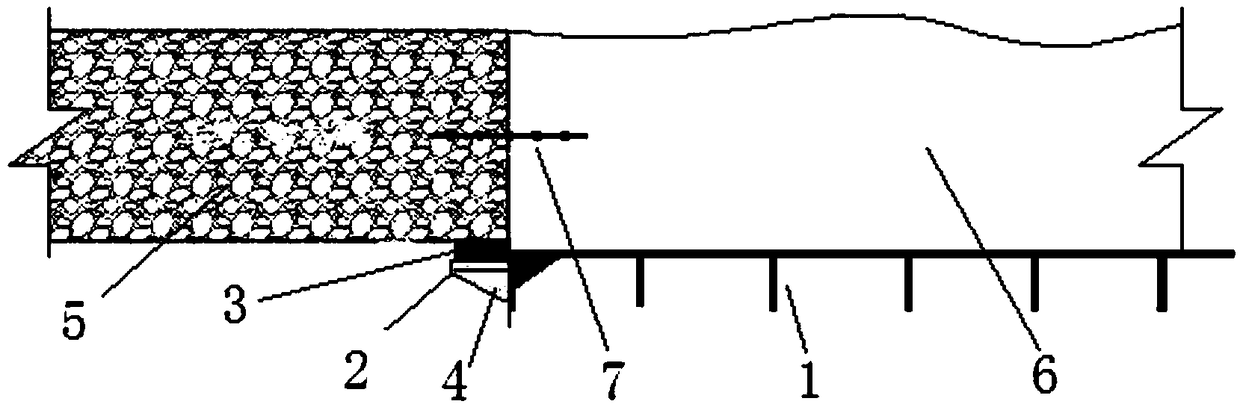

Construction method for additionally laying concrete precast slabs on airport pavement without suspending aviation service

ActiveCN103422410AImprove integrityGuarantee airworthinessTemporary pavingsPaving detailsAviationRunway

The invention relates to a construction method for additionally laying concrete precast slabs on an airport pavement, and discloses a construction method for additionally laying the concrete precast slabs on the airport pavement without suspending aviation service. The construction method for additionally laying the concrete precast slabs on the airport pavement without suspending the aviation service comprises the steps of (1) carrying out surface damage processing on an original pavement, (2) laying an isolation leveling layer, (3) laying the concrete precast slabs, (4) carrying out joint processing, carrying out processing on reserved connecting grooves of the concrete precast slabs, (5) carrying out connection between a newly-laid pavement and the original pavement, (6) carrying out runway shoulder processing, and (7) carrying out linking runway processing. The construction method for additionally laying the concrete precast slabs on the airport pavement without suspending the aviation service solves the problem of additionally laying the concrete precast slabs on the airport pavement without suspending the aviation service, firstly, targeted processing is carried out on damage of the original pavement, then, the concrete precast slab integral assembly covering technology is used for carrying out additional laying construction on the concrete precast slabs, construction is carried out at night according to the requirement for construction without suspending the aviation service, sequential connection slopes are additionally laid between the new pavement and the original pavement after construction at the night is accomplished, normal operation of flights of the next day cannot be influenced, and the requirement for construction without suspending the aviation service is met.

Owner:HANGZHOU ROADMENDER TECH CO LTD

Flexible connecting structure for old and new bridges and construction method of flexible connecting structure

PendingCN108411773AReduce local crackingContinuous deckBridge structural detailsBridge erection/assemblyRebarLap joint

The invention discloses a stable and durable flexible connecting structure for old and new bridges and a construction method of the flexible connecting structure. The flexible connecting structure isused for connecting the two adjacent ends of a new bridge body and an old bridge body; a spacing seam exists between the two adjacent ends of the new bridge body and the old bridge body; the upper portion of the end, adjacent to the new bridge body, of the old bridge body is provided with first grooves, and the first grooves are provided with first breaking joints; the upper portion of the end, adjacent to the old bridge body, of the new bridge body is provided with second grooves, and the second grooves are provided with second breaking joints; the flexible connecting structure of the old andnew bridges comprises an isolation layer in lap joint on the first grooves and the second grooves, a lower densified rebar net arranged at the upper end of the isolation layer, a connecting rebar net, an upper densified rebar net arranged at the upper end of the connecting rebar net, concrete layers and an asphalt bridge floor; and the connecting rebar net is arranged at the upper end of the lower densified rebar net, the two ends of the connecting rebar net penetrate through the first breaking joints and the second breaking joints correspondingly, the first grooves and the second grooves arefilled with the concrete layers, and the asphalt bridge floor is laid at the upper ends of the old bridge body and the new bridge body.

Owner:KUNMING SURVEY DESIGN & RES INST OF CREEC

Method for pouring ABR (Acrylate Butadience Rubber) reaction tank baffle

ActiveCN102635237AGood molding qualityGuaranteed impermeabilityTreatment with anaerobic digestion processesBuilding material handlingRebarSteel tube

The invention discloses a method for pouring an ABR (Acrylate Butadience Rubber) reaction tank baffle. The method comprises the following steps: 1) binding reinforcing bar nets: binding double-layer reinforcing bar nets by using reinforcing bars and binding stirrups between the double-layer reinforcing bar nets; 2) bracing formworks: respectively bracing beam supporting formworks on two sides of a beam reinforcing bar net, bracing plate supporting formworks on two sides of a plate reinforcing bar net, bracing an axilla supporting formwork outside an axilla reinforcing bar net, and meanwhile, supporting and fixing by using a longitudinal supporting rod and a horizontal supporting rod of a scaffold, and fixing and supporting the bottom of the plate reinforcing bar net on a steel tube of the scaffold; 3) pouring concrete: pouring a part below a preformed hole, a part from the preformed hole to the axilla and the beam with concrete layer by layer in turn; and 4) dismounting the formworks: dismounting the formworks when the concrete strength is 100%. The beam and plate of the ABR reaction tank baffle are integrally poured according to the method disclosed by the invention, so that the construction cold seam does not exist between the beam and plate and the forming quality is excellent.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

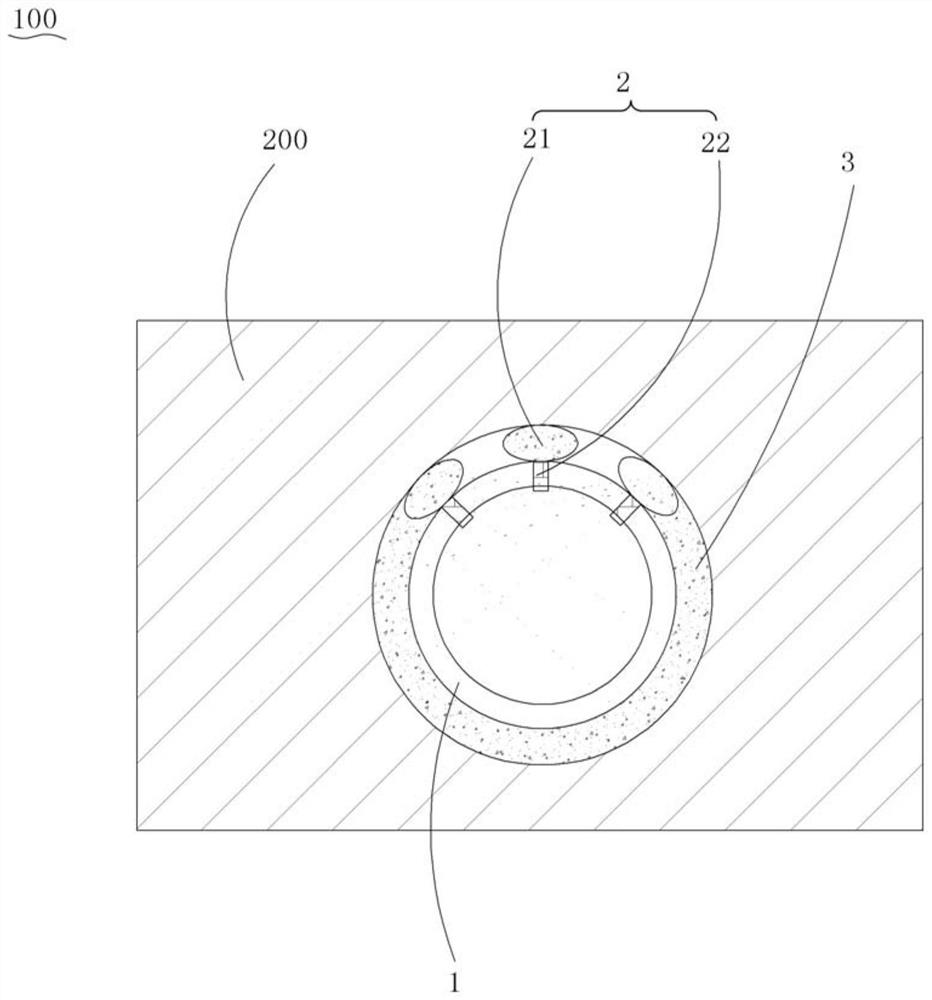

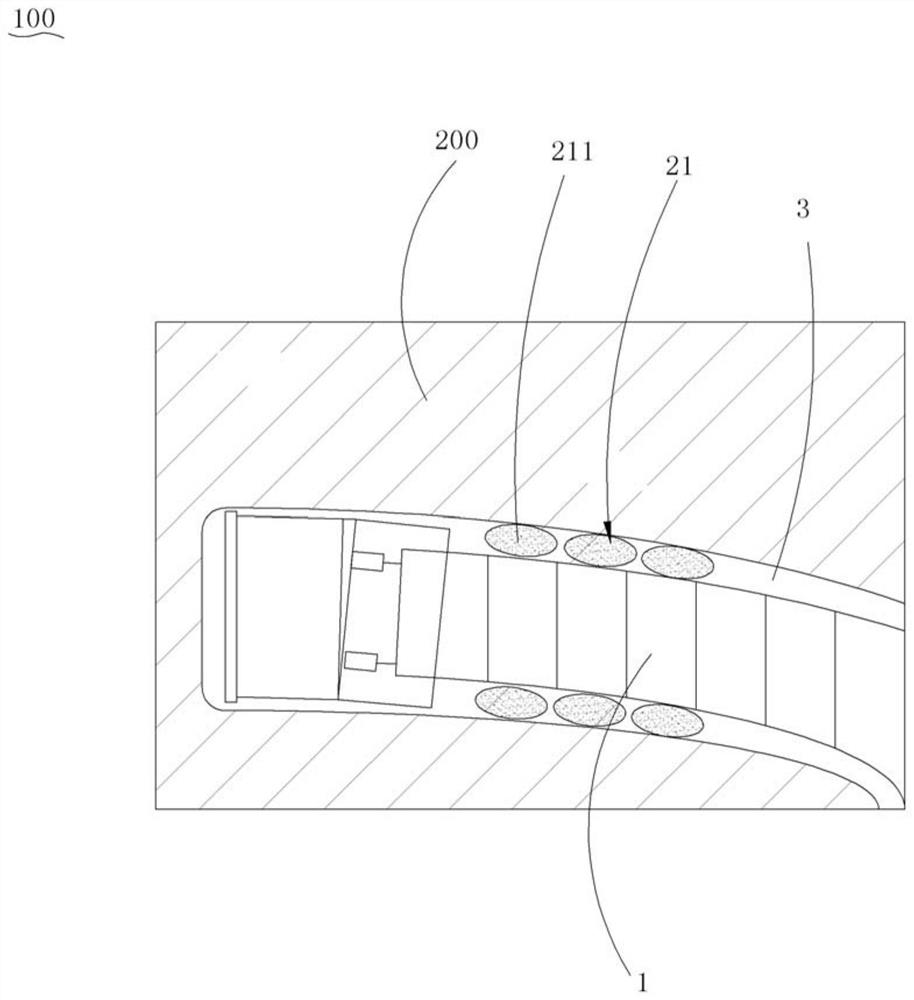

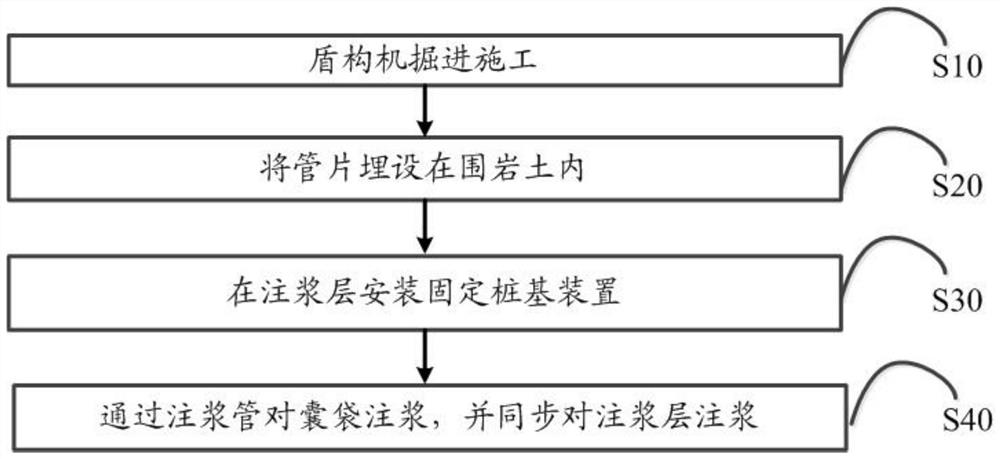

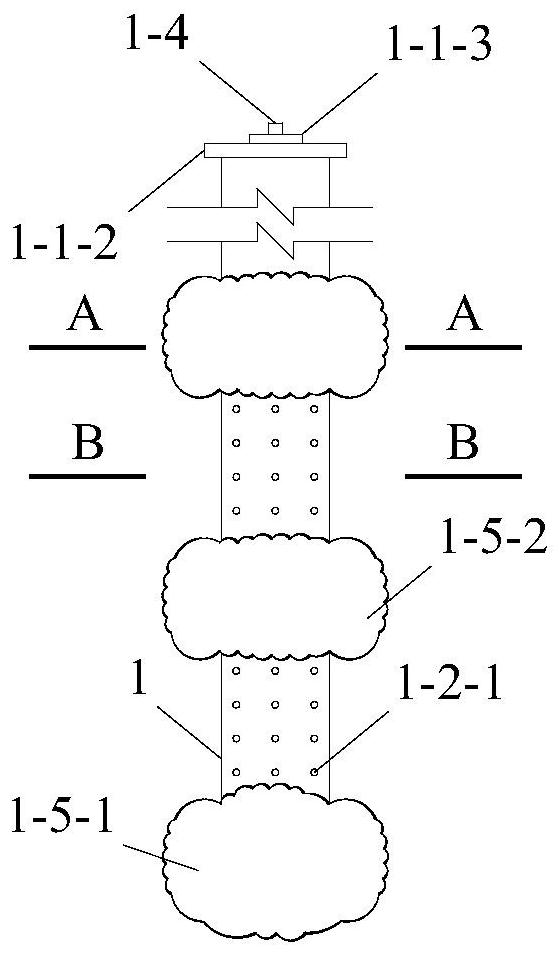

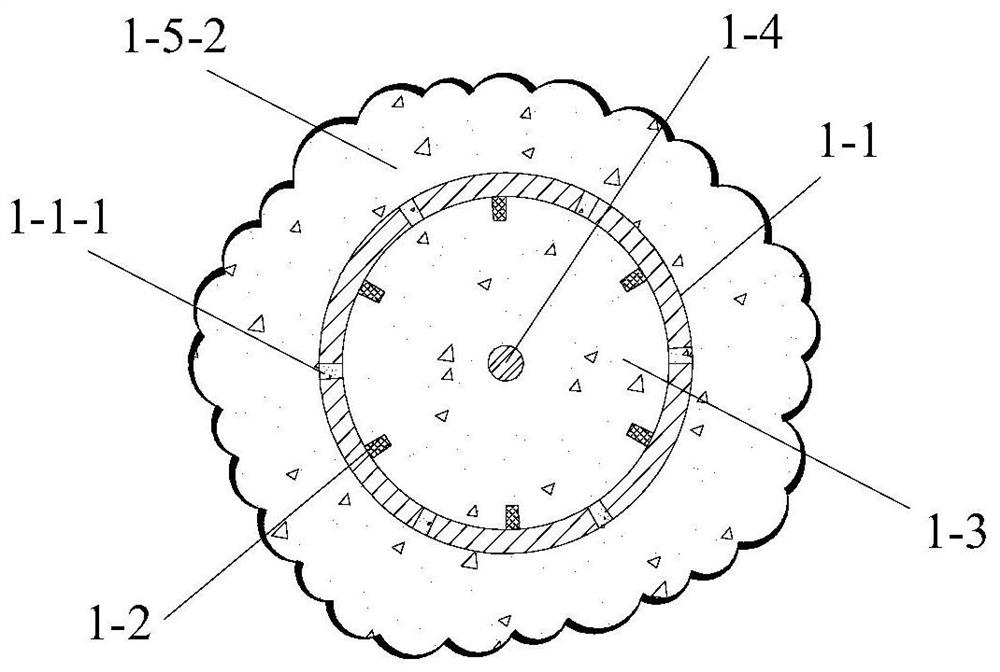

Tunnel segment structure and construction method

InactiveCN111963201AGuaranteed waterproof performanceImprove securityUnderground chambersTunnel liningWhole bodyStructural engineering

The invention discloses a tunnel segment structure and a construction method, the tunnel segment structure comprises a segment and a fixed pile foundation, the segment is buried in surrounding rock soil, and a grouting layer is arranged between the segment and the surrounding rock soil; the fixed pile foundation is arranged in the grouting layer, the fixed pile foundation comprises a bag device and a grouting pipe communicating with the bag device, grouting is conducted in the bag device through the grouting pipe to form the fixed pile foundation, one side of the fixed pile foundation abuts against the surrounding rock soil, and the other side of the fixed pile foundation abuts against the segment. According to the tunnel segment structure, the wrapping characteristic of the bag device isutilized; the slurry in the bag device can be prevented from being dispersed and diluted; the duct piece and the surrounding rock soil form a whole body; the constraint force of the surrounding rock soil is used for effectively controlling the segment to float upwards, so that the segment is stably arranged in the surrounding rock soil in time, the situations of segment staggering, crack damage and even axis deviation caused by floating upwards after the segment is separated from the shield tail are avoided, the waterproof performance of a tunnel is guaranteed, and the safety of the tunnel isimproved.

Owner:CHINA RAILWAY 20 BUREAU GRP

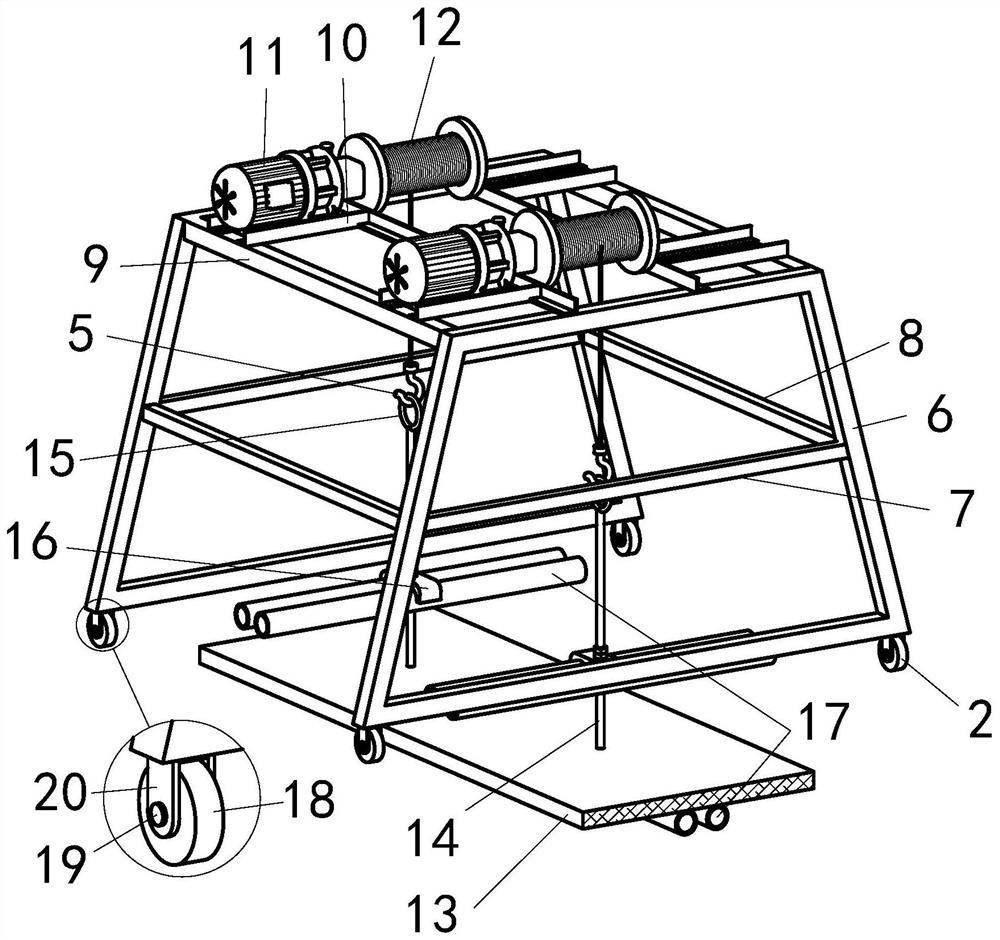

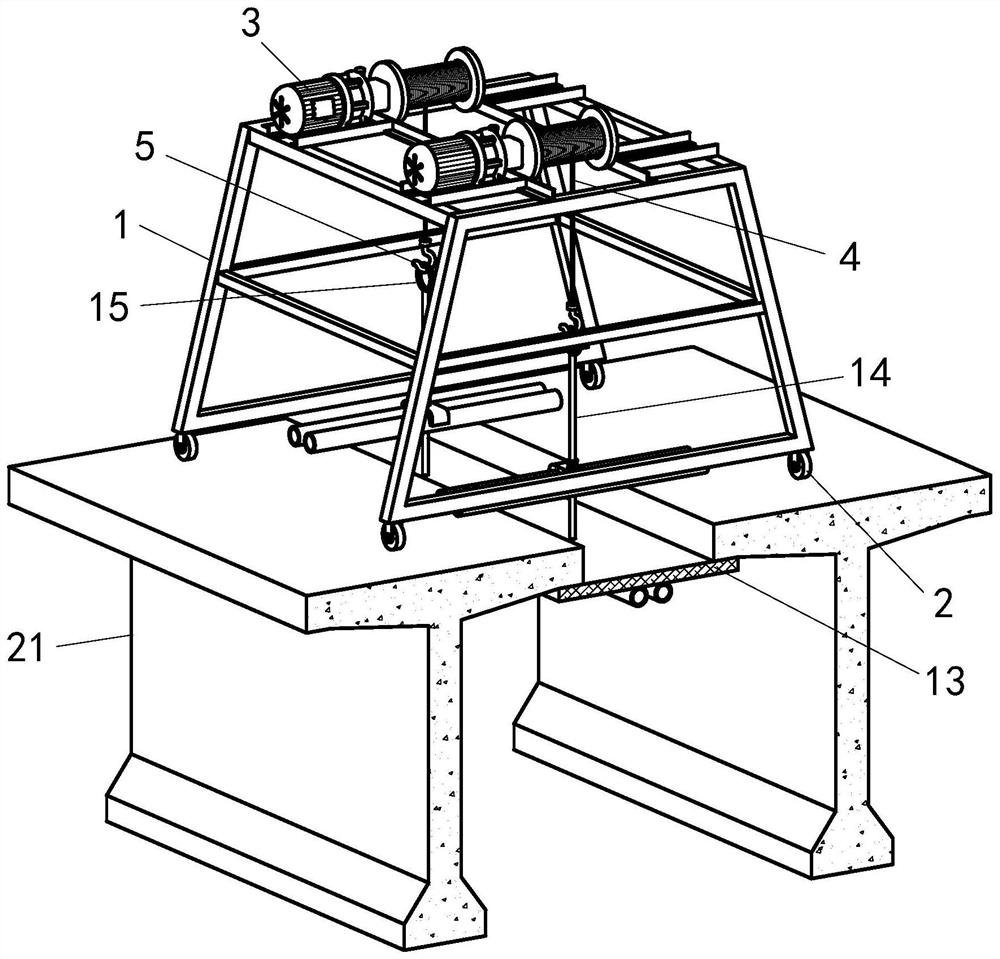

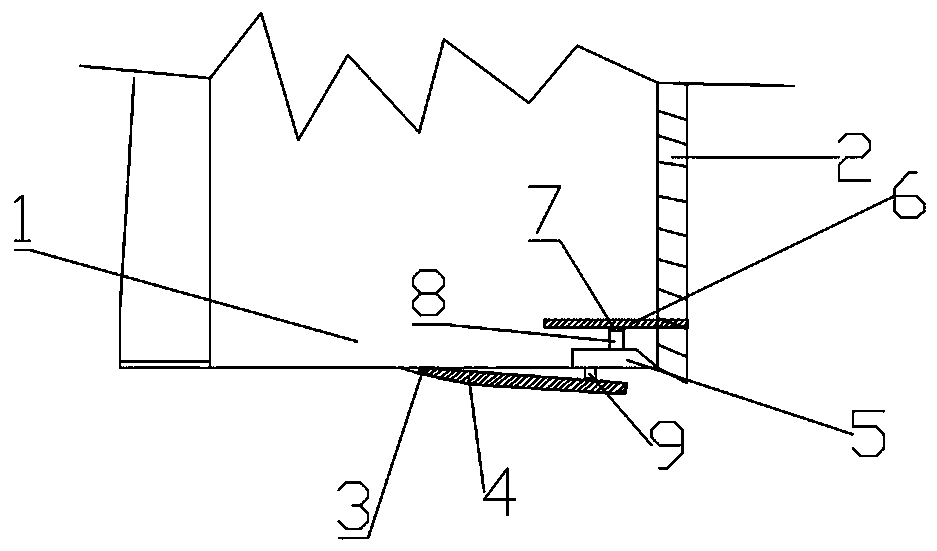

Elevating and installing method and device for T beam wet joint formwork

PendingCN111731988AEasy to processEasy and flexible to walkWinding mechanismsCranesT-beamArchitectural engineering

The invention discloses an elevating and installing method and device for a T beam wet joint formwork. According to the method, before the wet joint formwork used for pouring a T beam wet joint is installed at a wet joint position of a T beam, the T beam wet joint formwork elevating and installing device is manufactured out in advance, and then the wet joint formwork is installed according to thefollowing steps. The method comprises the steps that firstly, the T beam wet joint formwork elevating and installing device is pushed to a wet joint of the T beam as a whole; secondly, the wet joint formwork, an opposite pulling screw rod, a butterfly clamp and double steel pipes are connected into a whole below the T beam; thirdly, after the opposite pulling screw rod to which a lifting ring is welded is connected with a lifting hook, a winch is started to elevate the wet joint formwork to the wet joint position of the T beam and enable the wet joint formwork to be closely attached to a flange plate of the T beam, then the butterfly clamp and the double steel pipes are used for fixing the wet joint formwork to the T beam; and the installing work can be completed by repeating the steps oneto three. The method and the device can effectively improve the conduction efficiency, save cost and reduce labor and lifting machines, and can effectively ensure the construction safety.

Owner:CHINA CONSTR FOURTH ENG DIV

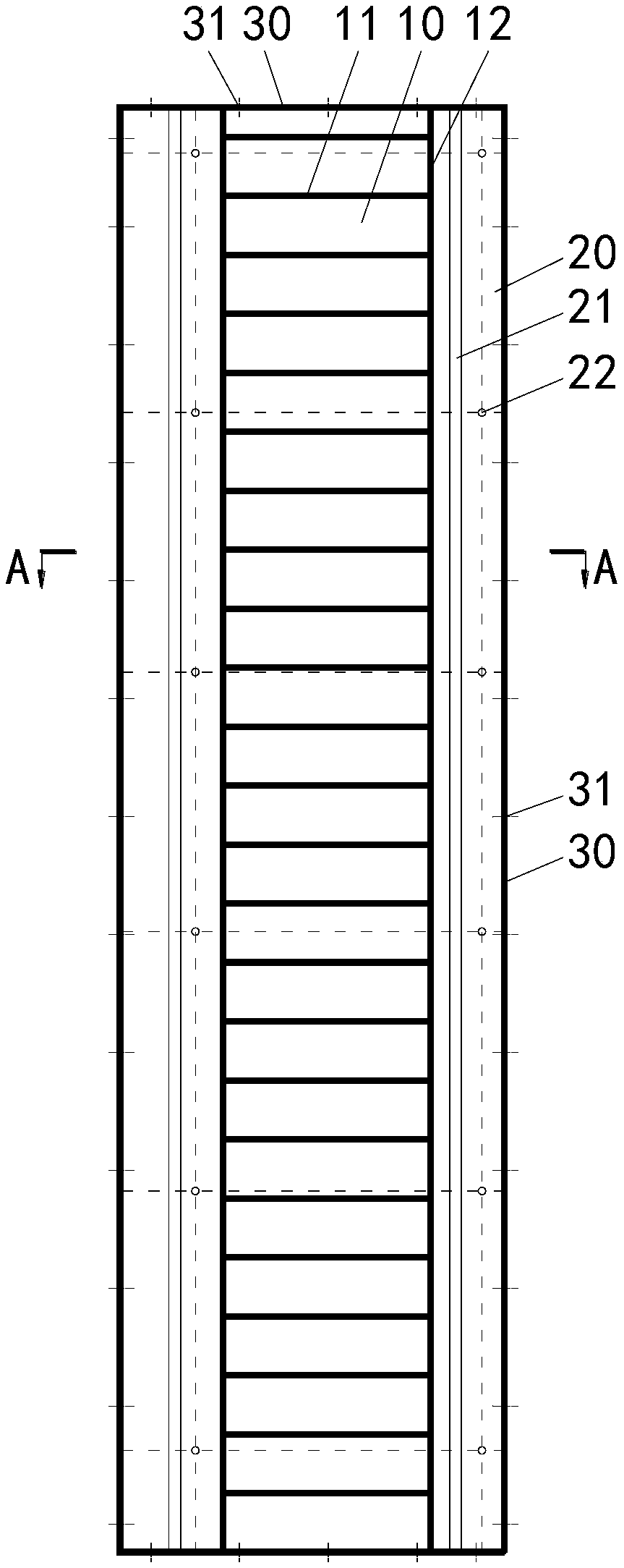

Flexible lap template assembly for lining trolley and flexible lap construction method thereof

ActiveCN108952767AAvoid damageReasonable designUnderground chambersTunnel liningEngineeringMechanical engineering

The invention belongs to the field of construction of tunnel secondary lining concrete, relates to no-damage lap between the rear portion of a tunnel secondary lining trolley and formed secondary lining concrete, and particularly discloses a flexible lap template assembly for the lining trolley and a flexible lap construction method thereof. The template assembly is formed jointly by a vault template, two side wall templates and an end mould, a limiting part is arranged on the other end, opposite to the end mould, on the template assembly in an extending mode, an annular recessed cavity coaxial to the template assembly is formed in the arc face of the limiting part, and an annular inflation bag is arranged in the annular recessed cavity. The annular inflation bag is provided with an air inlet and an air outlet, and the annular inflation bag which is inflated and expanded is extruded and matched with a formed secondary lining inner curved surface and the annular recessed cavity. The flexible lap template assembly for the lining trolley is reasonable in design, the flexible lap between the lining trolley and the formed secondary lining is realized by using the annular inflation bag,the damage to the formed secondary lining can be effectively avoided and the common quality problems such as wrong platform and pulp leakage of the annular lap position of the secondary lining concrete poured in section are prevented, and high practical value is achieved.

Owner:CHINA RAILWAY NO 17 BUREAU GRP

Rapid continuous construction method of single-compartment large-section cast-in-place frame-structure pipe gallery

InactiveCN109056800AAvoid wrong stationReduced strength requirementsArtificial islandsUnderwater structuresUltimate tensile strengthSingle compartment

The invention discloses a rapid continuous construction method of a single-compartment large-section cast-in-place frame-structure pipe gallery. The rapid continuous construction method comprises thefollowing steps: inner die plates on inner die trolleys and outer die plates on outer die trolleys are slightly adjusted through corresponding hydraulic rods, the die assembly and the adjustment are performed, the structural size and line style are determined, and then top plate reinforcing steel bars are bound; the pouring of concrete is performed, the inner die plates on the inner die trolleys are lowered and retracted through the corresponding hydraulic rods, the outer die trolleys are expanded and raised, and the corresponding die plates are dismounted; the outer die trolleys and a curingshed are moved forward, the outer die trolleys are moved to another inner mold trolley, the jumping-type construction is performed, and the above concrete section for pipe gallery forming is subjectedto spray curing; and after the concrete strength requirement is met, the inner die trolleys are moved forward. The rapid continuous construction method has the beneficial effects that the concrete staggering phenomenon caused by the splicing of small die plates can be avoided; pull ribs and holes generated due to the conventional die plate reinforcing process can be eliminated; the construction repair cost can be effectively reduced; and through the automatic retraction, rise and fall of the hydraulic rods, the automatic mounting and dismounting operation can be performed, and the conventional construction labor and construction time can be reduced.

Owner:CTCE GRP ROAD & BRIDGE ENG CO LTD +1

Lining construction seam anti-cracking lap joint structure and construction method

PendingCN108952754AAvoid direct overlapAvoid deformationUnderground chambersTunnel liningRailway tunnelLap joint

The invention provides a lining construction seam anti-cracking lap joint structure and a construction method and belongs to the construction field of railway tunnels, especially high-speed railway tunnels. The structure includes a lining trolley main framework, a supporting table is fixed to the tail part of the lining trolley main framework, the upper end face of the supporting table is parallelto the upper end face of the lining trolley main framework, and the upper end face of the supporting table is lower than the upper end face of the lining trolley main framework. Rubber strips are laid on the upper end face of the supporting table, and the thickness of each rubber strip is greater than the height difference between the supporting table and the upper end face of the lining trolleymain framework. The structure aims at solving the problems that during existing rigid lap joint of tunnel lining construction seams, cracks are easily generated on the construction seams, the trafficsafety is seriously threatened after a tunnel is put into use, main frameworks of the upper ends of trolleys are in rigid lap joint with poured concrete, the lap joint parts are not compact, leakage of slurry easily happens, the rigid lap joint can cause deformation of the main frameworks of the upper ends of the trolleys, and correspondingly faulting of slab ends on the lap joint parts are caused.

Owner:CHINA RAILWAY ERJU 1ST ENG

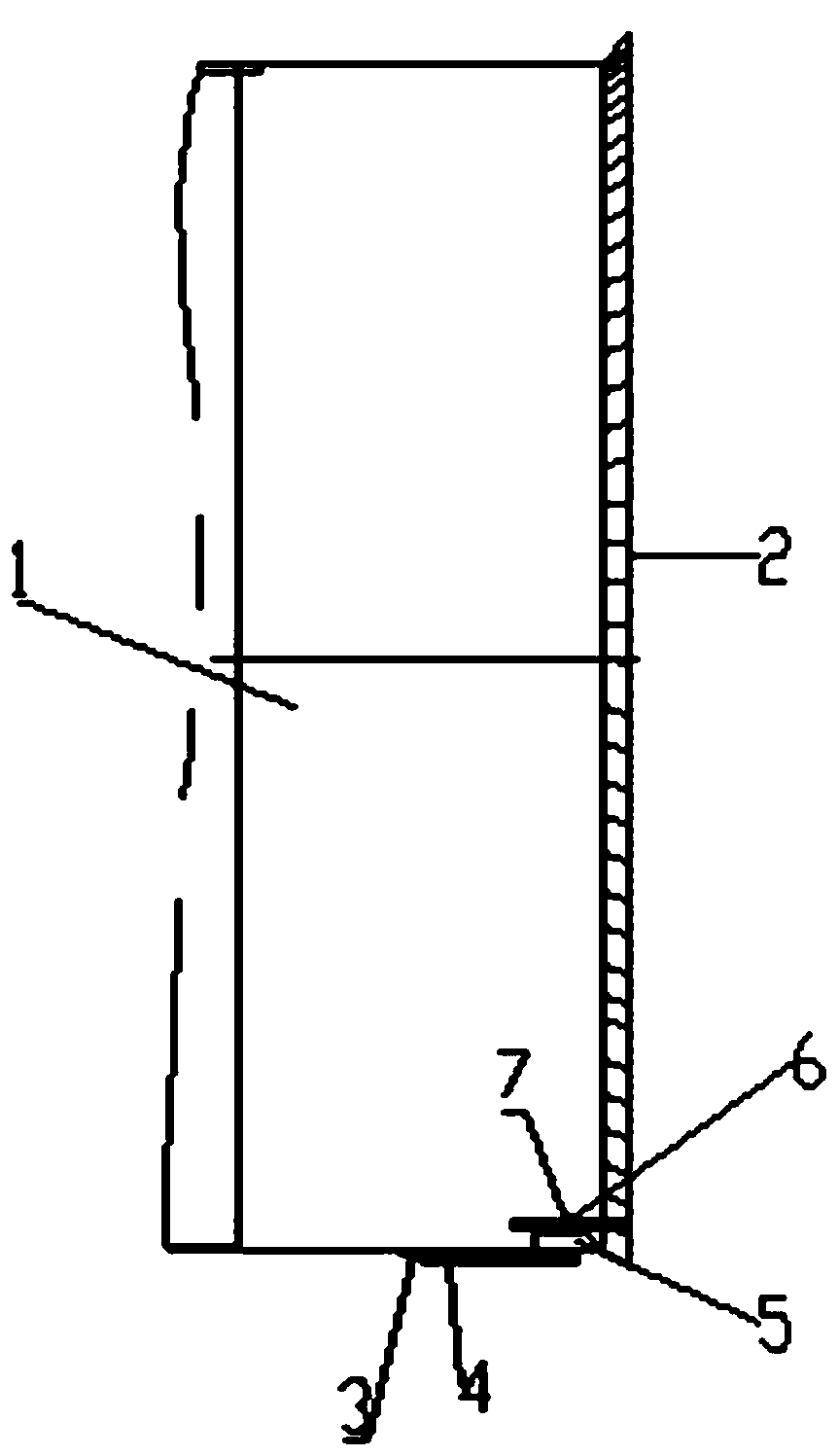

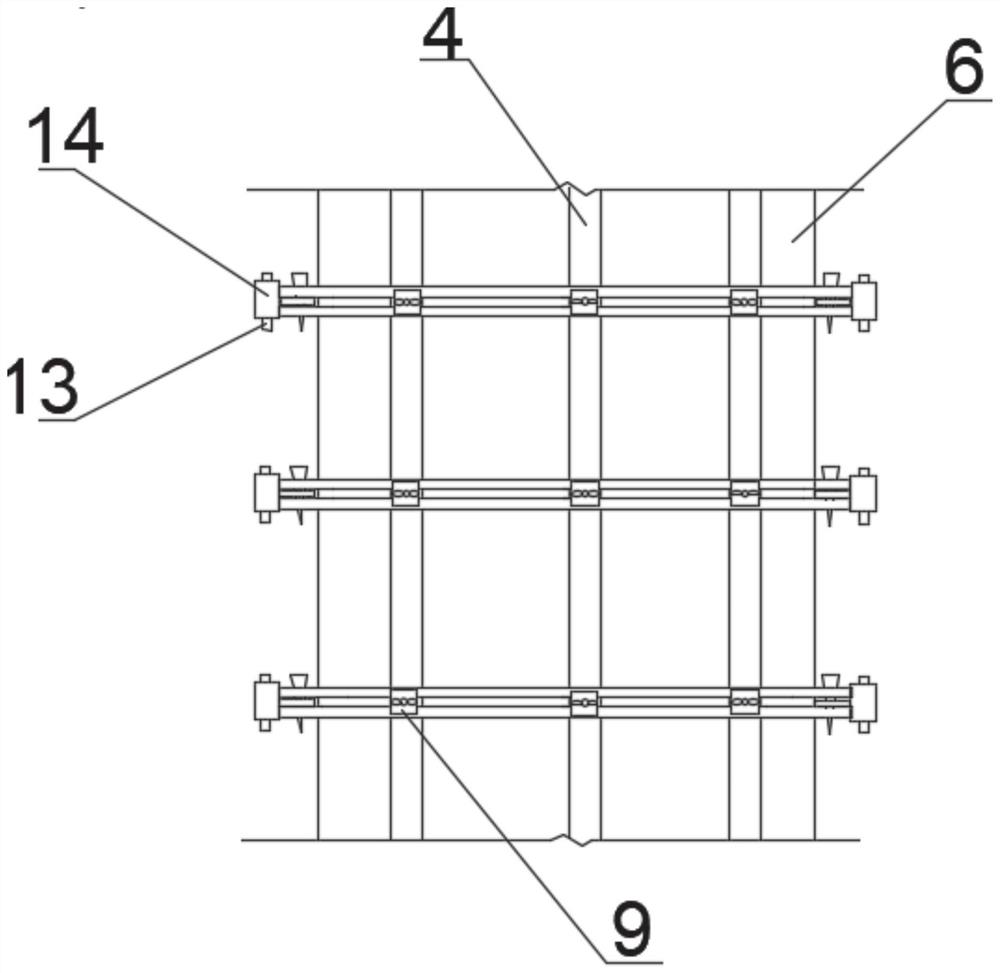

Formwork reinforcing structure at underground pipe gallery horizontal construction joint and construction method

InactiveCN108532631AImprove the quality of look and feelAvoid wrong stationArtificial islandsUnderwater structuresCounter-pullSlurry

The invention discloses a formwork reinforcing structure at the underground pipe gallery horizontal construction joint and a construction method, belongs to the technical field of building construction, and relates to urban underground comprehensive pipe gallery construction. The structure comprises a plurality of first counter-pull screws, a plurality of second counter-pull screws, a plurality ofsquare woods, a formwork, a bottom plate and steel pipes. Through optimization of materials and improvement of the construction method, the formwork reinforcing structure and the construction methodare utilized, so that the impression quality at the underground pipe gallery horizontal construction joint can be effectively improved, furthermore, the occurrence of quality problems such as dislocation, slurry leakage and the like at the horizontal construction joint can be effectively avoided, meanwhile, the construction material is common, the construction cost can be effectively reduced, andthe practicability is high.

Owner:CHINA MCC17 GRP

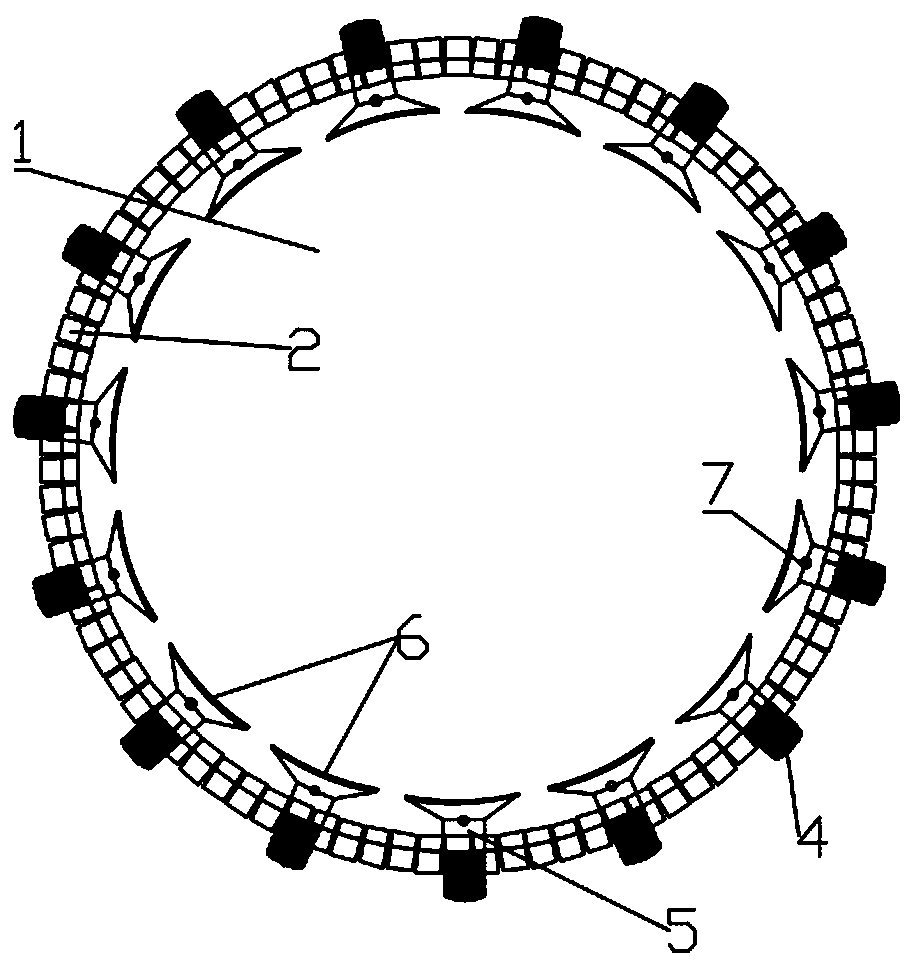

Control device for preventing duct piece staggering and shield tail postures for TBM

PendingCN109751055AAvoid wrong stationPlay a buffer roleUnderground chambersTunnel liningEngineeringTunnel boring machine

The invention discloses a control device for preventing duct piece staggering and shield tail postures for a tunnel boring machine (TBM). A plurality of the control devices are uniformly distributed on an excircle surface of a shield tail at the rear part of a shield tail brush in a manner of surrounding the axis of the shield tail; each control device comprises a streamline wear-resisting plate,a shield body posture adjusting oil cylinder, an oil cylinder connecting plate and a pipe piece supporting plate; the upper surface of the oil cylinder connecting plate is stopped in the shield tail through the shield tail outer shell; the upper surface of the duct piece supporting plate is an arc-shaped concave surface; the circle center of a circle defined by the upper surfaces of all the duct piece supporting plates coincides with the circle center of the cross section of the shield tail; the bottom of the duct piece supporting plate is hinged to the telescopic rod end of the duct piece posture adjusting oil cylinder, and the hinged point of the duct piece supporting plate and the telescopic rod end of the duct piece posture adjusting oil cylinder coincides with the symmetric center line of the arc inward-concave face of the upper surface of the duct piece supporting plate.

Owner:SHENZHEN METRO GROUP +2

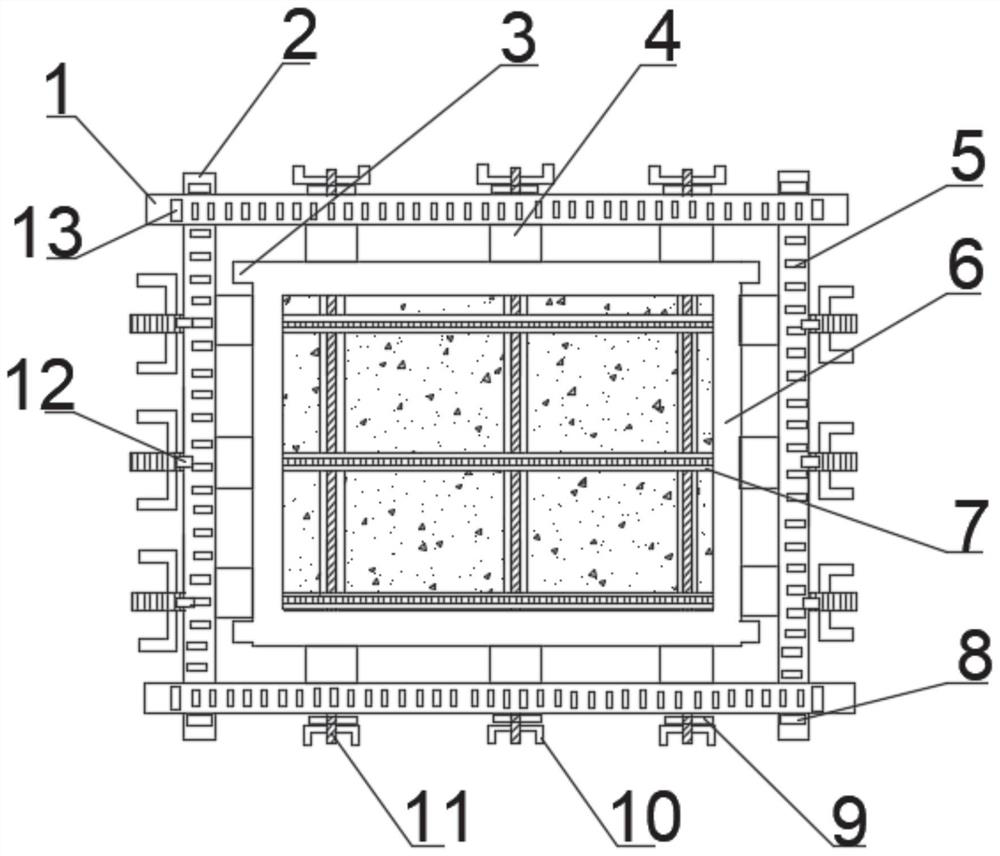

High and large concrete formwork reinforcing system

InactiveCN111779270AAvoid cold seamsAvoid wrong stationAuxillary members of forms/shuttering/falseworksWood plankSteel casting

The invention discloses a high and large concrete formwork reinforcing system. The high and large concrete formwork reinforcing system comprises two first channel steels, second channel steels, woodenboards, a steel formwork and split bolts. The edge portion of the steel formwork is provided with reinforced edges. The wooden boards are vertically arranged on the periphery of the steel formwork atintervals. The two opposite sides of the periphery of the wooden boards are transversely provided with the two first channel steels. The two ends of the two first channel steels are wrapped through fixed blocks. The two first channel steels are fixed through first fixed plates. The second channel steels are transversely arranged on the other two sides of the periphery of the wooden boards. The second channel steels are inserted in the gap between the two first channel steels. The second channel steels are fixed through second fixed plates. The corresponding positions of the wooden boards arefurther reinforced through split bolts. Each split bolt comprises gaskets, a cast steel nut and a screw rod, wherein the gaskets include the first gasket and the second gasket; the first gasket is square, and the second gasket is arc-shaped. The first gaskets are arranged on the corresponding sides of the first channel steels, and the second gaskets are arranged on the corresponding sides of the second channel steels. The high and large concrete formwork reinforcing system effectively improves the appearance quality and has high practicality.

Owner:SHANDONG WATER CONSERVANCY CONSTR ENG CO LTD

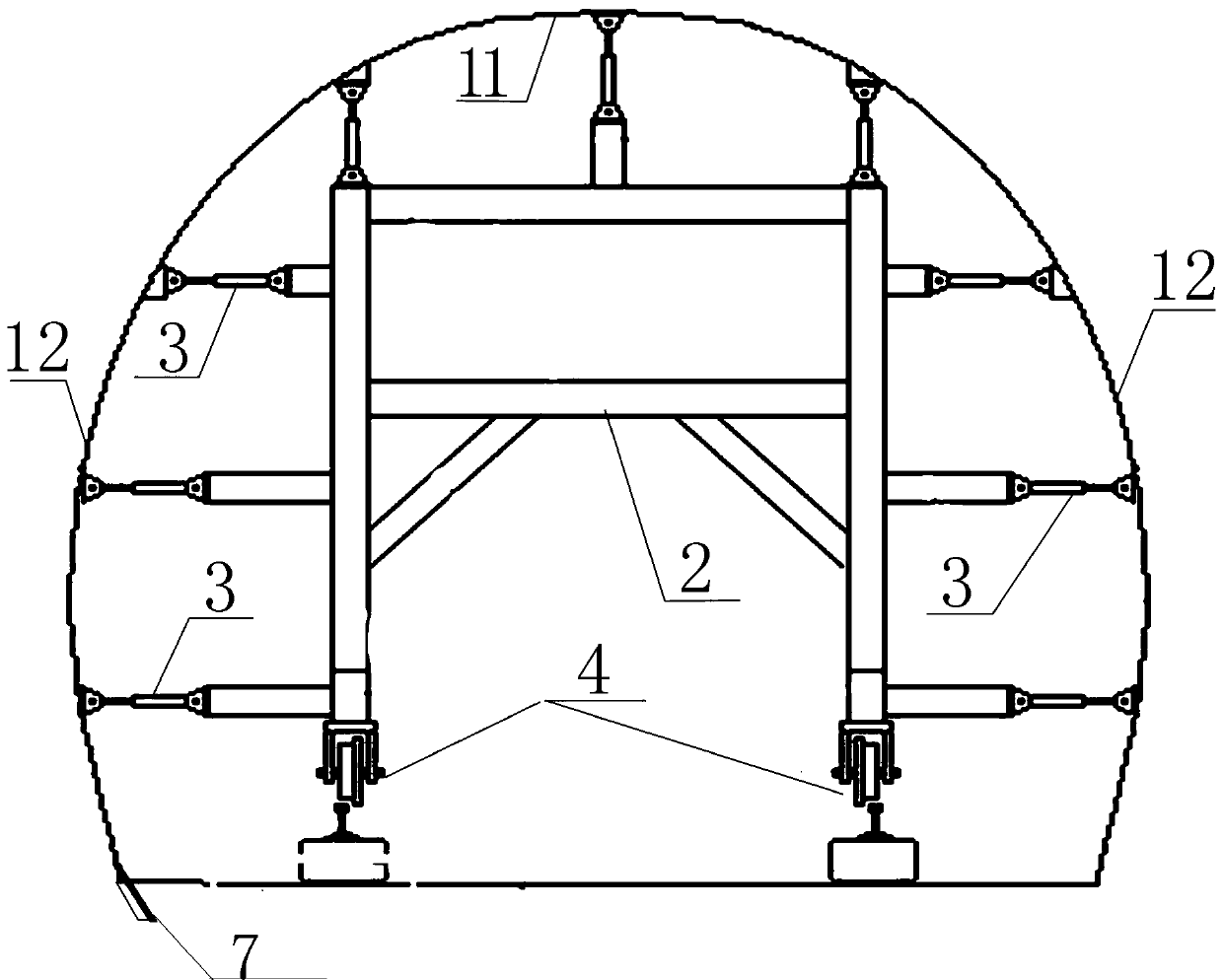

Large-diameter shield tunnel deformation control structure and construction method thereof

ActiveCN113137273ALow work efficiencyPrevent uneven flotation or settlingMining devicesUnderground chambersShield tunnelingRock bolt

The invention discloses a large-diameter shield tunnel deformation control structure and a construction method thereof. The structure is installed in the construction period of a shield tunnel and comprises a bag expansion type dewatering and drainage pre-stressed anchor rod, a bag expansion type pre-stressed anchor rod, a water storage and drainage tank and a control system. The contact area between the bag expansion type dewatering and drainage pre-stressed anchor rod and a soil layer below the shield tunnel and the contact area between the bag expansion type dewatering and drainage pre-stressed anchor rod and a soil layer above the shield tunnel are increased through expansion type bags, the pulling resistance is increased, and uneven floating or settlement disasters of the large-diameter shield tunnel can be effectively prevented; prestress is symmetrically applied to the bag expansion type dewatering and drainage pre-stressed anchor rod and the bag expansion type pre-stressed anchor rod, resistance for convergence deformation is formed on a large-diameter shield tunnel section, and convergence deformation of the large-diameter shield tunnel section and engineering diseases possibly caused by the convergence deformation are effectively prevented and treated; and floating or sedimentation of the large-diameter shield tunnel is controlled through the combined effect of the bag expansion type dewatering and drainage pre-stressed anchor rod and the water storage and drainage tank.

Owner:江苏中车城市发展有限公司 +1

Overall-type formwork of wall columns and construction method of overall-type formwork

PendingCN109555310AGuaranteed integrityGuaranteed verticalityForms/shuttering/falseworksEngineeringBolted joint

The invention provides an overall-type formwork of wall columns and a construction method of the overall-type formwork, and relates to the technical field of building construction. Aiming at the problems that through a construction method adopting a wooden formwork to pour the wall columns, formwork abutted seams in the connecting positions of a wall and the columns are not compact, and the construction quality is difficult to effectively control, the overall-type formwork is formed by a plurality of formwork units which are connected in a bolted mode and arranged in the height direction of the wall columns; the formwork units each comprise an arc-shaped face plate, two wing plates and a second outer arrise; the arc-shaped face plates are matched with the to-be-poured wall columns in outercontour, a plurality of inner arrises are parallelly arranged on the outer walls of the arc-shaped face plates at intervals, and the two sides of the inner arrises are connected with first outer arrises; every two wing plates are fixedly connected to the two sides of the corresponding arc-shaped face plate correspondingly, a plurality of first bolted holes are formed in the wing plates, and the first bolted holes in the wing shapes located on the two sides of the to-be-poured wall columns are opposite in position; the second outer arrises are arranged at the outer edges of the arc-shaped faceplates and the wing plates, wherein the arc-shaped face plates and the wing plates are connected into a whole; second bolted holes are formed in the second outer arrises, the multiple formwork unitsare connected into a whole in a bolted mode, and all the formwork units are connected with corresponding wall formworks in a bolted mode correspondingly; and the arc-shaped face plates and the wing plates are each made of a steel plate.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

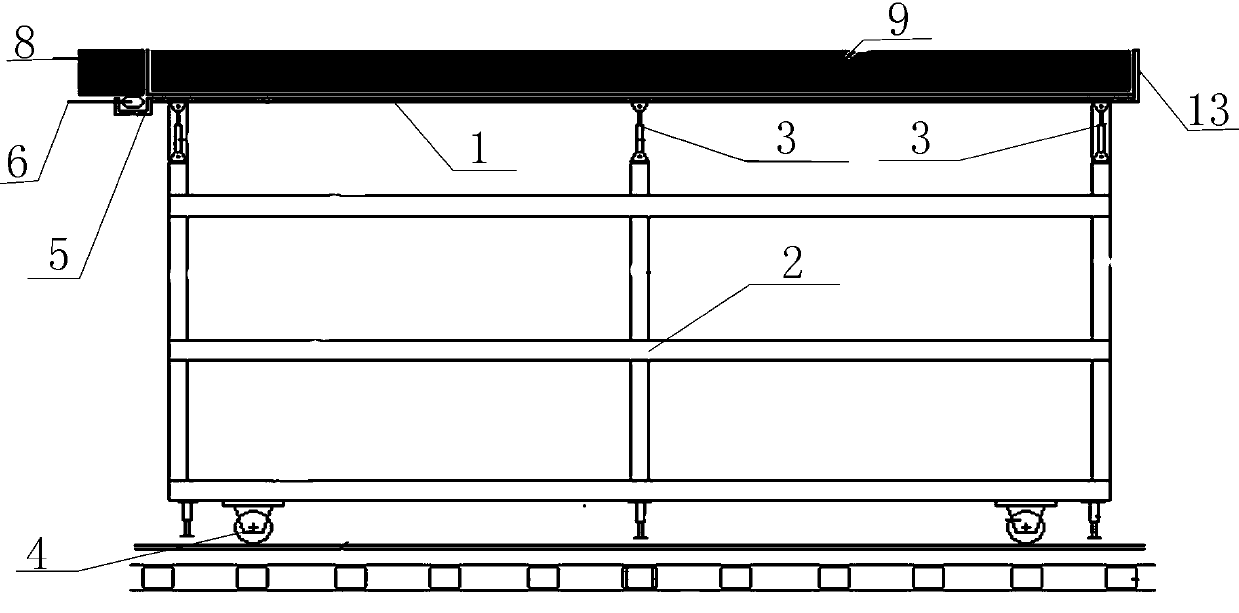

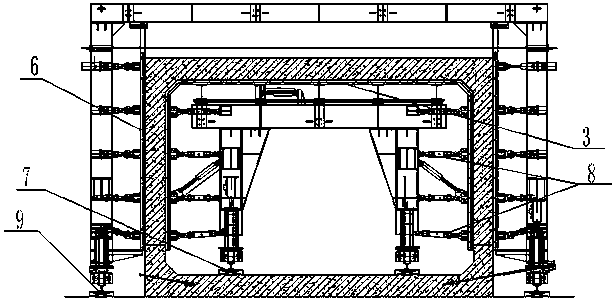

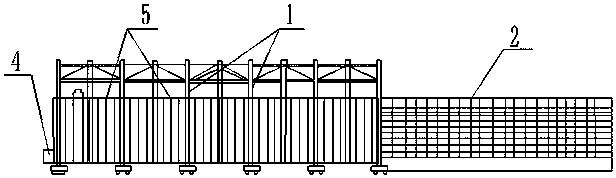

Full-hydraulic self-propelled culvert abutment body trolley and construction technology process

PendingCN108867420ASolve seam misalignmentIncrease incomeGround-workUnderground chambersDistribution systemCulvert

The invention discloses a full-hydraulic self-propelled culvert abutment body trolley and meanwhile discloses a construction technology process thereof. The full-hydraulic self-propelled culvert abutment body trolley comprises traveling wheels, a traveling bottom framework, rails, a main template framework, an inner template, an outer template, a hydraulic system, a vibration system and a power distribution system. Both of the inner template and the outer template are of integral structures and are fixedly arranged on a steel main frame. The inner template and the outer template are connectedwith the main template framework through template dismantling systems. Each of the template dismantling systems comprise a plurality of attached vibrators which are mounted on an inner template framework and an outer template framework. According to the full-hydraulic self-propelled culvert abutment body trolley and the construction technology process thereof, the problems of deviation of templatejoints and long assembly time of the templates and the finished concrete protection problem during dismantling of the templates in the culvert construction process are better solved; and the work efficiency is improved effectively, the operation cost is reduced effectively, and the income of workers are increased.

Owner:甘肃恒捷路桥养护科技有限公司

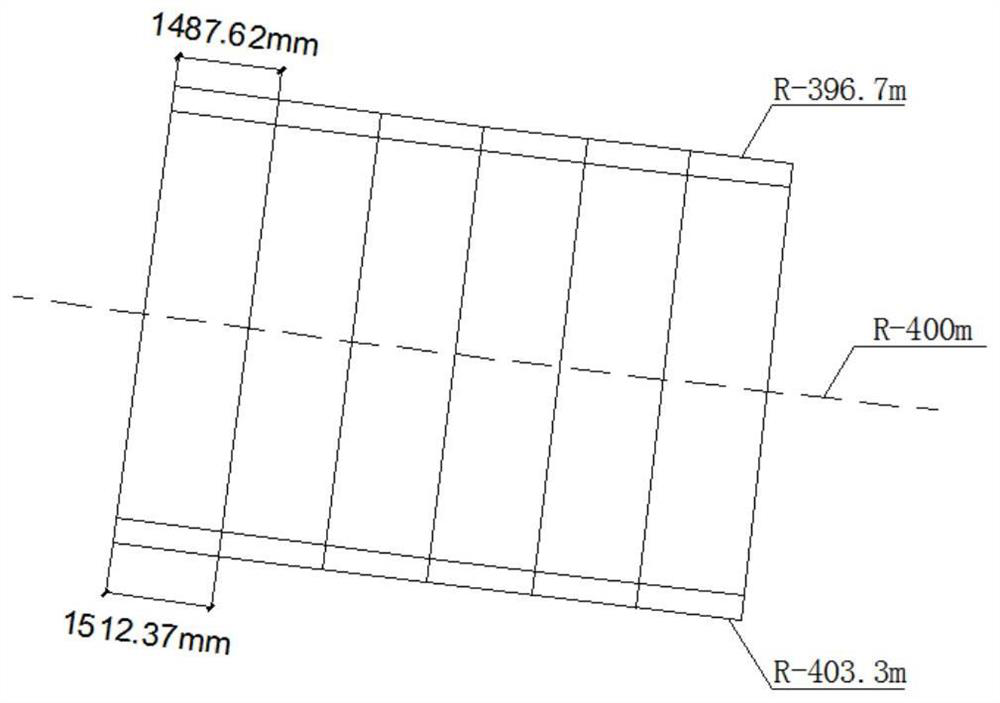

Segment assembly point position selection device and method in shield method construction and application of segment assembly point position selection device and method

PendingCN114109411AQuick fixAccurately determineUnderground chambersTunnel liningJackscrewTunnel construction

The invention belongs to the technical field of tunnel construction, and discloses a segment assembly point position selection device and method in shield method construction and application. Analysis is carried out in the aspects of segment types, splicing modes, axis fitting, shield tail gaps and jack stroke differences, proper splicing point positions of segments are selected, so that the horizontal included angle alpha 2 between the segments and the designed axis and the vertical included angle theta 2 between the segments and the designed axis tend to zero, the included angle between the axis of the segments and the axis of the shield tail is reduced, and the friction probability between the segments and the shield tail is reduced. And shield tail leakage, water gushing and sand gushing are prevented. According to the method, the splicing point positions of the duct piece top sealing blocks can be visually displayed, duct piece splicing operators can quickly and accurately determine the splicing point positions, and therefore the point selection precision is improved, and the situations that due to inaccurate selection of the splicing point positions, a gap between the outer arc face of a duct piece and the inner arc face of a shield tail is small, and the axis deviation of a formed duct piece is large are avoided. According to the method, the phenomena of slab staggering and damage caused by wrong segment splicing point positions are avoided to the maximum extent.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com