Lining construction seam anti-cracking lap joint structure and construction method

A technology for construction joints and joint structures, which is applied in shaft lining, tunnel lining, earthwork drilling and mining, etc. It can solve problems such as deformation of the main formwork at the upper end of the trolley, threats to driving safety, and loose joints, so as to prevent crescent-shaped cracks , Guaranteed safety and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

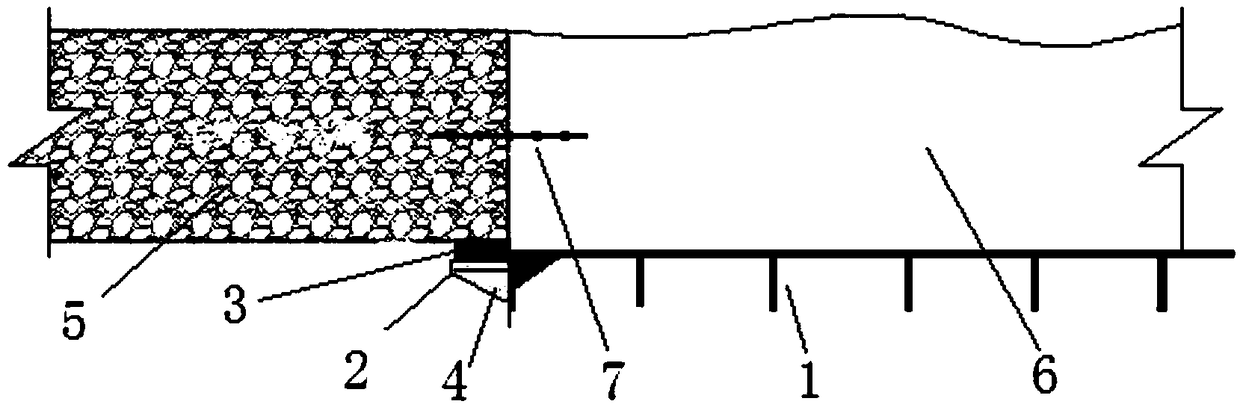

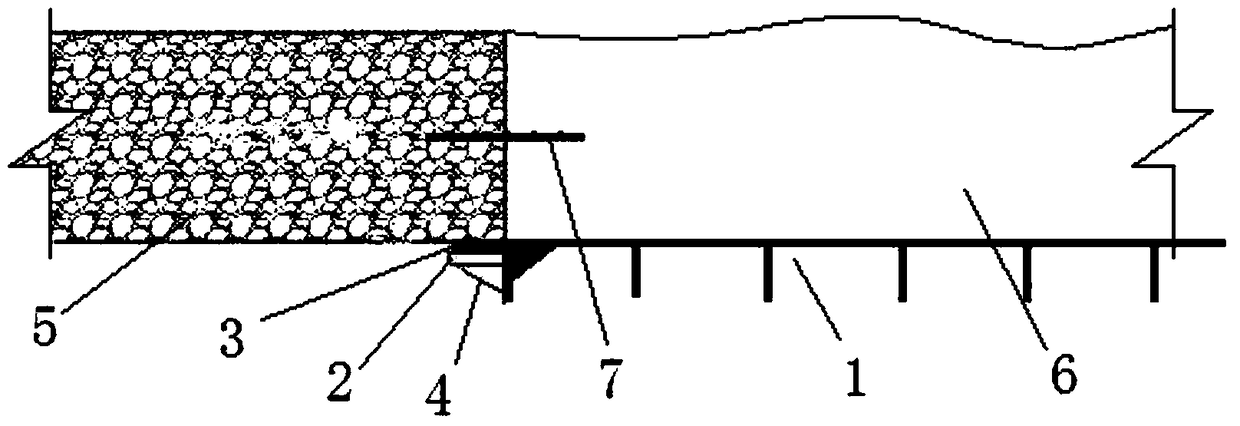

[0025] refer to figure 1 and figure 2 , this embodiment provides an anti-cracking lap joint structure for lining construction joints, including a main formwork 1 of a lining platform, a support platform 2 is fixed at the tail of the main formwork 1 of the lining platform, and the support platform 2 is a main formwork 1 along the lining platform. The design radian of the tail is welded and installed angle steel or channel steel in a circular direction. One end of the support platform 2 is welded and fixed to the tail of the main formwork 1 of the lining platform, and the bottom is reinforced by welding t=10mm steel plates at a distance of 100cm. Specifically, the support platform 2 The lower side is provided with a diagonal brace 4, one end of the diagonal brace 4 is welded and fixed to the other end of the support platform 2, and the other end of the diagonal brace 4 is also welded and fixed to the tail of the main formwork 1 of the lining platform, and the upper end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com