Simultaneous construction type wide-flanged guyed traveler

A simultaneous construction and wide-wing technology, applied in bridge form, erection/assembly bridge, cable-stayed bridge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

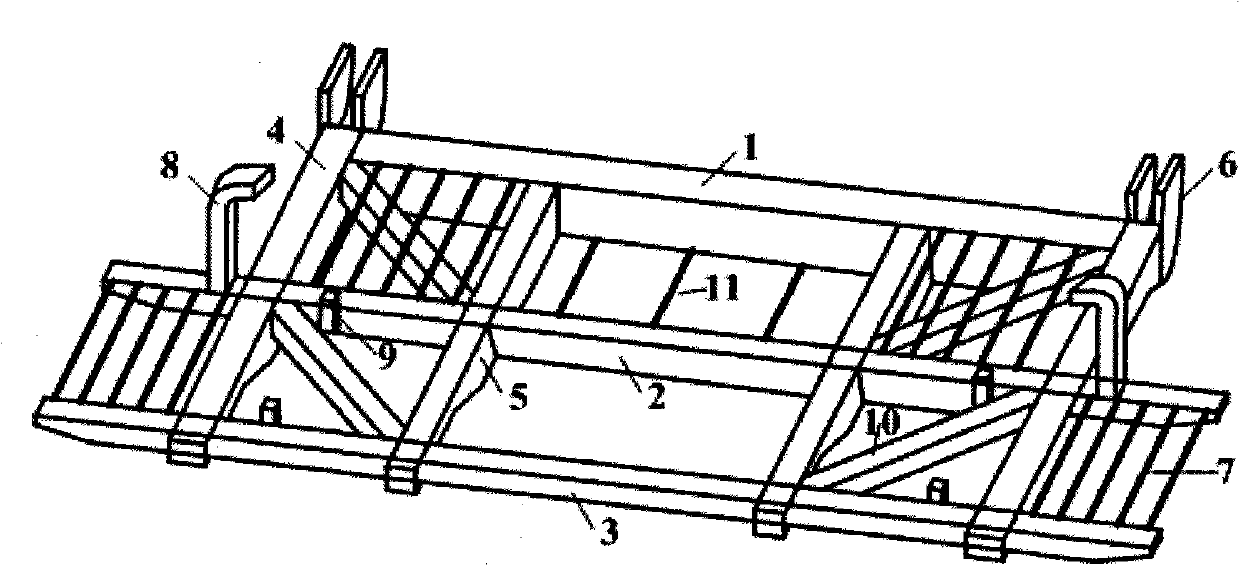

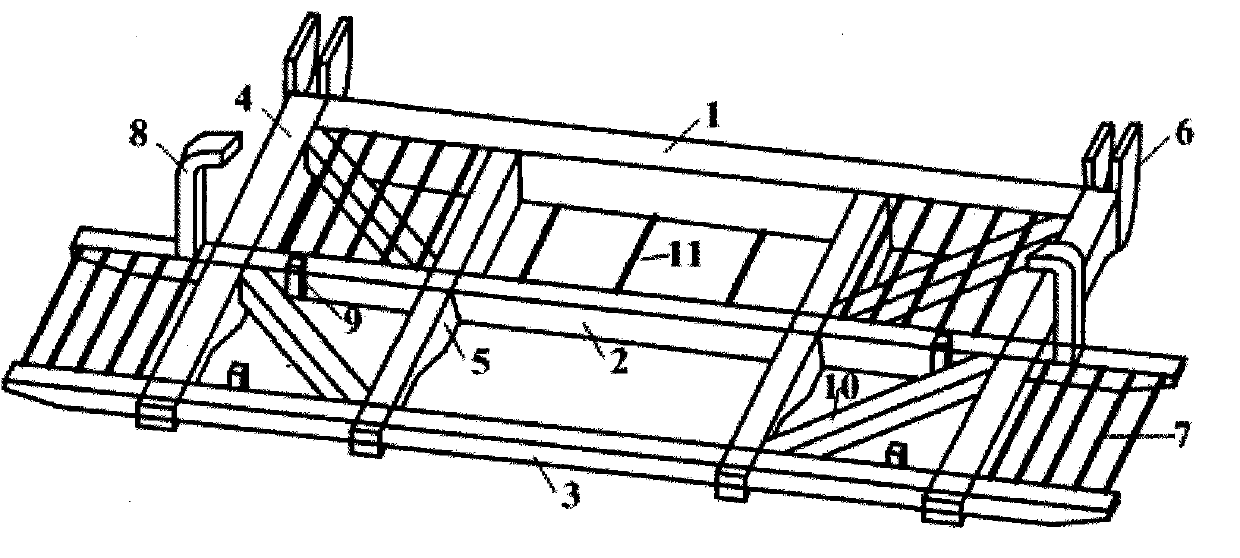

[0019] See attached figure 1 , wide flange synchronous construction type stay cable hanging basket, including front beam 1, middle beam 2, rear beam 3, the front beam, middle beam and rear beam are connected with main longitudinal beam 4, secondary longitudinal beam 5, main longitudinal beam The front end of the beam is fixedly connected with an arc-shaped head 6. The two ends of the middle beam and the rear beam respectively extend to the outside of the main longitudinal beam to form a wide flange plate pouring platform 7, and the two ends of the middle beam are respectively fixedly connected with C-shaped hooks 8, and the middle beam and the rear beam are fixedly connected with square anti-corrosion The shear column 9, the shear column extends into the positioning hole opened at the junction of the inclined web and the bottom plate of the bridge body, the diagonal brace 10 is connected between the main longitudinal beam and the secondary longitudinal beam, and the front bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com