Construction method for splicing duct pieces in shield idling manner

A shield tunneling and segment technology, which is used in wellbore lining, tunnel lining, underground chambers, etc., can solve the problems of tool wear, difficult to guarantee construction period, and difficult tunneling, and achieves prevention of floating, good economic and social benefits. , Improve the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

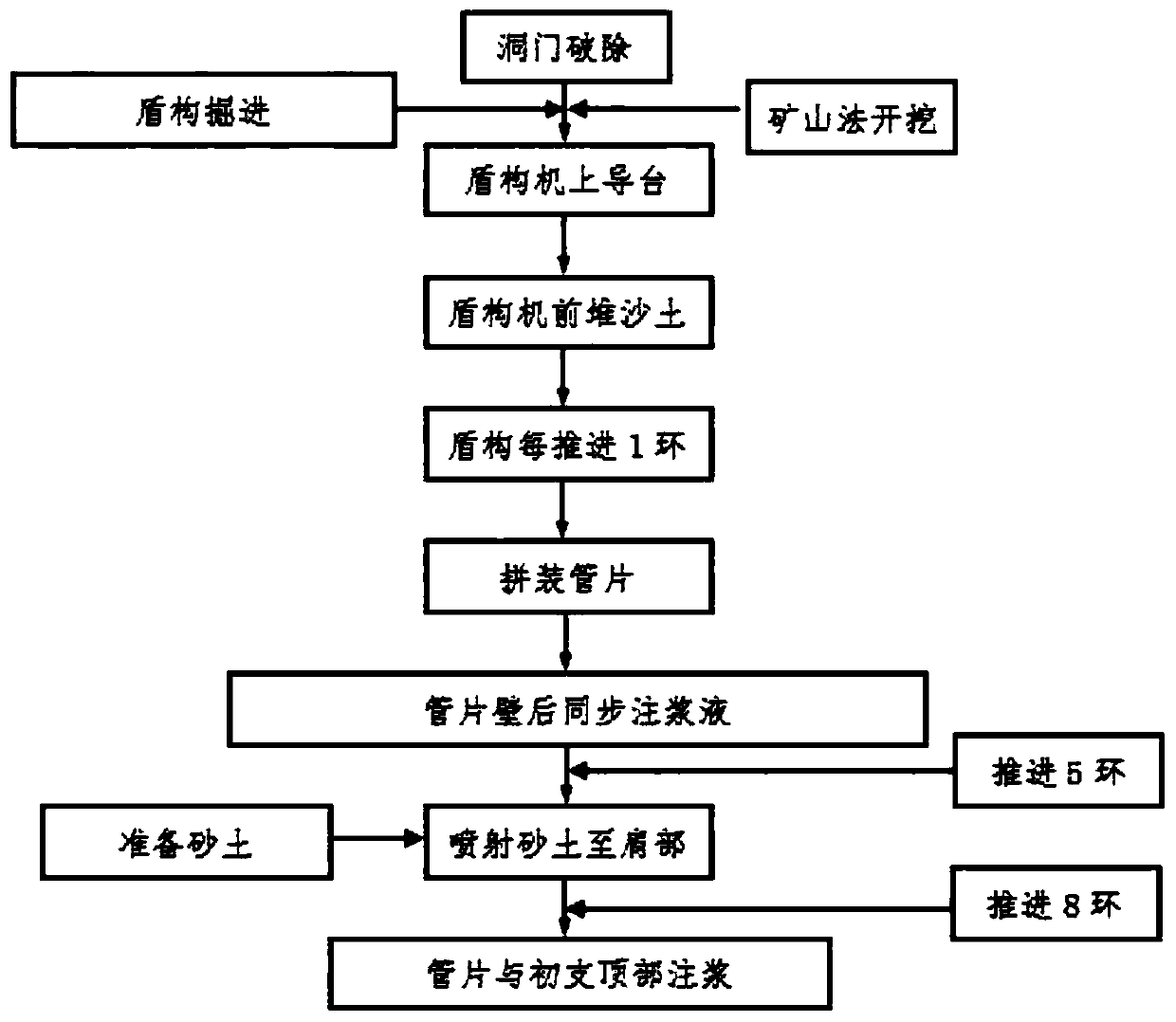

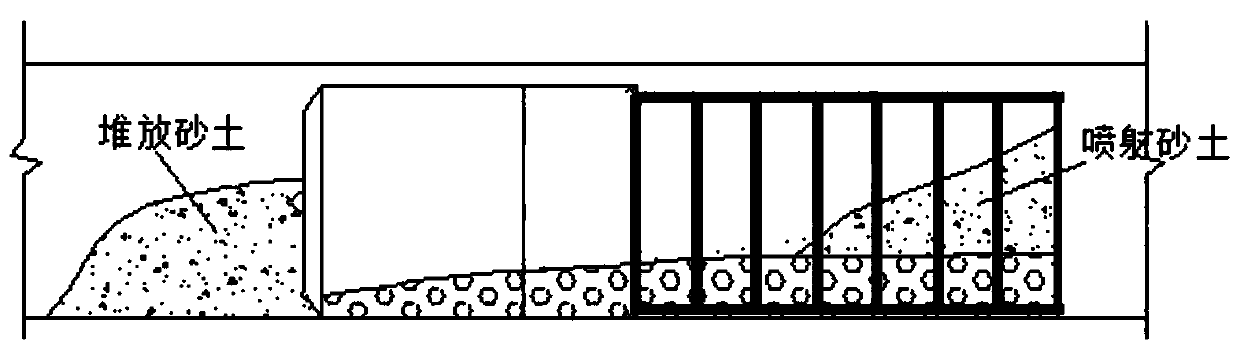

[0094] The Hangzhou-Lin’an intercity railway project uses a segment tunnel with a diameter of 6700mm, and the diameter of the cutter head of the shield machine is 7000mm. Due to the complex geological conditions of the Hangzhou-Lin’an underground tunnel, the frequency of shield tunnel tool change in hard rock areas is high, and the tool change operation takes a long time. long, affecting the normal excavation of the shield. Constrained by the construction period, the SGHL-4-1 tender section adopted the mining method for excavation for the first time and the initial support of the construction, and the optimized construction period of the scheme of shield tunneling and segmenting through the mining method tunnel. It has been proved by practice that the construction period can be greatly advanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com